Dual-output washing machine drum speed reducing clutch and washing machine

The technology of a drum washing machine and a deceleration clutch, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of unsatisfactory washing effect, increased cost and power consumption, and high motor price, so as to improve the washing ratio and save energy. Axial dimension, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

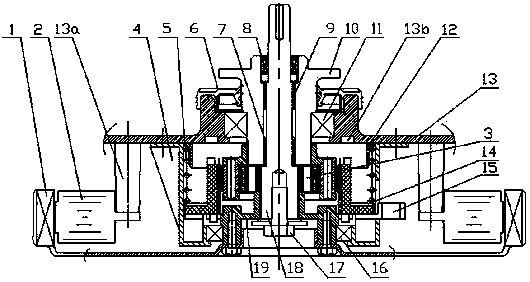

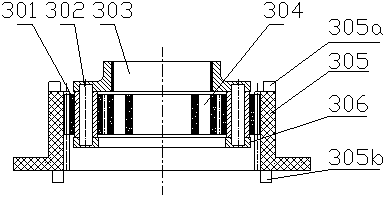

[0026] combine Figure 1-Figure 9 , is a schematic diagram of the principle structure of an embodiment of the deceleration clutch for a double-output drum washing machine of the present invention, which includes an inner cylinder shaft 10, an input shaft 18 placed inside the inner cylinder shaft 10, and an input shaft 18 placed between the inner cylinder shaft 10 and the input shaft 18. Between the wheel train assembly 3, the input shaft 18 is concentrically installed in the inner cylinder shaft 10 through the lower bush 7 and the upper bush 9, the input shaft 18 is the first output, and is connected with the rotor 1 through the rotor mounting plate 19, The inner cylinder shaft 10 is the second output, connected to the input shaft 18 through the gear train assembly 3; the gear train assembly includes planetary gear 301, planetary shaft 302, planetary carrier 303, sun gear 304, internal gear 305 and planetary carrier Cover 306, the planetary gear 301 is installed on the planeta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com