Manufacture method of semiconductor nano-pillar array structure

A technology of nano-pillar array and fabrication method, which is applied in the field of preparation of semiconductor nanostructures and can solve problems such as difficulties in semiconductor nanostructures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

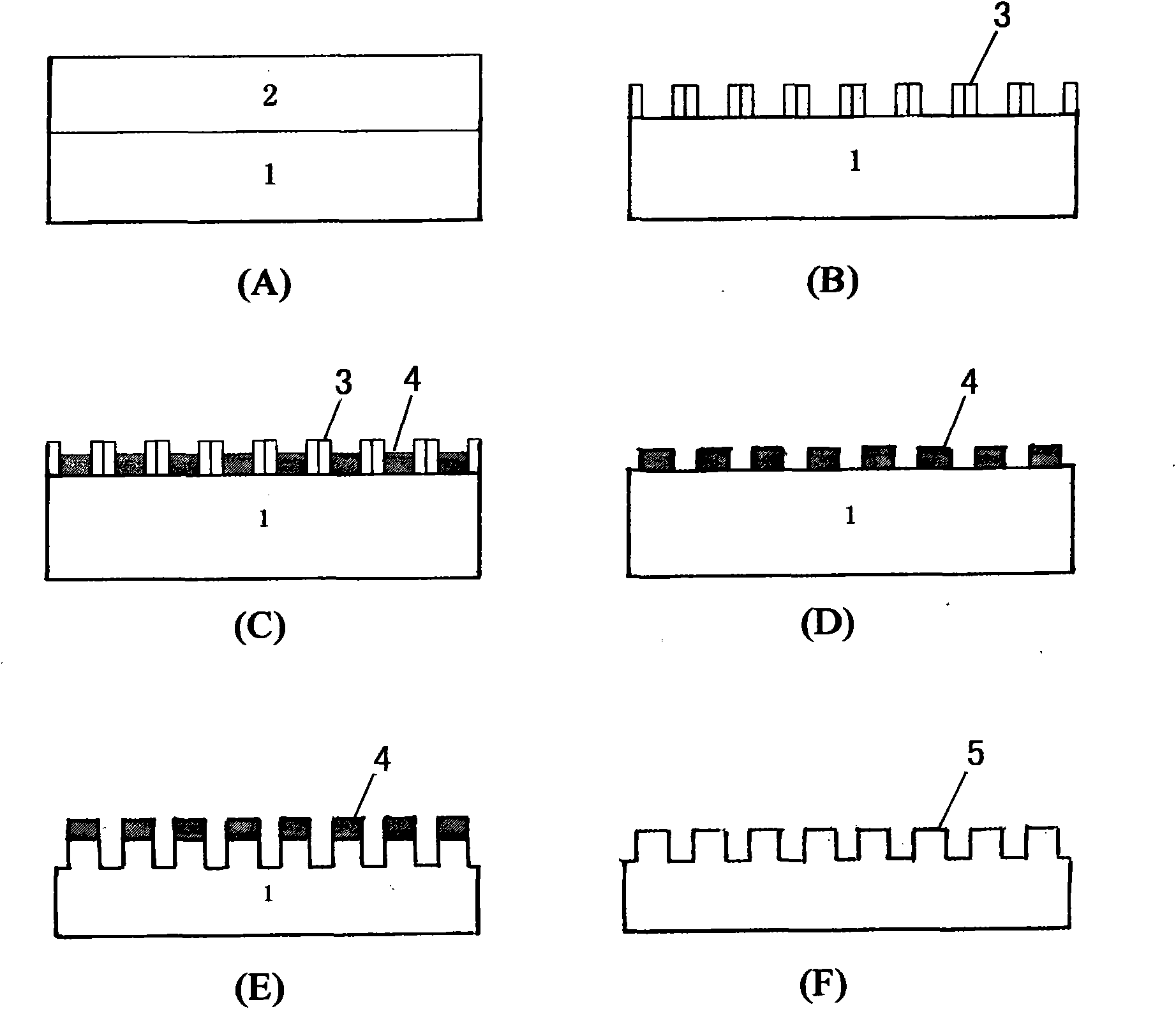

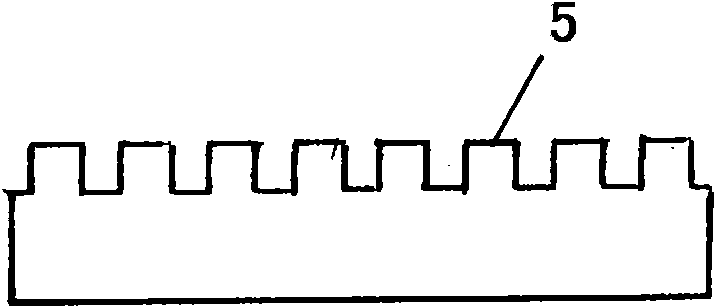

[0017] see figure 1 As shown, the present invention provides a method for manufacturing a semiconductor nanocolumn array structure, comprising the steps of:

[0018] Step 1: growing an aluminum layer 2 on a semiconductor substrate 1, such as figure 1 (A), the thickness of the aluminum layer 2 is 2 μm, the growth of the aluminum layer 2 is the method of electron beam evaporation, thermal evaporation or magnetron sputtering, and the semiconductor substrate is a group IV, III-V compound or II-VI Bulk materials or multi-layer structure materials of group compounds;

[0019] Step 2: anodize the aluminum layer 2 to form holes from the surface to the semiconductor substrate 1, forming a porous aluminum oxide film 3;

[0020] The anodic oxidation process adopts the secondary oxidation method. The specific method is to use the aluminum layer 2 as the anode and the platinum sheet as the cathode to perform the first oxidation in the electrolyte. The electrolyte is an aqueous oxalic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com