PERC solar cell manufacturing method capable of reducing winding plating and chromatic aberration

A technology of solar cells and manufacturing methods, applied in the field of solar cells, can solve the problems of yellowish or white, fast deposition rate, uneven coating, etc., and achieve the effects of offsetting thermal stress, reducing edge wrapping, and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

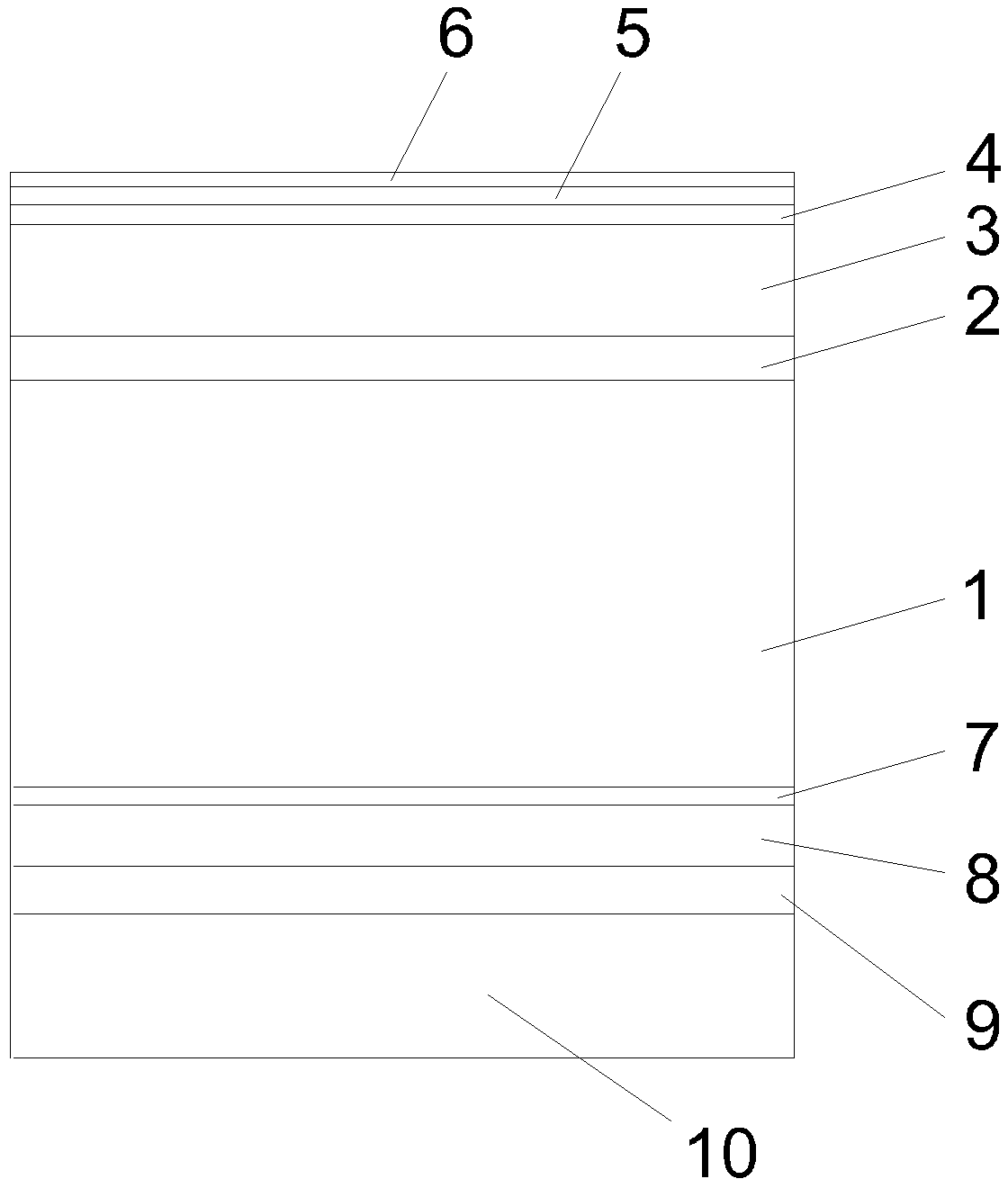

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0022] A method for manufacturing a PERC solar cell that reduces plating and chromatic aberration, comprising the following steps:

[0023] S1: Texturing, placing the silicon wafer 1 in a KOH solution for texturing;

[0024] S2: diffusion, diffusion to prepare PN junction;

[0025] S3: Front side laser, performing selective laser doping on the front side of the silicon wafer 1;

[0026] S4: etch, remove the PSG and N-type silicon on the back surface and sides of the silicon wafer 1, and remove the front PSG layer;

[0027] S5: annealing, using a thermal oxidation annealing process for annealing treatment.

[0028] S6: Deposit a passivation film on the back side. The eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com