Laundry Hamper For Insertion Into Clothes Washers And Dryers

a laundry basket and laundry technology, applied in the direction of hand rubbing apparatus, packaging, textiles and paper, etc., can solve the problems of not helping the user transport, sort, transfer, or group clothing during the laundry process, not facilitating the transport of soiled clothing to the laundry vicinity, and not helping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

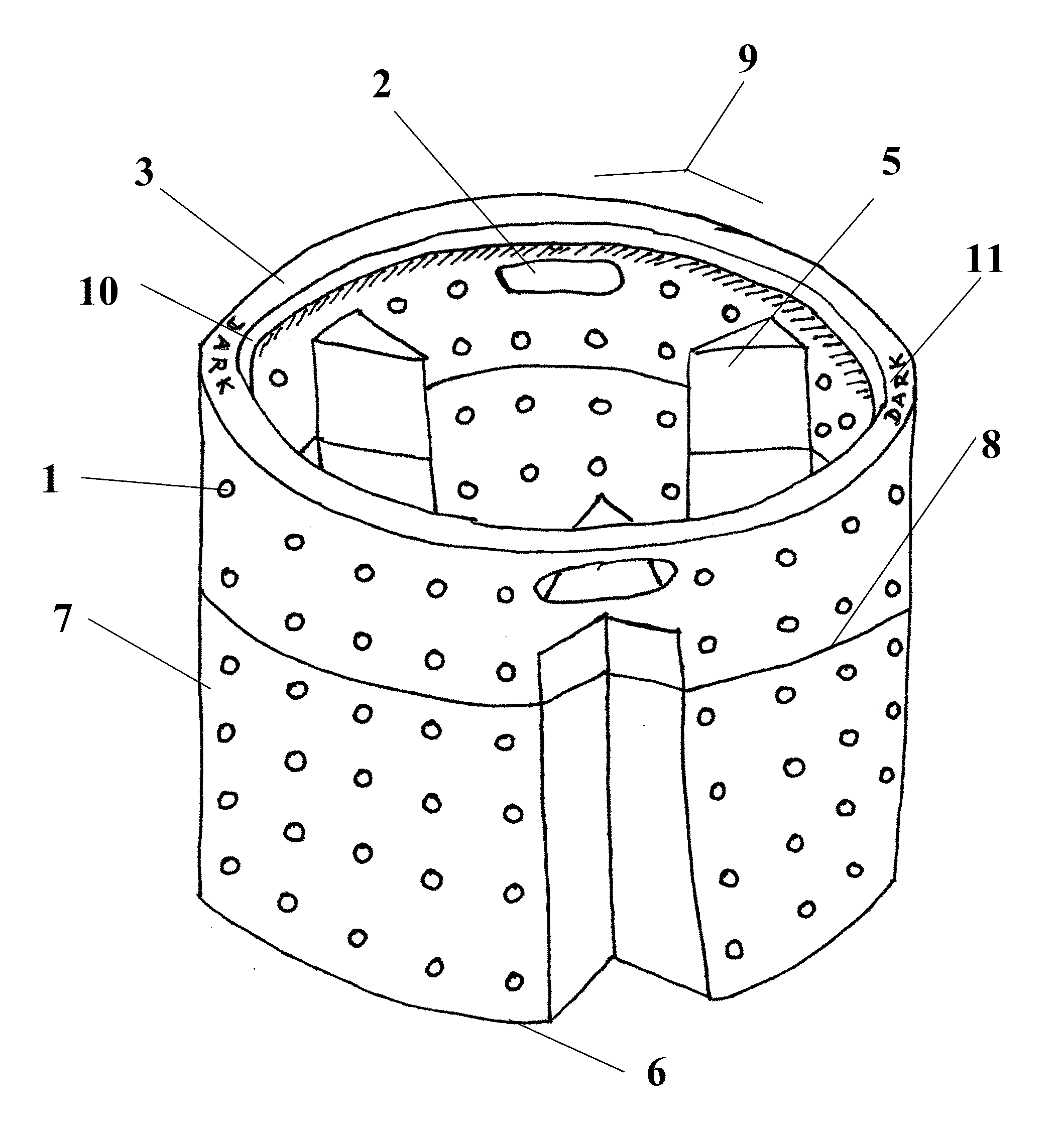

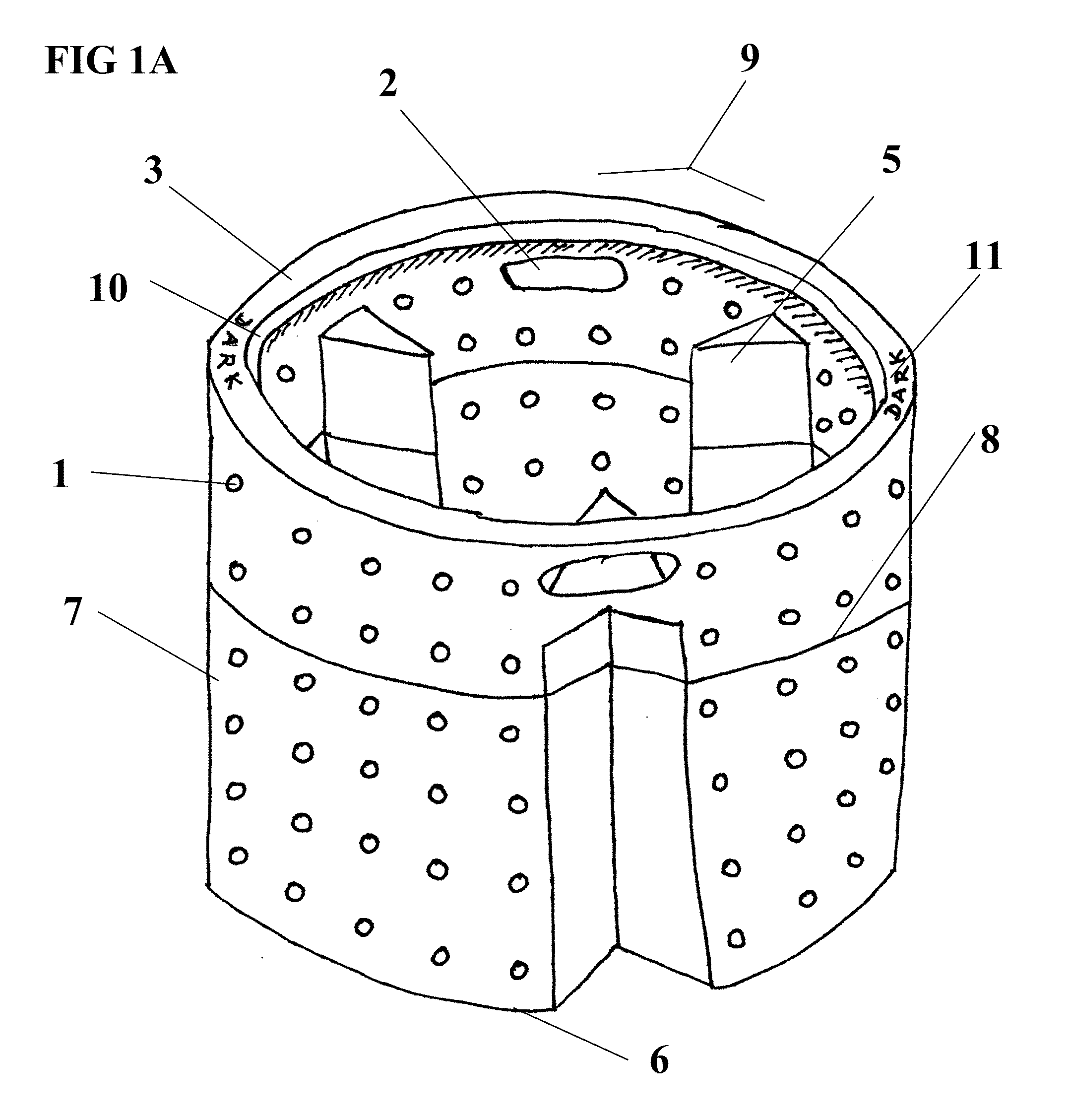

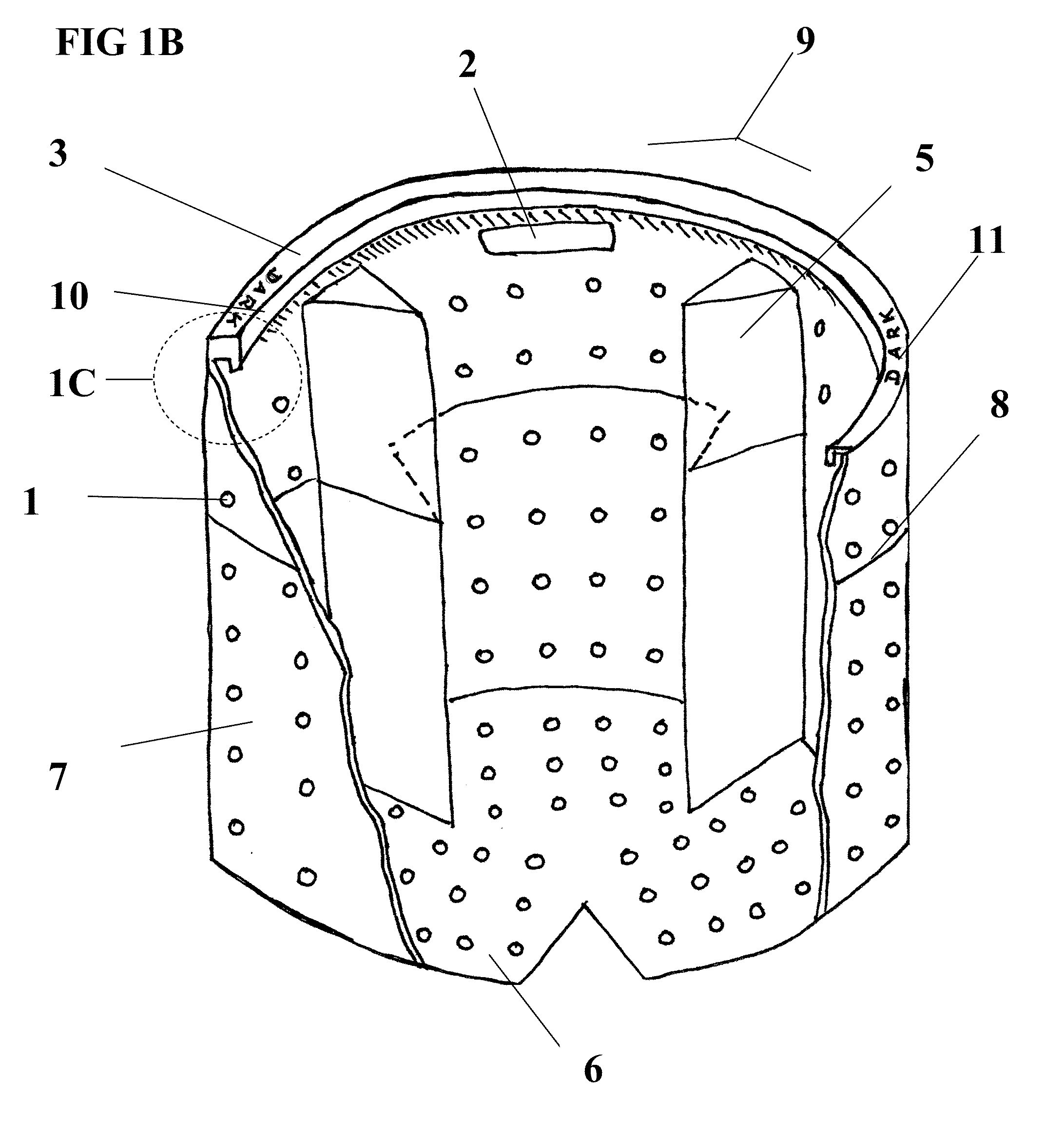

FIGS. 1A, 1B, 1C—Preferred Embodiment

[0046]One embodiment of a hamper is illustrated in FIG. 1A, FIG. 1B, and FIG. 1C. The hamper is composed of a heat-resistant and cleaning agent-resistant substance. The hamper has a hollow cylindrical shape with closed bottom 6 and an open top 9, cylindrical side walls 7, a bottom 6, and a plurality of apertures 1 for the ventilation of air and the drainage of liquids. The side walls 7 contain a capacity indicator 8 which indicates when the hamper has reached its maximum capacity to effectively launder clothing. The side walls 7 contain cut out handles 2 which allow a user to easily grab and transport the hamper. The interior of the cylinder conforms to the shape of a clothing washer or dryer. The cylinder may contain baffles 5 as is common in dryers and front load washers. An upper rim 3 has an internally facing handle 10. The inward handle 10 comprises an internally running lip along the circumference of the top. The lip is joined by a downward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com