Porous metal organic framework material based on transition metal cobalt and preparation method thereof

A technology of porous metals and organic frameworks, applied in separation methods, chemical instruments and methods, fuels, etc., can solve problems such as lack of research on MOFs materials, and achieve good application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: Synthesis of Co at high pressure 3 (BTC) 2

[0063] (1) Weigh 1.64g cobalt acetate (Co(CH 3 COO) 2 4H 2 O) and 0.80g trimesic acid (H 3 BTC) was dissolved in 60ml of absolute ethanol, and stirred for 30min until uniform to obtain a mixed solution;

[0064] (2) Transfer the mixed solution to a 150ml autoclave with a polytetrafluoroethylene liner, seal it tightly, place it in an oven at 150°C for 120h (5 days), and cool down naturally.

[0065] (3) Centrifuge (10000rpm, 5min) to separate the obtained solid;

[0066] (4) Wash the solid with water (4×25ml) and ethanol (2×25ml) respectively.

[0067] (5) The solid powder was dried at 110°C overnight to obtain 0.73 g of purple lumps.

[0068] N 2 The specific surface area is 109.04m 2 / g (determined by Langmuir method);

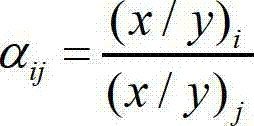

[0069] The obtained adsorbent is at 298K, between 0-1Mpa, CH 4 / N 2 The equilibrium adsorption separation factor is between 3.5-6, CO 2 / CH 4 The equilibrium adsorption separatio...

Embodiment 2

[0070] Example 2: Synthesis of CoBDC at high pressure

[0071] (1) Weigh 2.70g of cobalt acetate (Co(CH 3 COO) 2 4H 2 O) and 1.50g terephthalic acid (H 2 BDC) was dissolved in 60ml of DMF, stirred for 30min until uniform, to obtain a mixed solution;

[0072] (2) Transfer the mixed solution to a 150ml autoclave with a polytetrafluoroethylene liner, seal it tightly, place it in an oven at 140°C for 72h (3 days), and cool down naturally.

[0073] (3) Centrifuge (10000rpm, 5min) to separate the obtained solid;

[0074] (4) Wash the solid with water (2×50ml) and ethanol (50ml) respectively.

[0075] (5) The solid powder was dried at 110° C. for 12 hours to obtain 1.33 g of the product.

[0076] N 2 The specific surface area is 31.54m 2 / g (as determined by the Langmuir method).

[0077] The obtained adsorbent is at 298K, between 0-1Mpa, CH 4 / N 2 The equilibrium adsorption separation factor is between 3.5-5.5, CO 2 / CH 4 The equilibrium adsorption separation factor is ...

Embodiment 3

[0078] Embodiment 3: high pressure synthesis Co (bdc) (dabco) 0.5

[0079] (1) Weigh 1.25g cobalt acetate (Co(CH 3 COO)2 4H 2 O), 0.84g terephthalic acid (H 2 BDC) and 0.56g of triethylenediamine (DABCO) were dissolved in 60ml of DMF, stirred for 30min until uniform, and a mixed solution was obtained;

[0080] (2) Transfer the mixed solution to a 150ml autoclave lined with polytetrafluoroethylene, seal it tightly, place it in an oven at 120°C for 48 hours, and then cool down naturally.

[0081] (3) Centrifuge (10000rpm, 5min) to separate the obtained solid;

[0082] (4) The solid was washed with DMF (2×50ml) and methanol (2×50ml) respectively.

[0083] (5) The solid was dried overnight at 110°C to obtain 1.14 g of purple lumps.

[0084] N 2 The specific surface area is 830.12m 2 / g (as determined by the Langmuir method).

[0085] The obtained adsorbent is at 298K, between 0-1Mpa, CH 4 / N 2 The equilibrium adsorption separation factor is between 4-7, CO 2 / CH 4 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com