Preparation for self-supporting ordered through hole alumina film

A technology of aluminum oxide film and porous aluminum oxide, applied in the field of material chemistry, can solve the problems of restricting the industrial production of porous aluminum oxide film, complicated and complicated production process, high risk, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

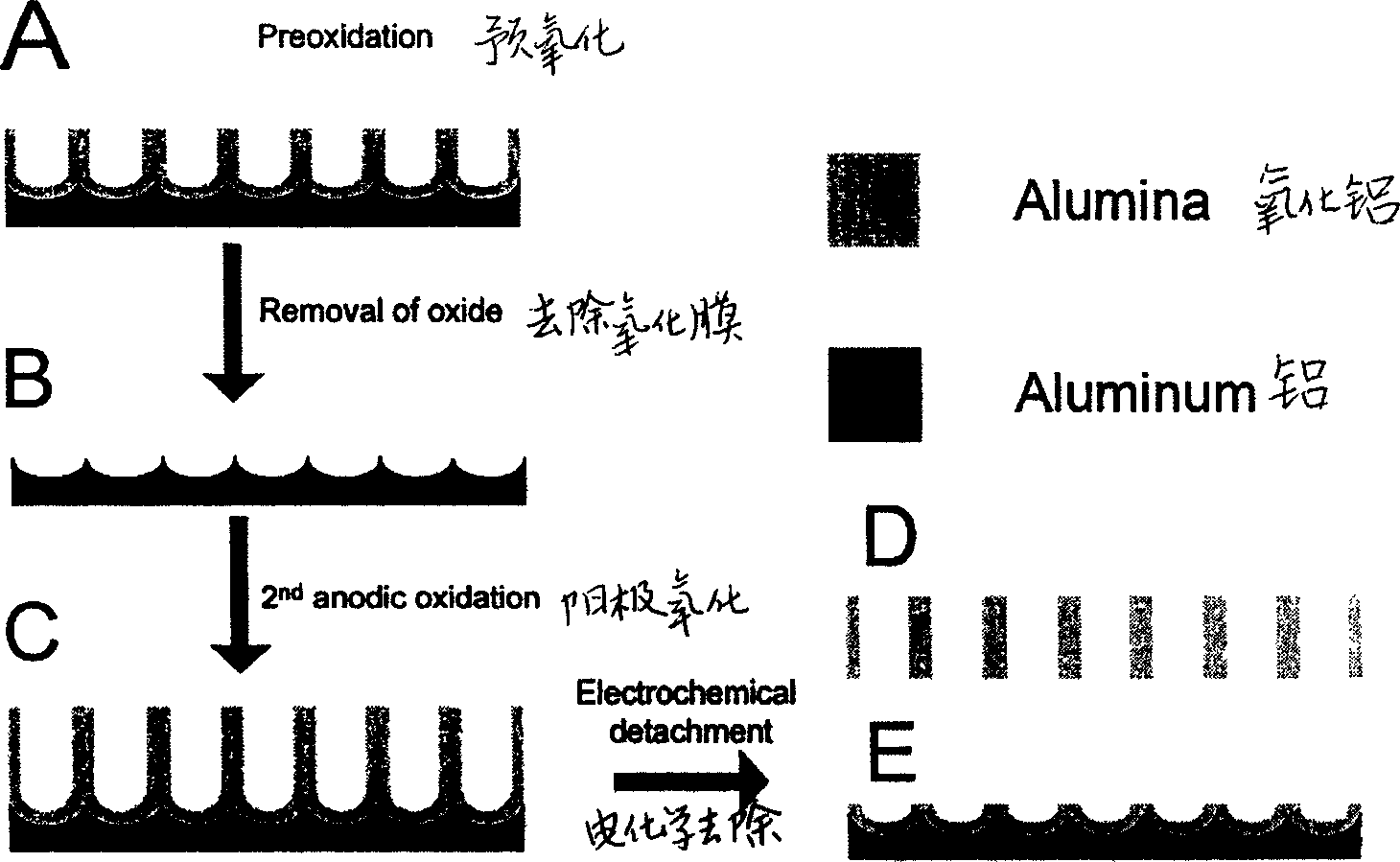

[0022] figure 1 The schematic diagram of the process of preparing self-supporting ordered through-hole aluminum oxide film in the present invention is given. A is the aluminum oxide film formed on the anodic aluminum substrate after the first electrochemical oxidation; B is after removing the aluminum oxide film in A. The anodized aluminum substrate, the concave shape left is the nucleation center of the second aluminum anodic oxidation, which acts as an inducer to improve the order degree of the aluminum oxide film pore distribution; C is the order generated after the second anodic oxidation Aluminum oxide film, the bottom of the hole is a tight barrier alumina thin layer, which is closely combined with the anodic aluminum substrate; D is the self-supporting ordered through-hole oxidation that falls off the substrate by itself in a certain stripping solution and a certain pulse condition Aluminum film; E is the anodized aluminum substrate after the aluminum oxide film of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com