System and method for automatically detecting oleic acid value

An automatic detection, oleic acid value technology, applied in chemical analysis by titration method, can solve the problems of easy intrusion of carbon dioxide, low repetition rate, color mutation error of titration end point, etc., and achieve rapid and economical determination of oil acid value. Value, Ease of Use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0039] An automatic detection method for oleic acid value, the steps are as follows:

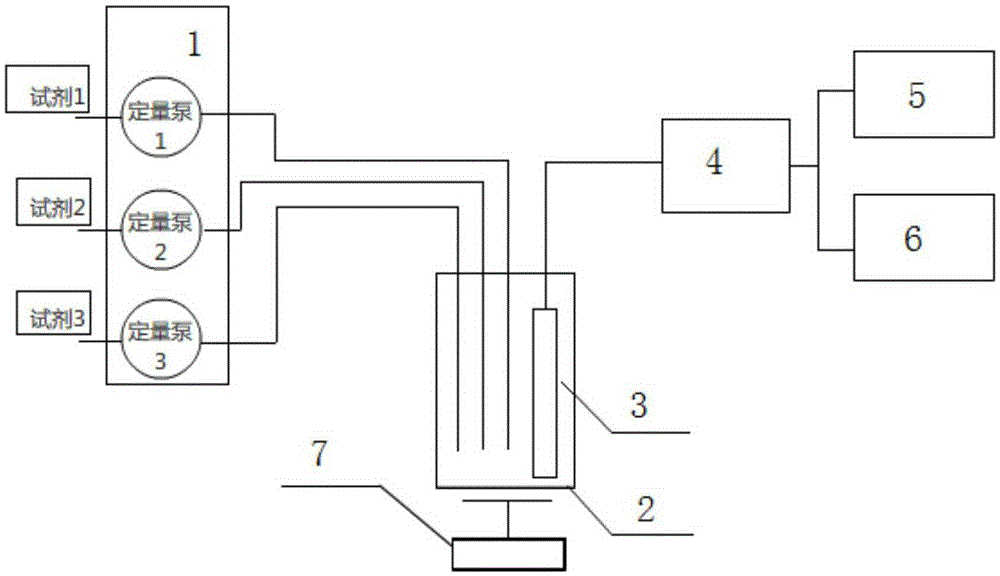

[0040] (1) Add the oil sample to be tested into the heat preservation titration tank 2, then inject the extraction solvent and the temperature indicator into the heat preservation titration tank 2 through the first quantitative pump and the second quantitative pump respectively, and pass through the heat preservation titration tank 2 bottom The magnetic stirring device 7 fully mixes the oil sample to be tested, the extraction solvent and the temperature indicator in the heat-keeping titration tank 2, and the temperature sensor 3 in the heat-keeping titration tank 2 continuously measures the temperature of the mixed liquid in the heat-keeping titration tank 2;

[0041] (2) The titration reagent is injected into the heat preservation titration tank 2 by the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com