Aliminium base wave absorbing material and preparing method

An absorbing material, aluminum-based technology, applied in electrical components, magnetic field/electric field shielding, etc., can solve the problems of narrow absorbing frequency range of conductive polymer, not wide enough absorbing frequency band, large proportion of absorbing material, etc. High-efficiency broadband absorbing performance, improving absorbing effect, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

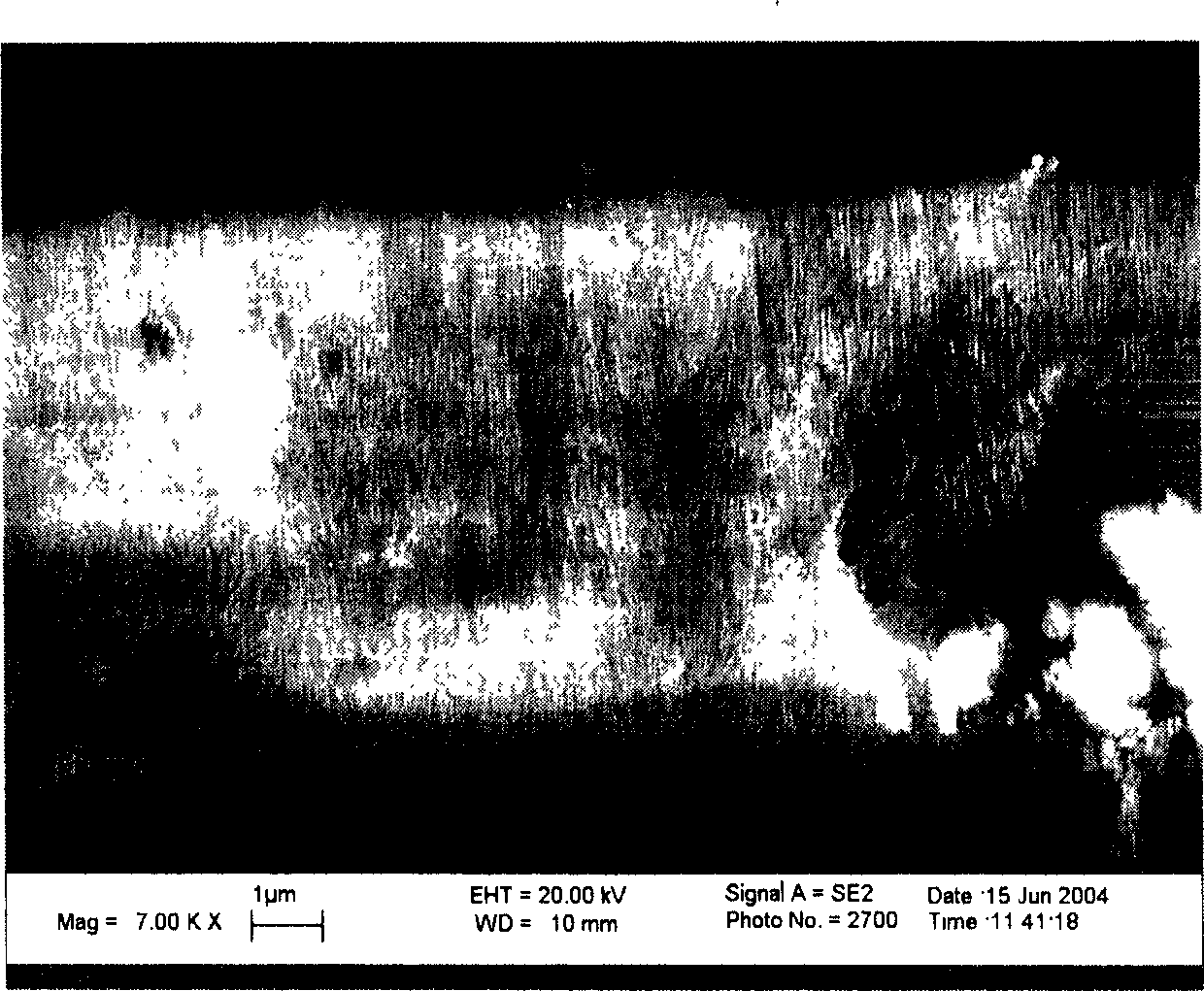

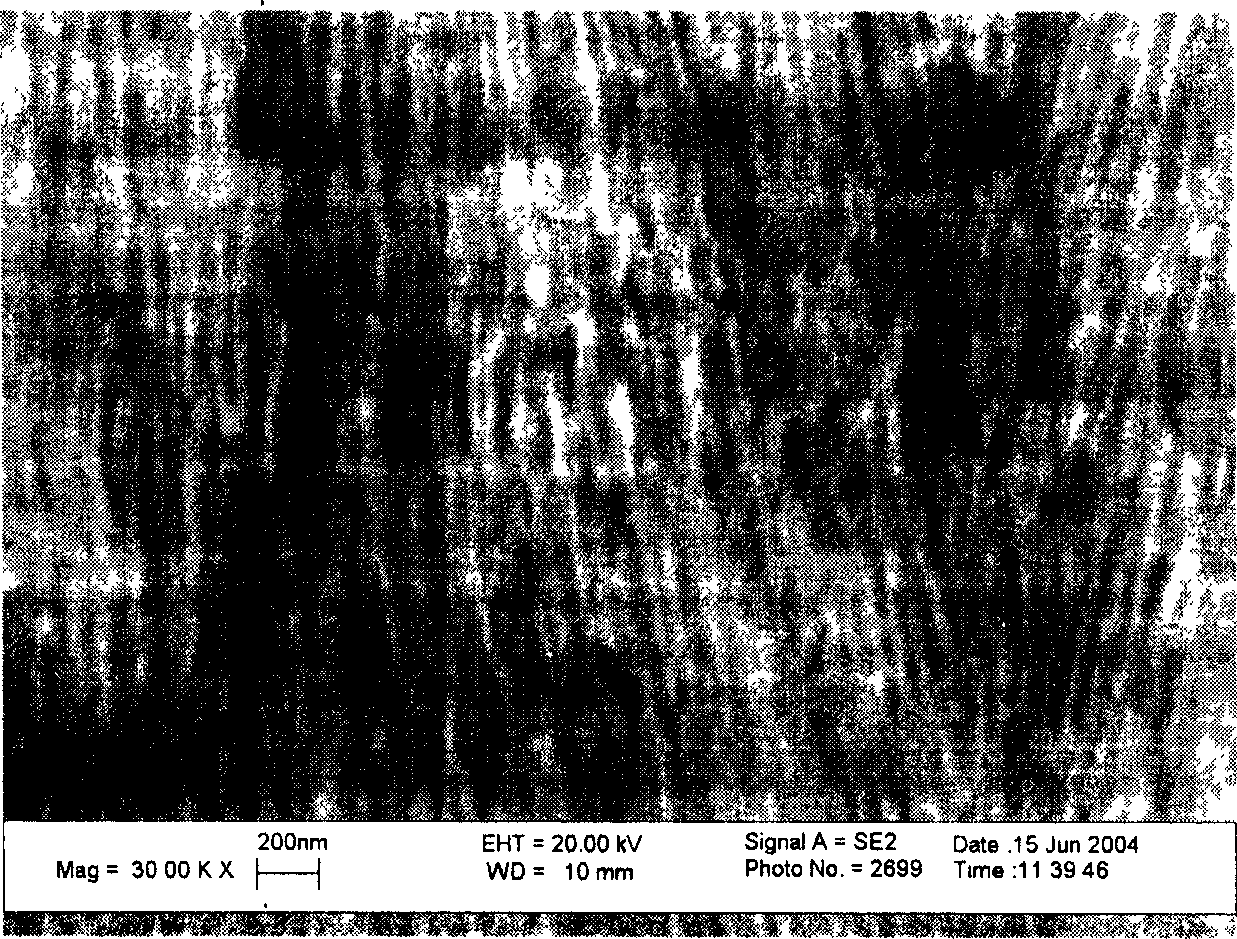

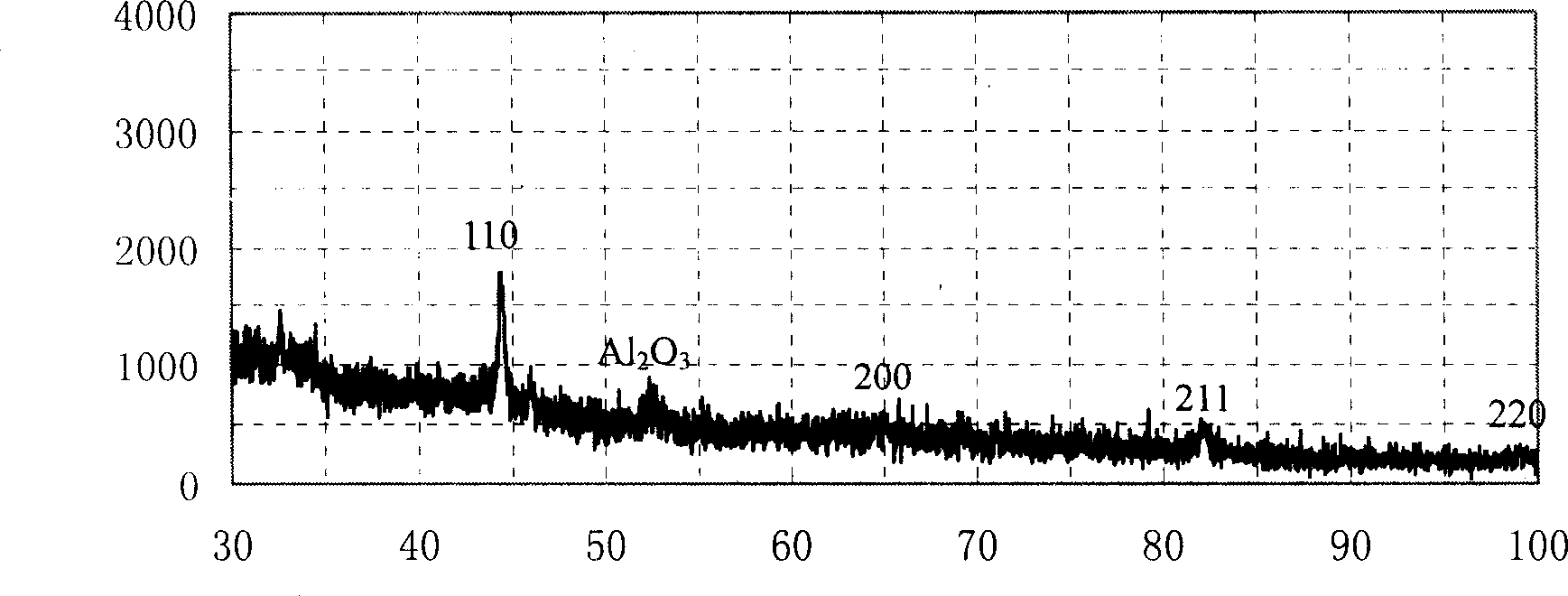

Image

Examples

Embodiment 1

[0020] ① Anneal the aluminum plate at 500°C, take it out, wash it several times with acetone and sodium hydroxide to remove the oil and the oxide film on the surface, and then wash it in perchloric acid (HClO 4 ) in ethanol solution to brighten.

[0021] ②A two-step AC anodization was carried out in 4wt% oxalic acid solution: first, the first step of anodization was carried out, the temperature of the solution was controlled at 20-35°C, the time was 1h, the voltage was gradually increased from 20V to 40V, and then the sample was placed at 6 % phosphoric acid, 1.8% H 2 CrO 4 solution, until the AAO film formed on the substrate aluminum was completely etched away, the sample was taken out and cleaned, and then the sample was subjected to the second anodic oxidation under the same conditions for 1 hour, taken out, air-dried, and stored in vacuum.

[0022] ③ Soak the two-step anodized sample in 1M oxalic acid at 30°C to adjust the dense barrier layer of the aluminum-based AAO fi...

Embodiment 2

[0028] ① Anneal the aluminum plate at 500°C, take it out, wash it several times with acetone and sodium hydroxide to remove the oil and the oxide film on the surface, and then wash it in perchloric acid (HClO 4 ) in ethanol solution to brighten.

[0029] ②A two-step AC anodizing method was used in 4wt% oxalic acid solution: the solution temperature was controlled at 20-35°C, and one-step anodizing was performed first for 1 hour, and the voltage was gradually increased from 20V to 40V. The one-step anodized samples were placed in 6% phosphoric acid, 1.8% H 2 CrO 4 solution, until the AAO film formed on the substrate aluminum was completely etched away, the sample was taken out and cleaned, and then the sample was subjected to the second step of anodizing under the same conditions for 1 hour, taken out, air-dried, and stored in vacuum.

[0030] ③ Soak the two-step anodized sample in 1M oxalic acid at 30°C to adjust the dense barrier layer of the aluminum-based AAO film to an a...

Embodiment 3

[0036] ①Immerse the aluminum plate in acetone for a day and night to remove oil, perform mechanical polishing, and then wash it in perchloric acid (HClO) 4 ) in ethanol solution to brighten.

[0037] ② Direct current anodic oxidation in 12wt% sulfuric acid solution by one-step method. The voltage is controlled at about 20V, the solution temperature is controlled at 0-10°C, and the time is 5-10h. The samples are taken out, cleaned, air-dried, and stored in vacuum.

[0038] ③ Soak the anodized sample in 0.3M phosphoric acid at 30°C to adjust the dense barrier layer of the aluminum-based AAO film to an appropriate thickness.

[0039] ④ Electrodeposition of iron nanowires: the anodized aluminum-based alumina template is charged into the cell, at 100g / L FeSO 4 , 15g / L (NH) 2 SO 4 , 30g / L MgSO 4 , 1g / L ascorbic acid, 2ml / L glycerol electrolyte at room temperature for direct current electrodeposition, the time is 4-6h, the voltage is controlled at 8-15V. The resulting sample wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absorption bandwidth | aaaaa | aaaaa |

| Absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com