Method and device for preparing ordered porous alumina template

A porous alumina and template technology, applied in the direction of anodic oxidation, etc., can solve the problems of expensive, time-consuming, energy and experimental materials, and restrict the progress of research topics, and achieve the effect of low cost and adjustable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

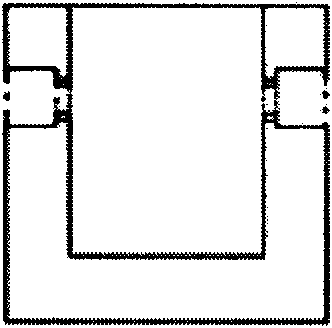

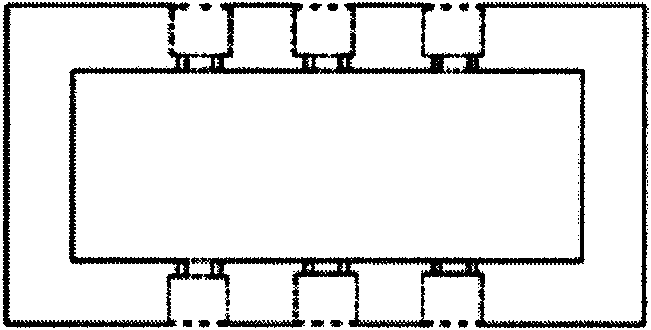

Image

Examples

Embodiment

[0042] (1) Annealing: the aluminum foil is annealed (500°C, 5h) to eliminate the stress generated during the shearing process of the aluminum foil.

[0043] (2) Cleaning oil stains: immerse the annealed aluminum foil in acetone, alcohol and deionized water in sequence, and ultrasonically clean them for 3 minutes respectively.

[0044] (3) Removing the natural oxide layer: immerse the cleaned aluminum foil in an 8% NaOH solution (at a constant temperature of 60° C.) for 1 min and 45 s, and then take it out and clean it with deionized water.

[0045] (4) Electropolishing: Put the aluminum foil on the electrolytic device (the anode is connected to the aluminum foil), and immerse it in the electropolishing solution (95vol%H 3 PO 4 (85%)+5vol%H 2 SO 4 (97%)+20g / L Cr 2 o 3 ) and polished for 4 minutes, and rinsed with deionized water. The electrolytic polishing parameters are: water bath constant temperature 85°C; electrolytic current 0.8A.

[0046] (5) Primary anodizing: Put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com