Method for producing biogas in large biogas project

A biogas and engineering technology, applied in chemical instruments and methods, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the hazards of livestock and poultry workers, deteriorate the quality of the atmospheric environment, and affect the production performance of livestock and poultry, etc. problems, to achieve the effects of less chemical pollution, improved product quality, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

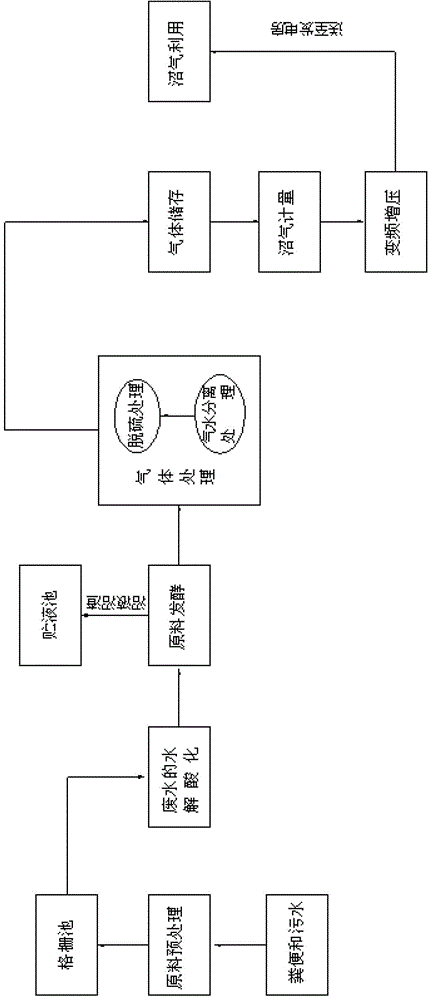

Image

Examples

Embodiment 1

[0031] (1) Transport the pig manure and waste water to the treatment station, and filter out the silt and suspended matter in the pig manure through the grid pool.

[0032] (2) Transfer the pig manure and wastewater treated in step (1) to the hydrolysis acidification tank for dilution, and stir them evenly through the agitator to degrade part of the suspended matter, convert macromolecular organic matter into small molecular forms, and improve the biochemical properties of wastewater and remove COD from wastewater.

[0033] (3) The raw materials processed in step (2) are transported to the fermentation chamber through the feed pump. The fermentation chamber is an integrated anaerobic fermentation tank, and the improved UASB fermentation process is used to seal the raw materials processed in step (2). Fermentation, the fermentation temperature is controlled at 35°, and biogas is produced after a long period of anaerobic fermentation. The biogas slurry and biogas residue produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com