Concealed automatic pool vacuum systems

a vacuum system and vacuum hose technology, applied in the direction of thin material handling, construction, building types, etc., can solve the problems of uncoiled labor-intensive and time-consuming, and at best haphazard storage of vacuum hoses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

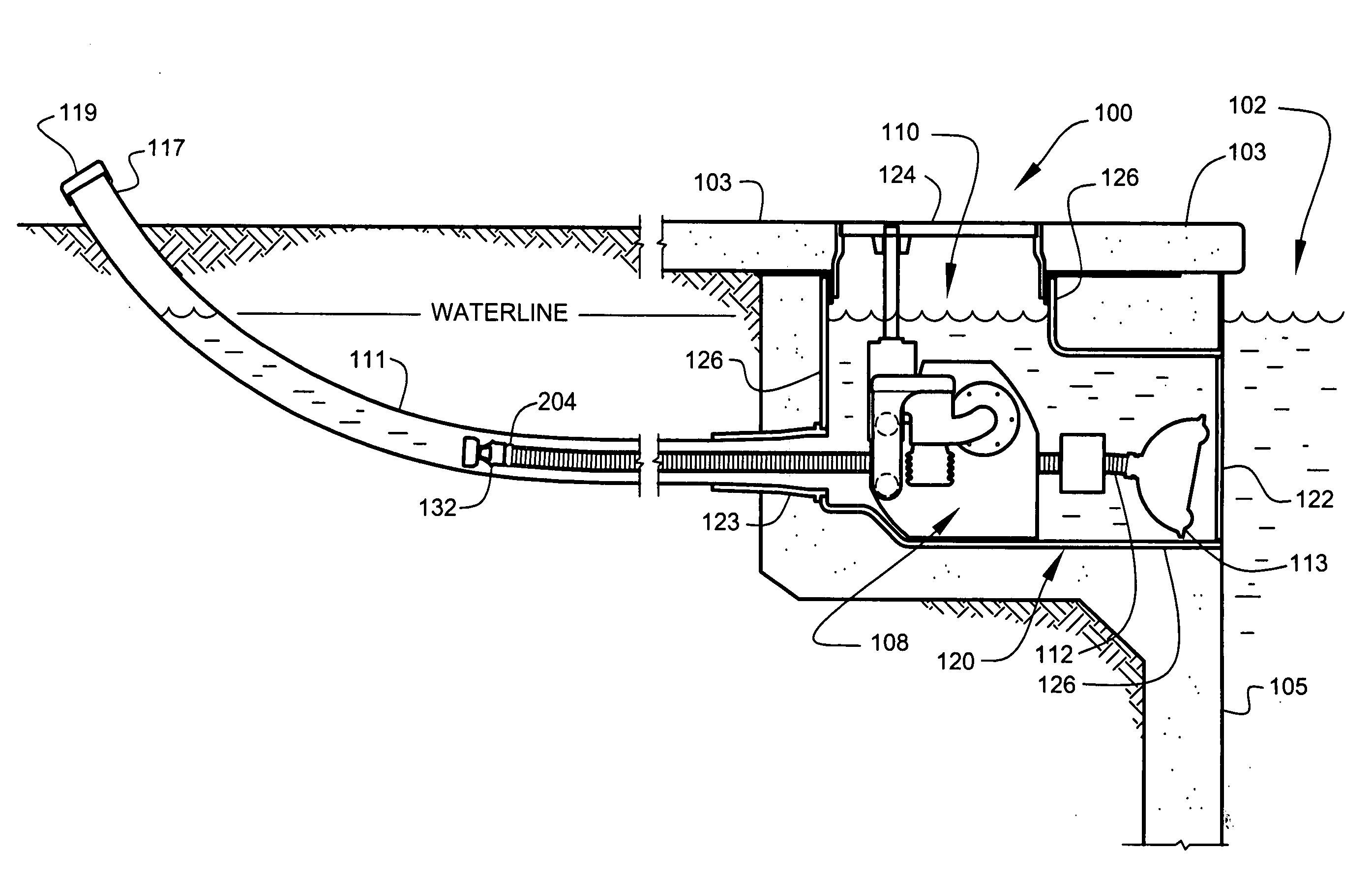

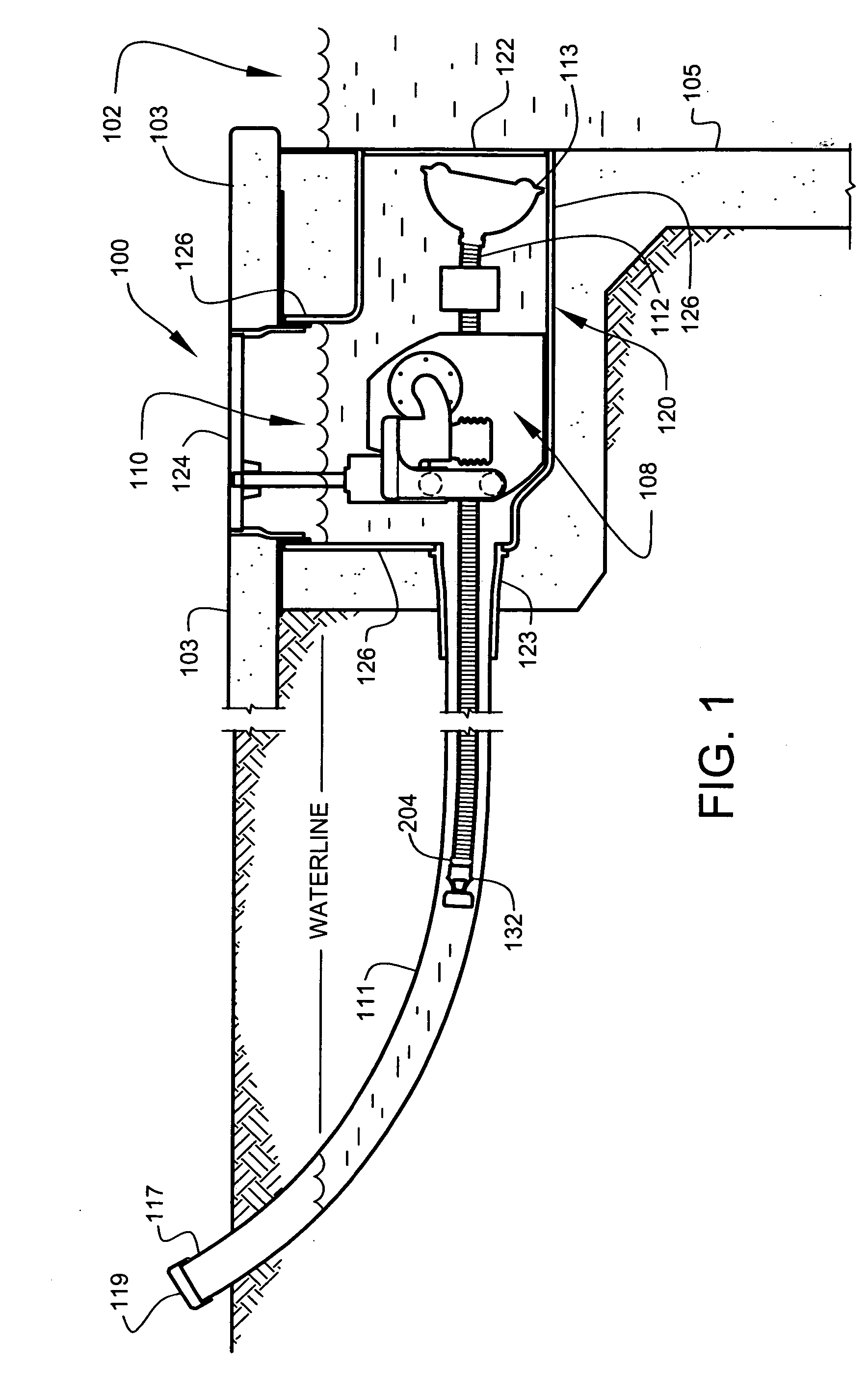

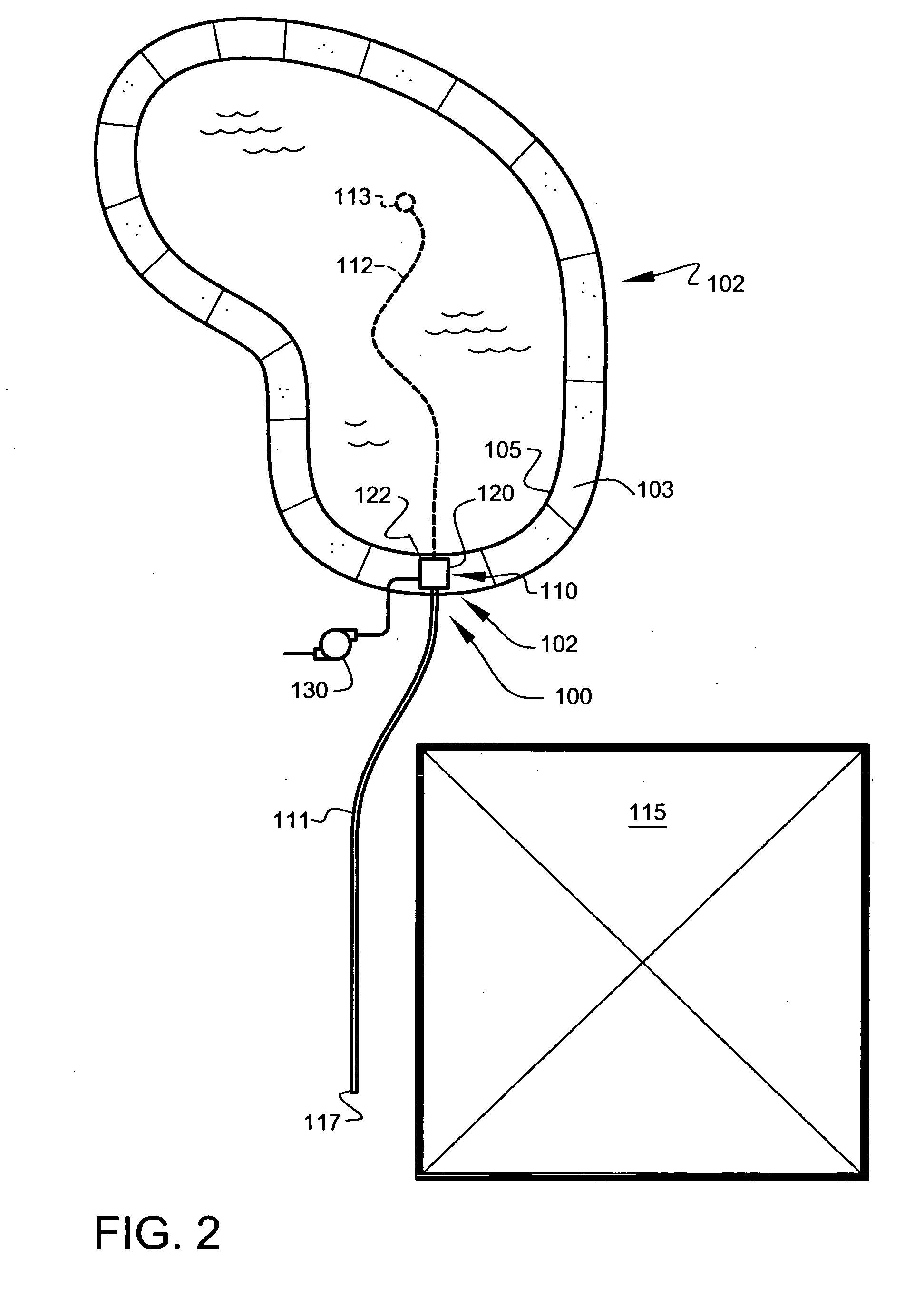

[0076]FIG. 1 shows a side view, in partial section, of automatic vacuum assembly 110 of pool-cleaning system 100, retracted into pool-wall housing 120, according to a preferred embodiment of the present invention. FIG. 2 shows a plan view of a water-filled swimming pool 102 incorporating pool-cleaning system 100 of FIG. 1.

[0077] In the following specification, the terms “suction” and “vacuum” are used interchangeably to define conditions of decreased fluid pressure within the fluid (water) transporting interstices of pool-cleaning system 100 (generally associated with plumbing assemblies on the “suction side” (low-pressure side) of a water circulation pump). In the present disclosure, “suction side” refers to the pipes and fittings that draw water out of swimming pool 102 to be filtered

[0078] Preferably, pool-cleaning system 100 comprises an automatic vacuum-cleaning system that automatically deploys swimming pool vacuum hose 112 with an attached pool vacuum head 113, to clean the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com