Method for coating surface of titanium dioxide with compact alumina

A surface coating, titanium dioxide technology, applied in the field of analysis and detection, can solve the problem of no obvious improvement and improvement in application performance, and achieve the effect of uniform and dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

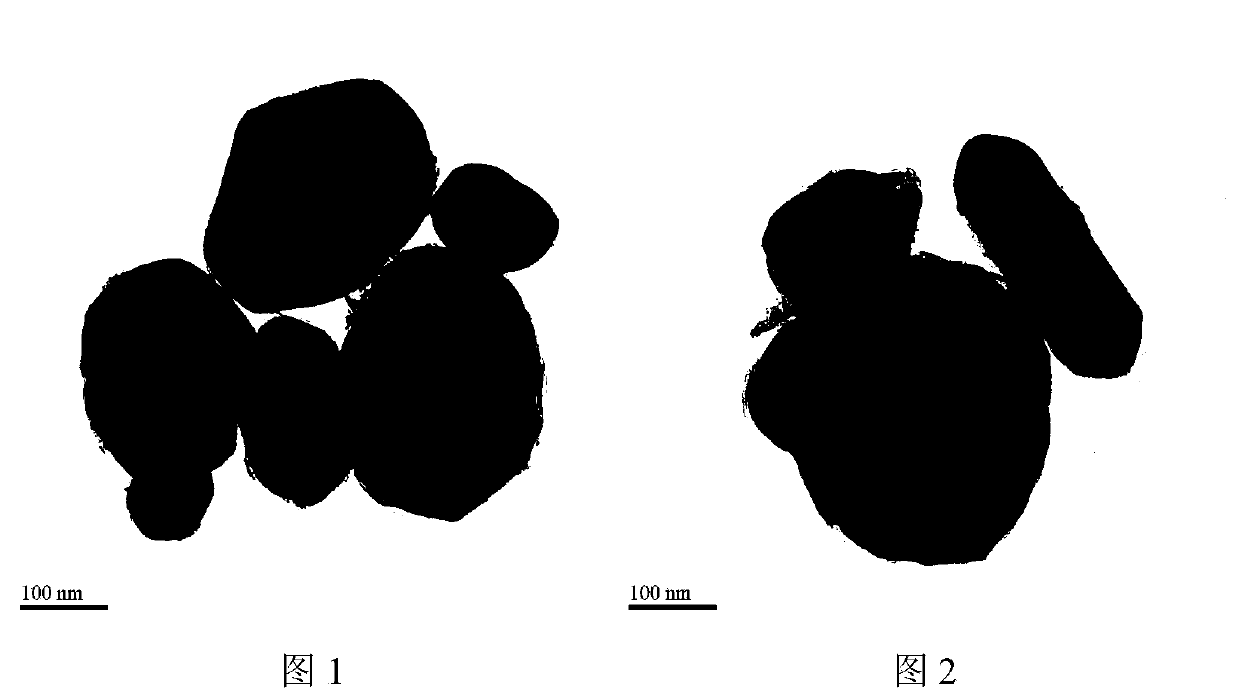

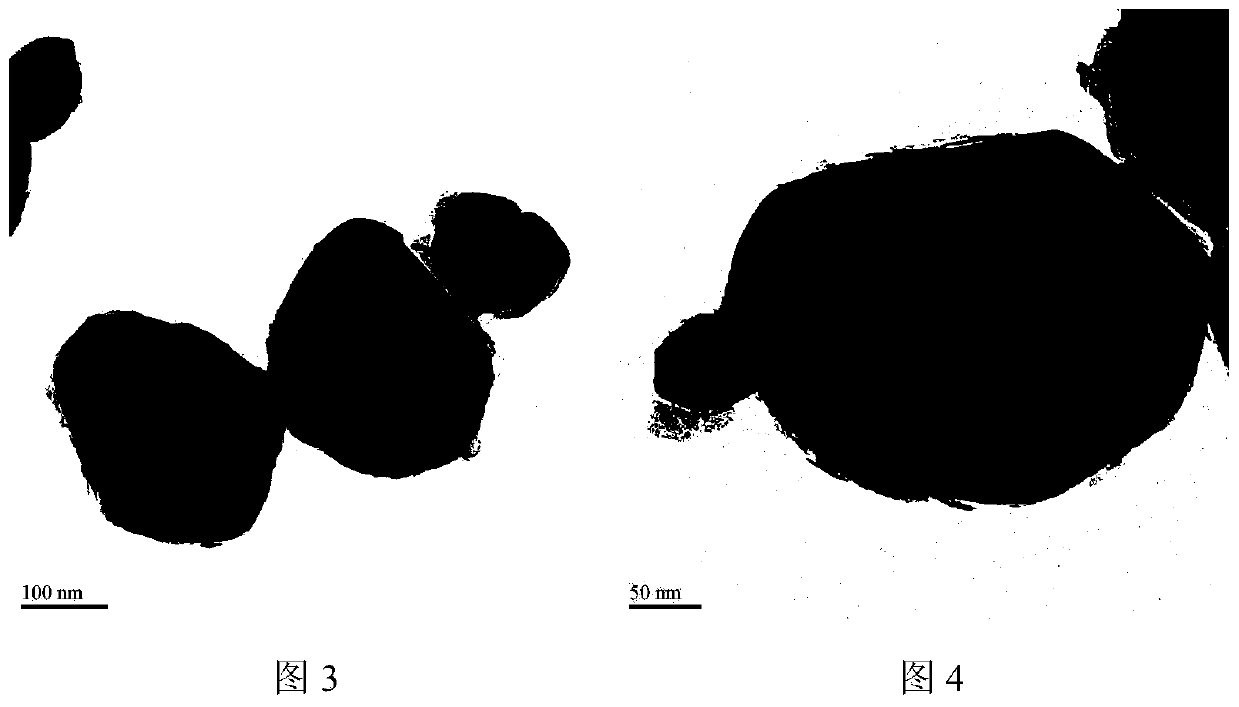

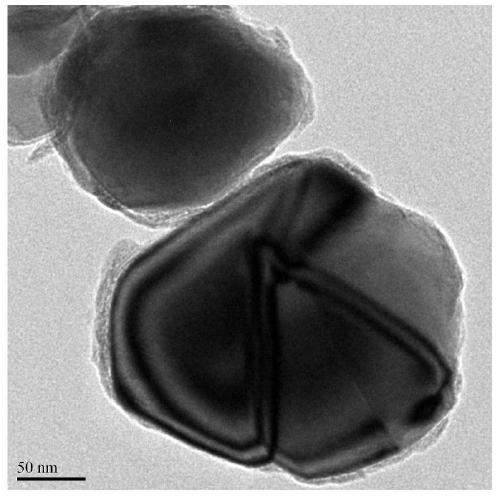

Image

Examples

Embodiment 1

[0049] A. Put rutile titanium dioxide particles into a stirring device, add deionized water or distilled water, add sodium silicate (SiO 2 : TiO 2 =0.3wt%) and sodium hydroxide as a dispersant, zirconium beads as a grinding medium, control the pH of the slurry in the beating process=9.0~10.0, beating and dispersing for 60min, and filtering with a 325 mesh screen to obtain a concentration of 620g / L. Membrane front slurry;

[0050] B. Take the slurry before coating and put it in the coating tank, add deionized water or distilled water, dilute the slurry concentration to 280g / L, turn on the heating device, and control the temperature of the slurry at about 60°C;

[0051] C. Add a dilute sulfuric acid solution with a mass concentration of 15% to the slurry, adjust the pH of the slurry to 8.5-10.0, and maintain the temperature of the slurry at about 60°C;

[0052] D. Add dilute sulfuric acid and sodium metaaluminate (calculated as alumina, the addition amount is 3.0% of the mass ...

Embodiment 2

[0056] A. Put rutile titanium dioxide particles into a stirring device, add deionized water or distilled water, add sodium silicate (SiO 2 : TiO 2 =0.3wt%) and sodium hydroxide as a dispersant, zirconium beads as a grinding medium, control the pH of the slurry in the beating process=9.0~10.0, beating and dispersing for 60min, and filter with a 325 mesh screen to obtain 620g / L pre-encapsulated pulp;

[0057] B. Take the slurry before coating and put it in the coating tank, add deionized water or distilled water, dilute the slurry concentration to 280g / L, turn on the heating device, and control the temperature of the slurry at about 60°C;

[0058] C. Add dilute hydrochloric acid solution with a mass concentration of 15% to the slurry, adjust the pH of the slurry to 8.5-10.0, and maintain the temperature of the slurry at about 60°C;

[0059] D. Add dilute hydrochloric acid and sodium metaaluminate (calculated as alumina, the amount added is 3.0% of the mass of titanium dioxide)...

Embodiment 3

[0063] A. Put rutile titanium dioxide particles into a stirring device, add deionized water or distilled water, add sodium silicate (SiO 2 : TiO 2 =0.3wt%) and sodium hydroxide as a dispersant, zirconium beads as a grinding medium, control the pH of the slurry in the beating process=9.0~10.0, beating and dispersing for 60min, and filter with a 325 mesh screen to obtain 620g / L pre-encapsulated pulp;

[0064] B. Take the slurry before coating and put it in the coating tank, add deionized water or distilled water, dilute the slurry concentration to 280g / L, turn on the heating device, and control the temperature of the slurry at about 60°C;

[0065] C. Add an appropriate amount of dilute phosphoric acid solution to the slurry, the mass concentration of dilute phosphoric acid is 15%, adjust the pH of the slurry to 8.5-10.0, and maintain the temperature of the slurry at about 60°C;

[0066] D. Add dilute phosphoric acid and sodium metaaluminate (calculated as alumina, the addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com