Patents

Literature

176 results about "Alumina membranes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for forming aluminum oxide film using Al compound containing alkyl group and alkoxy or alkylamine group

ActiveUS8784950B2Safety with regard to handling and storage of the precursor can be ensuredDamage is causedChemical vapor deposition coatingPlasma techniqueProduct gasPhotochemistry

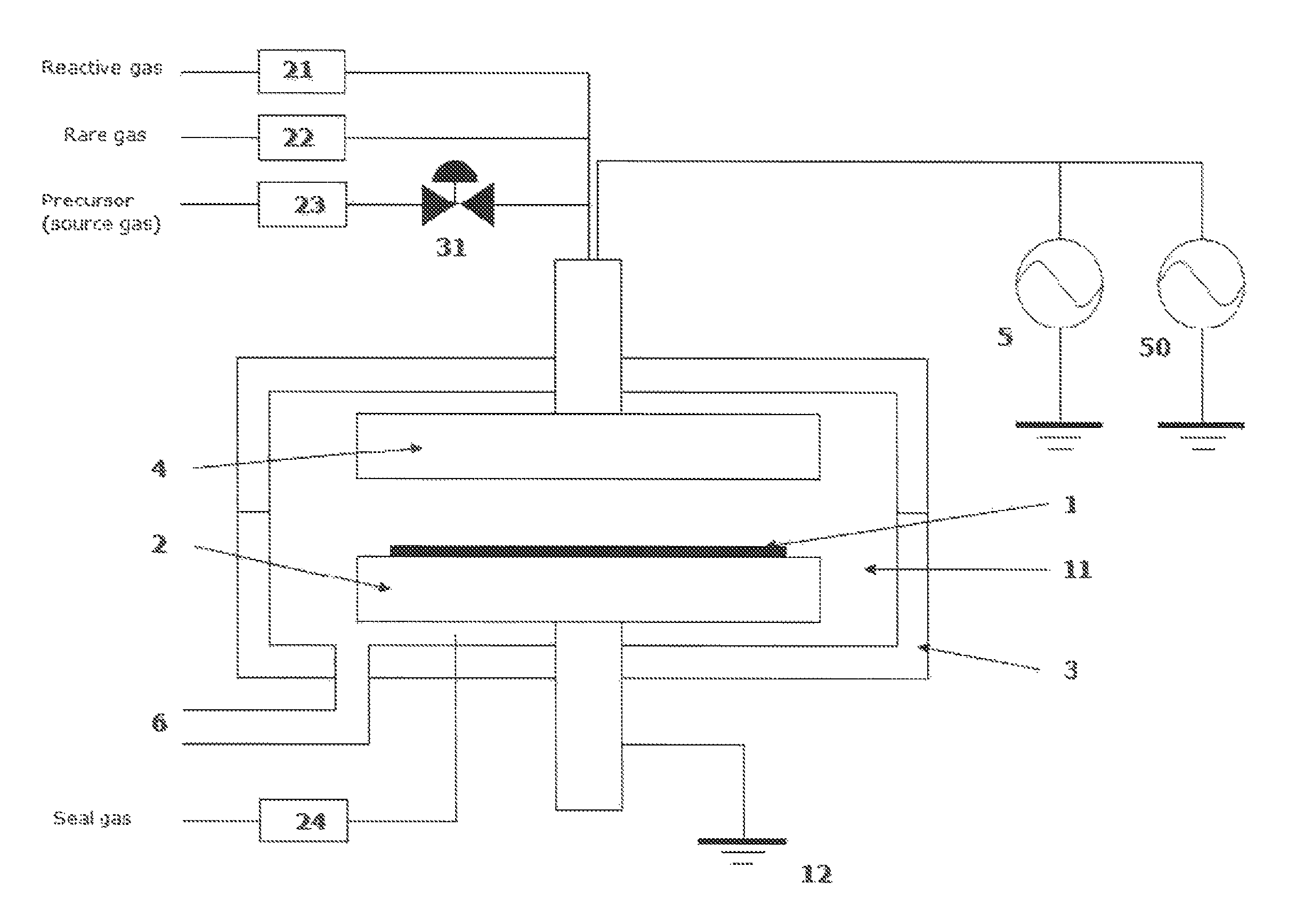

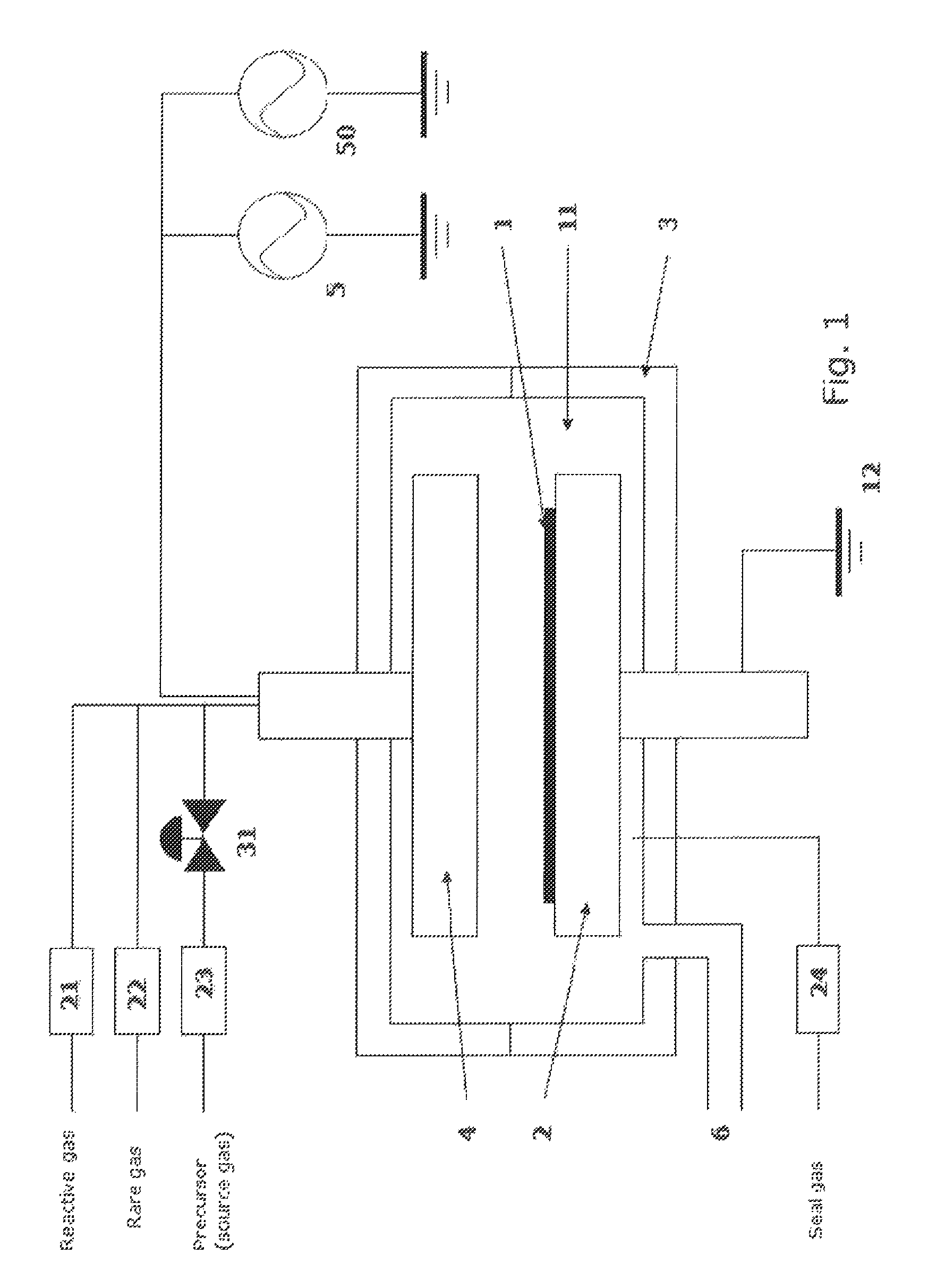

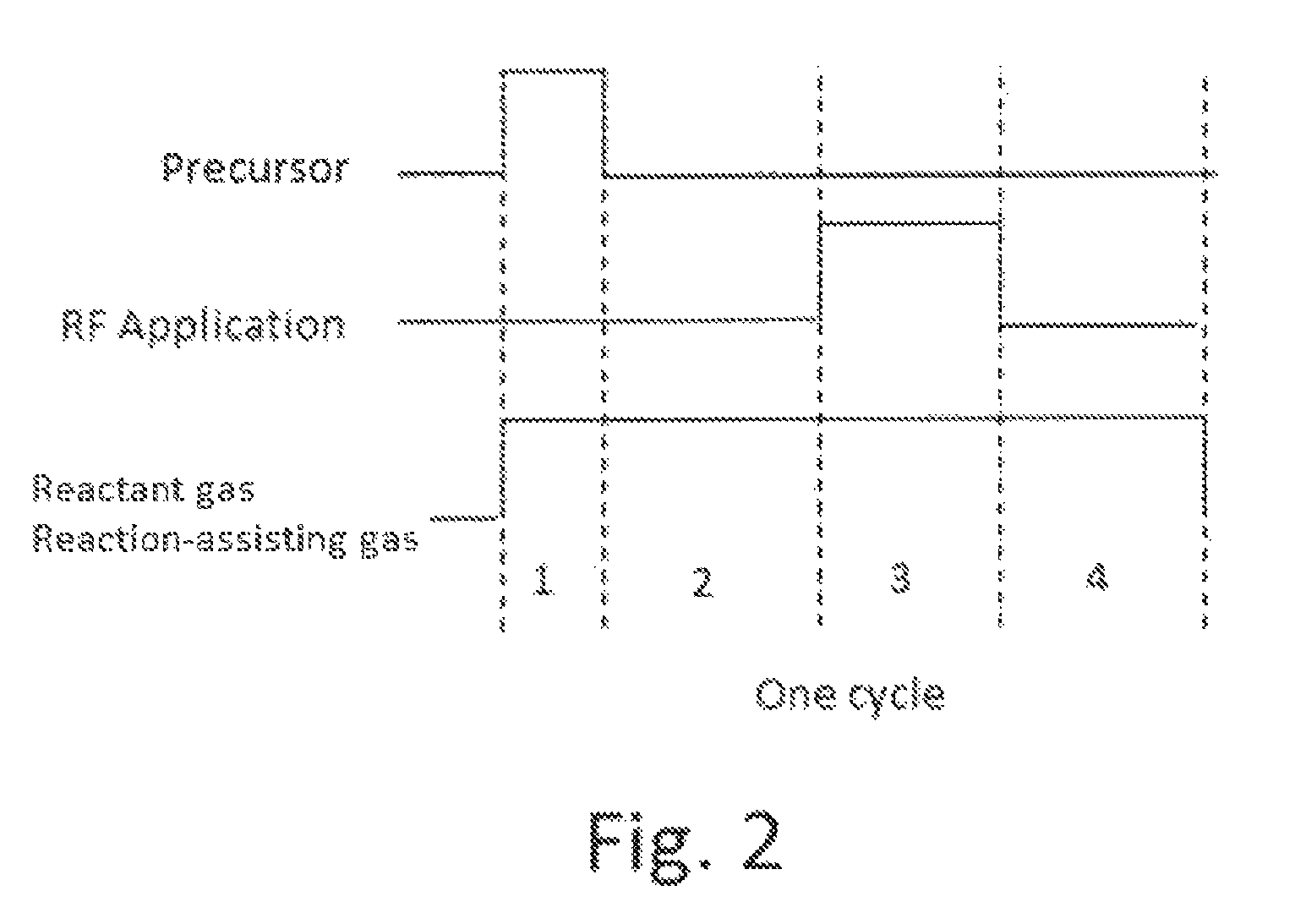

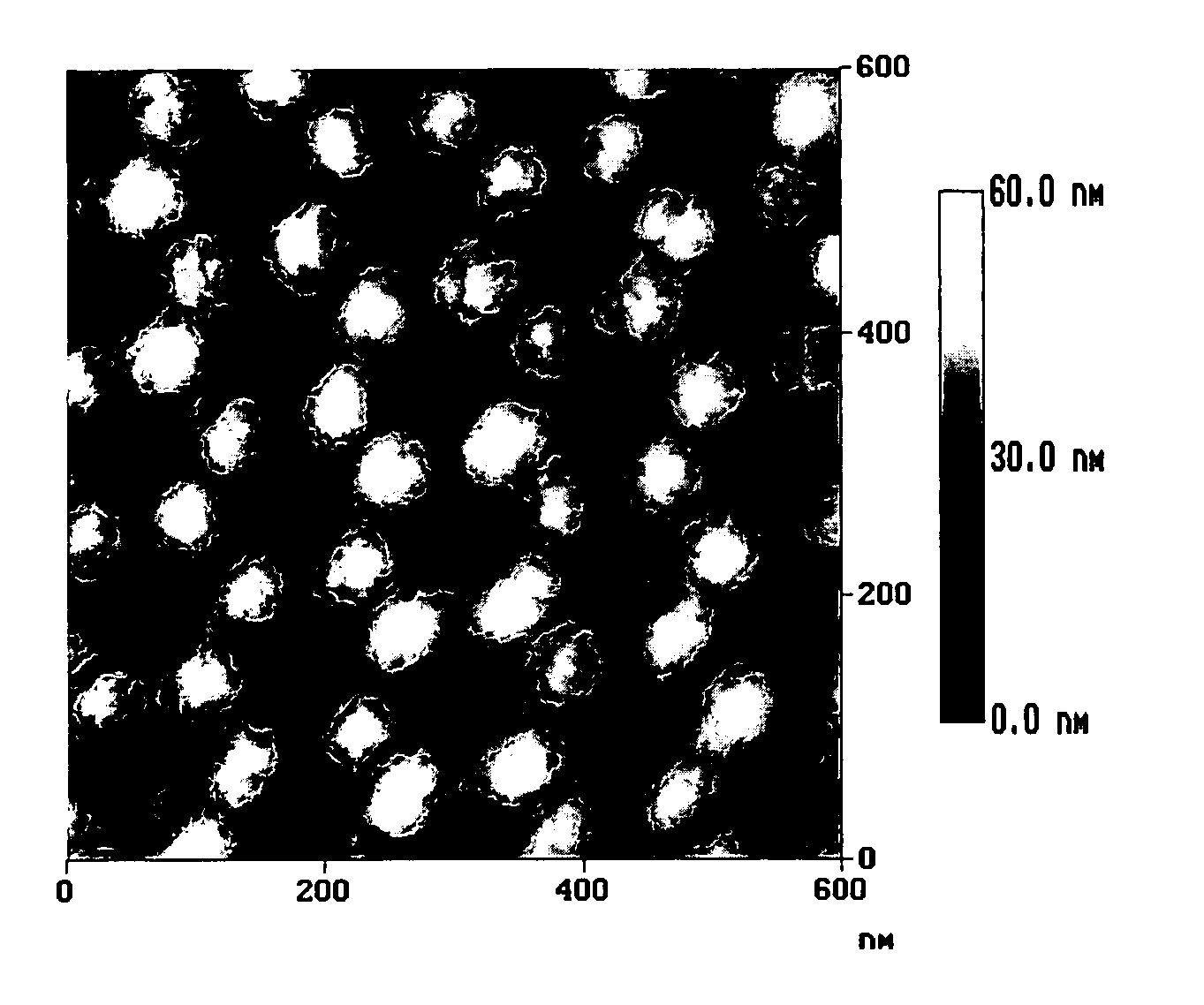

A method for forming a conformal film of aluminum oxide on a substrate having a patterned underlying layer by PEALD includes: adsorbing an Al precursor containing an Al—C bond and an Al—O—C or Al—N—C bond; providing an oxidizing gas and an inert gas; applying RF power to the reactant gas and the reaction-assisting gas to react the adsorbed precursor with the reactant gas on the surface, thereby forming a conformal film of aluminum oxide on the patterned underlying layer of the substrate, wherein the substrate is kept at a temperature of about 200° C. or lower.

Owner:ASM IP HLDG BV

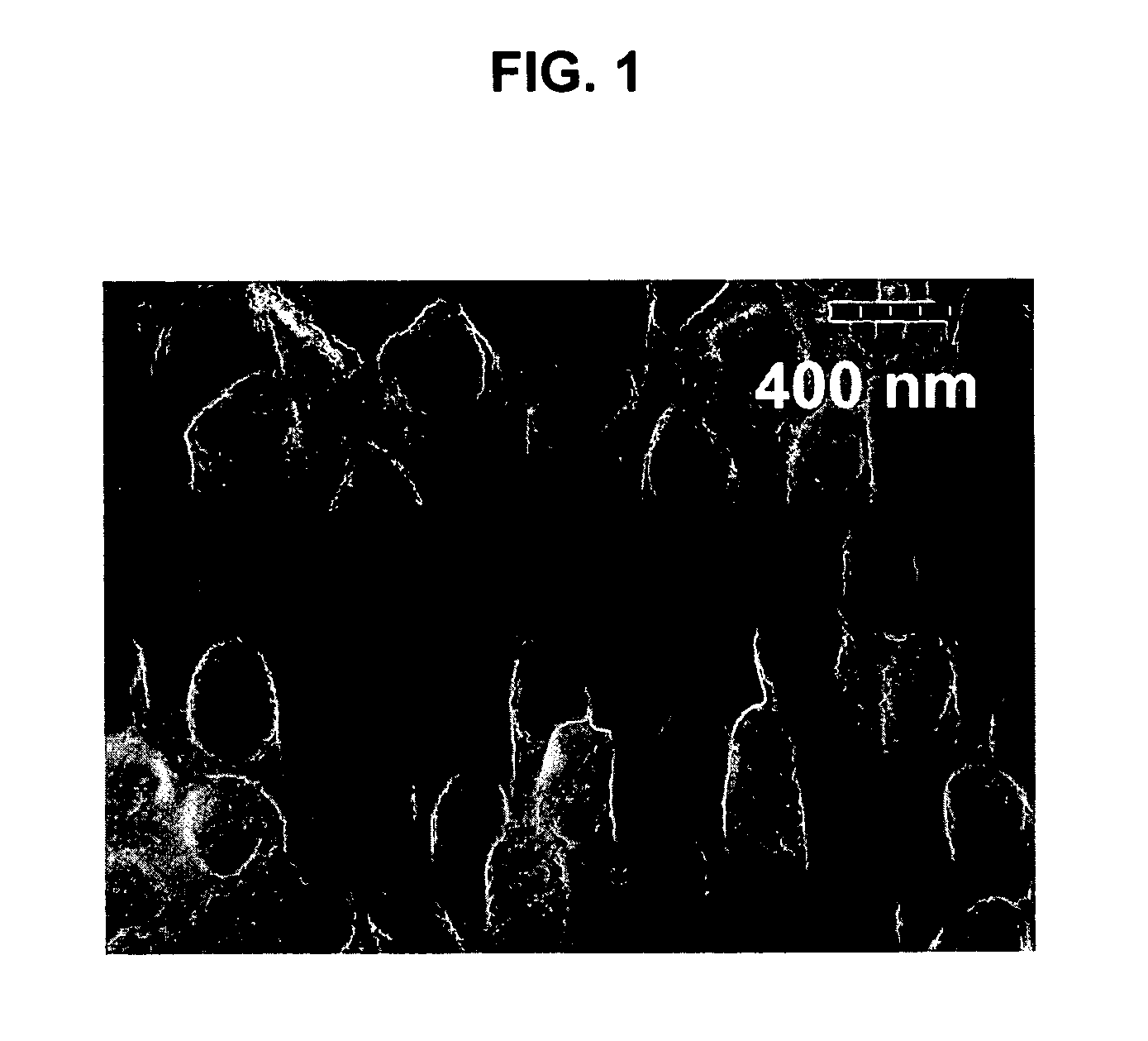

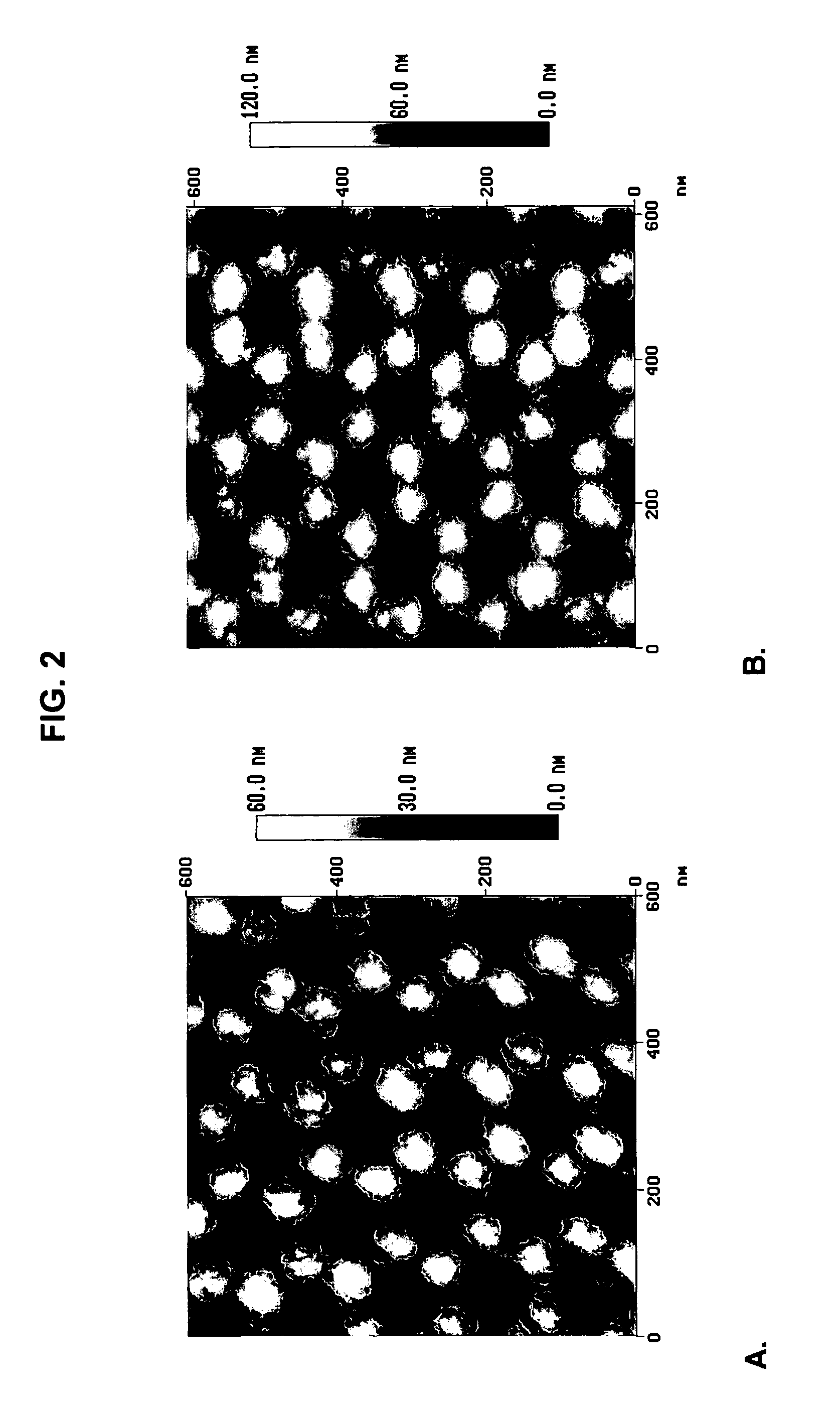

Nanostructures synthesized using anodic aluminum oxide

InactiveUS20060289351A1Simple methodEasy to makeMaterial nanotechnologyCoatingsHydrogen sensorNanostructure

This invention provides ways to fabricate nanotubes and nanobead arrays by utilizing nanopores in anodic aluminum oxide (AAO) membranes. Nanotubes of bismuth and other low melting point metals with controlled diameters and lengths can be fabricated by sintering AAO coated with appropriate metals at temperatures above their melting points. Carbon nanotubes may also be readily formed by carbonizing a polymer on the interior walls of the nanopores in AAO membranes. Palladium nanobead arrays which can be used as ultrafast hydrogen sensors are fabricated by coating the flat surface of AAO membranes with controlled pore-wall ratios.

Owner:UCHICAGO ARGONNE LLC

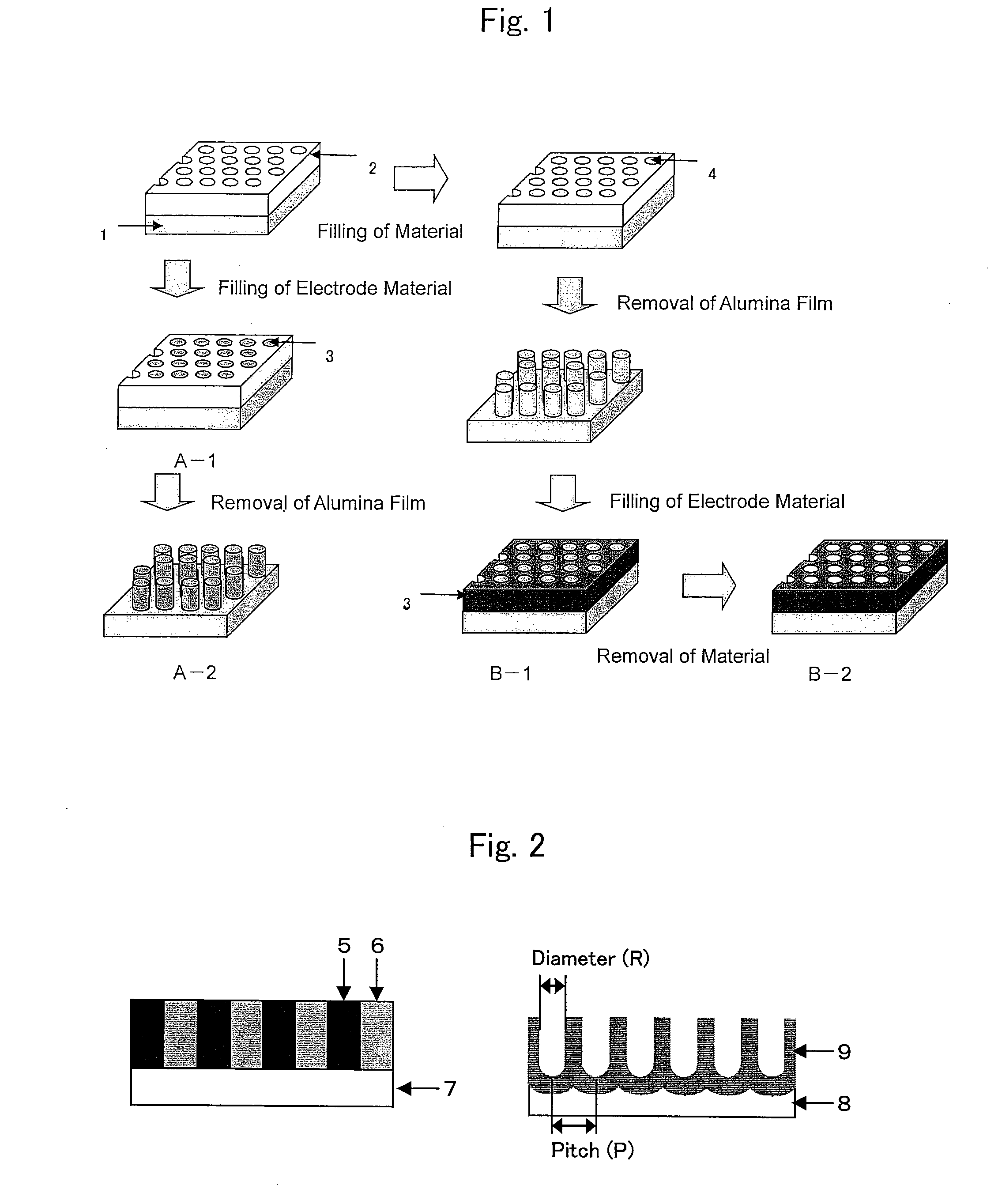

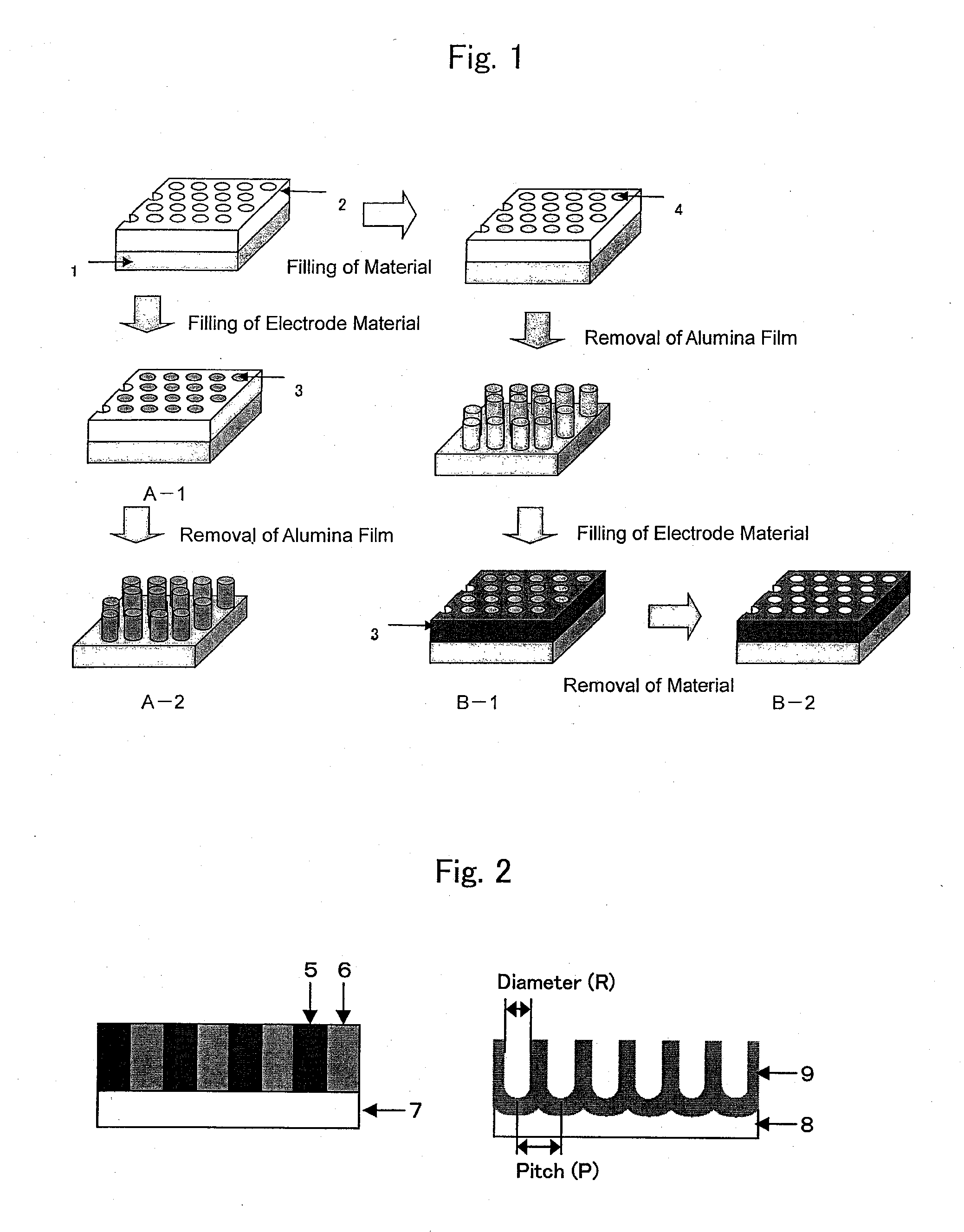

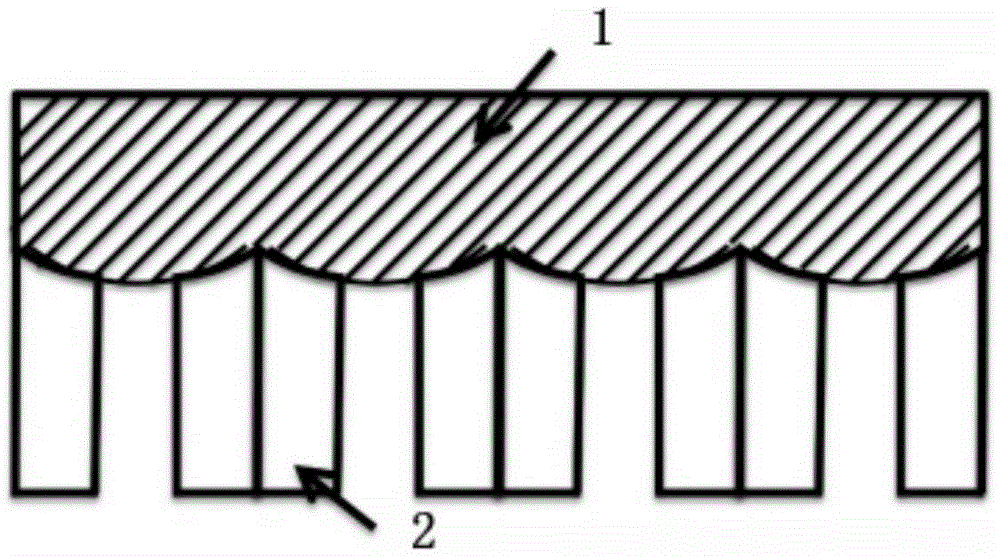

Method for manufacturing nano-array electrode and photoelectric conversion device using same

InactiveUS20060234505A1Improve efficiencyEfficient charge separationAnodisationFinal product manufactureNano structuringPhotoelectric conversion

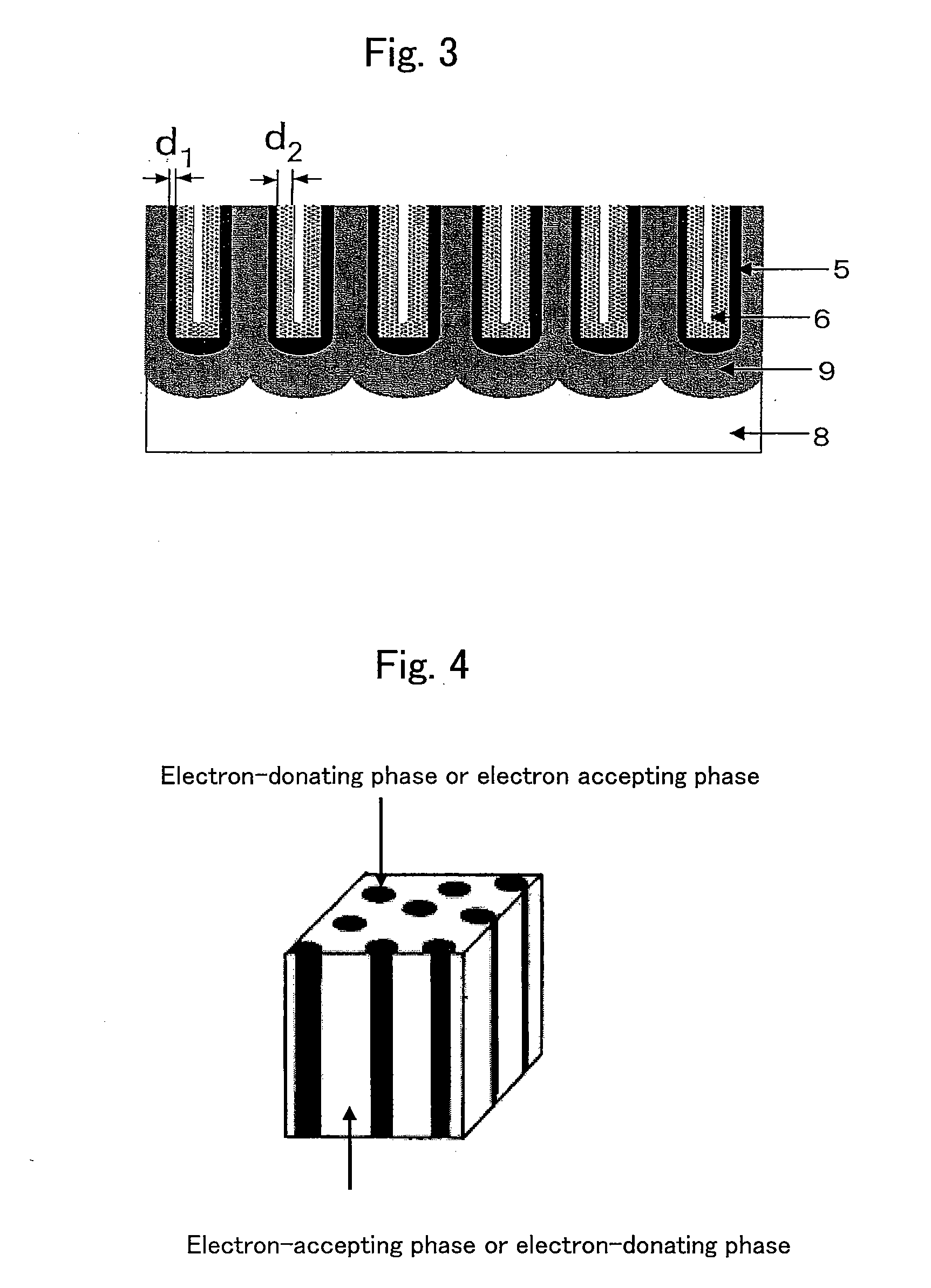

The present invention provides a method of manufacturing a nano-array electrode with a controlled nano-structure by filling an electrode material into the fine pores of an anodic-oxide porous alumina film obtained by anodically oxidizing aluminum in electrolyte, or by filling a material into the fine pores of an anodic-oxide porous alumina film obtained by anodically oxidizing aluminum in electrolyte and then filling an electrode material into the spaces defined by the nano-array formed by removing the anodic-oxide porous alumina film, or by filling repeatedly an electrode material in the fine pores of the anodic-oxide porous alumina film to fill a plurality of electrode materials. A high-performance, high-efficiency photoelectric converting device comprising a nano-array electrode manufactured by the method is also disclosed.

Owner:NIPPON OIL CORP

Solar cell with composite dielectric passivation layer structure and preparation process thereof

PendingCN110459615AIncrease short circuit currentIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationDielectricRefractive index

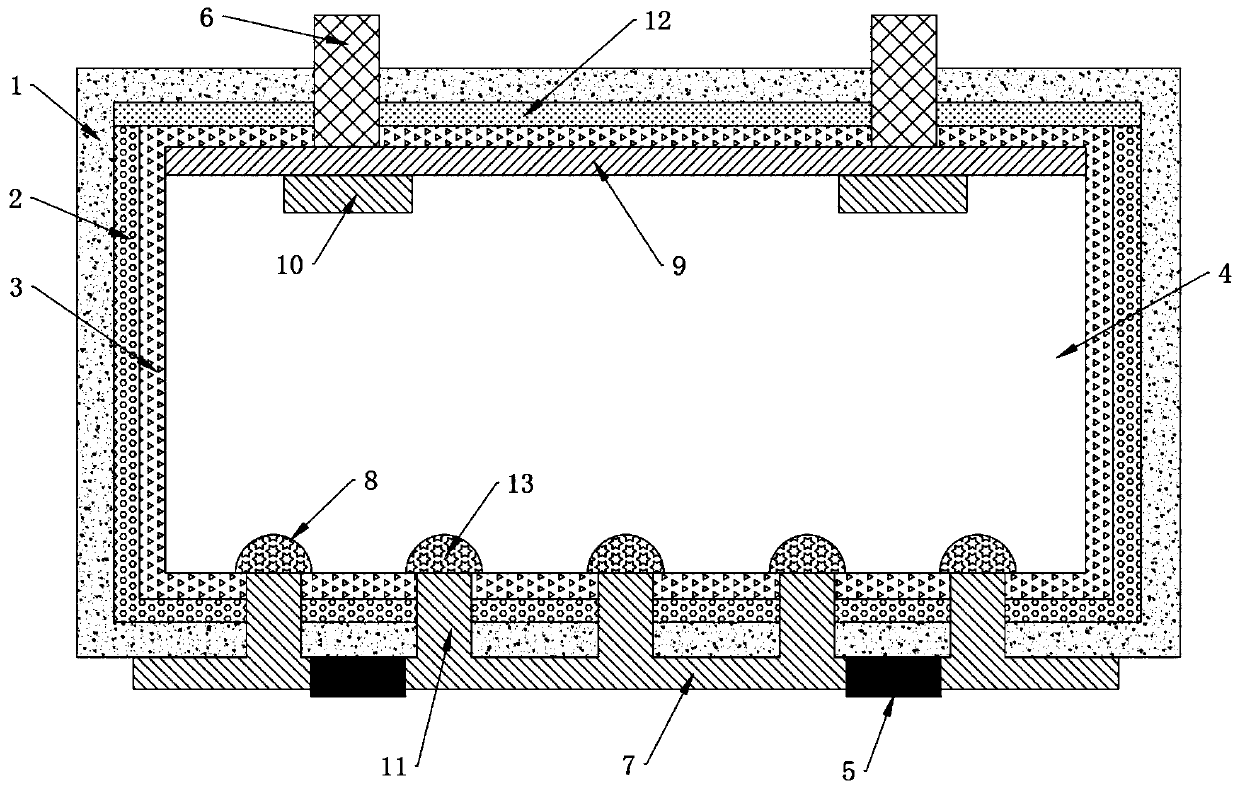

The invention discloses a solar cell with a composite dielectric passivation layer structure and a preparation process thereof. A silicon oxide film, an alumina film and a silicon nitride or silicon oxynitride film are deposited in turn on the front, back and sides of a p-type silicon substrate to form a composite dielectric film on the whole surface, and windows are opened locally to lead electrodes out. Through aluminum oxide, silicon dioxide, silicon oxynitride, silicon nitride with different refractive indexes and a back surface passivation layer with a laminated structure of the materials, the back surface recombination rate is greatly reduced, the back reflectivity is improved, the CTM of a module is reduced, and the light attenuation and heat-assisted light attenuation and the anti-PID performance of the cell are improved. The structure can be made on a boron / gallium-doped p-type monocrystalline silicon, p-type polycrystalline silicon or p-type monocrystalline-silicon-like substrate, and a passivation method based on the composite dielectric film passivation structure can be used to manufacture PERC cells, double-sided PERC+ cells and imbricate PERC cells. Based on the preparation process steps and sequence, the corresponding preparation mode and the process parameter range of the laminated structure, the making of the cell can be well completed.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID +2

Aliminium base wave absorbing material and preparing method

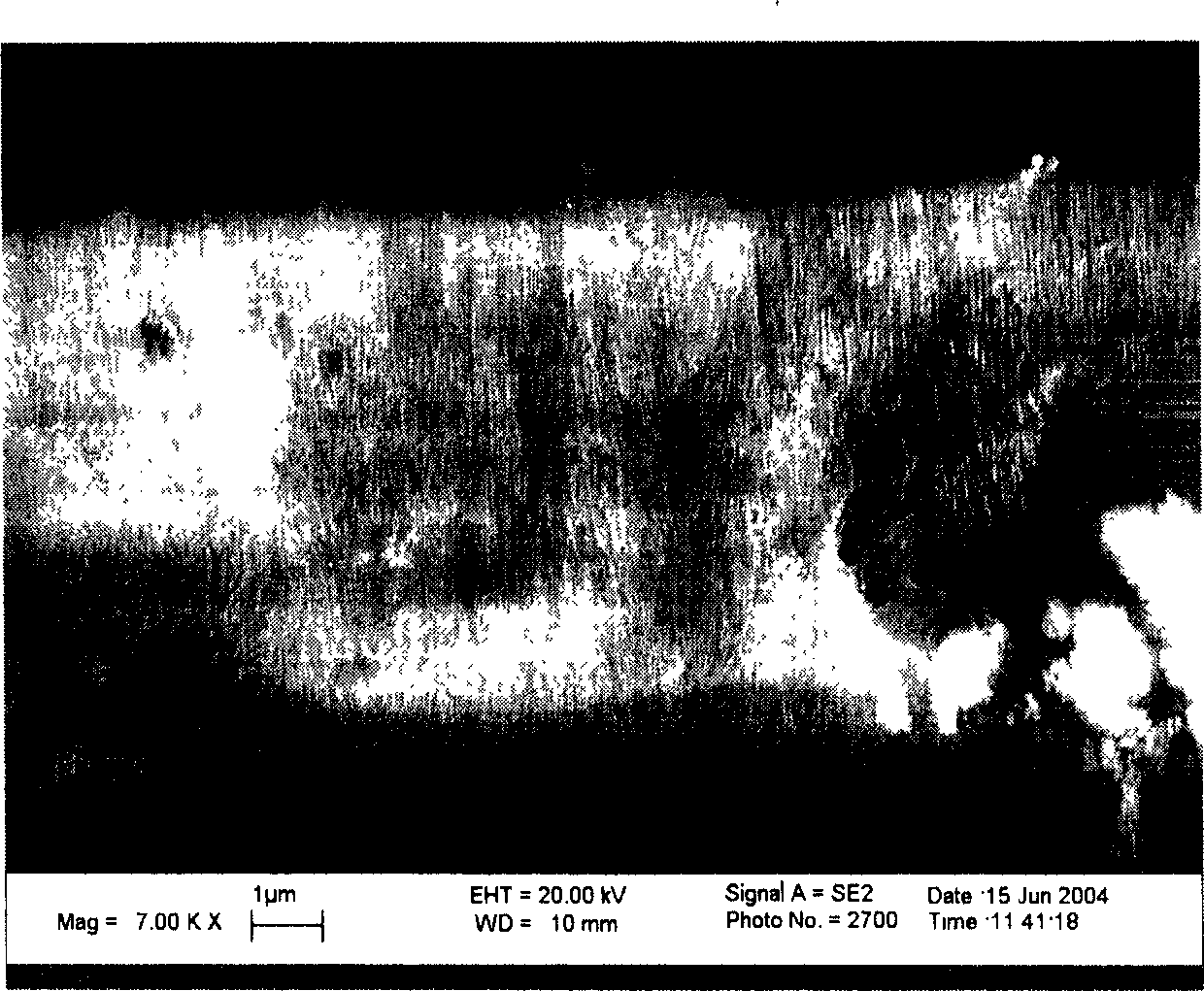

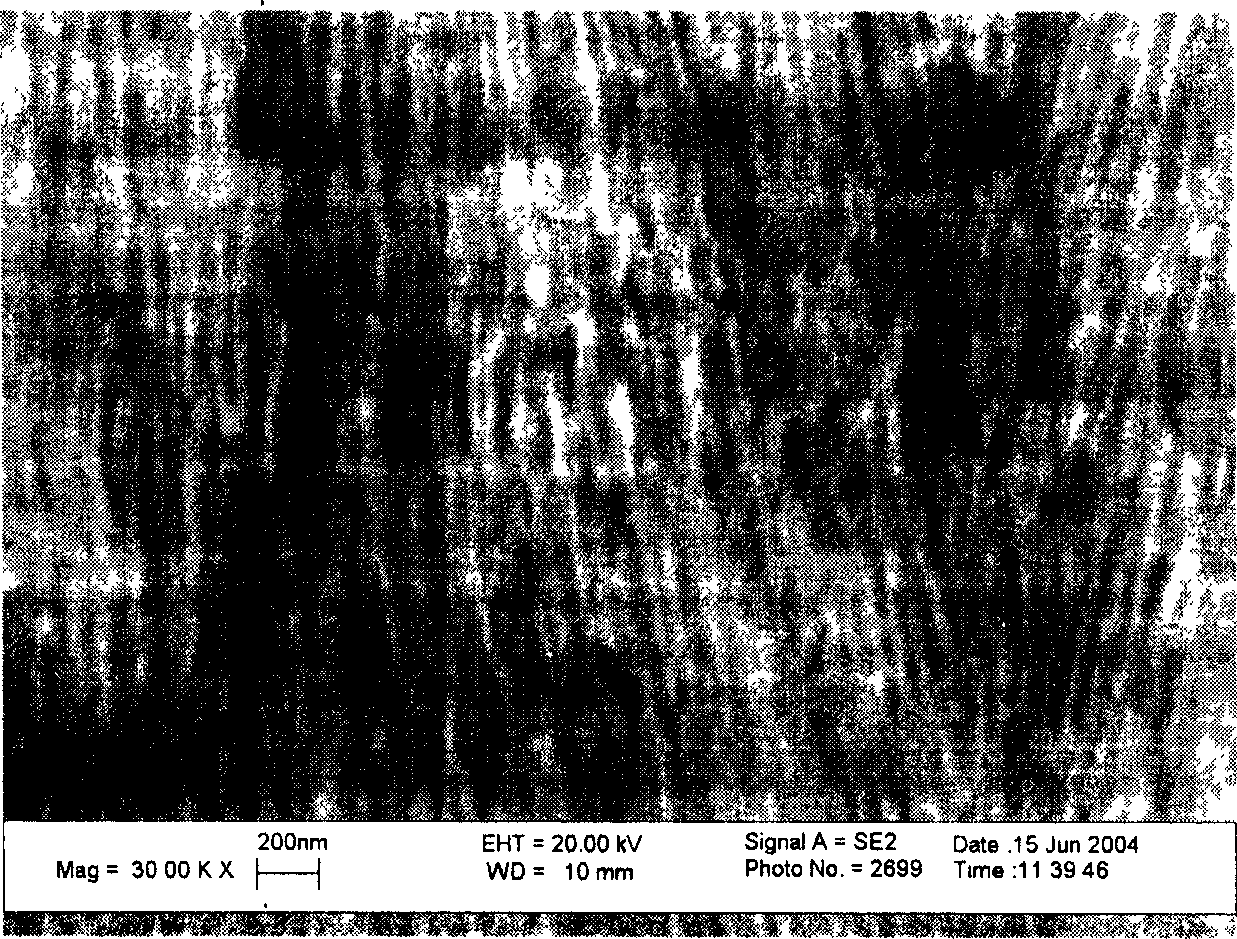

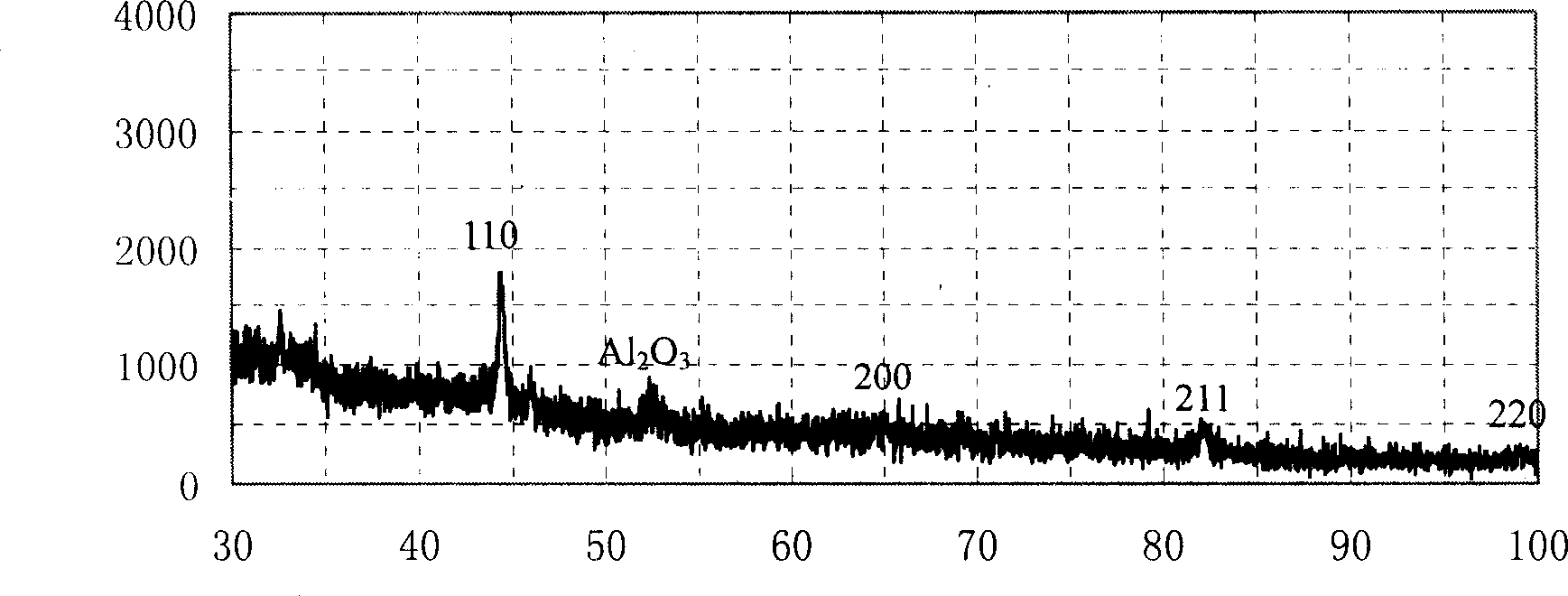

InactiveCN1715458AAvoid Tangle ProblemsImprove the absorbing effectMagnetic/electric field screeningSurface reaction electrolytic coatingAnode oxidationAluminium

The present invention belongs to the field of aluminum-base material in metallurgical technology, and is especially aluminum-base wave absorbing material and its preparation process. The present invention features that aluminum or aluminum alloy plate is treated first through one-step or two-step DC or AC anode oxidation process to form aluminum-base porous alumina template, or AAO template, with porous alumina film in the surface; and the template is then DC or pulse current electrochemically deposited to assemble nanometer magnetic metal wire array in the AAO porous film, so as to make the aluminum-base wave absorbing material with in-situ assembled nanometer magnetic metal wire array in the surface. The present invention has close combination between the wave absorbing material and the substrate and high wave absorbing effect caused by the coupling effect and the size effect of the nanometer wire array. The present invention may be used widely in stealth and electromagnetic shield.

Owner:CENT SOUTH UNIV

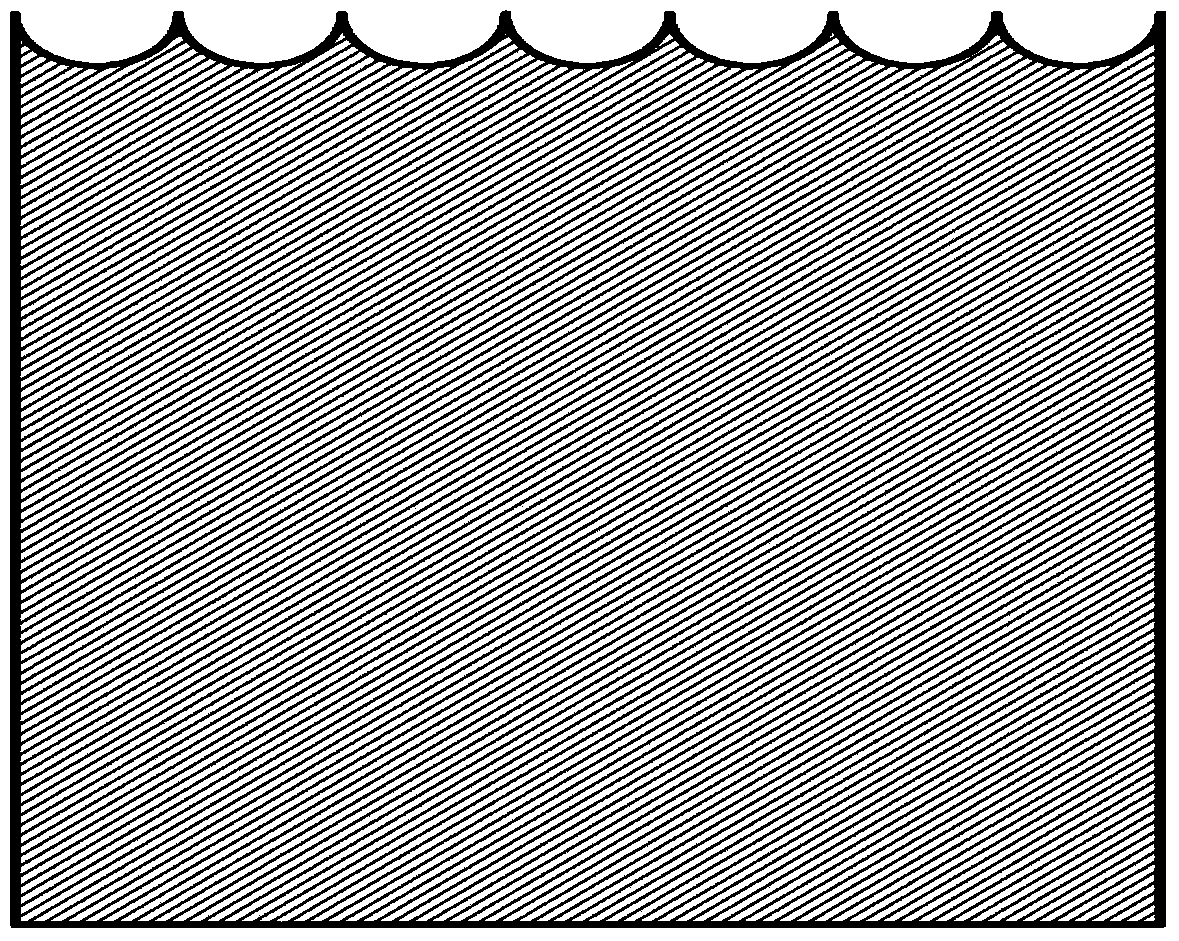

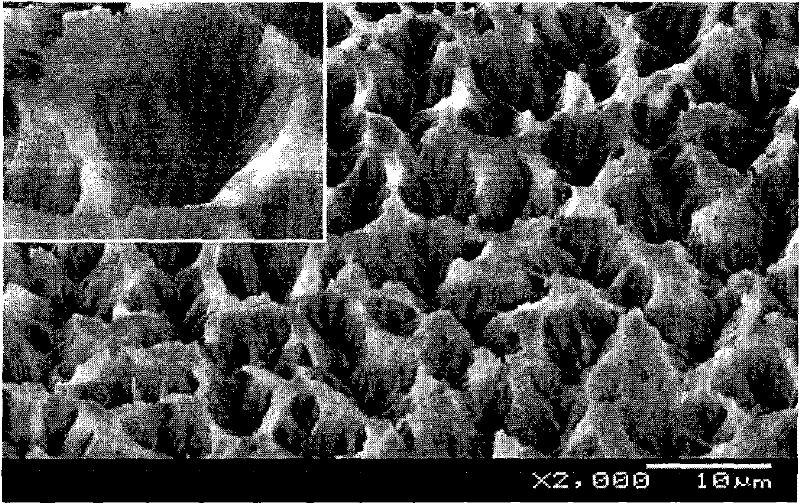

Hydrophobic composite polymer film in micron and nanometer structure and its prepn

The present invention belongs to the field of preparing micron and nanometer structure on the surface of solid, and is especially hydrophobic composite polymer film in micron and nanometer structure and its preparation process. The composite film is prepared on anode porous alumina film as substrate and through chemical etching to constitute special rough structure on the surface of the anode porous alumina film and modifying polymer material on the surface of the structure. Test shows that the hydrophobic composite polymer film has static contact angle to water greater than 140 deg and hydrophobic performance obviously higher than that of corresponding smooth film. The polymer film may be formed with different common polymer material and thus has wide application foreground.

Owner:INST OF CHEM CHINESE ACAD OF SCI

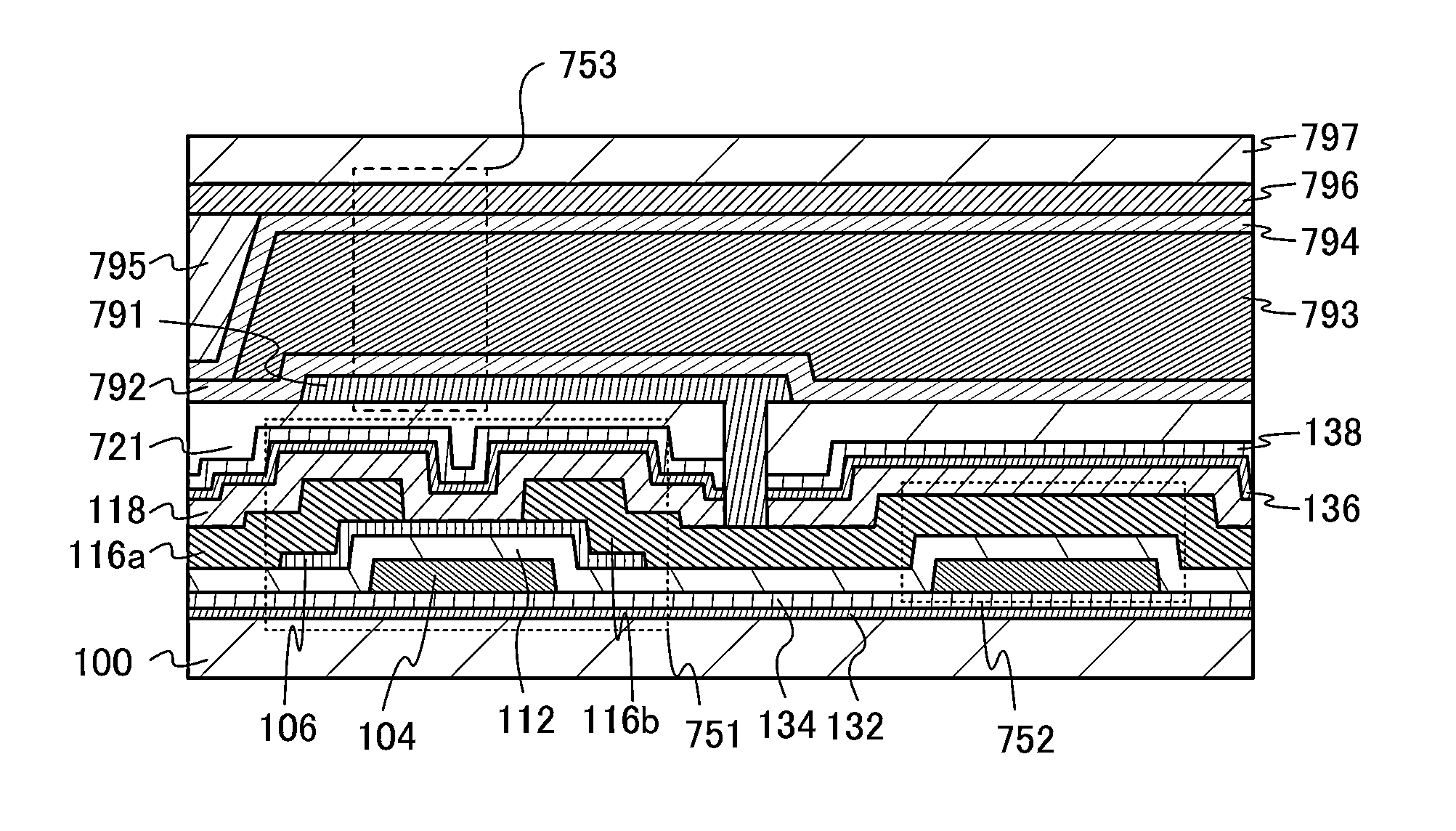

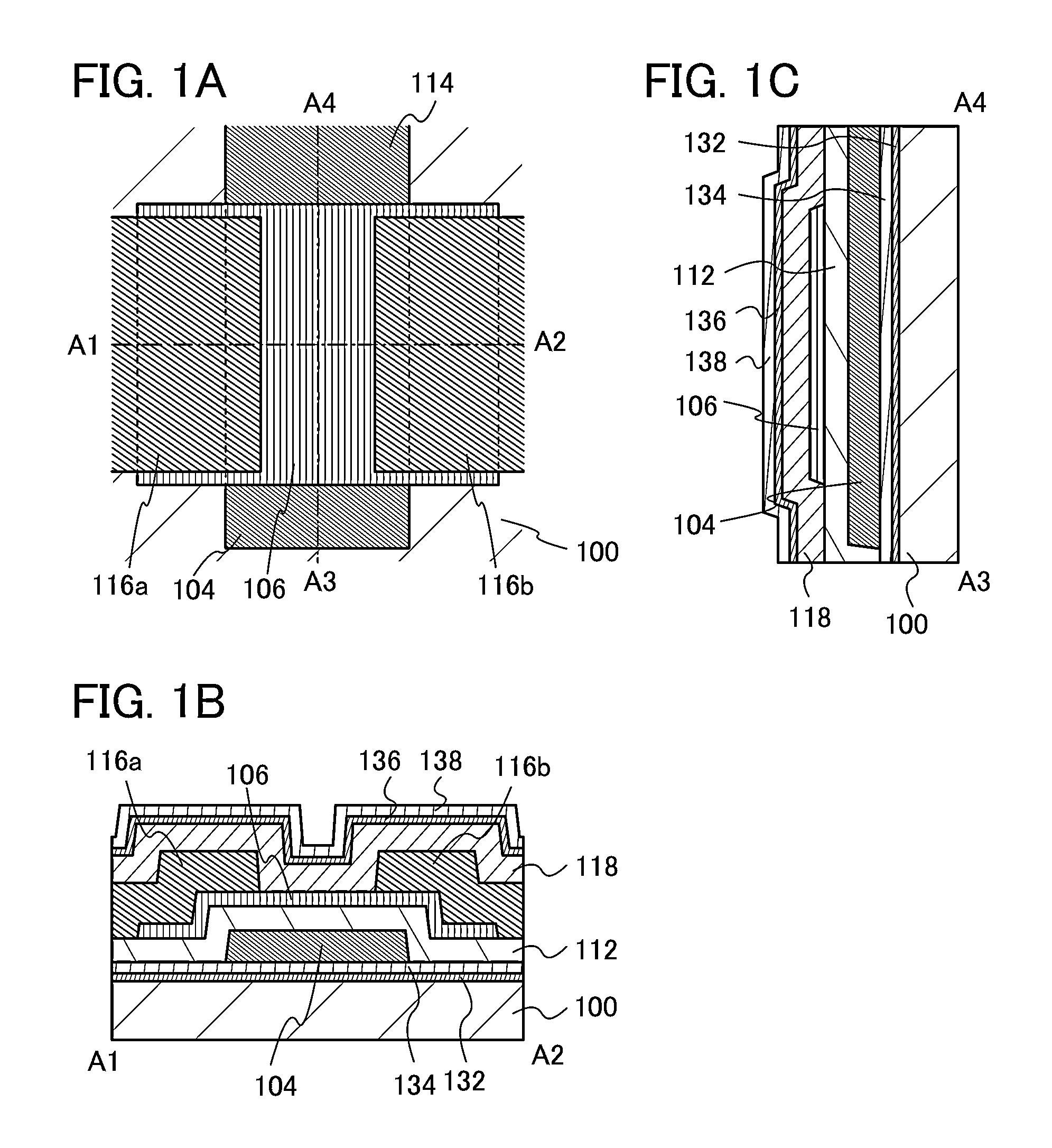

Semiconductor device

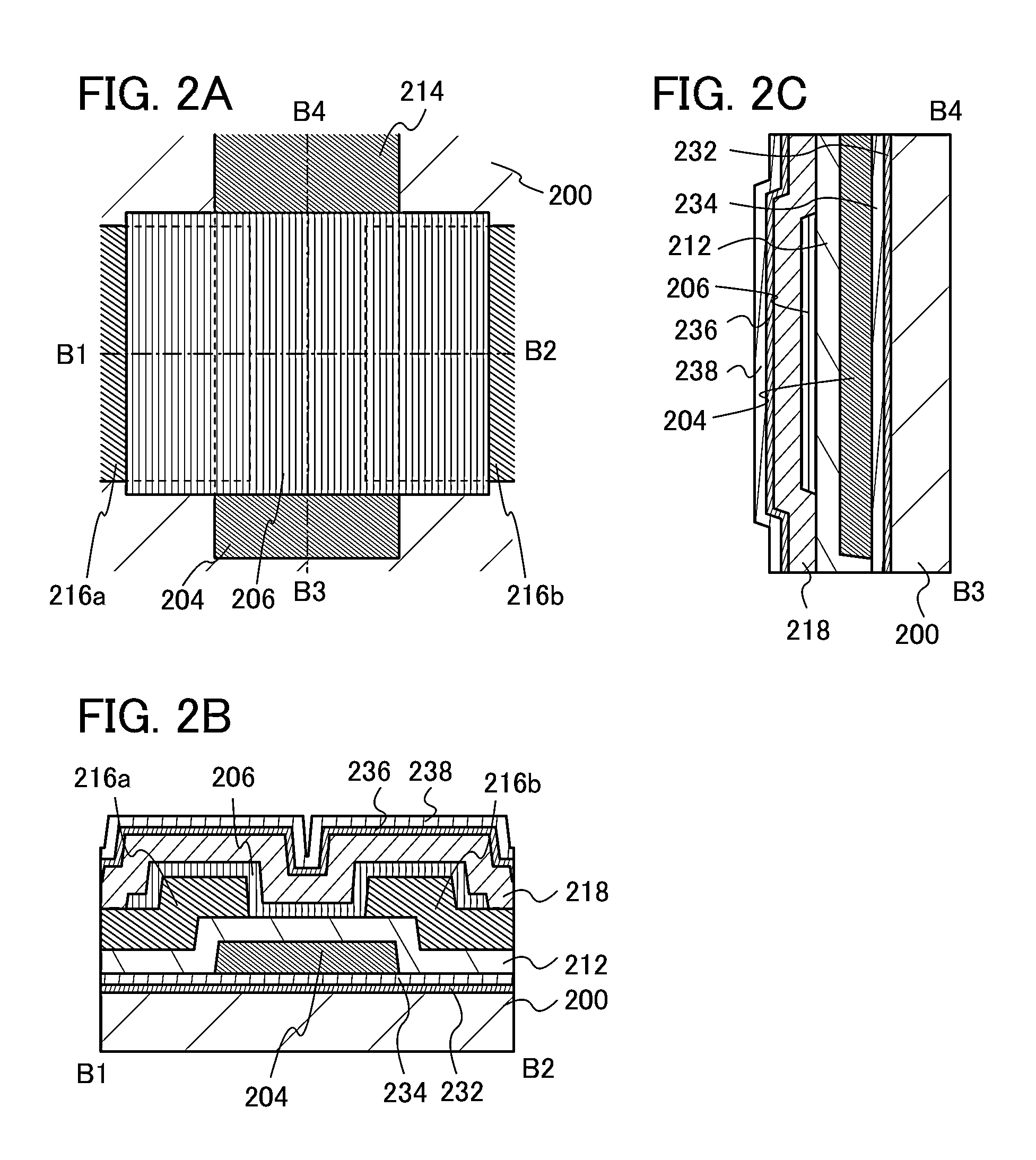

InactiveUS20130234131A1High barrier property against impurityAvoid changeTransistorDevice materialEngineering

A semiconductor device which has stable electrical characteristics and high reliability is provided. The semiconductor device includes a gate electrode over an insulating surface, a gate insulating film over the gate electrode, a semiconductor film which is over the gate insulating film and overlaps with the gate electrode, and a protective insulating film over the semiconductor film; and the protective insulating film includes a crystalline insulating film and an aluminum oxide film over the crystalline insulating film.

Owner:SEMICON ENERGY LAB CO LTD

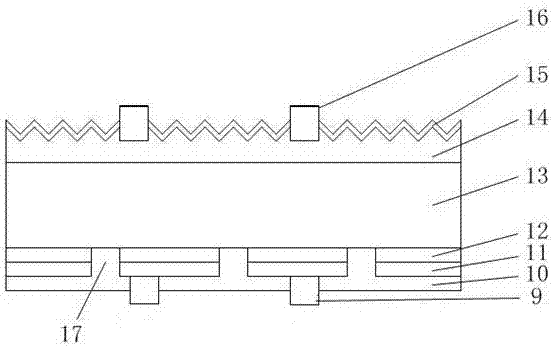

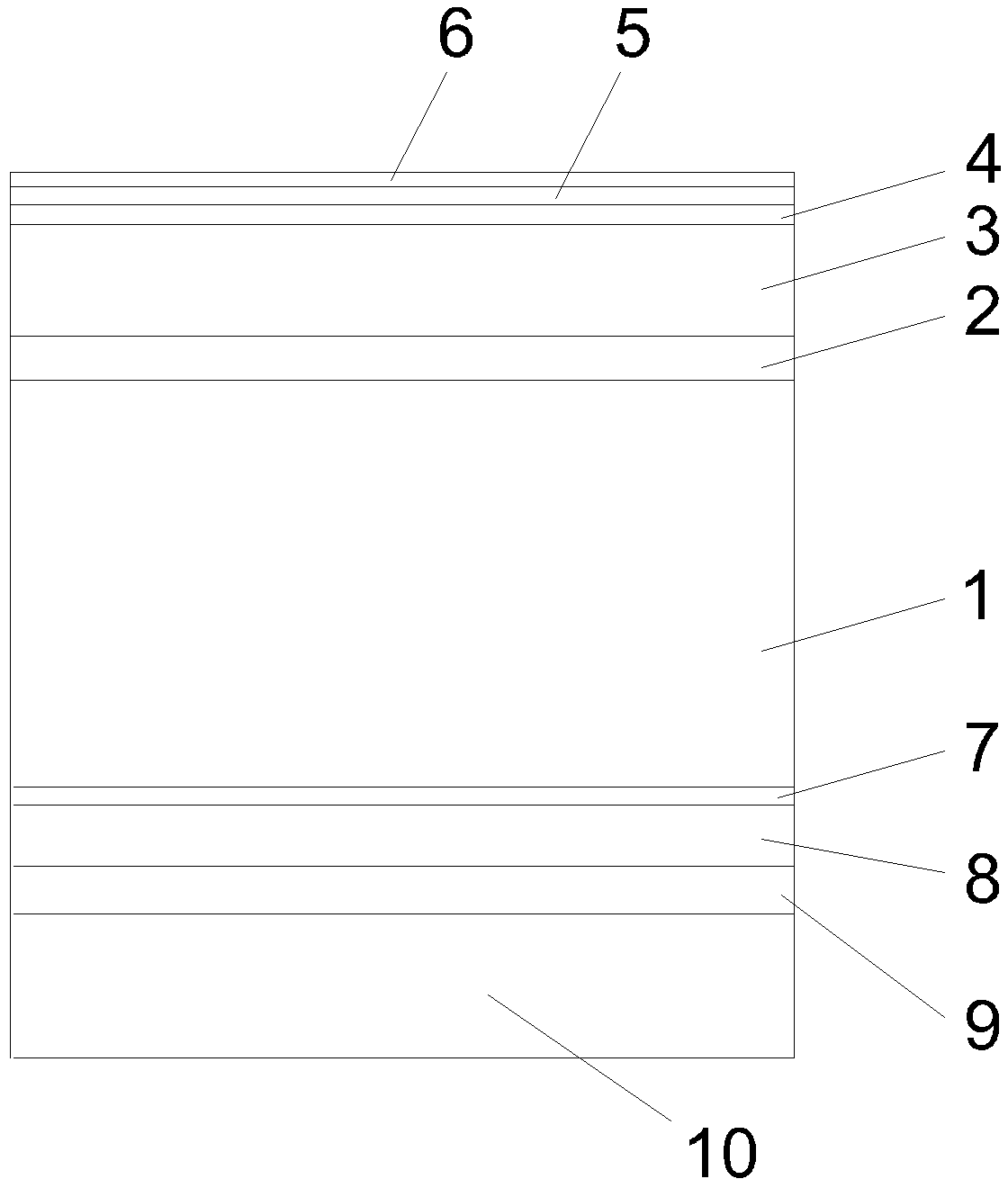

Manufacturing method of flexible TFT backplane and flexible TFT backplane

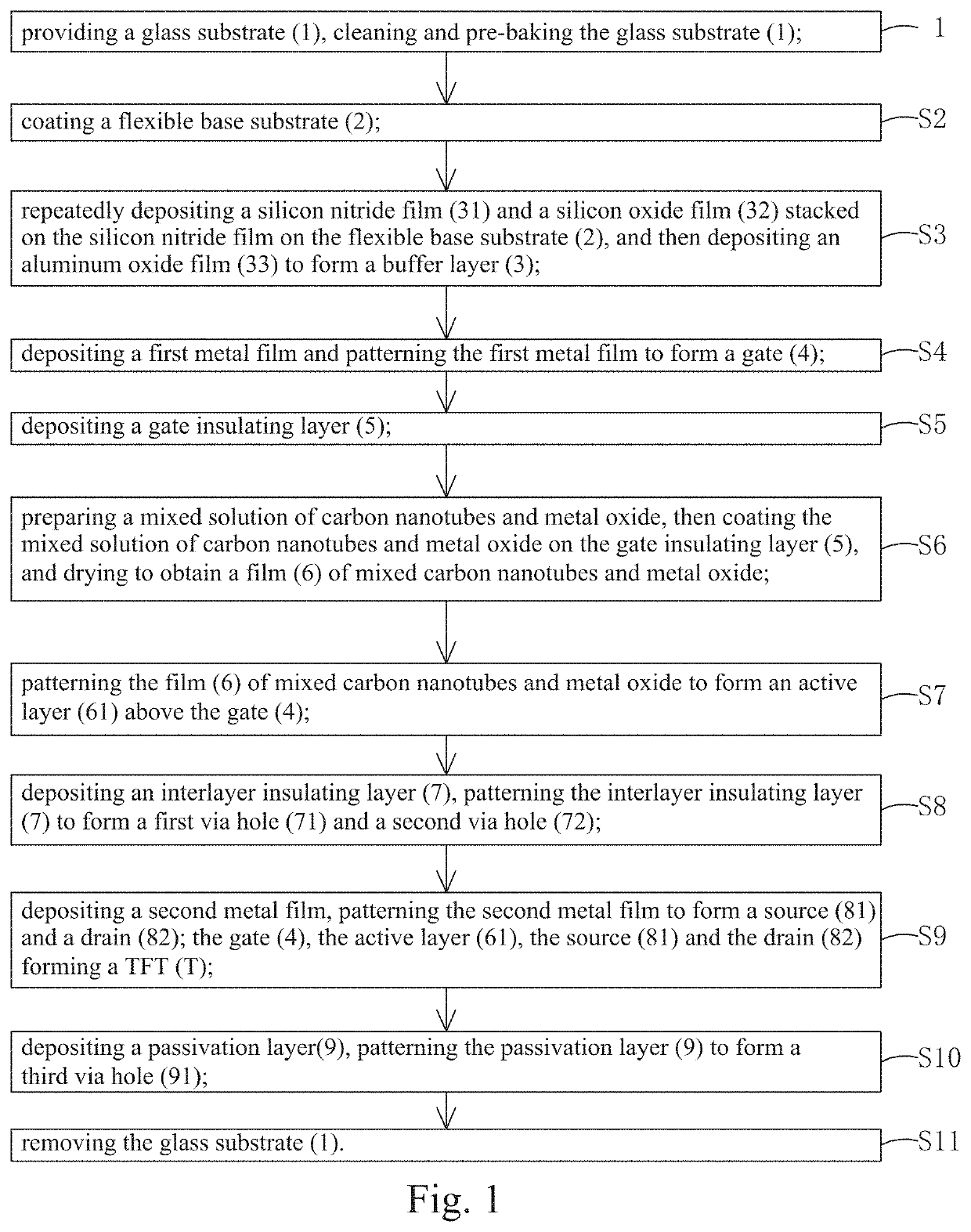

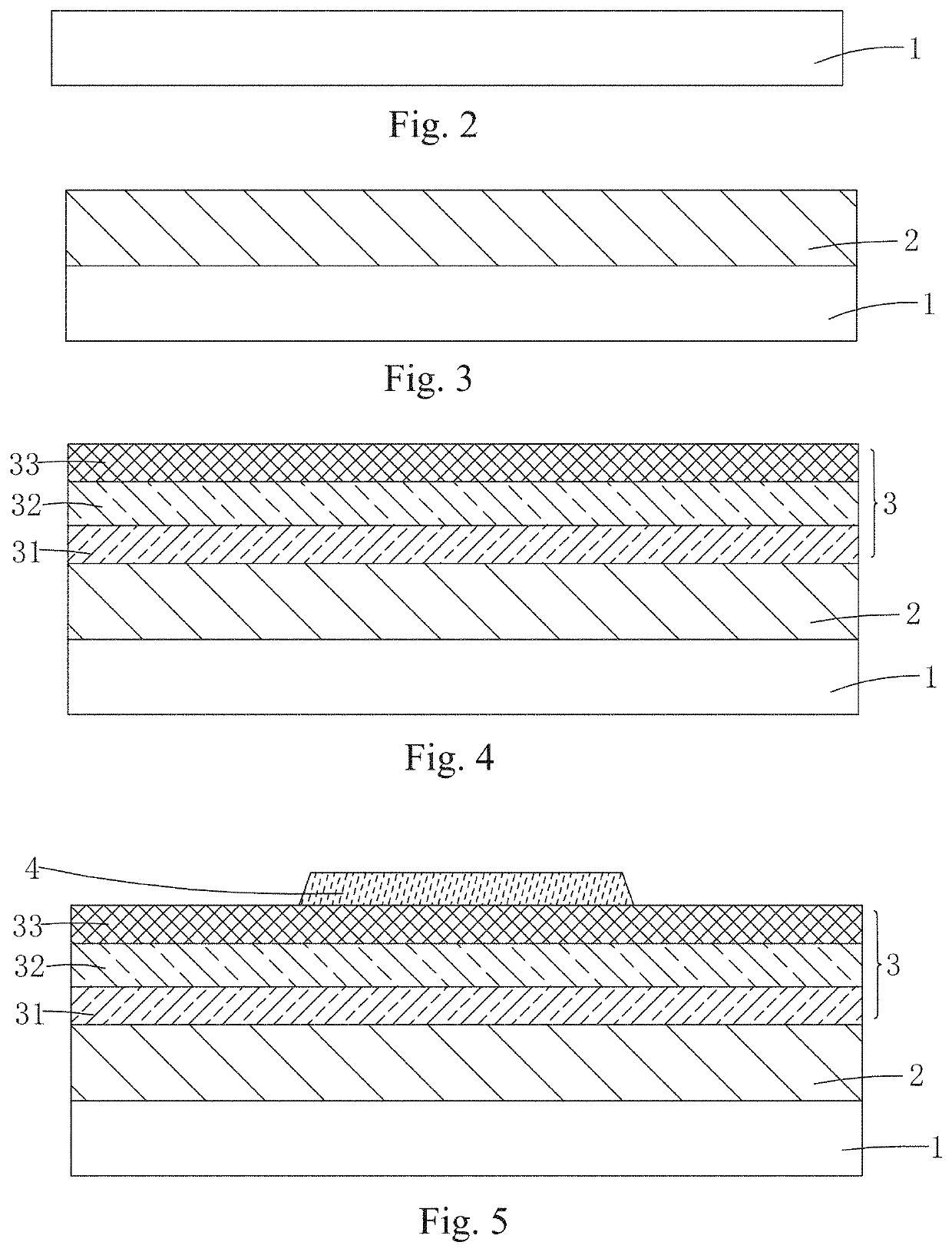

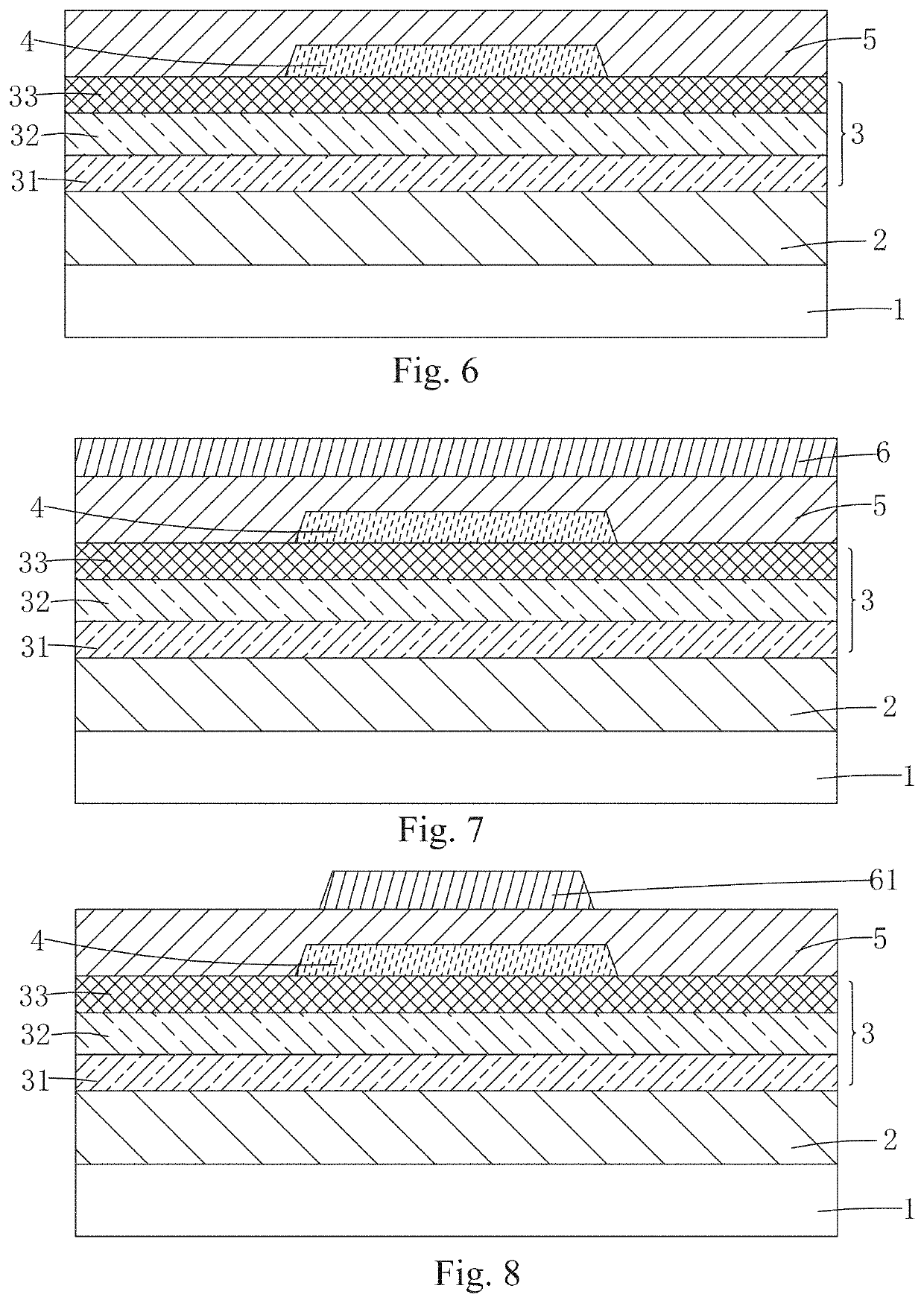

ActiveUS10665721B1High electron mobilityHigh strengthTransistorFinal product manufactureCarbon nanotubeEngineering

The invention provides a manufacturing method of flexible TFT backplane. The method uses a mixed solution of carbon nanotubes and metal oxide to prepare active layer (61) of TFT (T), and the temperature is lower and will not cause damage to the flexible base substrate (2), and the material of flexible base substrate (2) is not restricted. The use of vacuum equipment is reduced to save production cost. The carbon nanotubes have excellent conductivity, and the mixture with metal oxide as the active layer (61) of the TFT can improve the electron mobility. The buffer layer (3) has a silicon nitride film (31) as the lowest layer contacting the flexible base substrate (2), making good adhesion between buffer layer (3) and flexible base substrate (2). The topmost layer of the buffer layer (3) is an aluminum oxide film (33), which enables the buffer layer (3) to resist to water.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

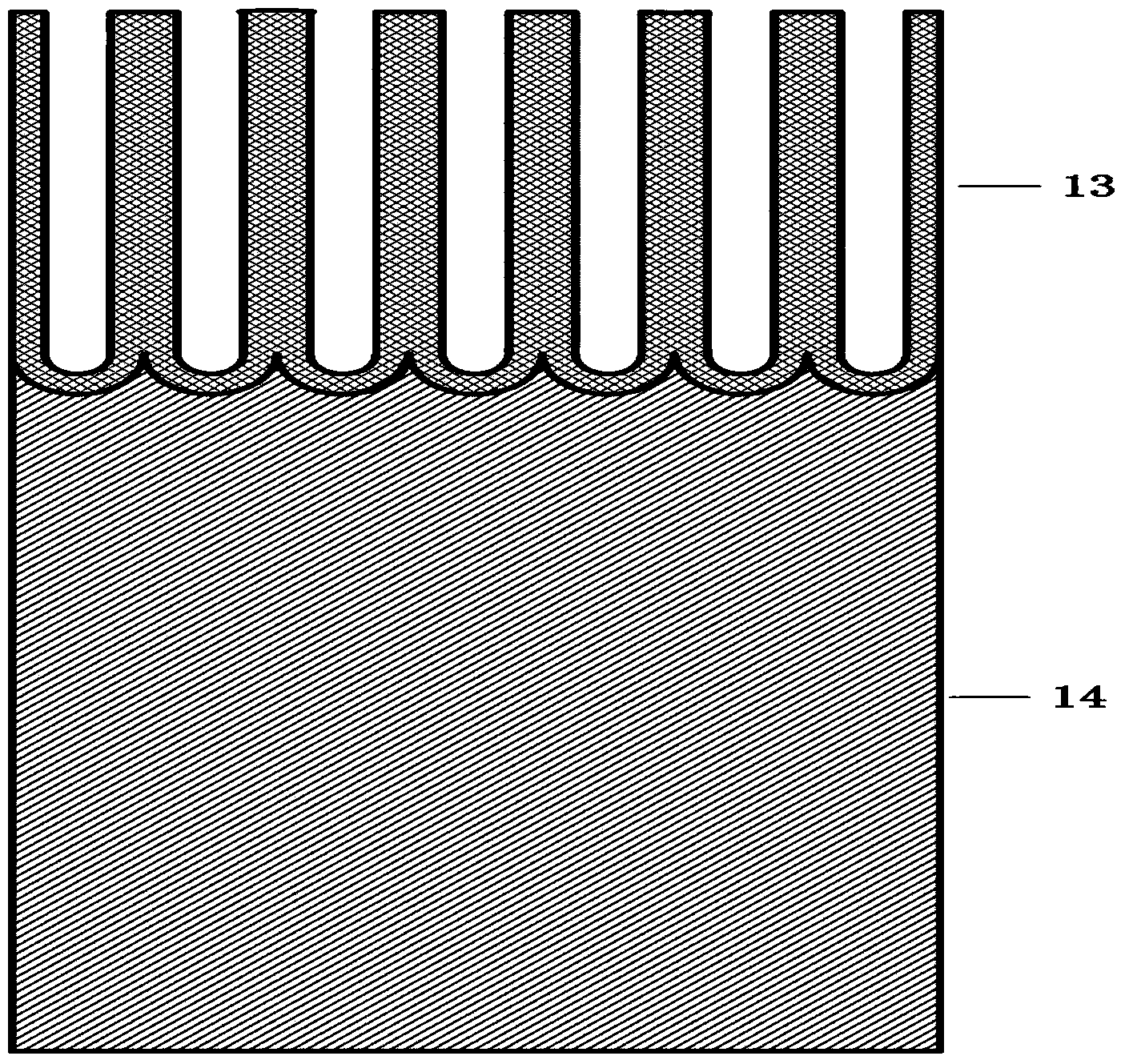

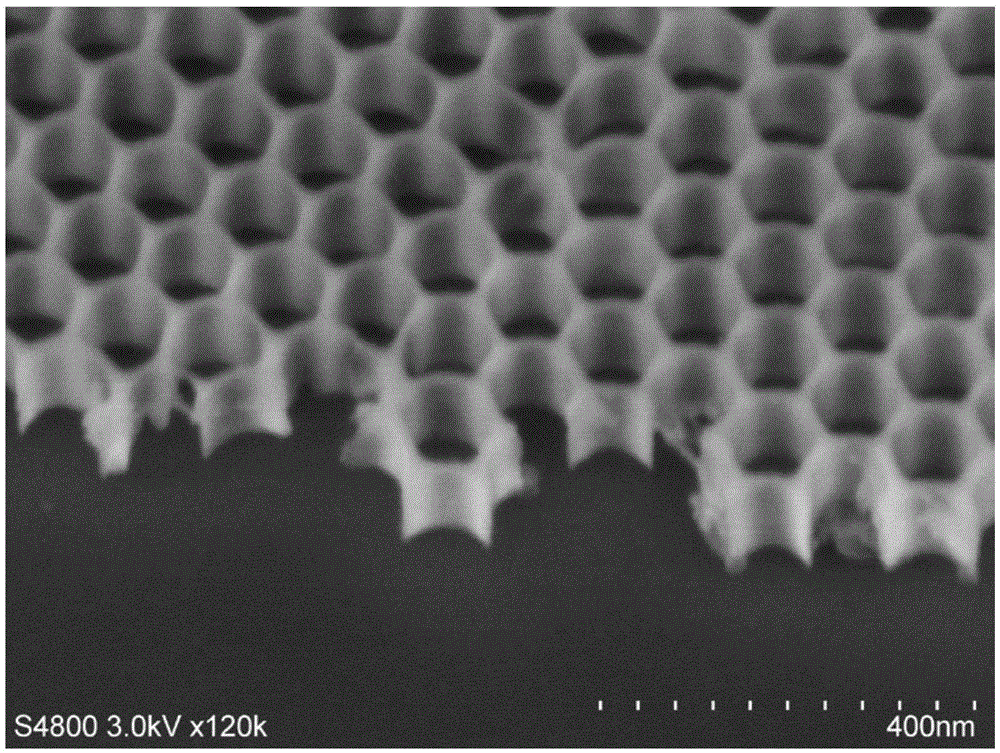

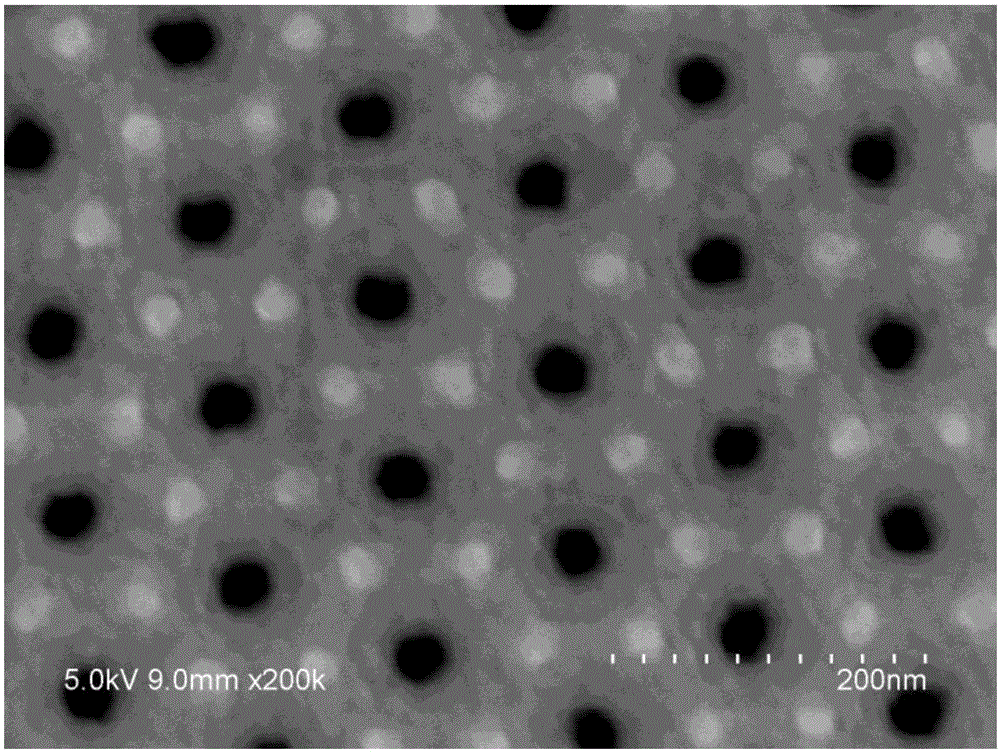

Preparation methods of nanopore-arrayed anodic alumina membrane and nanopore-arrayed anodic alumina microchannel plate

InactiveCN104233430AOvercoming noiseOvercoming temporal resolutionSurface reaction electrolytic coatingCold cathode manufactureDark count rateSilicate glass

The invention relates to preparation methods of a nanopore-arrayed anodic alumina membrane and a nanopore-arrayed anodic alumina microchannel plate. The preparation method of the nanopore-arrayed anodic alumina membrane comprises the following steps of preparation of an alumina membrane and directional pore broadening. The preparation method of the nanopore-arrayed anodic alumina microchannel plate comprises the following steps of preparation of an alumina membrane, directional pore broadening and preparation of a microchannel plate. According to the preparation methods of the nanopore-arrayed anodic alumina membrane and the nanopore-arrayed anodic alumina microchannel plate, the technical bottleneck that the channel aperture of the traditional lead-containing silicate glass microchannel plate cannot be easily reduced is overcome; the difficult problems that the area of the microchannel plate is increased if the ultra-small aperture of the microchannel plate is realized and the like are solved; and the excellent properties of the microchannel plate are achieved, i.e., the space resolution and time resolution of the microchannel plate are improved, the gain is increased, the dark count rate is decreased, the area array is enlarged, a higher temperature can be borne and the like.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Red schorl type titanium dioxide coating method and preparation of used reagent

InactiveCN101463195AHigh whitenessHigh glossPigment treatment with non-polymer organic compoundsAluminateWeather resistance

The invention relates to a rutile type titanium dioxide coating method and a preparation method of reagent used thereby. A layer of ZrO2 is firstly coated on a TiO2 particle, thus improving the white content, lustrousness and weather resistance of the product; four layers of pellumina are coated in batches to further improve the performances such as weather resistance, dispersivity (dry powder fluidness), hiding power, lustrousness and the like of the product; finally, the main function of organic coating is to improve the dry powder fluidness of the product and the dispersivity in the application media; meanwhile, the lustrousness of the product is improved, and the aggregation resistant performance of the product in storage and transportation can be enhanced. Sodium aluminate or aluminium sulphate is added at the different stages of the coating process, so that the pH value the sizing agent can be regulated by utilizing the different pH values of the two aluminates, and the complicated operation that the pH value the sizing agent is regulated after coating agent is added every time is omitted. The titanium dioxide which coated and finally obtained has the advantages of high lustrousness, dispersivity, dry powder fluidness and weather resistance.

Owner:HENGYANG TIANYOU CHEM

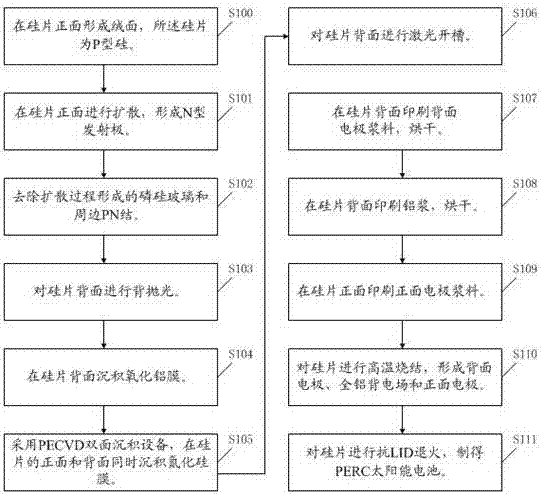

P-type PERC solar energy cell preparation method, cell, assembly and system

InactiveCN107068790AImprove conversion efficiencyImprove broken rateFinal product manufacturePhotovoltaic energy generationSlurryOptoelectronics

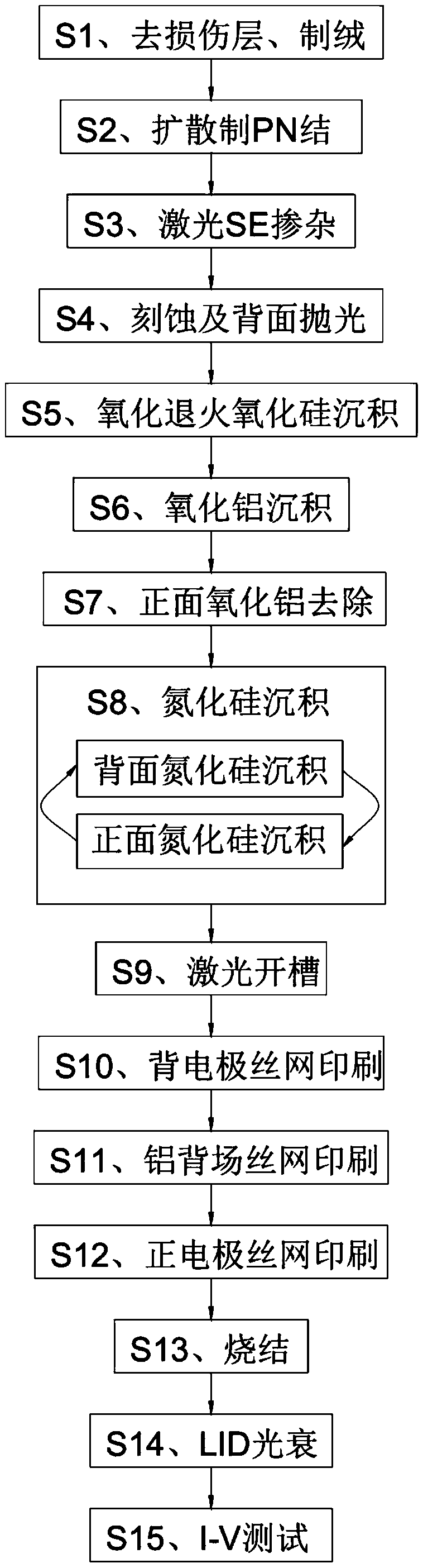

The invention discloses a P-type PERC solar energy cell preparation method. The P-type PERC solar energy cell preparation method comprises steps that (1), a suede-like surface is formed at a front surface of a silicon chip; (2), diffusion is carried out at the front surface of the silicon chip, and an N-type emitter electrode is formed; (3), phosphorosilicate glass and peripheral PN junctions are removed; (4), an alumina film is deposited at a back surface of the silicon chip; (5), PECVD double-surface deposition equipment is employed, and silicon nitride films are deposited at the front surface and the back surface of the silicon chip; (6), laser grooving at the back surface of the silicon chip is carried out; (7), back surface electrode slurry is printed at the back surface of the silicon chip and is then dried; (8), aluminum slurry is printed at the back surface of the silicon chip and is then dried; (9), front surface electrode slurry is printed at the front surface of the silicon chip; (10); high temperature sintering is carried out for the silicon chip, and a back surface electrode, a full aluminum back electric field and a front surface electrode are formed; and (11), anti-LID annealing for the silicon chip is carried out, and the P-type PERC solar energy cell is acquired. The invention further discloses the P-type PERC solar energy cell, an assembly and a system. The method is advantaged in that production efficiency can be improved, and scratch of the silicon chip is reduced.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

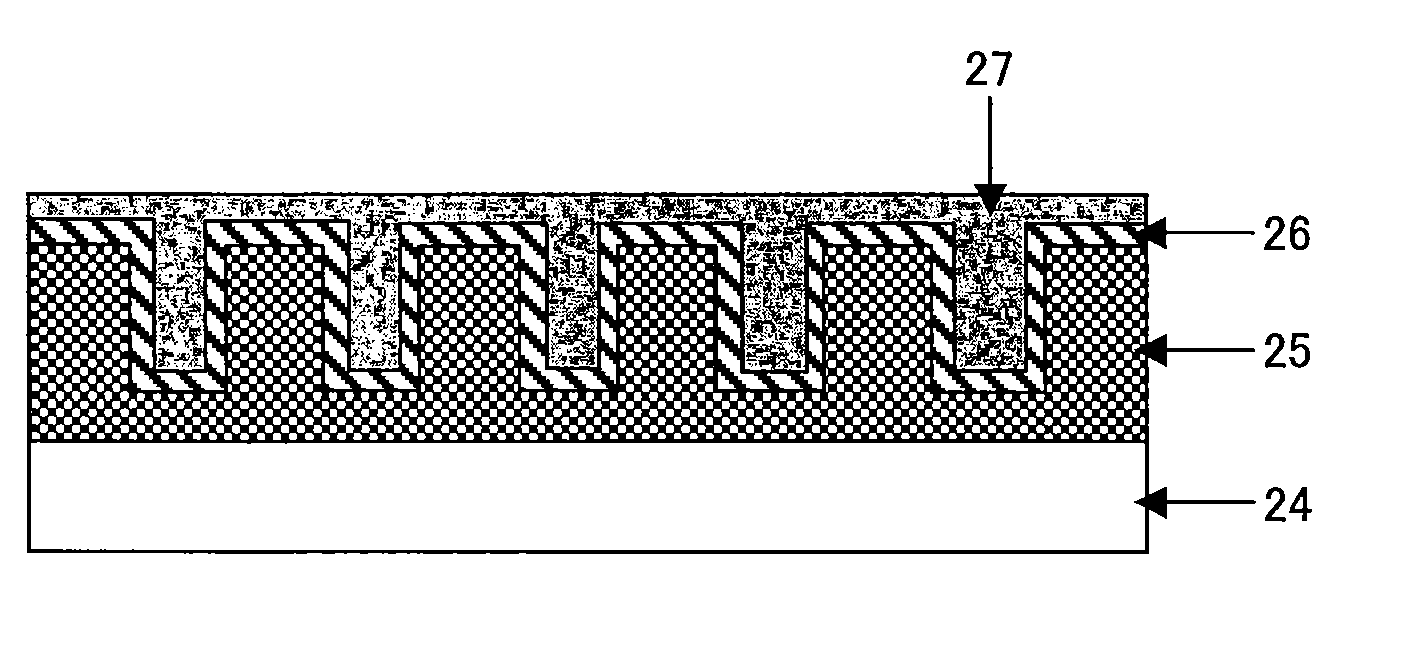

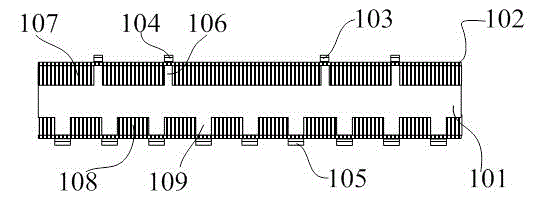

Embedded chip interconnecting and packaging method based on aluminum anodizing technology and structure

ActiveCN104157580ALow costHigh precisionSemiconductor/solid-state device detailsSolid-state devicesInterconnectionEmbedment

The present invention relates to an embedded chip interconnecting and packaging method based on an aluminum anodizing technology and a structure. The method comprises the steps of selecting a low-cost aluminum sheet as a chip embedded substrate, and making a double-face and porous alumina film by the aluminum anodizing technology; obtaining a cavity structure of an embedded chip by utilizing the aluminum chamber protection characteristic of a rectangular ring and the selective corrosion characteristic of the porous alumina film, and finishing the chip coplanar embedment; finishing the interconnection of the embedded chip by the technologies, such as a right side dielectric layer filling photoetching technology, a film metal layer wiring technology, etc. According to the present invention, the positioning precision is high, the size of an embedded cavity matches the chip very well, and the low-cost and coplanar embedment problem of the chips of different sizes is solved effectively. By designing the back side aluminum flux columns, the heat radiation problem of the chip can be solved very well. A dielectric layer having a low dielectric constant can be used as a surface protection film, an interlayer insulation film or a porous alumina depth groove filler of the chip, especially can solve the problems of flattening the surface of an aluminum substrate, improving the bending or warping of the substrate, and satisfies a film technology.

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

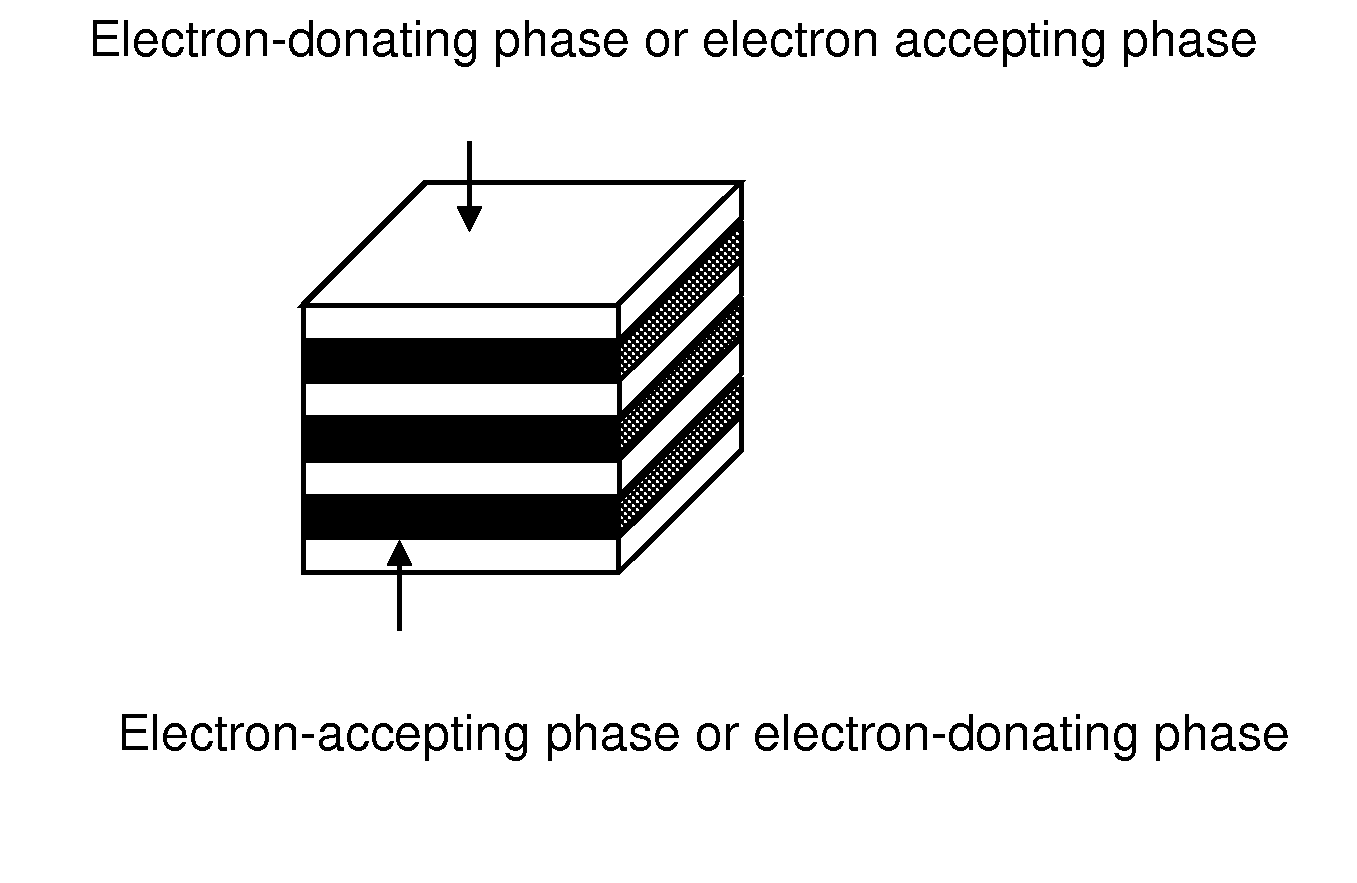

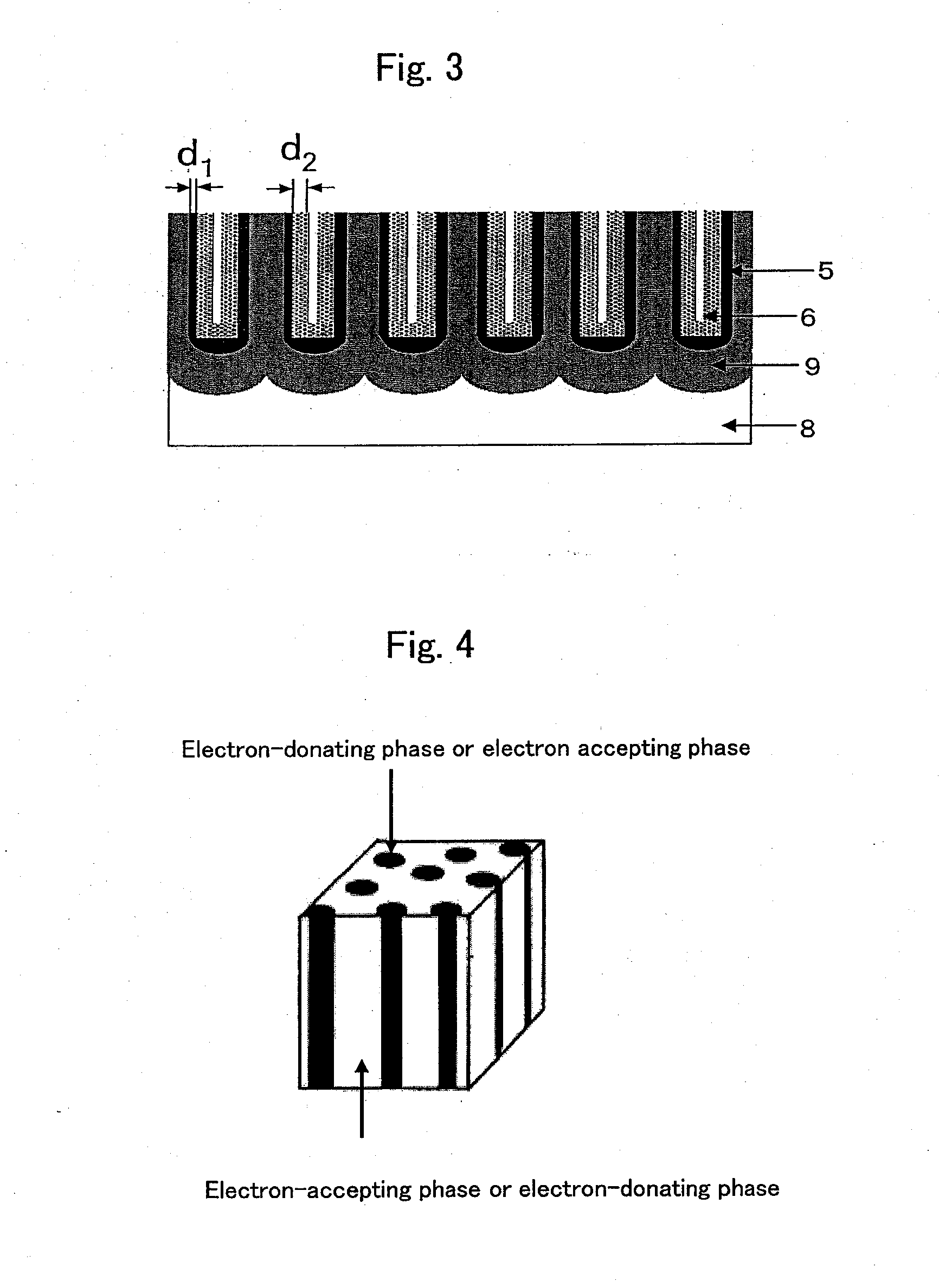

Method for manufacturing nano-array electrode and photoelectric conversion device using same

InactiveUS20100132772A1Improve energy conversion efficiencyEasy to controlAnodisationFinal product manufactureElectronic structurePhotoelectric conversion

The present invention provides a method of manufacturing a nano-array electrode with a controlled nano-structure by filling a compound having an electron-accepting structure or an electron donating structure into the fine pores of an anodic-oxide porous alumina film obtained by anodically oxidizing aluminum in electrolyte. The spaces defined between the nano-arrays formed of the compound by removing the alumina film are filled with a compound having an electron-donating structure if the nano-arrays have an electron-accepting structure and a compound having an electron-accepting structure if the nano-arrays have an electron-donating structure. A high-performance, high-efficiency photoelectric converting device comprising a nano-array electrode manufactured by the method is also disclosed.

Owner:NIPPON OIL CORP

Head comprising a crystalline alumina layer

Owner:GLOBALFOUNDRIES U S INC

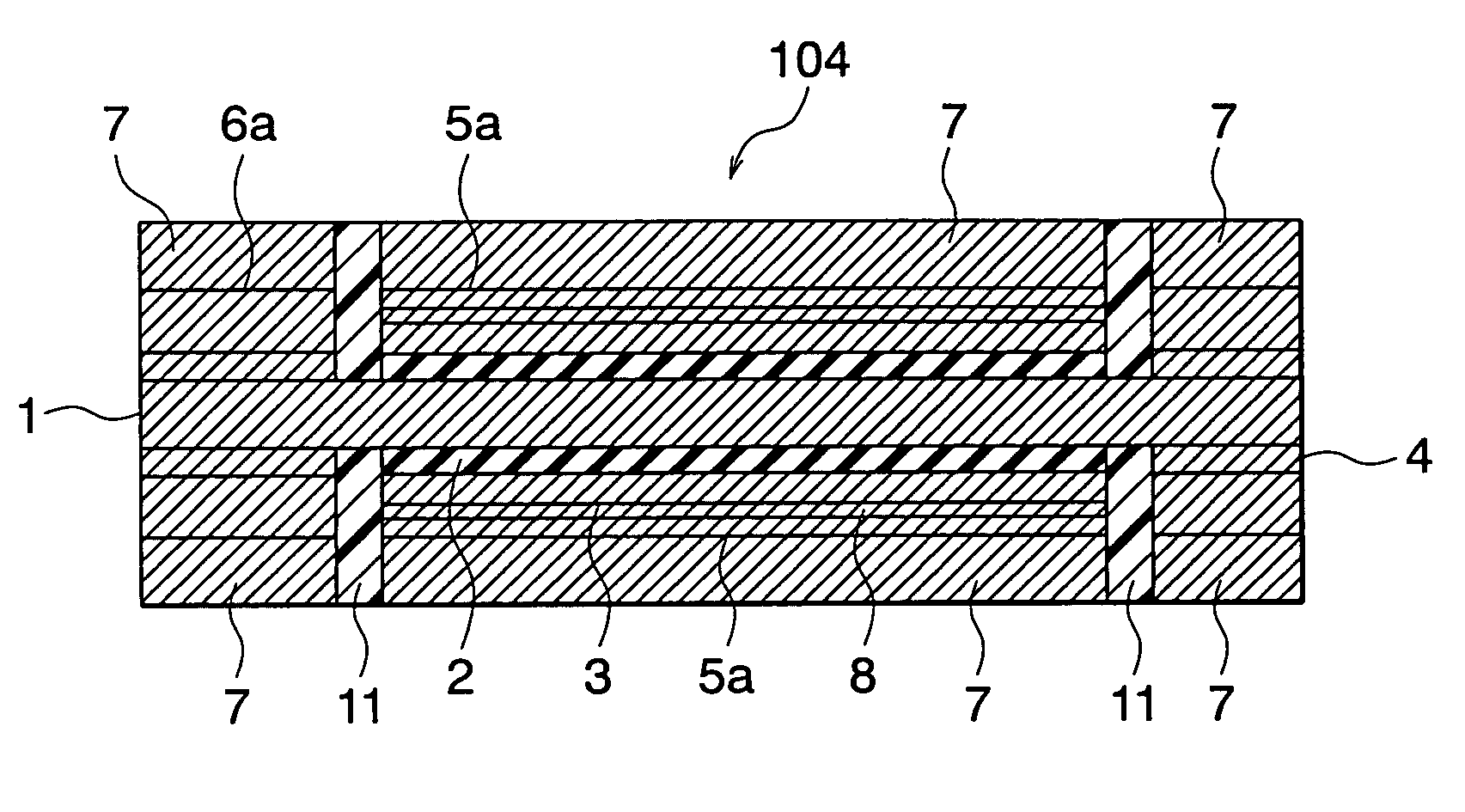

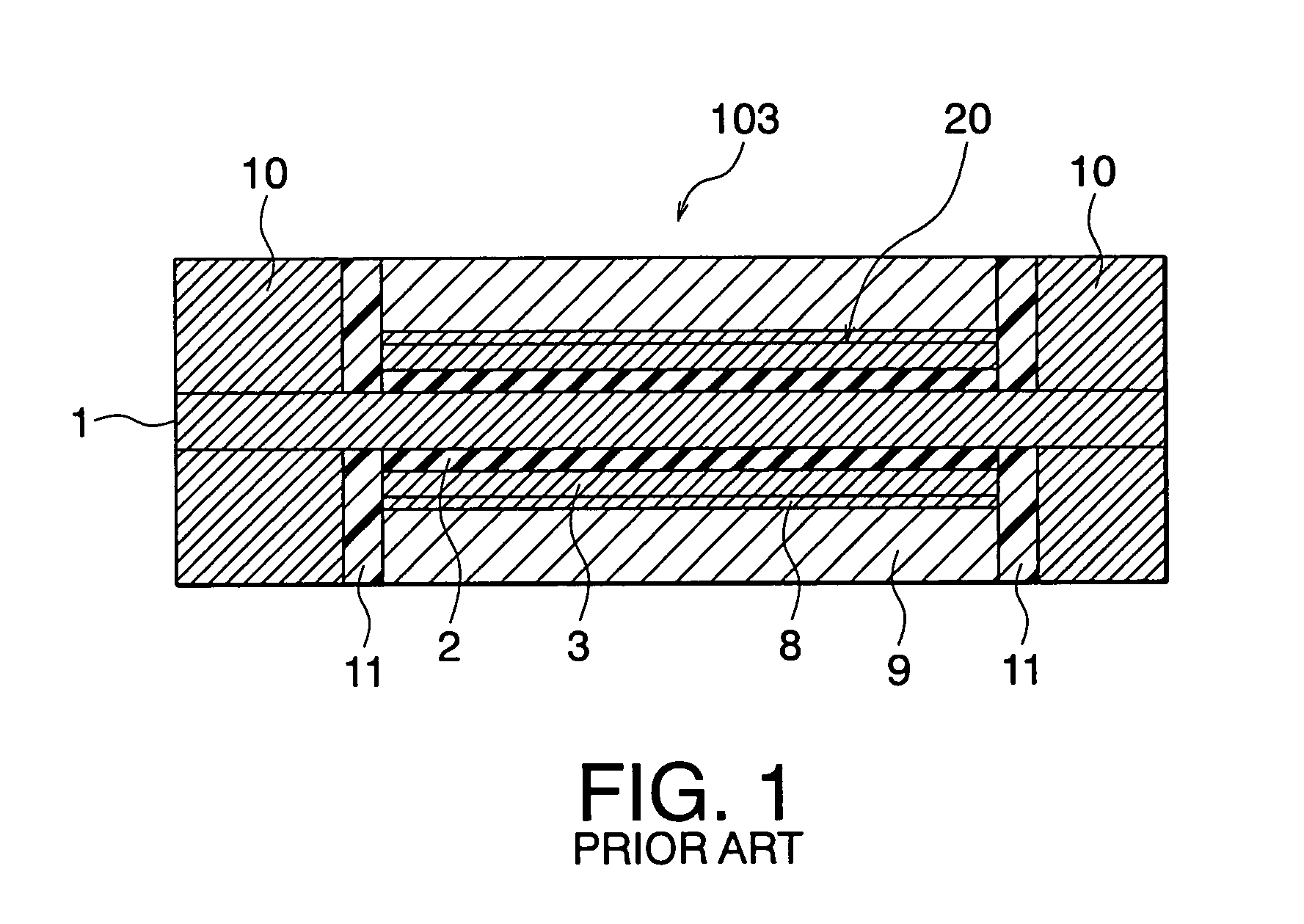

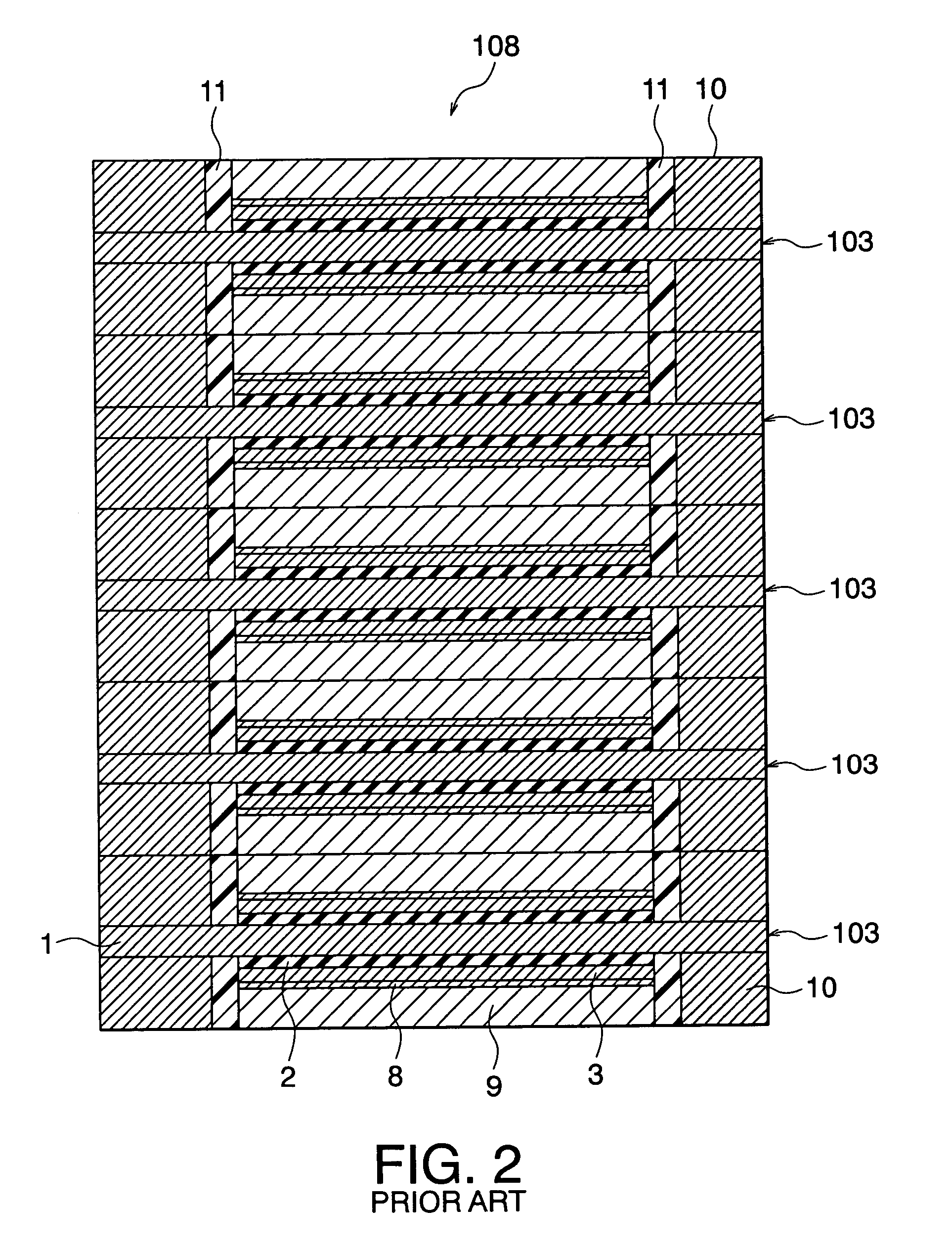

Solid electrolytic capacitor, stacked capacitor using the same, and fabrication method thereof

InactiveUS7215534B2Solid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisConductive polymer

On a surface-roughened aluminum foil, an aluminum oxide film as an anodic oxide film is formed. Then, a conductive polymer layer as a solid electrolyte is formed thereon and thereafter a first metal plating layer is directly formed on the conductive polymer layer, thereby forming a cathode portion. On the other hand, a second metal plating layer is formed on another portion of the surface-roughened aluminum foil, which is not subjected to anodic oxidation or which is subjected to anodic oxidation followed by polishing or formation of an anode deposition film, to thereby form an anode portion. Third metal plating layers are formed at the anode and the cathode portions to obtain a capacitor element. A plurality of capacitor elements are stacked and bonded together by fusion after formation of the third metal plating layers. Alternatively, the capacitor elements may be bonded together by a conductive paste without the third metal layers.

Owner:TOKIN CORP

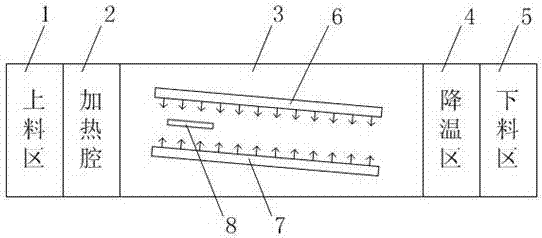

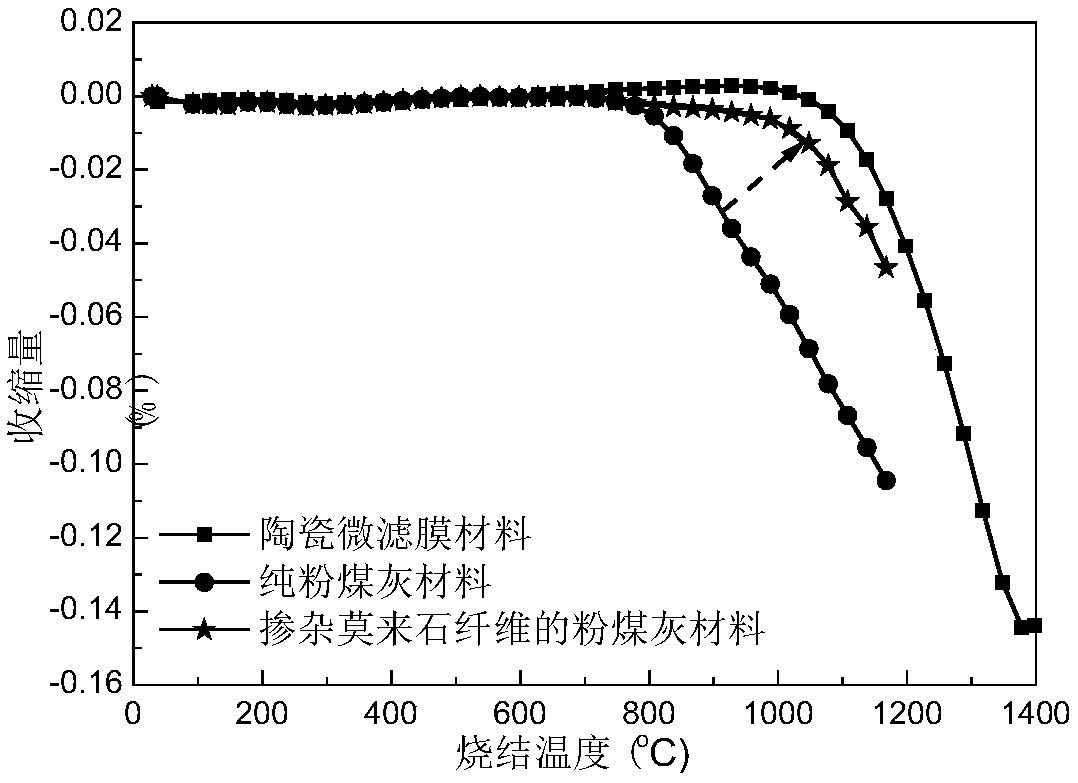

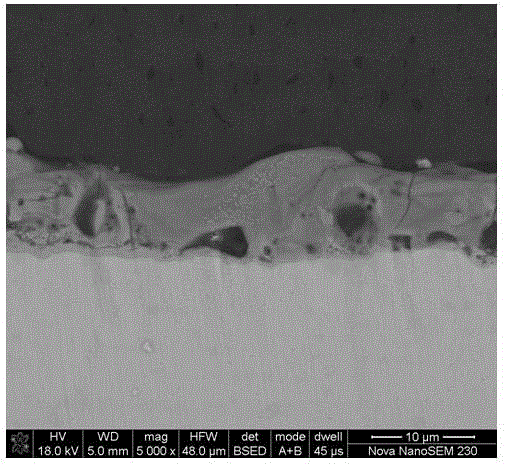

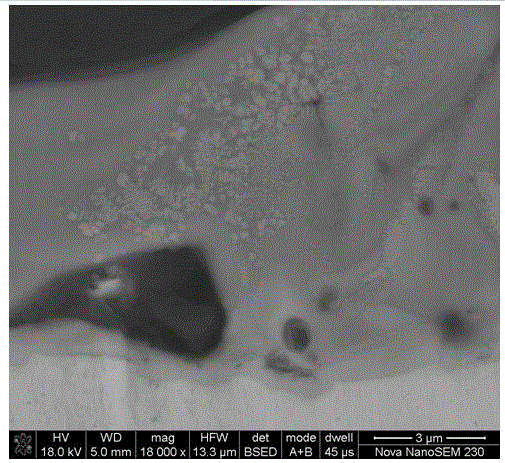

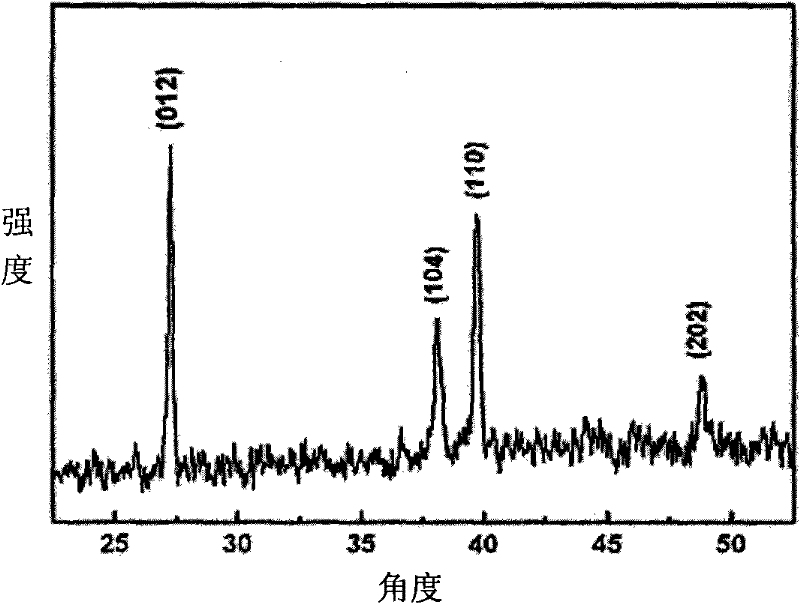

Co-sintering preparation method for flyash-based ceramic microfiltration membrane

ActiveCN108911706AAlleviate Matching ProblemsLow raw material costCeramic materials productionClaywaresMaterials scienceRaw material

The invention relates to a co-sintering preparation method for a flyash-based ceramic microfiltration membrane. The fly-ash-based ceramic microfiltration membrane is prepared by doping flyash whiskerswith rigid oxide whiskers, then coating a green flyash-based carrier with an alumina ceramic microfiltration membrane and then carrying out one-step sintering by using a co-sintering technology. Thedoping of the rigid whiskers alleviates the excessive shrinkage of the flyash-based carrier, and the thermodynamic properties of the top-layer aluminum oxide membrane are matched, so the complete defect-free flyash-based ceramic membrane can be prepared in one step by using the co-sintering technology. The prepared flyash-based ceramic microfiltration membrane is greatly reduced in raw material cost and sintering energy consumption, and has higher performance than the ceramic microfiltration membranes reported in the prior art.

Owner:NANJING UNIV OF TECH

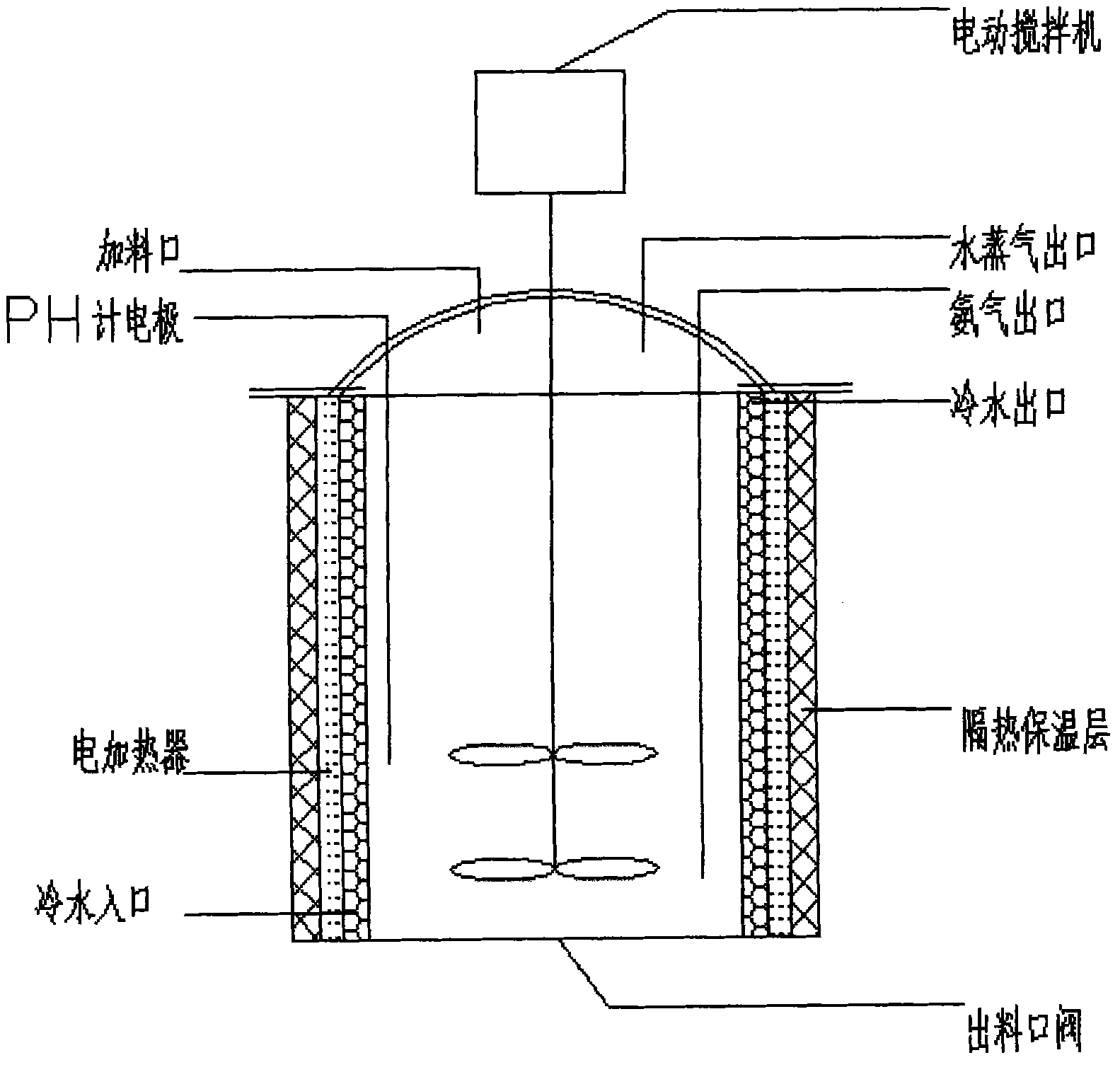

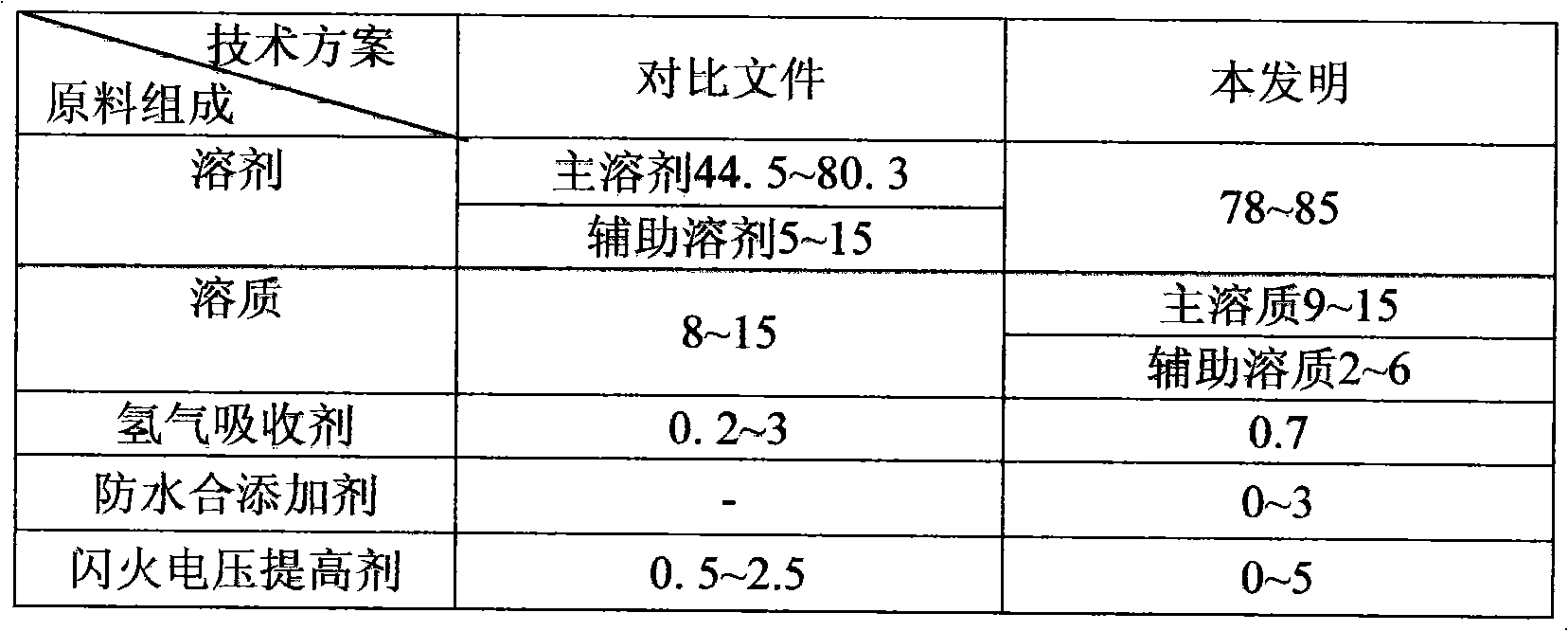

Preparation method, product and application of electrolyte for high voltage aluminum electrolytic capacitor

InactiveCN102074357AImprove conductivityElectrolyte for high voltage aluminum electrolytic capacitors has high conductivityElectrolytic capacitorsPhosphorous acidNitro compound

The invention provides a preparation method of an electrolyte for a high voltage aluminum electrolytic capacitor and the electrolyte obtained by the preparation method. The electrolyte comprises the following components by weight portion: 78-85 main solvent, 0.7 hydrogen absorber, 9-15 main solute, 0.3 waterproof combined additive, 2-6 auxiliary solute and 0-3 sparking voltage improving agent. The invention comprises the key technology that: high-molecular-weight aliphatic dicarboxylic acid with branched-chain alkyl is used as a main electrolyte, and an aromatic nitro compound cathode depolarizing agent is added, and an ammonium phosphorous acid is added to prevent an alumina membrane from hydration. The electrolyte provided by the invention can withstand more than 3,000 hours under the loads that the sparking voltage is greater than 470V and the temperature is 125 DEG C, has the advantages of high sparking voltage, high conductivity and high reliability, and can be applied to the manufacture of the high voltage electrolytic capacitor.

Owner:东莞宏强电子有限公司

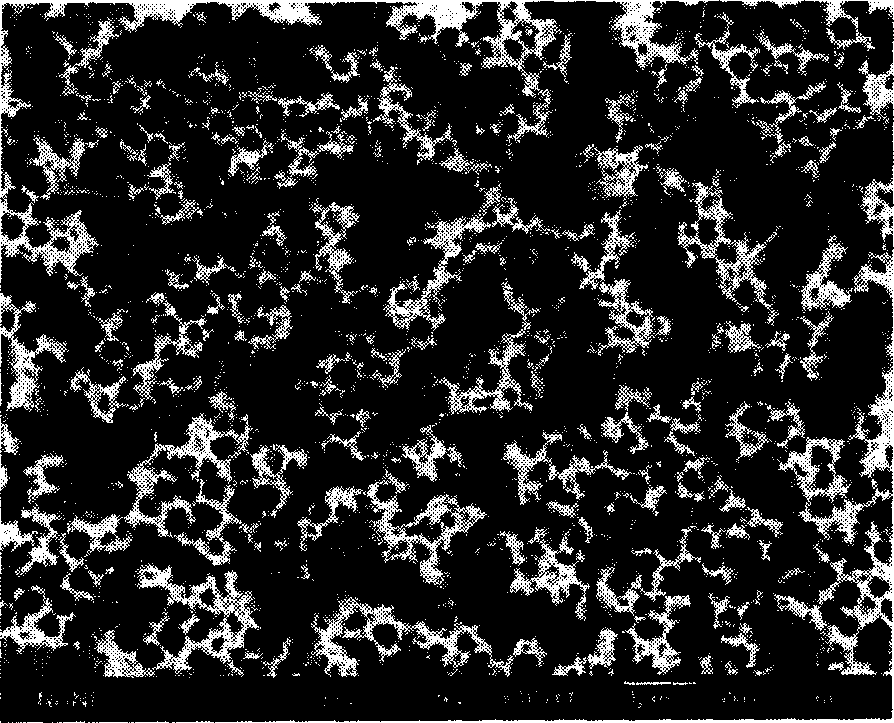

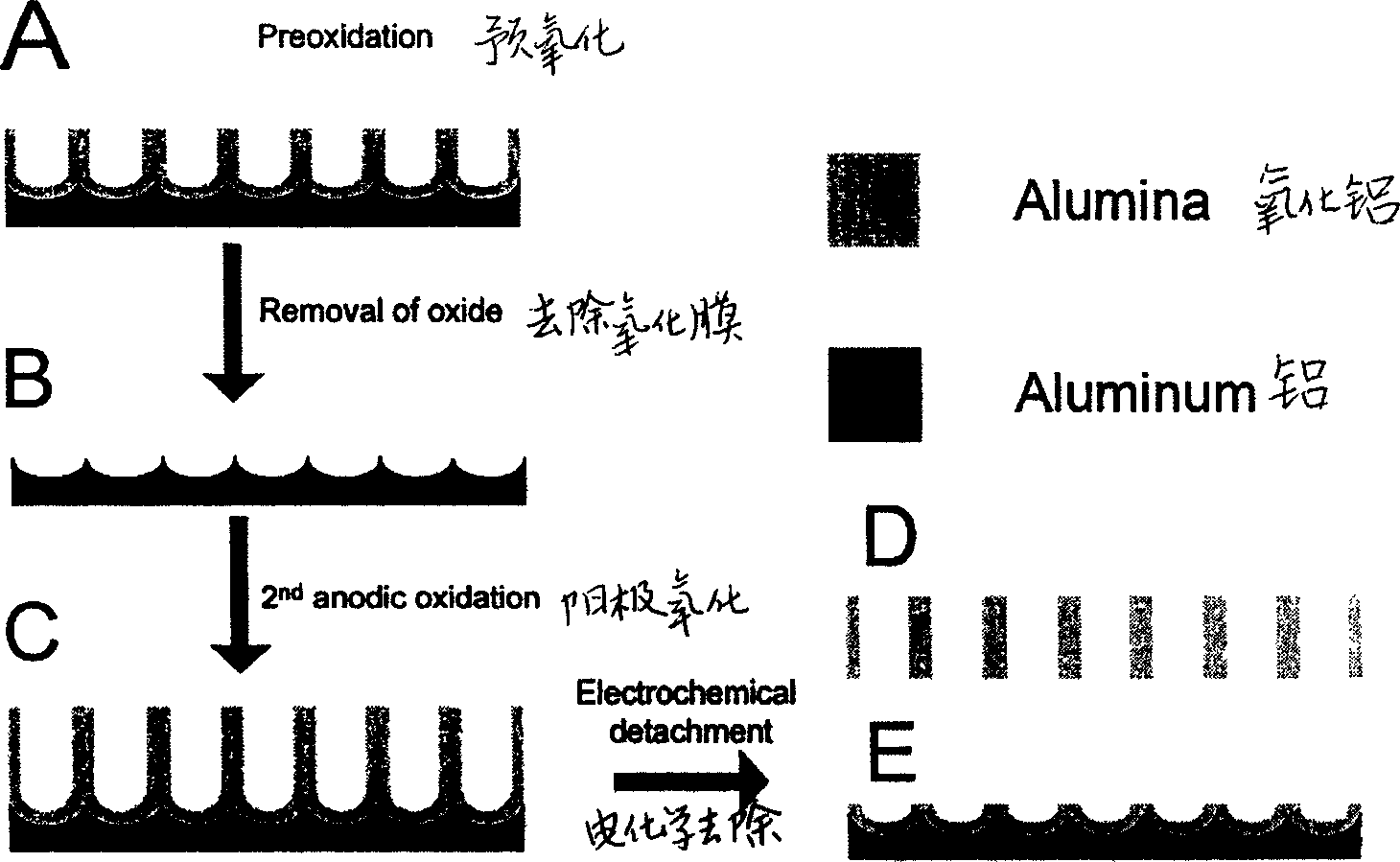

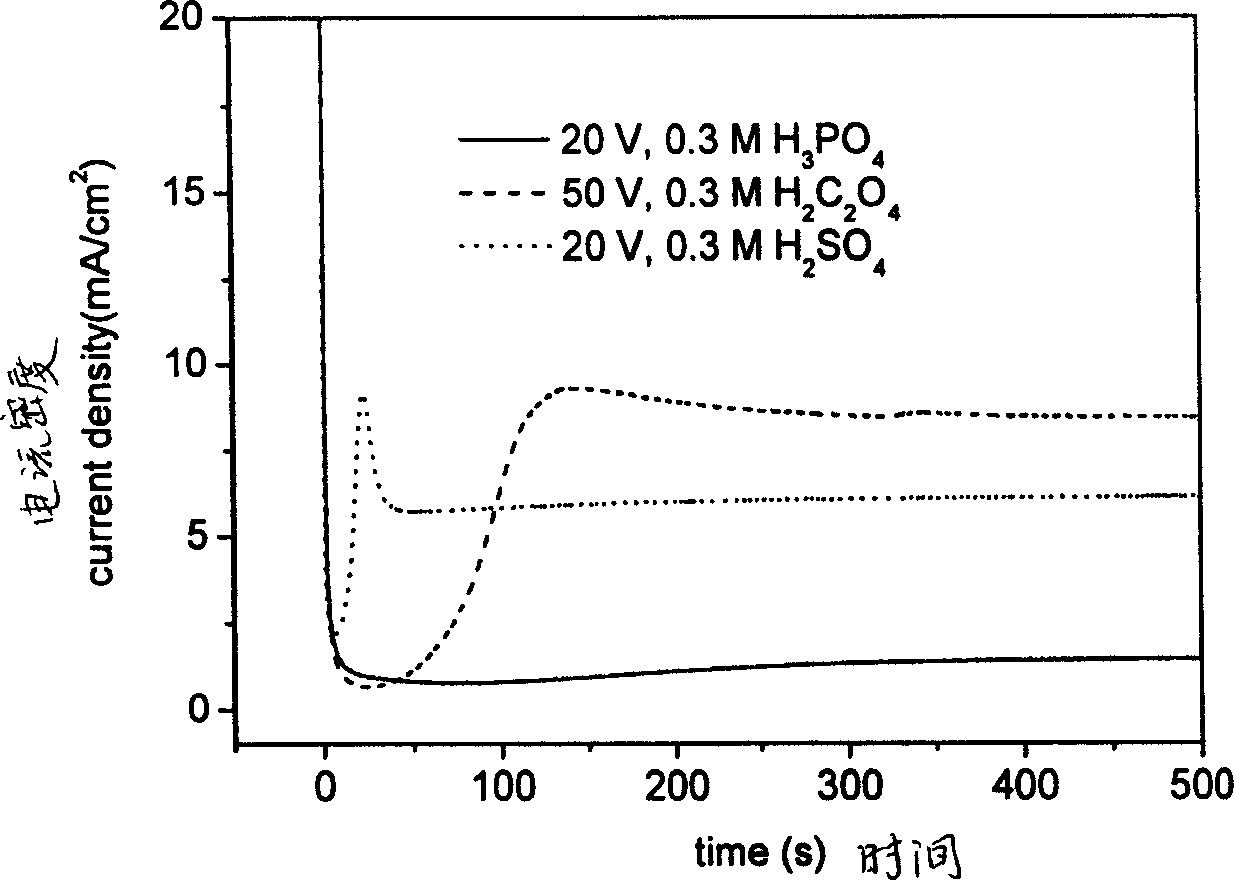

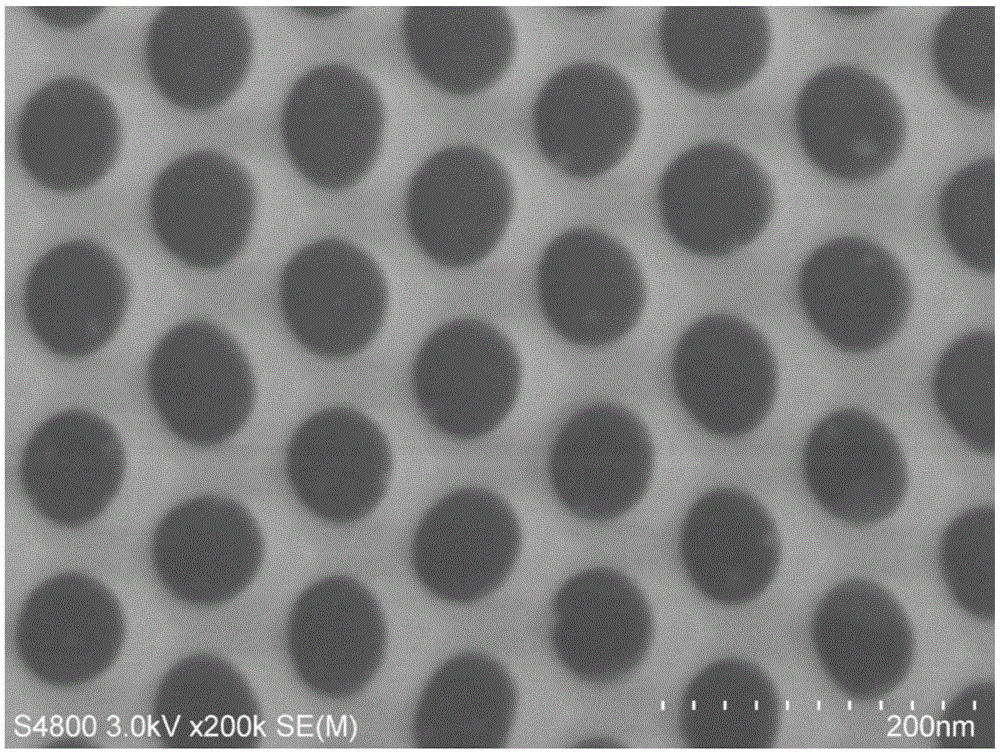

Preparation for self-supporting ordered through hole alumina film

InactiveCN1614102ASolve highSimple stepsAnodisationSemi-permeable membranesMaterials scienceHigh voltage

This invention relates to preparation of free-standing oder pylome pellumina. It includes: (1) Aluminium flake with smooth surface is directly treated to remove grease and oxides. (2) The pre-treated aluminium flake was acted as anode, another clear aluminium flake as cathode. They were electrolyzed for the first time in the acid electrolyte solution for 0.5-2h.The anode contacted the solution by single-side. The anode voltage was 10-150V at 0-25deg.C. (3) The unordered pellumina on the surface was washed by the acid electrolyte solution. (4) The second electrolysis was done. The anode voltage was 10-150V for 3-10h according to the thickness of the pellumina. (5) The oder pylome pellumina was produced by selecting suitable solution for stripping of film with short-time higher voltage by using electrochemical impulse. Then the free-standing oder pylome pellumina was formed and the fenestra was not corroded.

Owner:NANJING UNIV

PERC solar cell manufacturing method capable of reducing winding plating and chromatic aberration

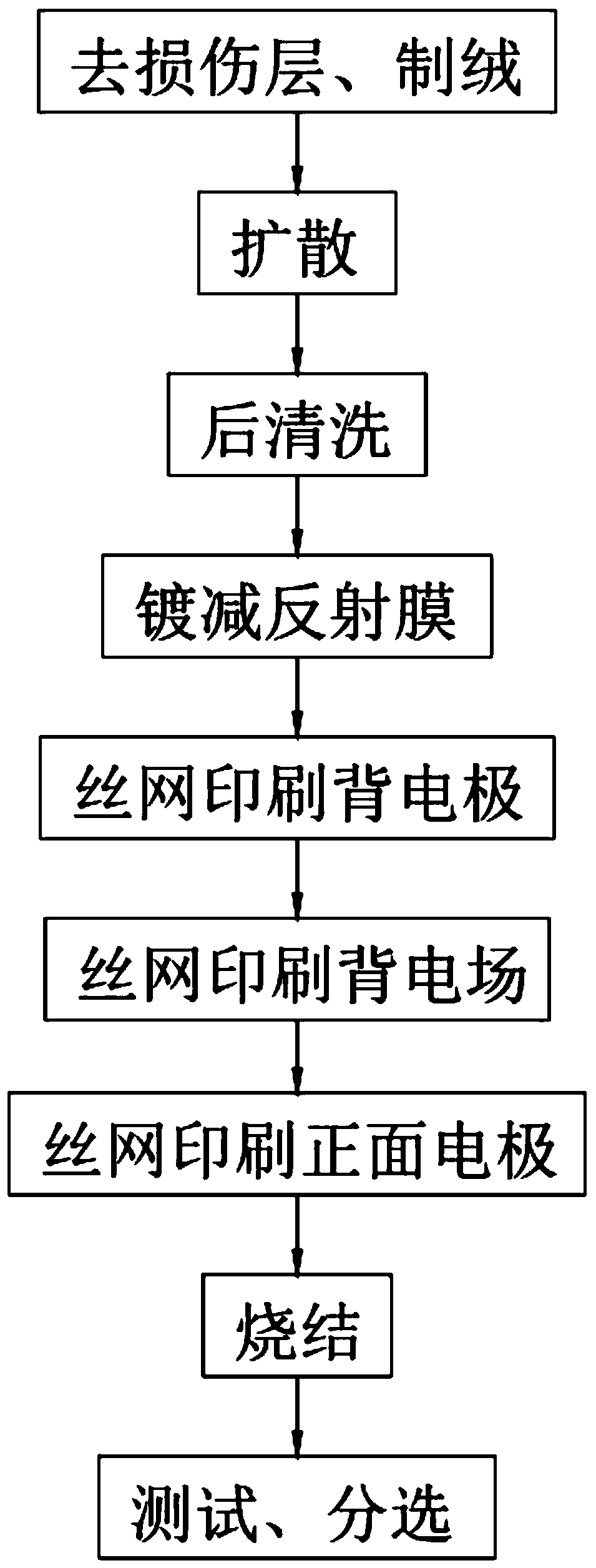

ActiveCN111081823AAround plating reductionImprove yieldFinal product manufacturePhotovoltaic energy generationSilicon oxideSolar battery

The invention discloses a PERC solar cell manufacturing method capable of reducing winding plating and chromatic aberration. The method comprises the steps of texturing, diffusion, front laser, etching, annealing, back passivation film deposition, front antireflection film deposition, back laser, silk-screen printing and sintering. In the step of the back passivation film deposition, a back surface aluminum oxide film, a back surface silicon oxide film and a first layer of back surface silicon nitride film are sequentially deposited on a back surface of a silicon wafer; and a step of depositing a second layer of silicon nitride film on the back surface is added after the step of front antireflection film deposition and before the step of back laser, and in the step of depositing the secondlayer of silicon nitride film on the back surface, a second layer of back surface silicon nitride film with low refractive index and large film thickness is deposited on the back of a silicon wafer.The cell piece manufactured by the method has the advantages that the front surface appearance color is dark and slightly black, the edge winding plating is less, the front surface film color is uniform and free of color difference, and the strict requirement of a black back plate assembly for the front surface appearance film color of the cell piece can be met.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD +3

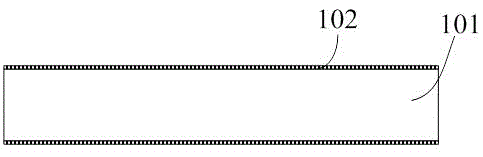

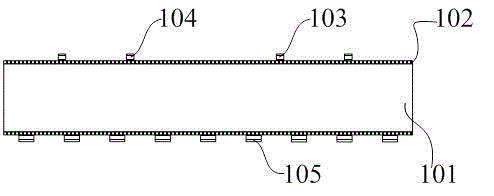

Preparation method for large-area ultrathin porous anodized alumina membranes

ActiveCN105316743ARegular structureUnbreakableSurface reaction electrolytic coatingPorous membraneAluminum substrate

The invention discloses a preparation method for large-area ultrathin porous anodized alumina membranes. The preparation method comprises the steps of S1, preparing porous alumina membranes; S2, pre-chambering; S3, preparing organic matter supporting layers; S4, removing aluminum substrates and barrier layers. According to the preparation method for the large-area ultrathin porous anodized alumina membranes, the large-area ultrathin porous anodized alumina membranes can be prepared, the structure is regular, and the thickness ranges from 100 nm to 400 nm. By carrying out pre-chambering treatment on the porous membranes and controlling the thickness of the organic matter supporting layers, the porous membranes are insusceptible to breakage and can tightly adhere to the organic matter supporting layers so as to be conveniently transferred to a target substrate. The ultrathin porous anodized alumina membranes with the area larger than 50 cm<2> can be obtained. The preparation method has the advantages that the number of the steps is small, the operation is easy and the preparation conditions are mild and easy to realize.

Owner:SHENZHEN TOPMEMBRANES INC

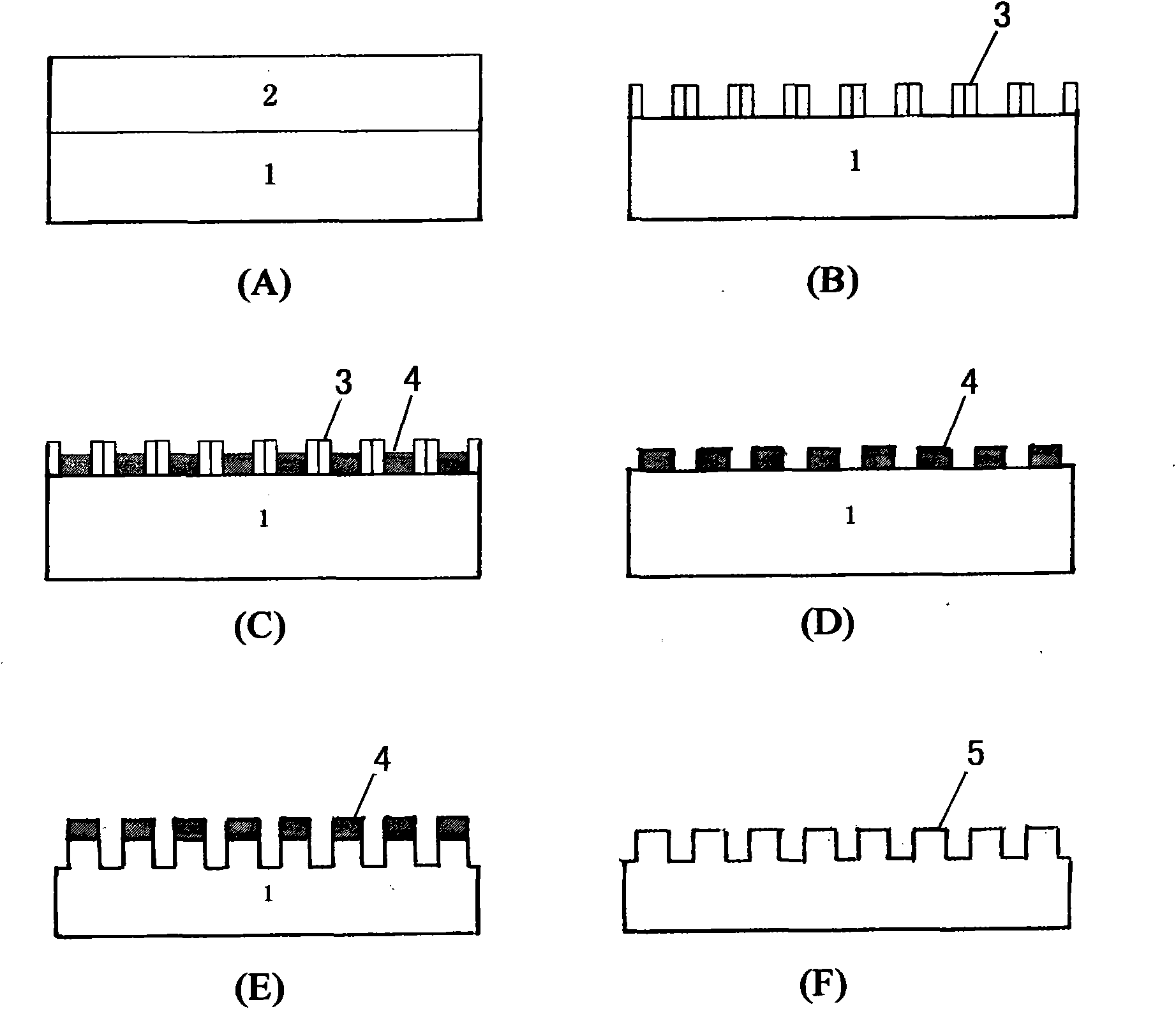

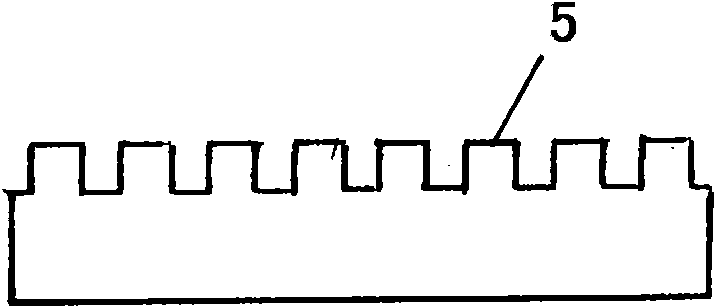

Manufacture method of semiconductor nano-pillar array structure

The invention relates to a manufacture method of a semiconductor nano-pillar array structure, comprising the following steps of: 1. growing an aluminum layer on a semiconductor substrate; 2. carrying out anodic oxidation on the aluminum layer to form holes which are directly communicated with the semiconductor substrate from the surface so as to form a porous alumina film; 3. depositing metal on the surface of the porous alumina film and forming metal points in the holes of the porous alumina film; 4. carrying out wet etching on the porous alumina film so as to form a metal point array on the semiconductor substrate; and 5. carrying out etching on the semiconductor substrate by taking the metal point array as a mask film, removing the metal point array and forming a semiconductor nano-pillar array on the semiconductor substrate.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method for coating surface of titanium dioxide with compact alumina

InactiveCN111100481AGood loose stateUniform and dense coatingPigment treatment with organosilicon compoundsWeather resistanceSodium aluminate

The invention discloses a method for coating the surface of titanium dioxide with compact alumina, and belongs to the technical field of analysis and detection. In order to improve pulverization resistance, weather resistance and glossiness of titanium dioxide and reduce the oil absorption amount of the product, the invention provides a method for coating the surface of titanium dioxide with compact alumina. The method comprises the following steps: mixing titanium dioxide, water and a dispersing agent; pulping and dispersing to obtain pre-coating slurry, diluting the pre-coating slurry with water, adjusting the pH value and temperature of the slurry, adding sodium metaaluminate and dilute acid, controlling the pH value to carry out primary curing and secondary curing, screening, filtering, washing, and carrying out organic treatment, drying and crushing to obtain uniform and compact alumina-coated titanium dioxide. By analyzing conventional indexes, TEM, BET and the like of the product, uniform and compact coating of the alumina film is determined.

Owner:CHONGQING TITANIUM IND OF PANGANG GROUP

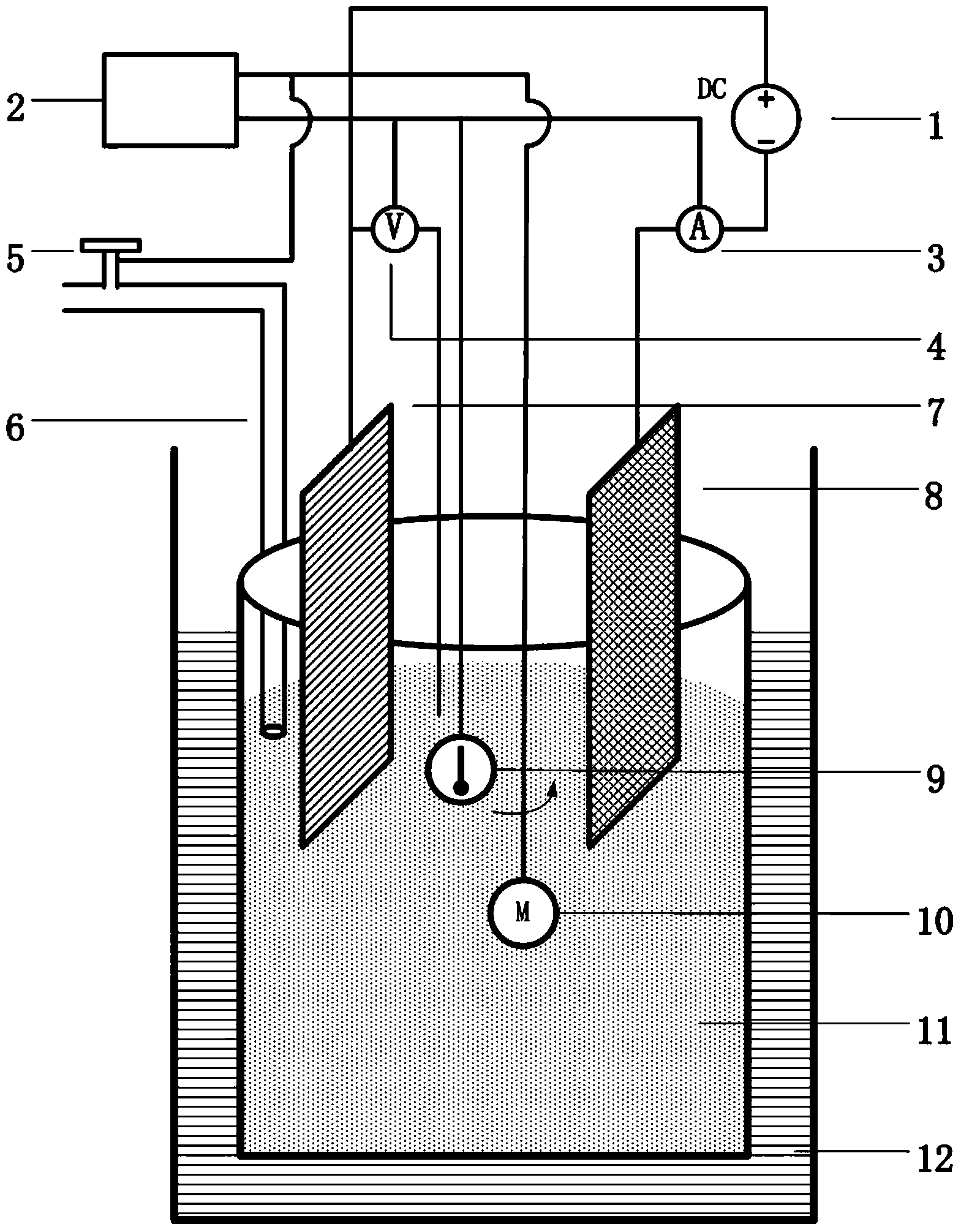

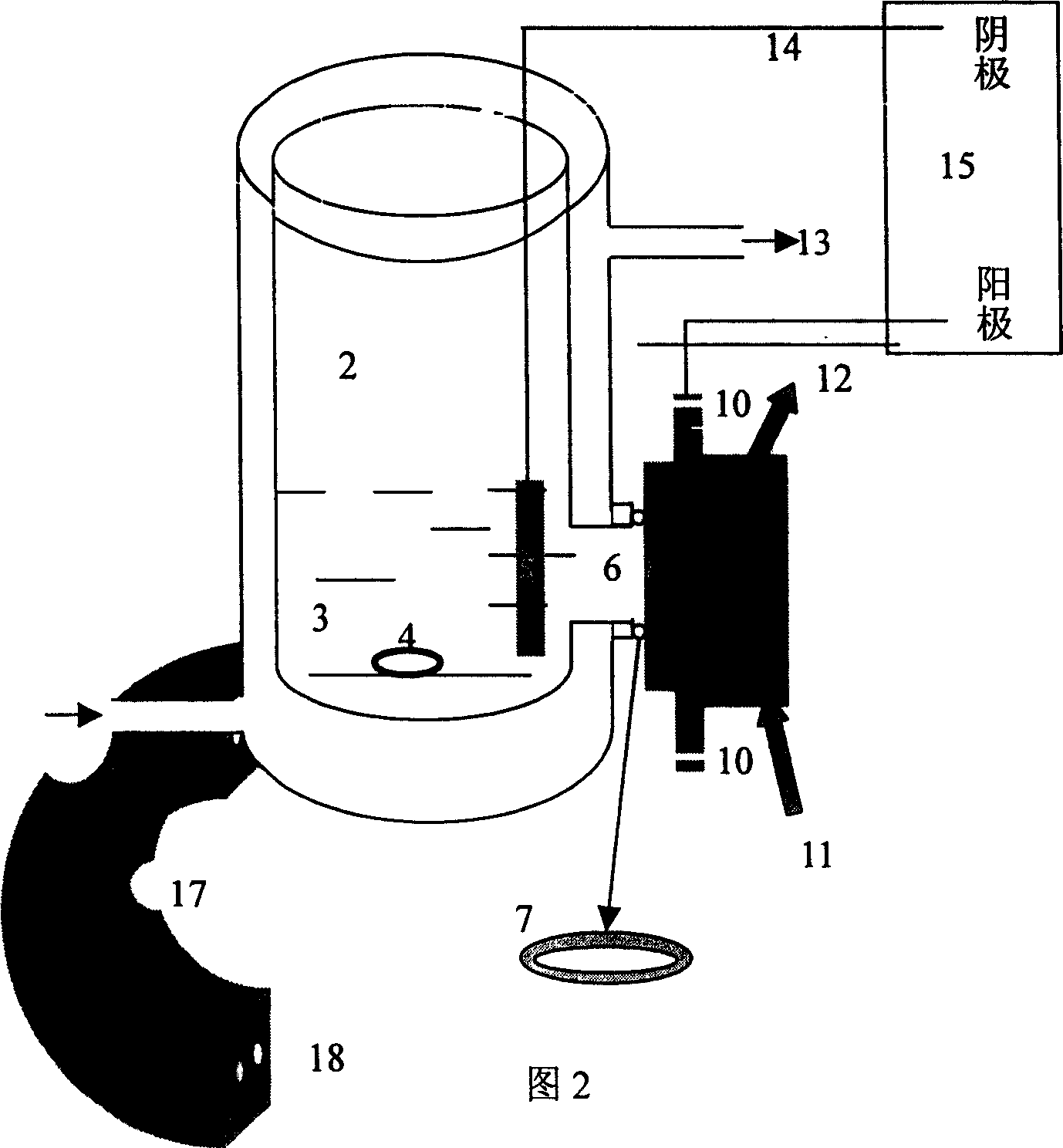

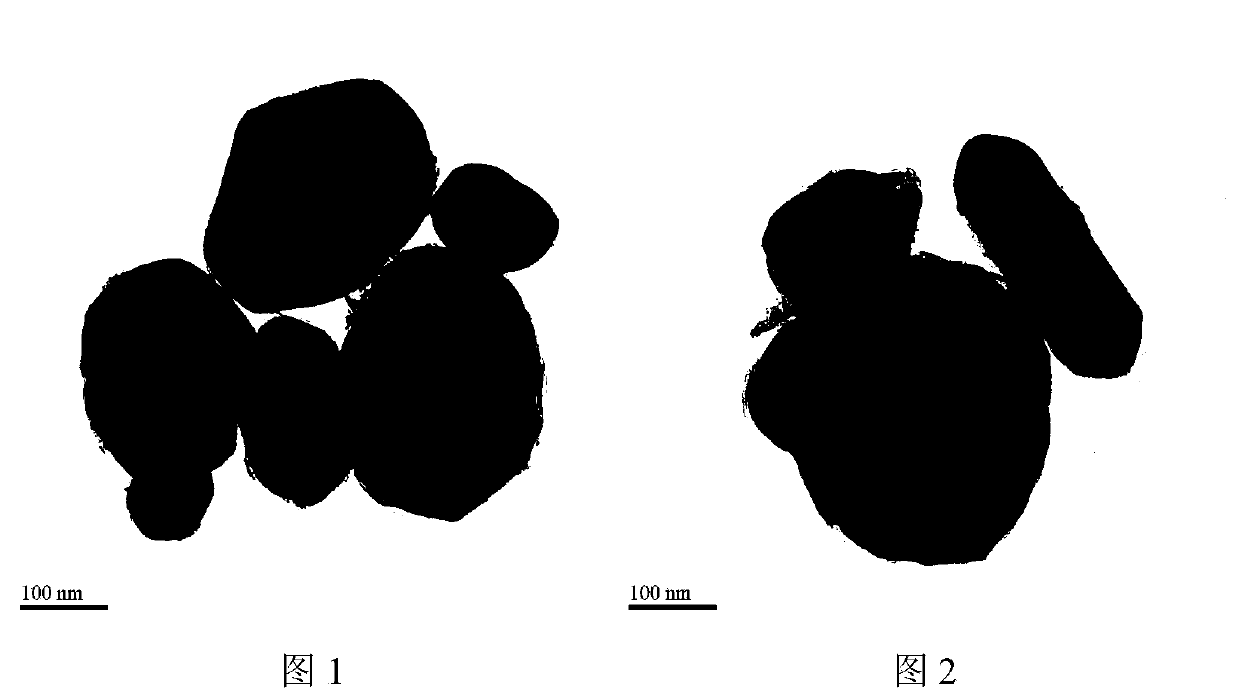

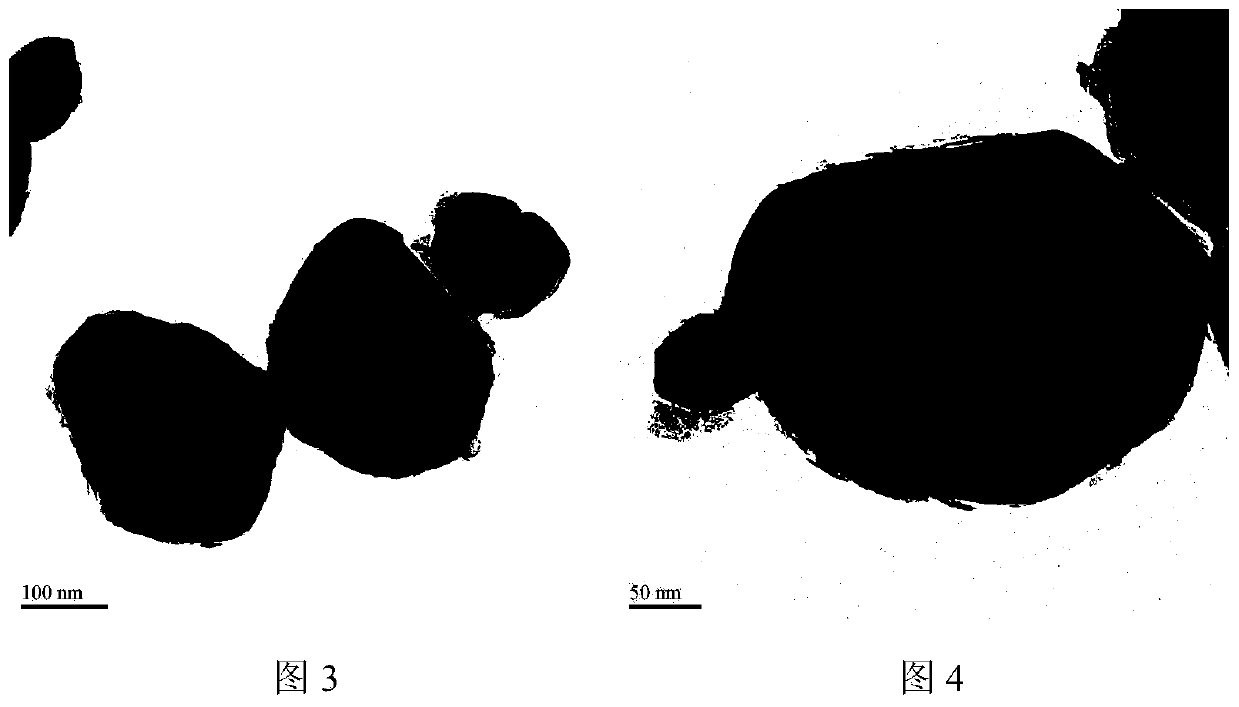

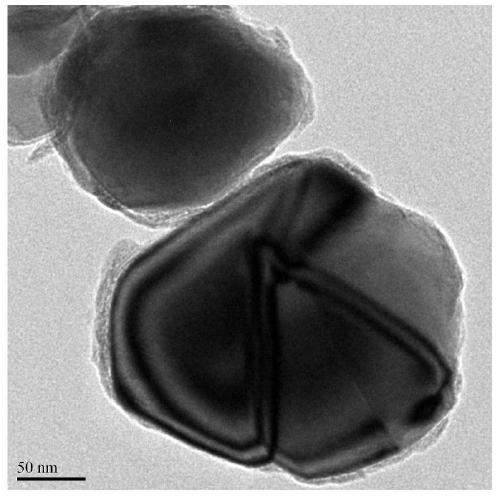

Novel high-sensitivity LM (listeria monocytogene) detection method based on aptamer modified porous alumina membrane

InactiveCN106018508ADetection has no effectHigh selectivityMaterial electrochemical variablesEscherichia coliPotassium ferricyanide

The invention relates to a fast ultra-sensitive LM (listeria monocytogene) detector based on nanochannel confinement characteristics and constructed according to the nature of specific identification between a target molecule and an aptamer of the target molecules. The invention further relates to a method for detecting the LM by taking potassium ferricyanide ions as probe ions and taking an LM DNA modified porous alumina membrane as an electrode for assembling a self-made electrolytic tank. When LM is present and the concentration is lower, a current increasing value is remarkably reduced with the increase of the concentration; a current change value is reduced with increase of the LM concentration; when the LM concentration is in a range of 100-1,250 CFU / mL, a linear relation is formed between the LM concentration and the current increasing value; when the LM concentration is higher than 1,500 CFU / mL, the current change value becomes stable. Therefore, the lowest detection limit of the detection method for the LM can reach 100 CFU / mL, the linear range is 100-1,250 CFU / mL, and the detection can be completed within 10 min; a 108 CFU / mL of escherichia coli and staphylococcus aureus control experiment indicates that the method has high selectivity on the LM.

Owner:GUANGDONG OCEAN UNIVERSITY

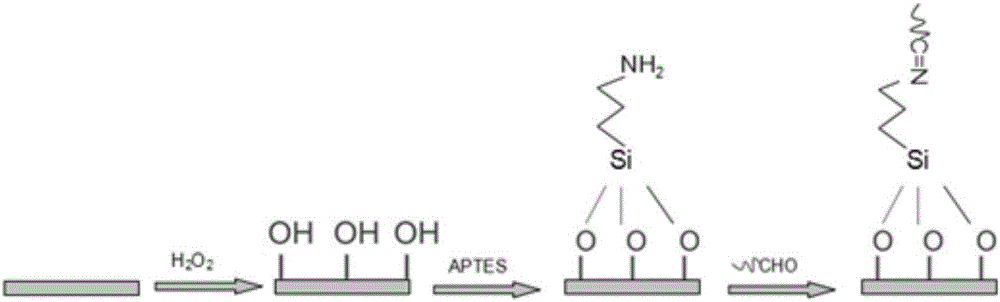

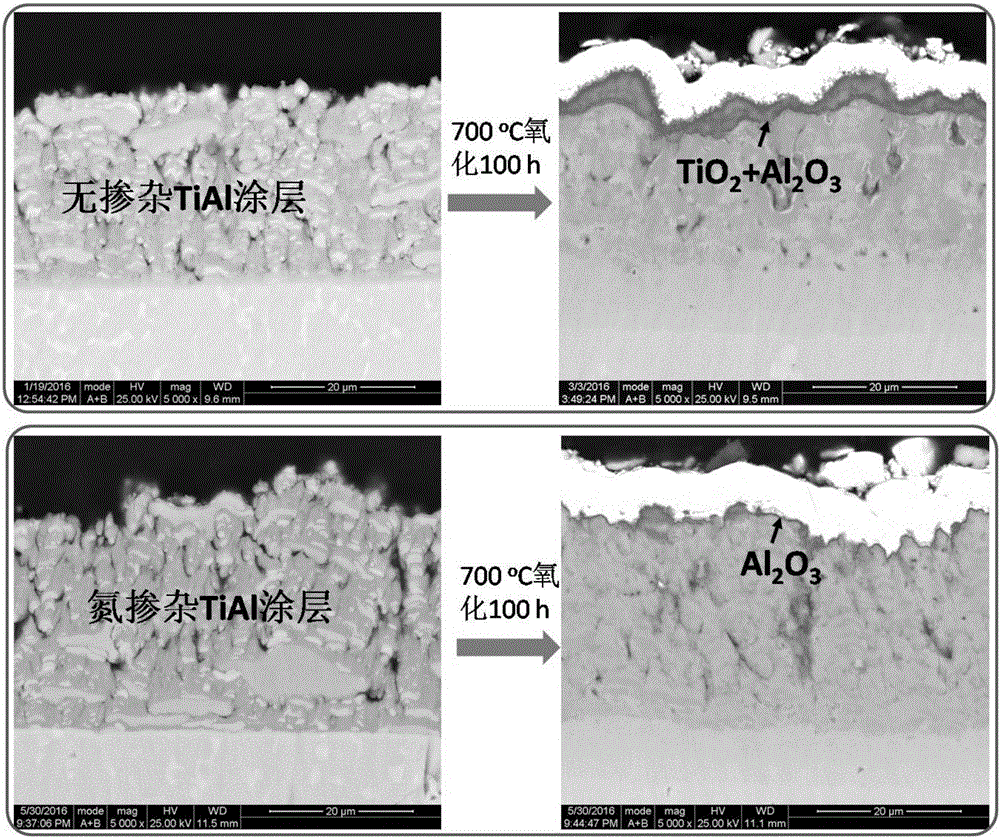

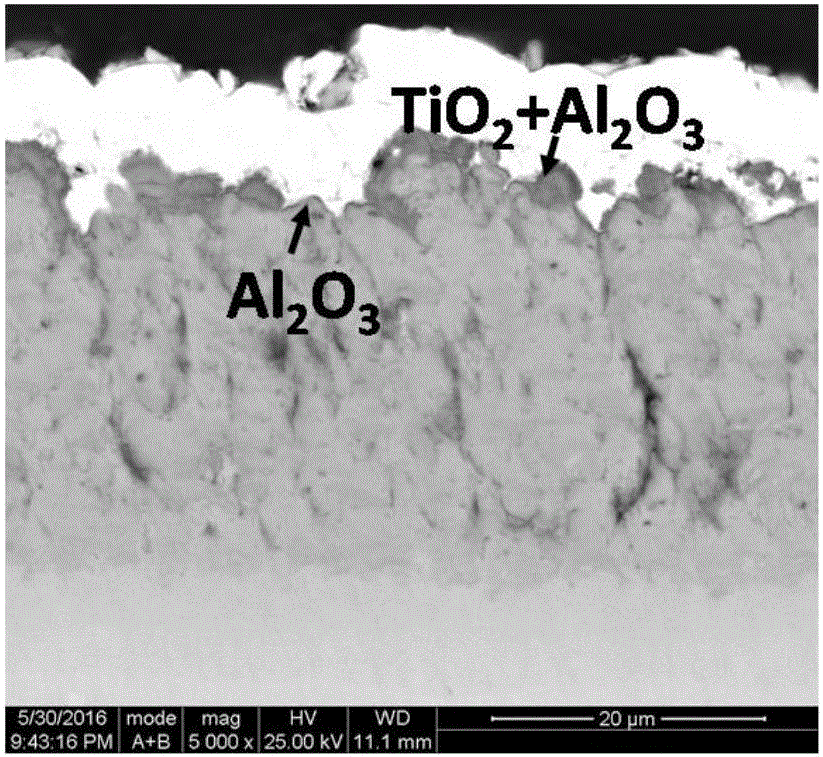

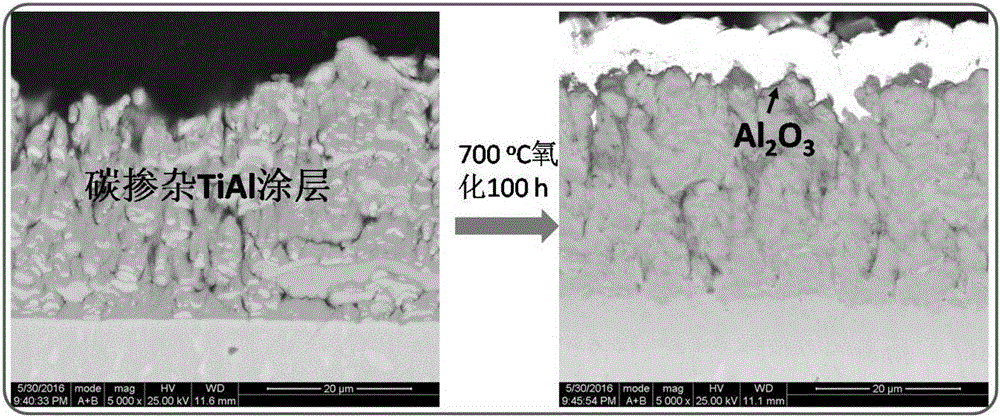

TiAl coating capable of achieving heat growth of aluminum oxide film and preparing method of TiAl coating

ActiveCN105908131APrecise control of nitrogen contentPrecise control of carbon gas contentVacuum evaporation coatingSputtering coatingGas phaseChemical compatibility

The invention provides a TiAl coating capable of achieving heat growth of an aluminum oxide film and a preparing method of the TiAl coating, and belongs to the technical field of coatings. The TiAl coating can be used for high-temperature oxidation protection of a titanium alloy, a titanium aluminum intermetallic compound and other materials. According to the TiAl coating with the selective aluminum oxide film forming capability, the Al atom ratio content of a TiAl alloy target material ranges from 38%-58%. TiAl serves as a target material, in the physical vapor deposition process, a trace of carbon or nitrogen is doped, the TiAl coating with the selective aluminum oxide film forming capability is obtained, a new thought and method are provided for designing a titanium alloy and titanium aluminum intermetallic compound anti-oxidation protection coating, the chemical compatibility between the coating and a base body is good, and brittleness is low. Meanwhile, the technology is simple, controllable, environment-friendly, low in cost and suitable for industrial application. Compared with existing related protection coatings, obvious technical advantages are achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing composite material with nano hybrid lubricant on surface

InactiveCN1698998AWide range of applicationsSimple and efficient operationTurbinesOther manufacturing equipments/toolsPhosphoric acidAnodic oxidation

This invention relates to a method for preparing a nanometer confounding lubricant material, which belongs to materials engineering field. The method comprises the following steps: (1) anodic oxidation aluminum products: applying phosphoric acid and malic acid as the anodic oxidation liquid, creating a layer of poriness anodized film in the aluminum products surface. (2) preparing nanometer confounding lubricant: mixing MoS2 and PTFE powder absolutely, adding surface activator OP, then ball grinding in the high-energy ball grinder; ultrasonic dispersing in water. (3) filling of the lubricant: filling the lubricant to the porous aluminum oxide through ultrasonic hot dipping method; heating in the baking oven and insulation. Said invention uses synergistic effect of polyphase lubrication in nanometer dimension, which can increase the frictional factor of surface composite material.

Owner:SHANGHAI JIAO TONG UNIV

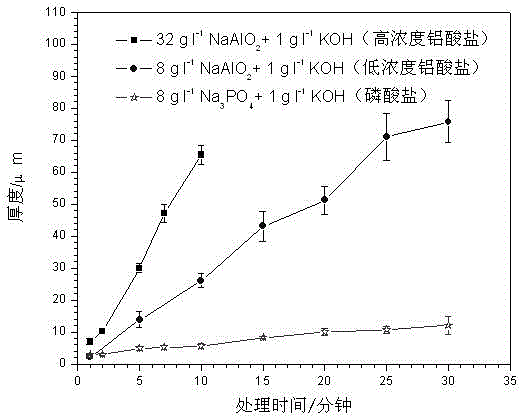

Microarc oxidation method for quickly preparing wear-proof zirconia and alumina mixed coating on surface of zirconium alloy

InactiveCN103334143AFast growthHigh Al contentSurface reaction electrolytic coatingAluminateElectrolytic agent

The invention relates to the field of electrochemistry, and discloses a microarc oxidation method for quickly preparing a wear-proof zirconia and alumina mixed coating on the surface of a zirconium alloy. The microarc oxidation method comprises the steps of taking the pretreated zirconium alloy as an anode and a steel plate as a cathode, controlling the temperature of an electrolytic solution to be 10-30 DEG C, setting microarc oxidation power supply parameters, turning on a power supply, treating for 2-12min, turning off the power supply, taking the zirconium alloy out, washing the surface of the zirconium alloy with deionized water, and obtaining the wear-proof zirconia and alumina mixed coating, wherein the electrolytic solution comprises 30-60g sodium aluminate, 1-10g strong base, and 1000ml of deionized water. According to the method, the film-forming speed is high, a film layer is uniform in structure and contains a large amount of alumina, the abrasive resistance of the film layer is much higher than that of a general microarc oxidation film, obtained in an electrolytic solution with low concentration of aluminate, phosphate and the like, of the zirconium alloy.

Owner:HUNAN UNIV

Magnetic tunnel structure suitable for device and its use

ActiveCN1988199AImprove performanceImprove signal-to-noise ratioMagnetic measurementsMagnetic-field-controlled resistorsPhysicsMagnetic layer

This invention relates to a device-like magnetic tunnel junction including a substrate and a buffer layer on it, in which, a nail prick layer, a nailed soft magnetic layer, an insulation layer, a free soft magnetic layer and a covering layer are deposited on the buffer layer orderly characterizing that the insulation layer is a compound film layer, the top and bottom are metal layers of 0.2-2nm thick or insulator potential layer, the mid layer is an Al2O film layer of 0.5-5 thick. The junction can be widely used in various devices with the magnetic tunnel junction as the core.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

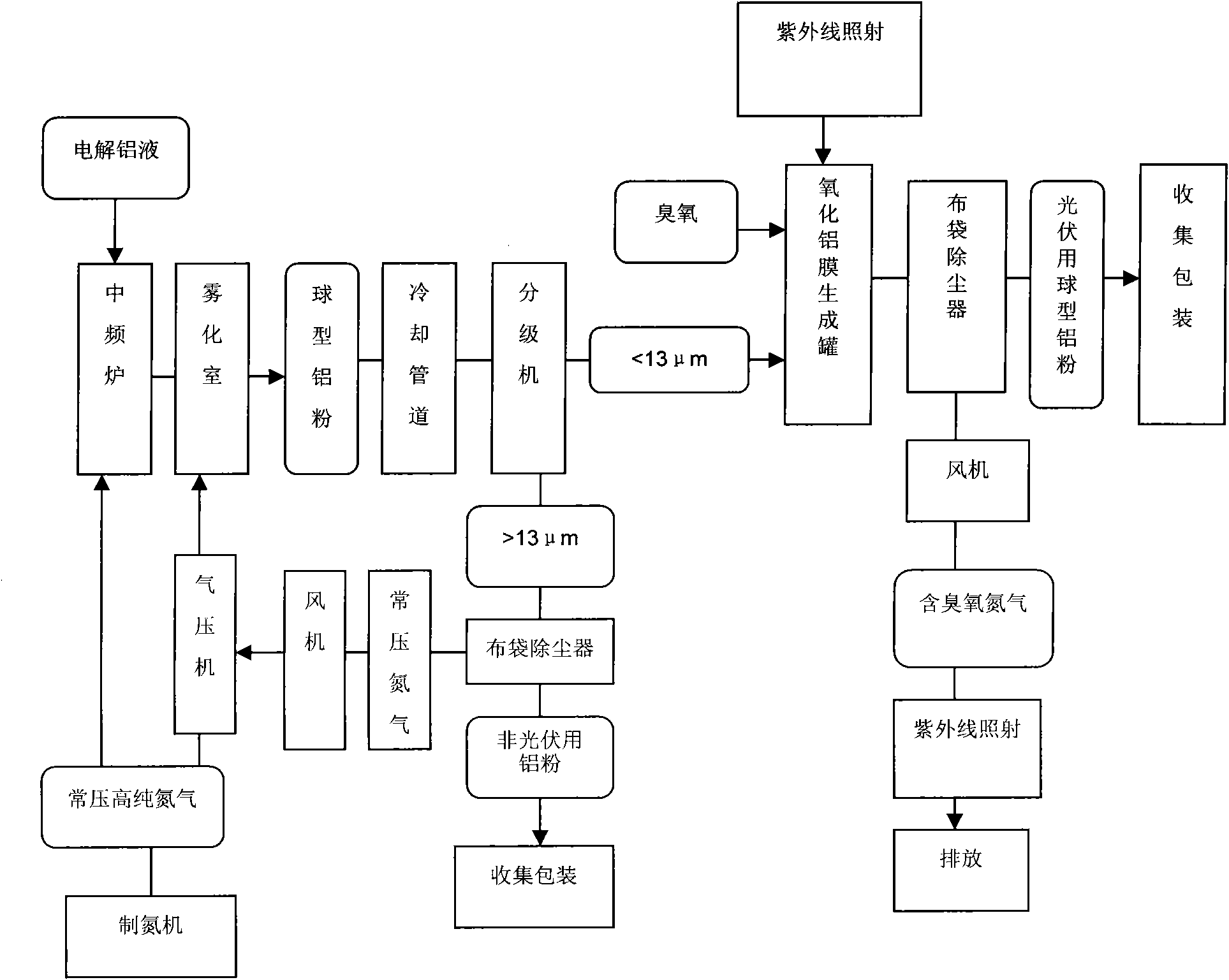

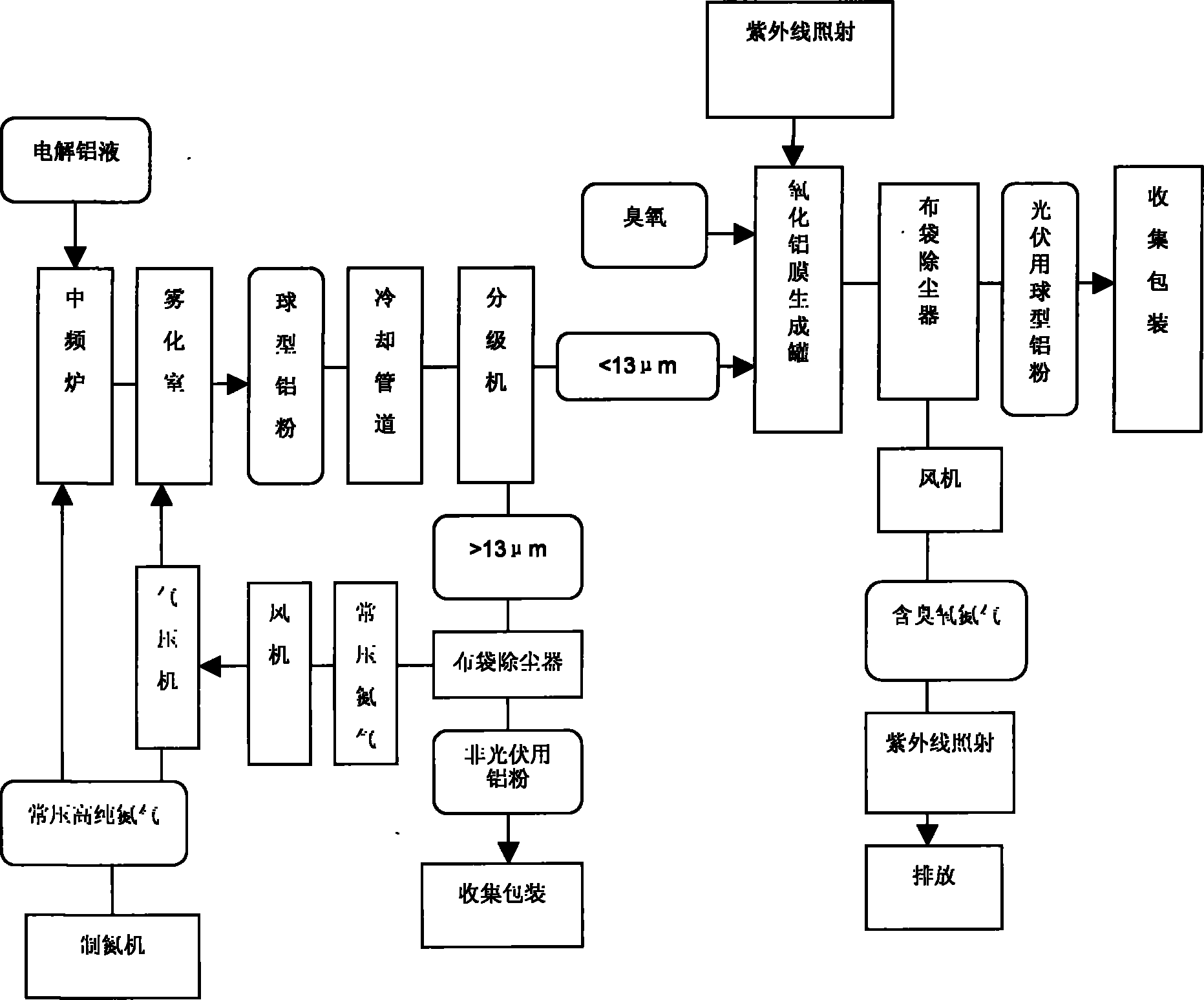

Method for producing spherical aluminium powder for p-type aluminum-doped back electrodes of crystalline silicon solar cells

The invention discloses a method for producing spherical aluminium powder, and the aluminium powder is used for aluminum-doped back electrodes (with the characteristics of p-type semiconductors) of crystalline silicon solar cells such as mono-crystalline silicon solar cells, polycrystalline silicon solar cells and the like. The contents of the invention comprise production process and equipment composition as well as the contents of elements including aluminium, silicon, iron and gallium and a method for blending the elements; the method comprises the following steps: preparing spherical aluminium powder blanketed with high-purity nitrogen; adding ozone into the nitrogen to mix with the aluminium powder, and then carrying out ultraviolet irradiation on the obtained mixture so as to form an amorphous activated aluminium oxide film on the surface of the spherical aluminium powder at low temperature; and carrying out ultraviolet irradiation on the ozone in the nitrogen so as to decomposethe ozone into oxygen, and then carrying out harmless emission. The invention overcomes the defect that the existing spherical aluminium powder for aluminum-doped back electrodes of the crystalline silicon solar cells is prepared by using remelting aluminium ingots as raw materials; the metal gallium content of the spherical aluminium powder is increased to reach a certain range, which improves the characteristics of the P-type semiconductors; and an amorphous activated aluminium oxide film is formed on the surface of the spherical aluminium powder at low temperature, which can reduce the resistance of the electrode, and increase the adhesive power of silicon and aluminium.

Owner:SHANDONG XINNENG NEW MATERIAL

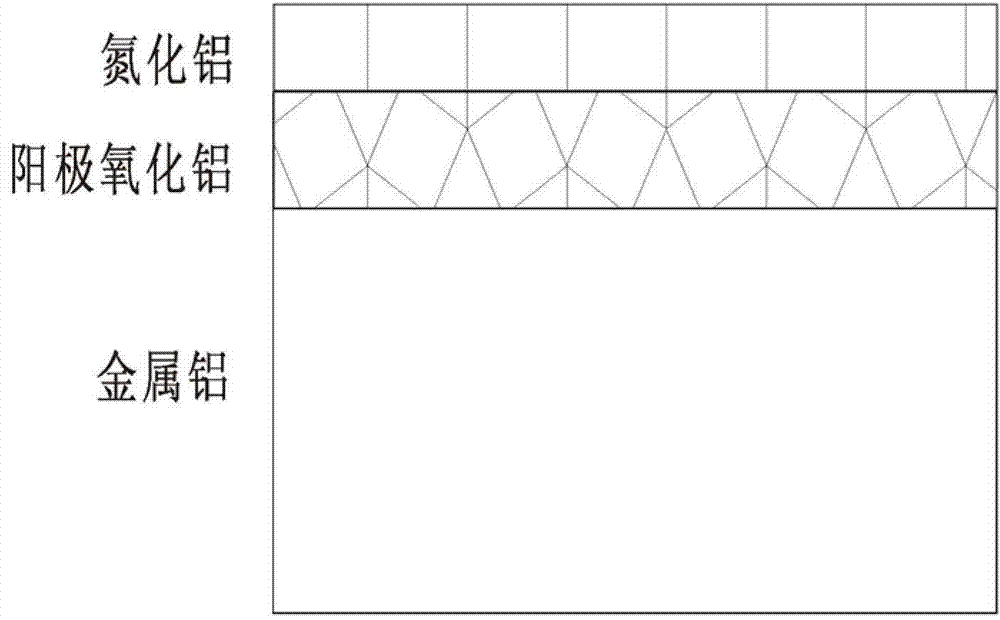

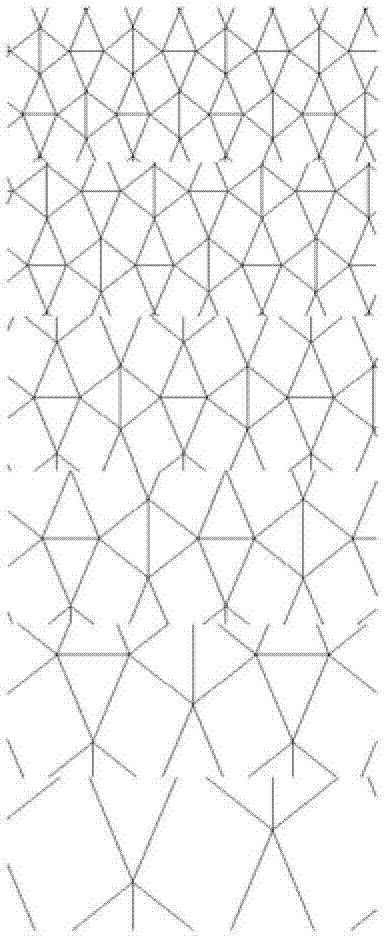

Metal aluminum base aluminum nitride package substrate and preparation method thereof

InactiveCN103035585AImprove thermal shock resistanceNo crackingAnodisationSemiconductor/solid-state device detailsThermal dilatationMetallic aluminum

The invention discloses a metal aluminum base aluminum nitride package substrate and a preparation method thereof, and belongs to the field of microelectronic materials. The package substrate comprises a metal aluminum base, a porous anodic alumina film formed on the surface of the metal aluminum base, and an aluminum nitride film formed on the surface of the anodic alumina film, wherein the porosity of the anodic alumina film is reduced gradually along the direction from the metal aluminum base to the aluminum nitride film. According to the preparation method of the package substrate, metal aluminum is used as the base, anodic oxidation is carried out on one surface of aluminum to generate a layer of the porous anodic alumina film, and then the aluminum nitride film is deposited on the anodic alumina film in a vacuum mode. According to the metal aluminum base aluminum nitride package substrate, the anodic oxidation is carried out on the metal aluminum base, an anodic alumina thermal stress buffer layer with a coefficient of thermal expansion gradually varied is formed between the aluminum base and the aluminum nitride film, thermal shock resistance is improved obviously, cracking does not occur under 300 DEG C thermal shock, and therefore the metal aluminum base aluminum nitride package substrate can be applied in a subsequent process of semiconductor chip package well.

Owner:WUHAN BOOYEN TECH

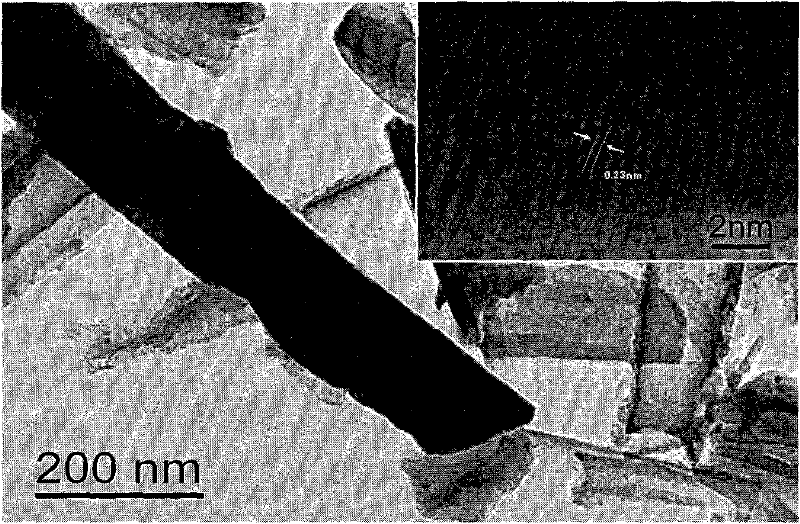

Method for preparing bunchy bismuth nanostructure material

The invention discloses a method for preparing a bunchy bismuth nanostructure material, which comprises the following steps: performing ultrasonic cleaning of an alumina AAO template in an alcohol solution, performing electrodeposition by multi-potential step, and removing the alumina membrane so as to obtain the bunchy bismuth nanostructure material. The invention has simple preparation and high filling ratio. The invention also discloses the prepared bunchy bismuth nanostructure material which has a unique high-density nano-wire array structure, can receive various heat energy from the environment, and has wide commercial application perspectives.

Owner:EAST CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com