Microarc oxidation method for quickly preparing wear-proof zirconia and alumina mixed coating on surface of zirconium alloy

A micro-arc oxidation and zirconium alloy technology, applied in the field of electrochemistry, can solve the problems of inability to form a thick film layer, mechanical peeling of the film layer, low alumina content, etc., to achieve increased film forming speed, improved performance, and wear resistance sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

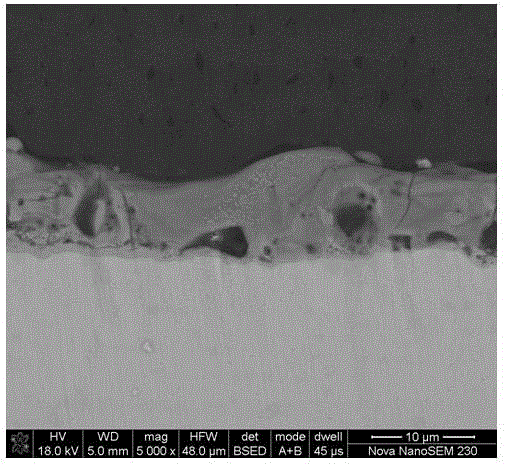

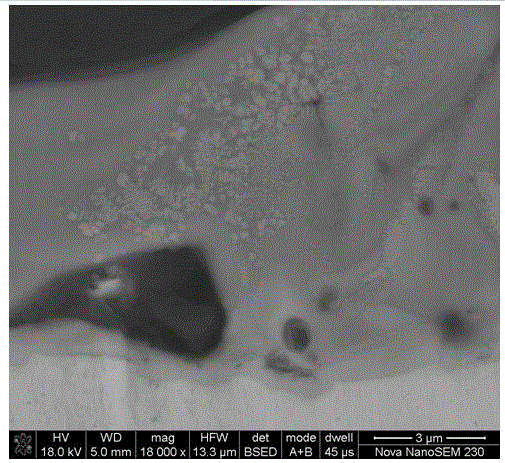

Image

Examples

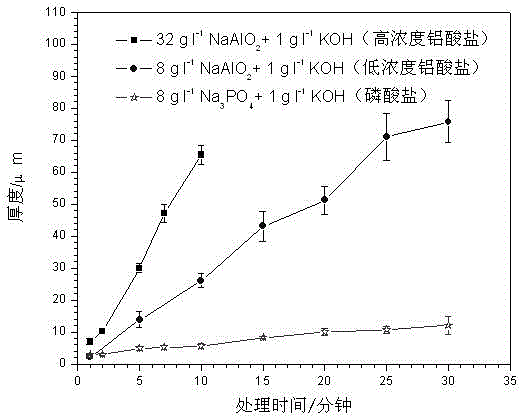

Embodiment 1

[0056] 1. Rapid preparation of wear-resistant ZrO on the surface of zirconium alloy 2 / Al 2 o 3 Micro-arc oxidation coating methods, including:

[0057] (1) Preparation of electrolyte for micro-arc oxidation on zirconium alloy surface;

[0058] The composition of described electrolytic solution is, every 1000 ml deionized water contains:

[0059] NaAlO 2 : 32g

[0060] KOH: 1g

[0061] (2) Setting of micro-arc oxidation power supply parameters: positive current 15 A / dm 2 Negative current 10 A / dm 2

[0062] Frequency: 1000Hz

[0063] Positive and negative duty cycle: 20%

[0064] (3) Treatment of the zirconium alloy surface sample: the sample size is 10×20mm, sealed with E-44 epoxy resin, and after the sample is cured, use 800-2000# metallographic sandpaper on the surface of the zirconium alloy participating in the reaction Gradually polished, then washed with tap water, ultrasonically cleaned with alcohol, and cleaned with deionized water.

[0065] (4) The proces...

Embodiment 2

[0084] Example 2: The rest of the preparation and detection steps are the same as in Example 1, except that the electrolyte and parameters are different:

[0085] (1) Preparation of electrolyte for micro-arc oxidation on zirconium alloy surface;

[0086] The composition of described electrolytic solution is, every 1000ml deionized water contains:

[0087] NaAlO 2 : 45g

[0088] NaOH: 5g

[0089] (2) Setting of micro-arc oxidation power supply parameters: positive current 15 A / dm 2 Negative current 15 A / dm 2

[0090] Frequency: 2500Hz

[0091] Positive and negative duty cycle: 10%

[0092] The effect is the same as in Example 1, the film forming speed is fast, the film layer structure is uniform, and contains a large amount of alumina; the wear resistance of the film layer far exceeds the micro-arc obtained by ordinary zirconium alloys in low-concentration aluminate and phosphate electrolytes. Oxide film.

Embodiment 3

[0093] Example 3: The rest of the preparation and detection steps are the same as in Example 1, except that the electrolyte and parameters are different:

[0094] (1) Preparation of electrolyte for micro-arc oxidation on zirconium alloy surface;

[0095] The composition of described electrolytic solution is, every 1000ml deionized water contains:

[0096] NaAlO 2 : 60g

[0097] KOH: 10g

[0098] (2) Setting of micro-arc oxidation power supply parameters: positive current 20A / dm 2 Negative current 10 A / dm 2

[0099] Frequency: 5000Hz

[0100] Positive and negative duty cycle: 30%

[0101] The effect is the same as in Example 1, the film forming speed is fast, the film layer structure is uniform, and contains a large amount of alumina; the wear resistance of the film layer far exceeds the micro-arc obtained by ordinary zirconium alloys in low-concentration aluminate and phosphate electrolytes. Oxide film.

[0102]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com