Washing machine and washing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

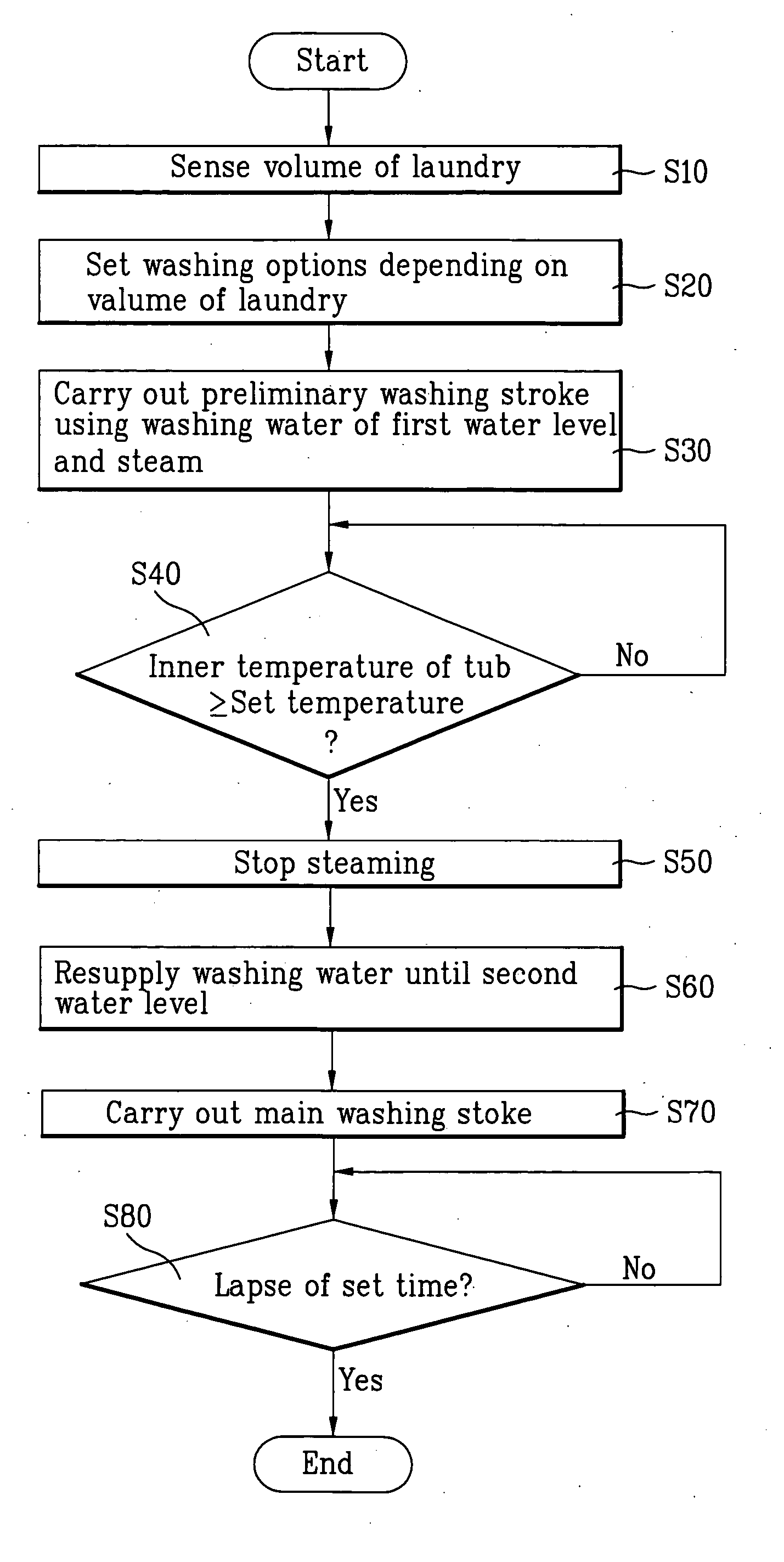

[0063]FIG. 6 is a flow chart illustrating a washing method according to the first embodiment of the present invention. Referring to FIG. 6, if a washing stroke starts, the controller 700 senses the volume of the laundry (S10). The controller 700 repeatedly rotates the drum 300 in forward and reverse directions to sense the volume of the laundry. The controller 700 determines the volume of the laundry based on load and rotational speed of the drum 300 detected when the drum 300 is rotated. Another methods of determining the volume of the laundry may be applied to the present invention.

[0064] If the volume of the laundry is determined, the controller 700 selects various washing options depending on the volume of the laundry (S20). For example, the controller 700 can determine the volume of the washing water (first water level) to be used for a preliminary washing stroke, the volume of the washing water (second water level) to be used for a main washing stroke, duration of the washing...

second embodiment

[0073]FIG. 7 is a flow chart illustrating a washing method according to the second embodiment of the present invention. Referring to FIG. 7, if a washing stroke starts, the controller 700 determines the volume of the laundry (S110) and selects various washing options depending on the volume of the laundry (S120). For example, the controller 700 can set the volume of the washing water (first water level) to be used for the preliminary washing stroke, the volume of the washing water (second water level) to be used for the main washing stroke, number of times / duration of the rinsing stroke, number of times / duration of the dehydrating stroke, duration of the preliminary washing stroke (first set time), duration of the main washing stroke (second set time), and so on depending on the volume of the laundry.

[0074] Then, the controller 700 carries out the preliminary washing stroke using the steam and the washing water of the first water level during the preliminary washing stroke duration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com