Method for preparing hydrogen and liquefied natural gas through using gas retort raw gas

A technology for liquefied natural gas and waste gas, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of low utilization efficiency of hydrogen recycling efficiency and low comprehensive utilization of raw materials, so as to improve recycling efficiency, improve industrial chain, and comprehensively utilize Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

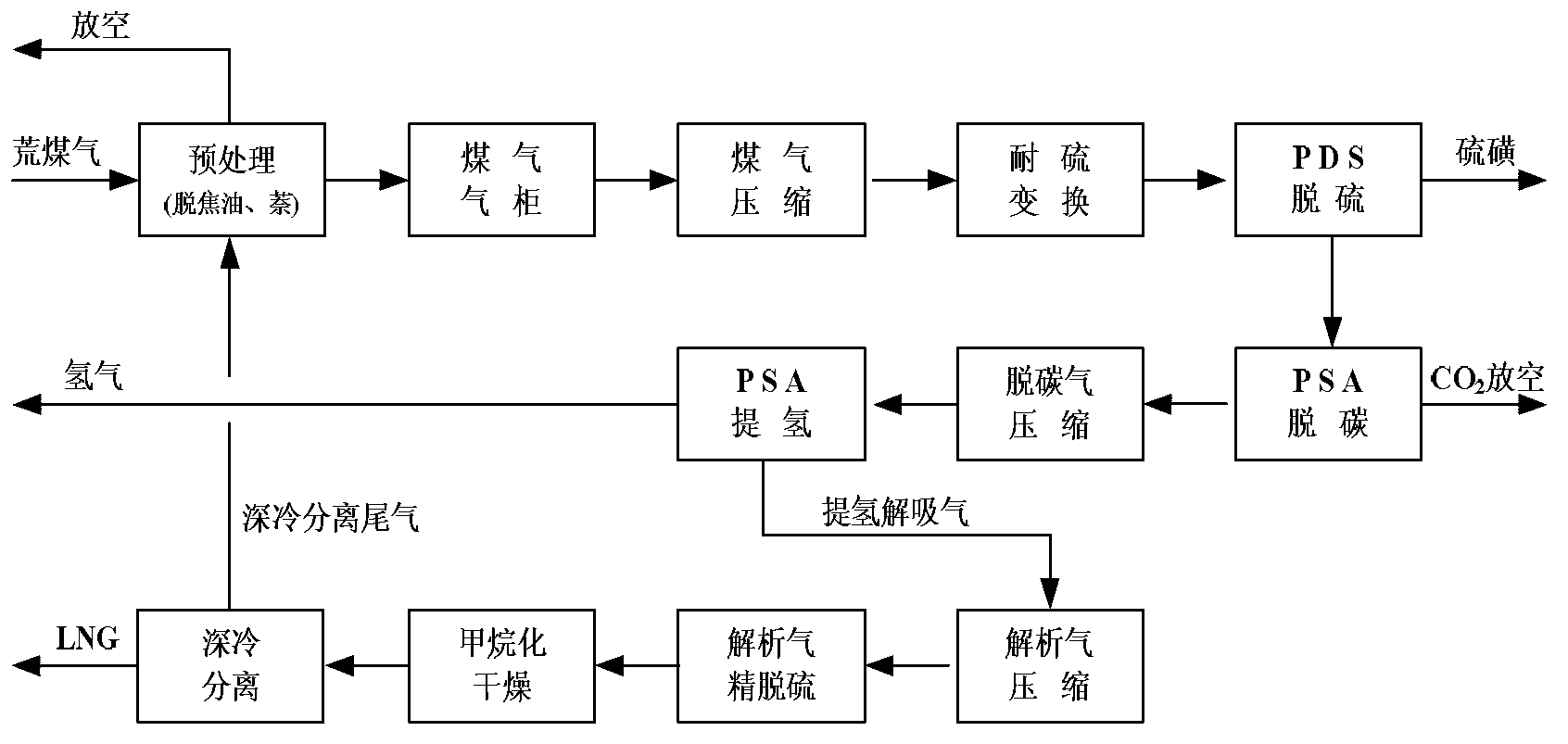

[0033] Embodiment 1: A kind of method for preparing hydrogen and liquefied natural gas from dry distillation furnace raw gas, such as figure 1 shown, including the following steps:

[0034] ① The raw gas of retort furnace is pretreated by adsorption to remove tar and naphthalene, and then enters the gas tank for buffering;

[0035] ②The buffered raw coal gas is pressurized and enters the sulfur-tolerant shift reactor to make carbon monoxide react with steam to generate carbon dioxide and hydrogen;

[0036] ③The shift gas is desulfurized by PDS wet method, the desulfurization liquid is regenerated and recycled, and sulfur is produced as a by-product;

[0037] ④ The shifted gas after desulfurization is decarburized and hydrogenated by two-stage PSA pressure swing adsorption process; the obtained hydrogen is sent to the tar hydrogenation unit as raw material;

[0038] ⑤ The hydrogen extraction and desorption gas enters the methanation reactor after pressurization and fine desul...

Embodiment 2

[0049] Embodiment 2: A kind of method for preparing hydrogen and liquefied natural gas from dry distillation furnace raw gas, such as figure 1 shown, including the following steps:

[0050] ① The raw gas of retort furnace is pretreated by adsorption to remove tar and naphthalene, and then enters the gas tank for buffering;

[0051] ②The buffered raw coal gas is pressurized and enters the sulfur-tolerant shift reactor to make carbon monoxide react with steam to generate carbon dioxide and hydrogen;

[0052] ③The shift gas is desulfurized by PDS wet method, the desulfurization liquid is regenerated and recycled, and sulfur is produced as a by-product;

[0053] ④ The shifted gas after desulfurization is decarburized and hydrogenated by two-stage PSA pressure swing adsorption process; the obtained hydrogen is sent to the tar hydrogenation unit as raw material;

[0054] ⑤ The hydrogen extraction and desorption gas enters the methanation reactor after pressurization and fine desul...

Embodiment 3

[0060] Embodiment 3: A method for preparing hydrogen and liquefied natural gas from dry distillation furnace raw gas, comprising the following steps:

[0061] ① The raw gas of retort furnace is pretreated by adsorption to remove tar and naphthalene, and then enters the gas tank for buffering;

[0062] ②The buffered raw coal gas is pressurized and enters the sulfur-tolerant shift reactor to make carbon monoxide react with steam to generate carbon dioxide and hydrogen;

[0063] ③The shift gas is desulfurized by PDS wet method, the desulfurization liquid is regenerated and recycled, and sulfur is produced as a by-product;

[0064] ④ The shifted gas after desulfurization is decarburized and hydrogenated by two-stage PSA pressure swing adsorption process; the obtained hydrogen is sent to the tar hydrogenation unit as raw material;

[0065] ⑤ The hydrogen extraction and desorption gas enters the methanation reactor after pressurization and fine desulfurization, and the hydrogen in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com