Preparation method for large-area ultrathin porous anodized alumina membranes

A kind of technology of anodized aluminum and porous film, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of difficult maintenance and transportation, film curling, damage, etc., and achieve convenient storage and use, not easy to break, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

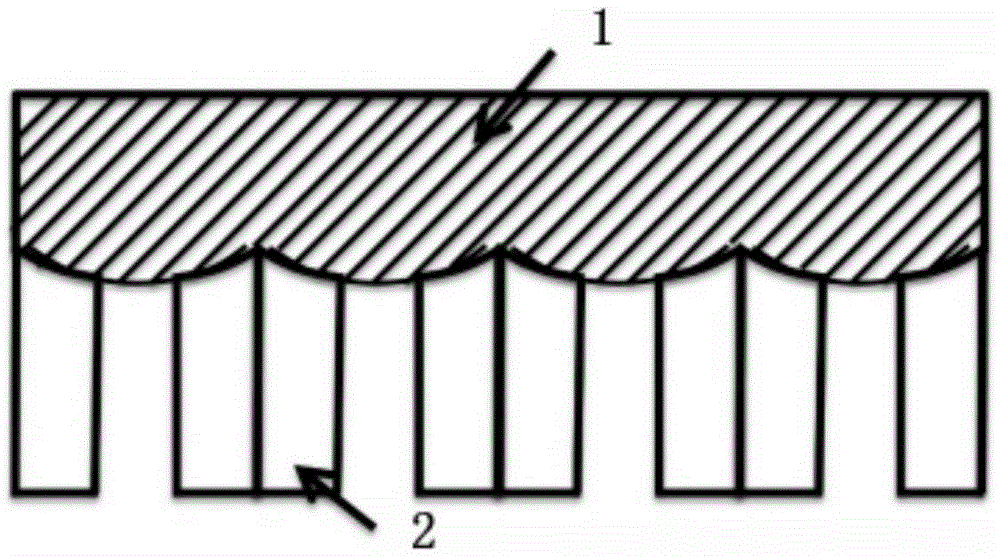

[0036] A method for preparing a large-area ultra-thin anodized aluminum porous membrane, comprising the following steps:

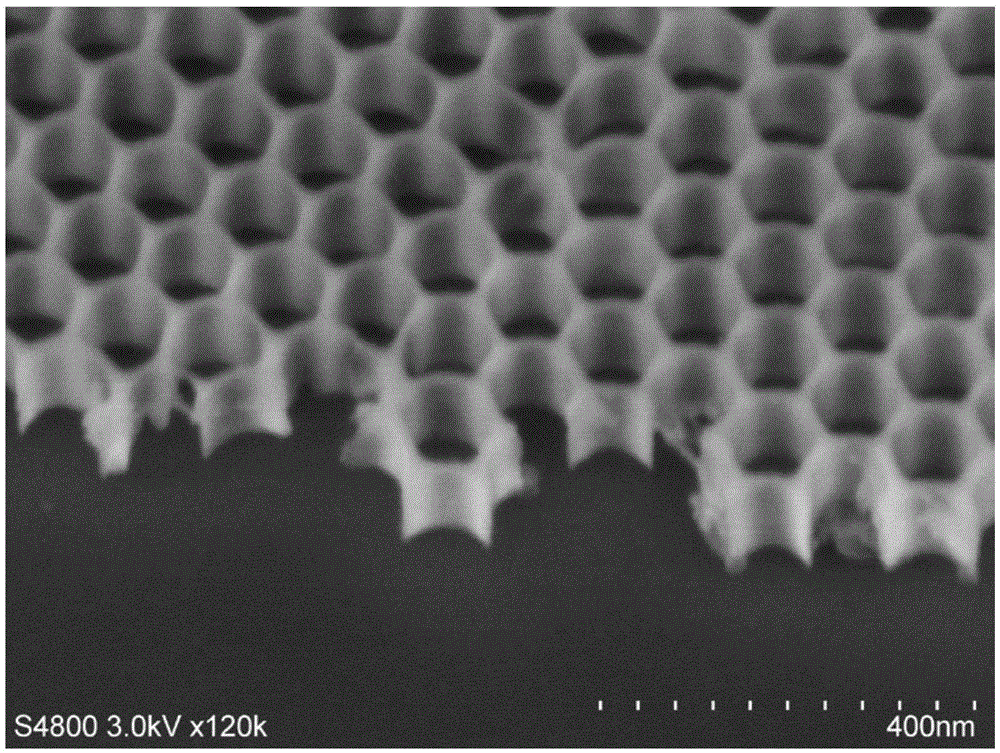

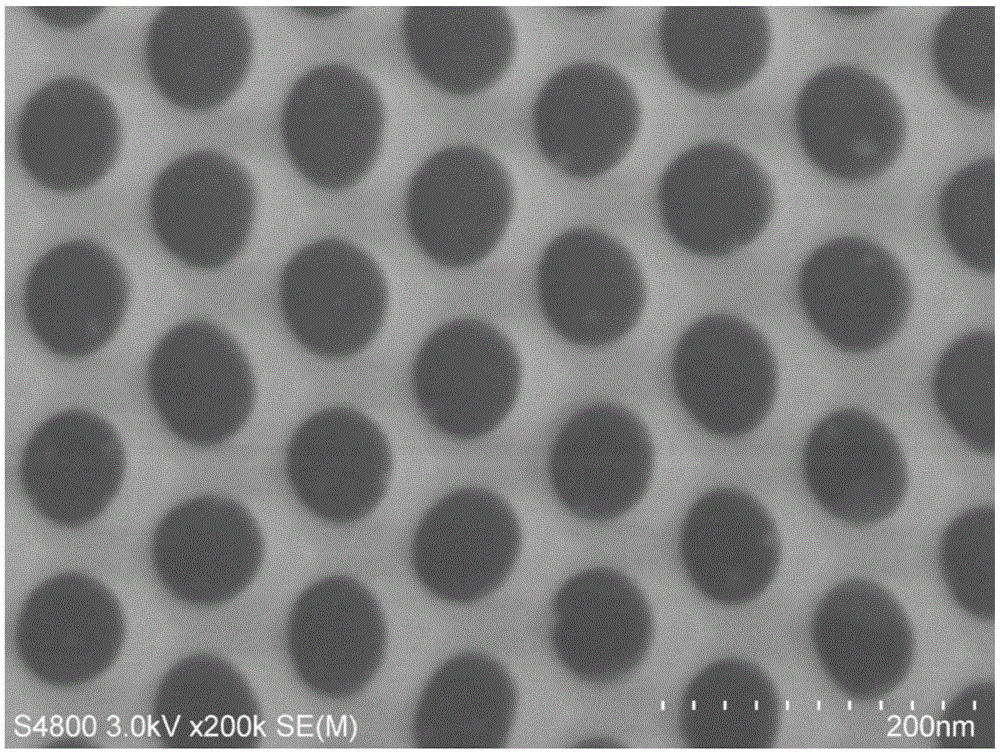

[0037] S1. Preparation of aluminum oxide porous membrane: a polished aluminum sheet is anodized twice in a sulfuric acid solution with a mass percentage concentration of 1% to obtain a single-pass ultra-thin anodized aluminum oxide porous membrane with an aluminum base;

[0038]S2. Pre-expansion treatment: put the single-pass ultra-thin anodized aluminum porous membrane with aluminum base into a phosphoric acid solution with a concentration of 10% by mass, and expand the pores at 35° C. for 5 minutes;

[0039] S3. Preparation of the organic support layer; drop an organic solution on the surface of the pre-expanded single-pass ultra-thin anodized aluminum porous membrane with an aluminum base, shake to make the organic solution evenly distributed on the surface, and then heat it at 120 ° C. Bake for 25min, and the time interval between adding the organic so...

Embodiment 2

[0042] A method for preparing a large-area ultra-thin anodized aluminum porous membrane, comprising the following steps:

[0043] S1. Preparation of aluminum oxide porous membrane: a polished aluminum sheet is anodized twice in a phosphoric acid solution with a mass percent concentration of 10% to obtain a single-pass ultra-thin anodized aluminum oxide porous membrane with an aluminum base;

[0044] S2. Pre-expanding treatment: put the single-pass ultra-thin anodized aluminum porous membrane with aluminum base into a phosphoric acid solution with a mass percentage concentration of 1%, and expand the pores at 25° C. for 50 minutes;

[0045] S3. Preparation of the organic support layer; drop an organic solution on the surface of the pre-expanded single-pass ultra-thin anodized aluminum porous membrane with an aluminum base, shake to make the organic solution evenly distributed on the surface, and then heat it at 150°C Bake for 5s to form an organic support layer; wherein, the so...

Embodiment 3

[0048] A method for preparing a large-area ultra-thin anodized aluminum porous membrane, comprising the following steps:

[0049] S1. Preparation of aluminum oxide porous membrane: a polished aluminum sheet is anodized twice in sulfuric acid and oxalic acid with a mass percentage concentration of 5% to obtain a single-pass ultra-thin anodized aluminum oxide porous membrane with an aluminum base;

[0050] S2. Pre-expanding treatment: put the single-pass ultra-thin anodized aluminum porous membrane with an aluminum base into a phosphoric acid solution with a mass percent concentration of 4%, and expand the pores at 25° C. for 100 minutes;

[0051] S3. Preparation of organic support layer; drop an organic solution on the surface of the pre-expanded single-pass ultra-thin anodized aluminum porous membrane with an aluminum base, shake it to make the organic solution evenly distributed on the surface, and then heat it at 135°C Baking for 15min, the time interval between the dropping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com