Dish-washing machine spray thrower, dish-washing machine provided with the spray thrower and control method

A control method and technology for dishwashers, which are applied to dishwashers/washing machines for tableware, parts of dishwashers/rinsing machines for tableware, household cleaning devices, etc. The position of the sprinkler is uncontrollable, etc., to achieve the effect of remarkable effect, simple structure and suitable for popularization and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

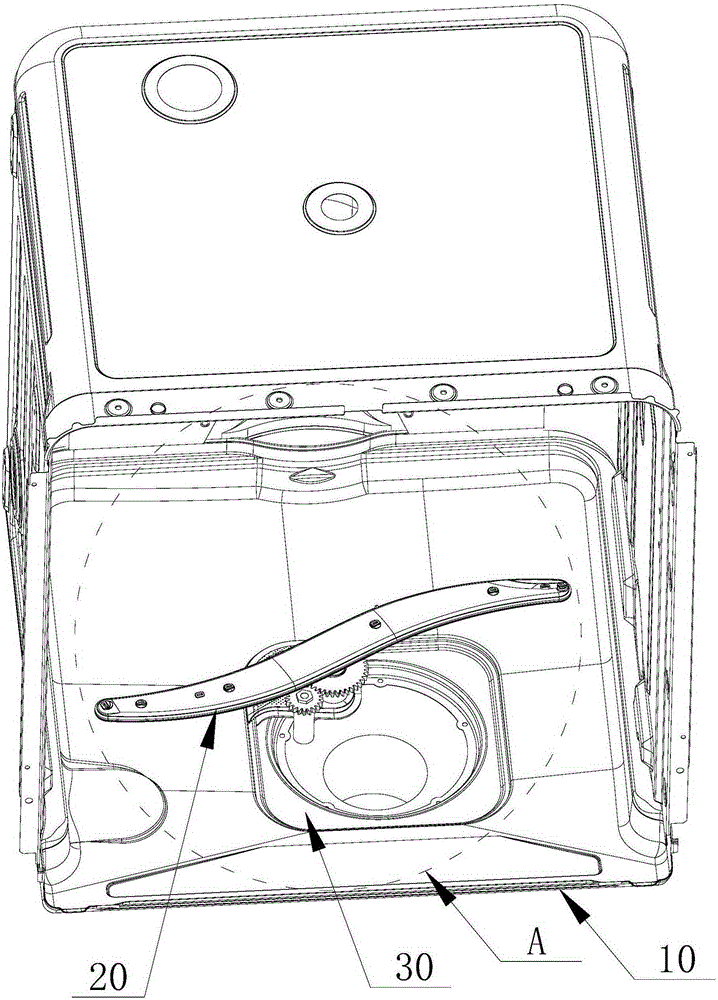

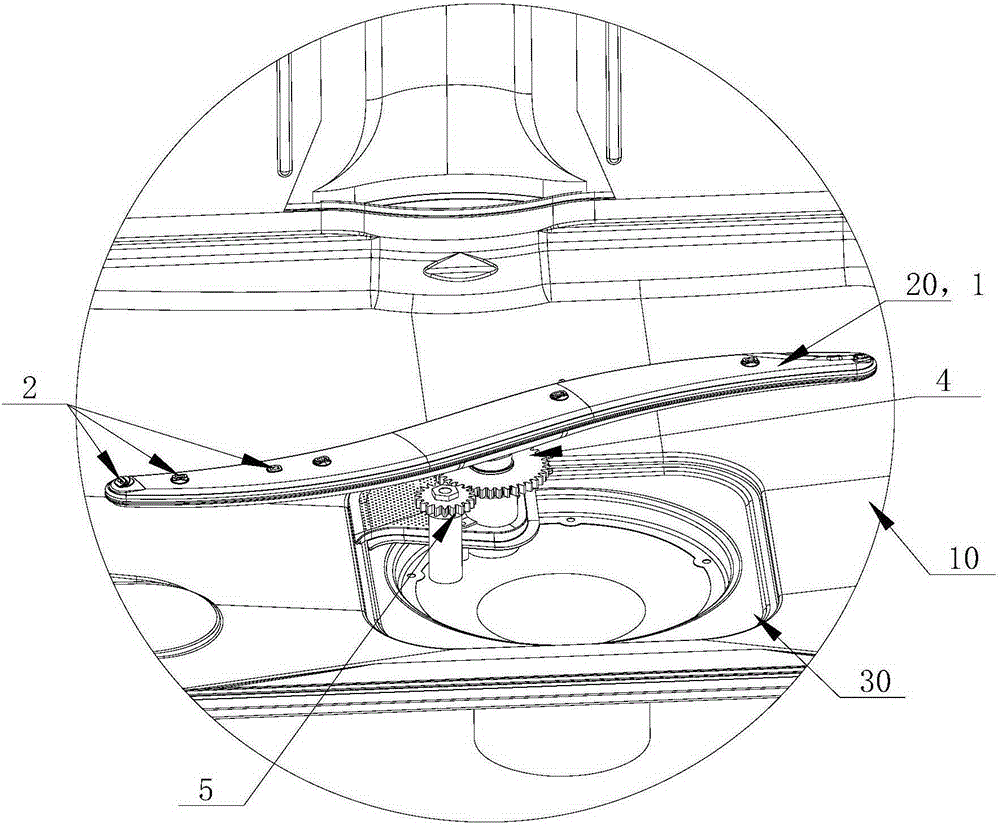

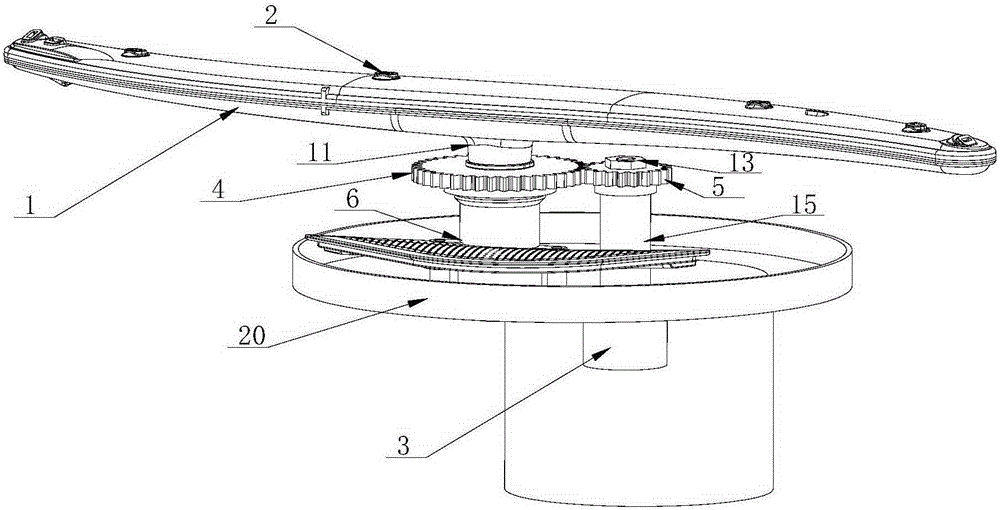

[0049] Such as Figure 1 to Figure 4 As shown, in this embodiment, a sink 30 for discharging washing water is provided at the center of the lower part of the inner container 10 of the dishwasher, and the shower 20 is disposed at the sink 30 . The spray arm 1 of the shower 20 is installed above the sink 30 of the dishwasher, and the motor 3 is arranged below the sink 30 . The motor shaft 31 of the motor 3 passes through the water tank 30 and engages with the rotating shaft 11 of the spray arm 1 on the other side; The motor shaft 31 is meshingly connected. Through the above arrangement, the connection between the motor shaft 31 and the rotating shaft 11 is ensured, so that the motor 3 drives the spray arm 1 to rotate;

[0050] Such as Figure 4 As shown, in this embodiment, the first gear 4 is fixedly installed on the rotating shaft 11 of the spray arm 1, and the second gear 5 is fixedly installed on the motor shaft 31 of the motor 3; The two gears 5 are meshed for transmiss...

Embodiment 2

[0059] The difference between this embodiment and the first embodiment above is that a sealing device is provided at the place where the motor shaft 31 and / or the rotating shaft 11 passes through the water tank 30, so as to prevent the water from passing through the water tank under the premise of ensuring the rotation of the motor shaft and / or the rotating shaft. Outflow everywhere.

[0060] Such as Figure 5 As shown, in this embodiment, the motor shaft 31 passes through the through hole 9 on the water tank 30 , and the through hole 9 is provided with a waterproof shaft seal 12 for fixing the motor shaft 31 . The waterproof shaft seal 12 is made of elastic rubber material; and the outer circumference of the waterproof shaft seal 12 is in sealing contact with the through hole 9 , and the inner circumference is in sealing contact with the motor shaft 31 .

[0061] Through the above-mentioned arrangement, it is also possible to prevent the water in the water tank from flowing ...

Embodiment 3

[0063] The difference between this embodiment and the first embodiment above is that: the rotating shaft 11 of the spray arm 1 is directly engaged with the motor shaft 31 of the motor 3 , so that the spray arm 1 is driven by the motor 3 to rotate around the rotating shaft 11 .

[0064] Such as Figure 6 As shown, in this embodiment, the motor 3 is arranged at the lower part of the water tank 30 , the spray arm 1 is arranged at the upper part of the water tank 30 , and the rotating shaft 11 of the spray arm 1 is coaxially arranged with the motor shaft 31 of the motor 3 . The motor shaft 31 of the motor 3 passes through the water tank 30 from top to bottom, and is directly fixedly connected with the rotating shaft 11 . The fixed connection mode between the motor shaft 31 and the rotating shaft 11 can be any fixed connection mode in the prior art, such as: threaded connection, buckle connection, shaft sleeve connection, key connection, etc.; Figure 6 In the shown manner, the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com