Milk foam machine directly driven by motor

A milk frother, a direct technology, applied in the field of household appliances, can solve the problems affecting the control of stirring and frothing, restricting stirring or frothing, magnetic disturbance, etc., and achieves the effects of simple structure, stable heating and free control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

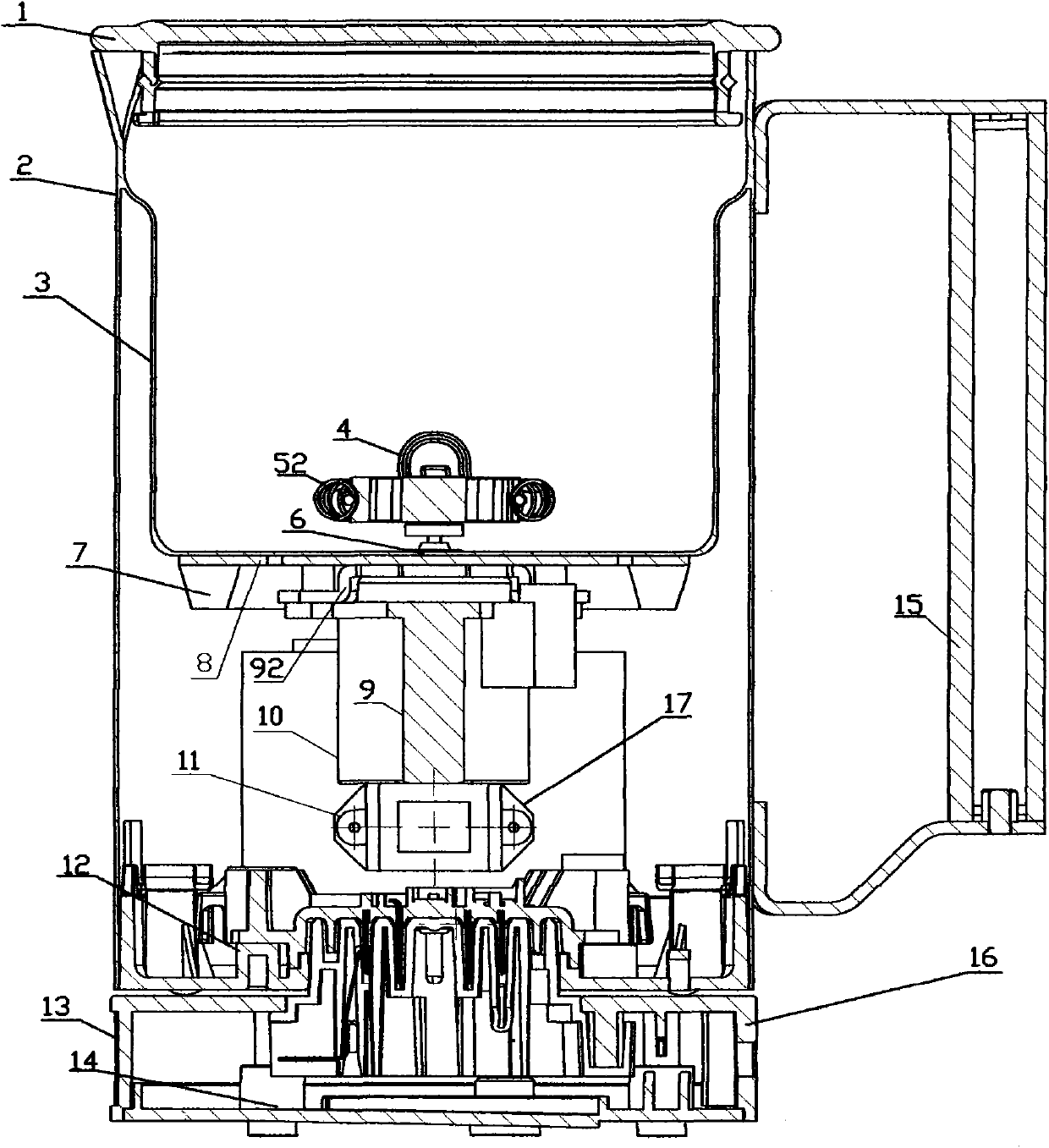

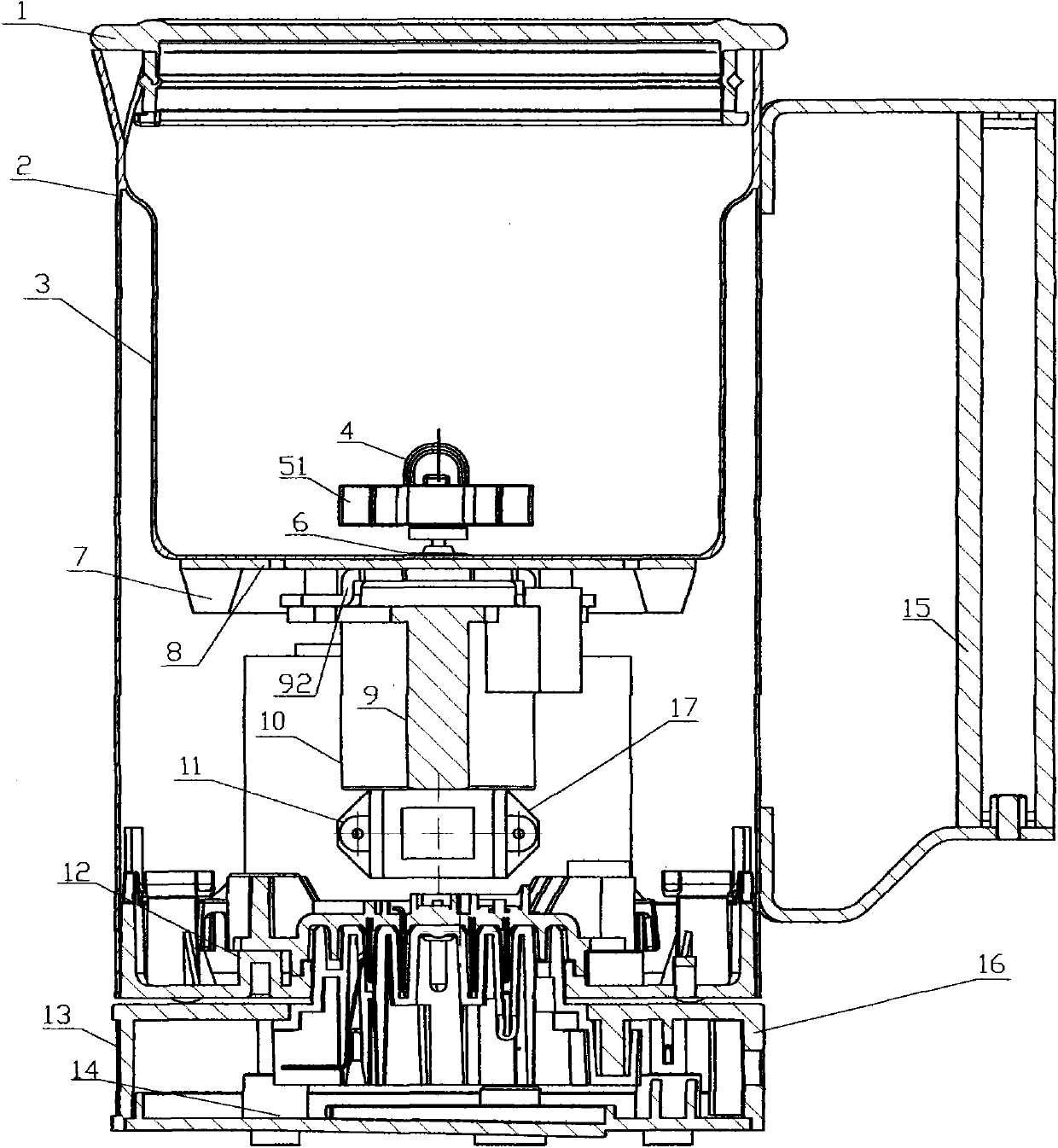

[0037] Made of stainless steel as image 3 , Figure 4 A two-type milk frother with the structure shown. The milk frother is divided into two parts: the upper cup body and the lower power supply seat. The upper cup body includes a double-layer stainless steel cup composed of the cup body 2 and the inner cup 3. There is a cup cover 1 on the top. Through a silicone sealing ring 21, the cup cover 1 is fastened with the upper edge of the inner cup 3, and the cup Lid 1 can be made transparent lid with plexiglass, and the side of cup body 2 is equipped with handle 15, and control panel 11. The cup body on the upper part of the milk frother and the power supply seat on the lower part are a kind of figure 1 The suit structure shown adopts the electric connector of the existing electric teapot, the upper part 12 of the electric connection is arranged at the bottom of the cup body, and there is a bottom cover 13 at the bottom of the cup body, and the lower part 14 of the electric con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com