Milk foam kettle

A milk foam and cup body technology, which is applied in the field of milk foam pots, can solve the problems of increased weight, difficult to clean, and cannot be separated, and achieves the effect of enhancing the taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

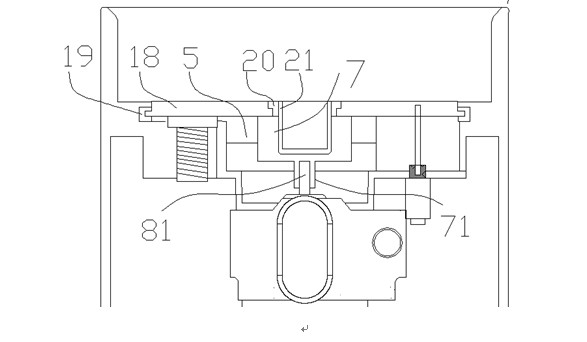

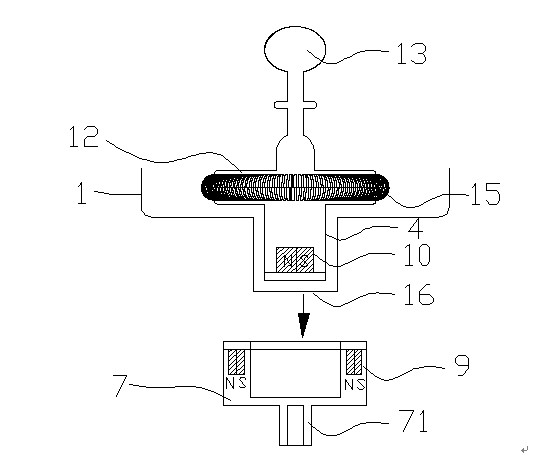

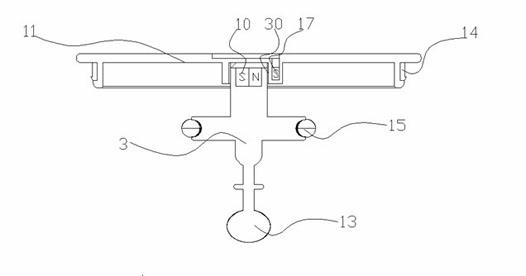

[0026] A milk frothing jug includes a cup body 1 and a base 2, and a cup cover 11 is provided above the cup body 1. The cup body 1 and the base 2 are independent parts, and the two can be separated; the cup body 1 can be placed on the base 2 arbitrarily at 360 degrees. The cup body 1 can be separated from the base 2 without destroying or disassembling, the cup body 1 can be taken out from the base 2, and the cup body 1 and the base 2 can be cleaned, maintained and replaced separately.

[0027] The bottom of the cup body 1 is provided with a stirrer 3 and a positioning sleeve 16; Among them, a driving device 7 for driving the stirrer 3 to rotate is provided below the heating element 5 , and the driving device 7 is connected with a driving motor 8 . The driving device 7 is driven by the output shaft 81 of the driving motor 8 , the output shaft 81 is connected with the joint 71 of the driving device 7 , and the driving motor 8 is installed on the base 2 . In order to facilitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com