Washing machine with steam-washing function and control method

A control method and washing machine technology, which are applied to the control device of washing machine, other washing machines, washing devices, etc., can solve the problems of occupying the inner space of washing machine, increasing the production cost of washing machine, and increasing the size of the whole washing machine, so as to achieve suitable promotion and use, Simple structure and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

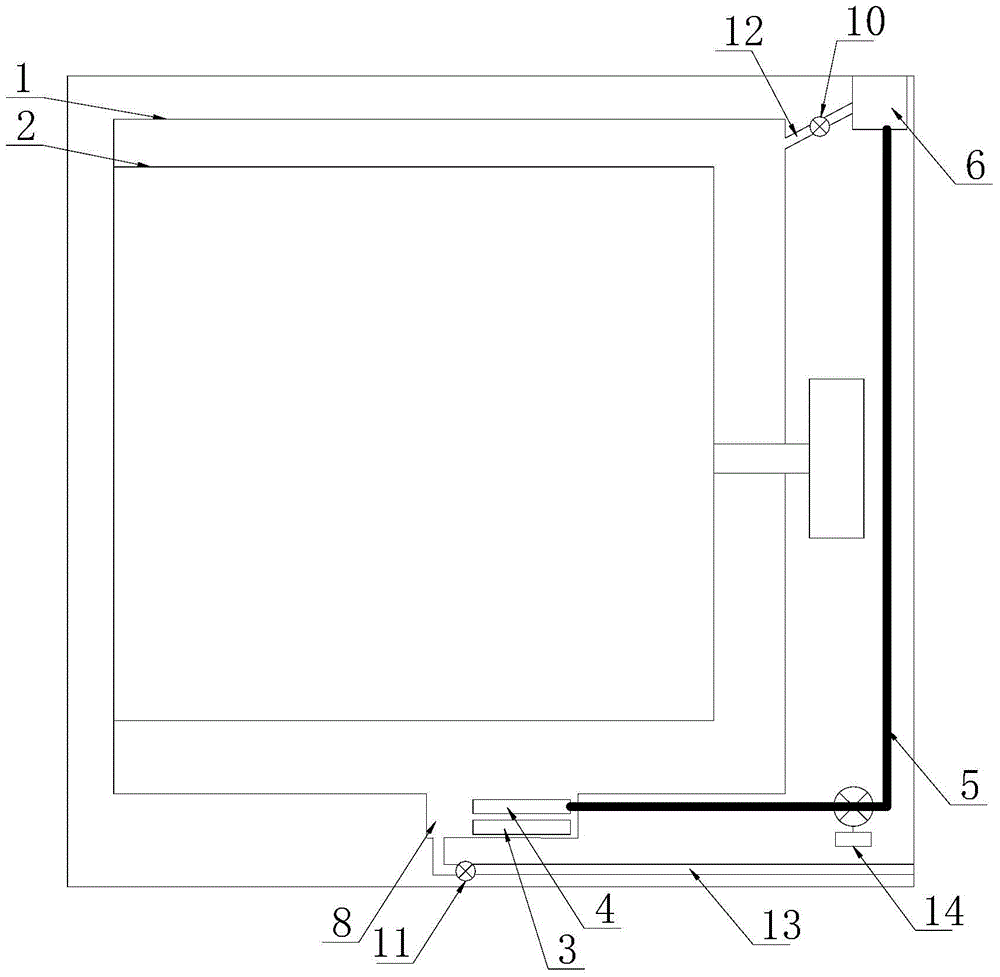

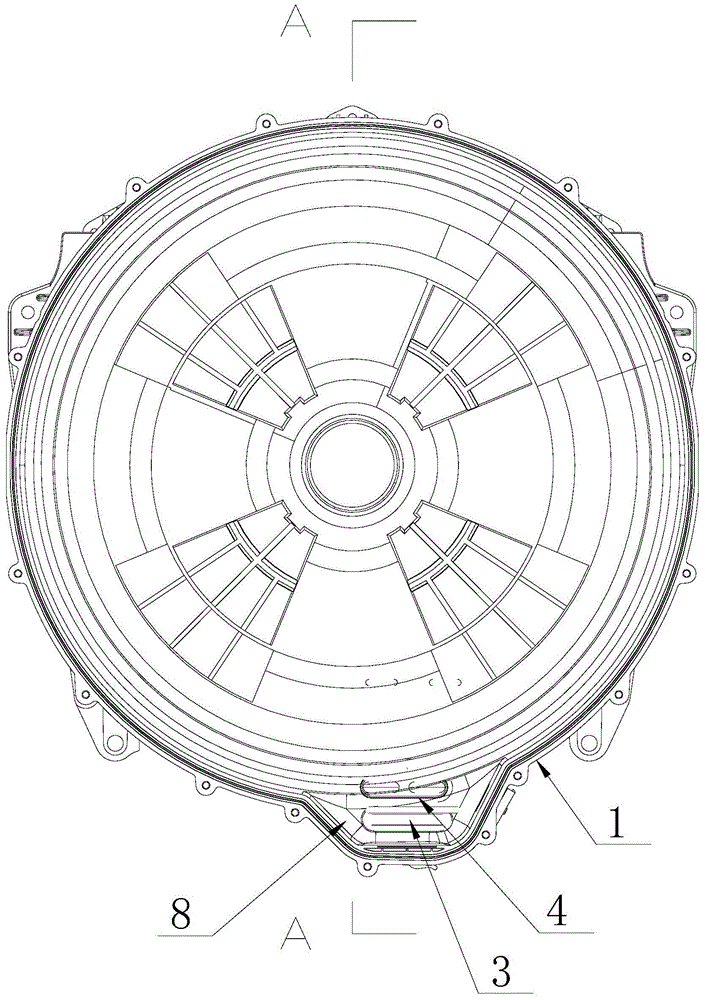

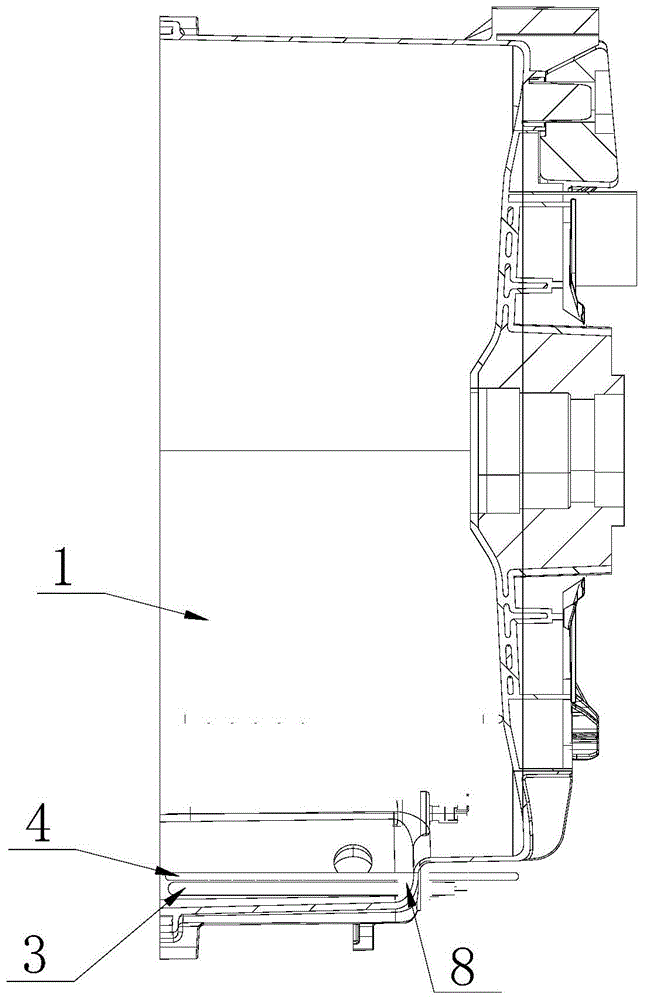

[0039] like Figure 1 to Figure 4 As shown, in this embodiment, the sprayer 4 and the heater 3 are correspondingly attached or arranged at intervals, and a plurality of spray holes for spraying water to the heater 3 are arranged on the corresponding side of the sprayer 4 7. Preferably, in order to improve the coverage area of the spray holes 7, the sprayer 4 and the heater 3 are arranged at a certain gap; at the same time, the distance between the adjacent spray holes 7 is smaller than the diameter of the area covered by the spray water flow, All parts of the heater 3 can be in contact with the spray water, so as to improve the steam generation efficiency.

[0040] like Figure 4 and Figure 5 As shown, in this embodiment, the heater 3 is composed of a plurality of heating pipes arranged in an "S" shape; A plurality of spray holes 7 for spraying water to the heater 4 are arranged on the pipeline 40 at equal intervals along the axial direction. By arranging the same type...

Embodiment 2

[0044] like figure 1As shown, in this embodiment, the heater 3 and the shower 4 are both arranged between the outer cylinder 1 and the inner cylinder 2, and the steam generated at the heater 3 can pass through the dehydration holes provided on the inner cylinder 2, etc. It flows into the inner space of the inner cylinder 2 to perform steam washing, sterilization, deodorization and other treatments on the clothes in the inner cylinder 2 .

[0045] like figure 2 and 3 As shown, in this embodiment, the heater 3 is arranged at the bottom of the outer cylinder 1 , the shower 4 is arranged on the corresponding top of the heater 3 , and the shower hole 7 is arranged on the lower surface of the shower 4 . Since the steam density is low, it will move upward in the outer tub 1. By arranging the heater 3 at the bottom of the outer tub 1, the steam generated in the outer tub 1 is evenly distributed in the inner space of the outer tub 1, so that the clothes and the Steam can be fully ...

Embodiment 3

[0049] In this embodiment, the washing machine has a corresponding process of generating high-temperature steam, and the process specifically includes the following steps:

[0050] 1) Disconnect the water inlet and outlet pipes of the outer cylinder to make the inner space of the outer cylinder airtight;

[0051] 2) The washing machine feeds water to the sprayer, the sprayer sprays water to the heater, and the heater starts to work to generate high-temperature steam, so that the steam fills the inner space of the closed outer cylinder;

[0052] 3) While performing step 2), the inner cylinder rotates at a certain turn-to-stop ratio.

[0053] Through the above method, the inner space of the outer cylinder can be quickly and evenly filled with steam, and the steam can be used to heat and moisten the clothes, so that the washing machine has the functions of steam washing, drying clothes, sterilization, deodorization and ironing, and the effect is remarkable. .

[0054] In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com