Vehicle air-conditioner system with battery heat management function

A battery thermal management and vehicle air-conditioning technology, which is applied in the field of vehicle air-conditioning systems, can solve problems such as low heat exchange efficiency, adverse effects on battery life, and difficulty in charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

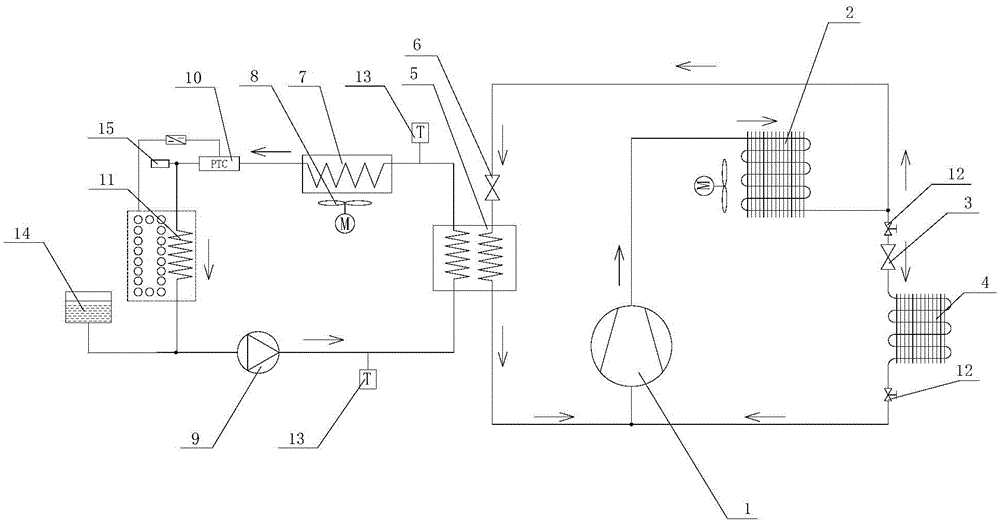

[0020] See figure 1 , vehicle air conditioning system with battery thermal management function, including compressor 1, condenser 2, first expansion valve 3, evaporator 4, plate heat exchanger 5, second expansion valve 6, air-water heat exchanger 7. The fan 8, the water pump 9, the electric heater 10 and the built-in heat exchanger 11 of the battery pack, the fan is arranged on the air intake side of the air-water heat exchanger, and the above-mentioned electric heater can be connected to the battery pack through a voltage converter, so that , when electric heating is required, power can be taken directly from the battery pack. According to the first flow direction of the refrigerant, the outlet of the compressor and the inlet of the condenser, the outlet of the condenser and the inlet of the first expansion valve, the outlet of the first expansion valve and the inlet of the evaporator, and the outlet of the evaporator and the inlet of the compressor The inlets are respective...

Embodiment 2

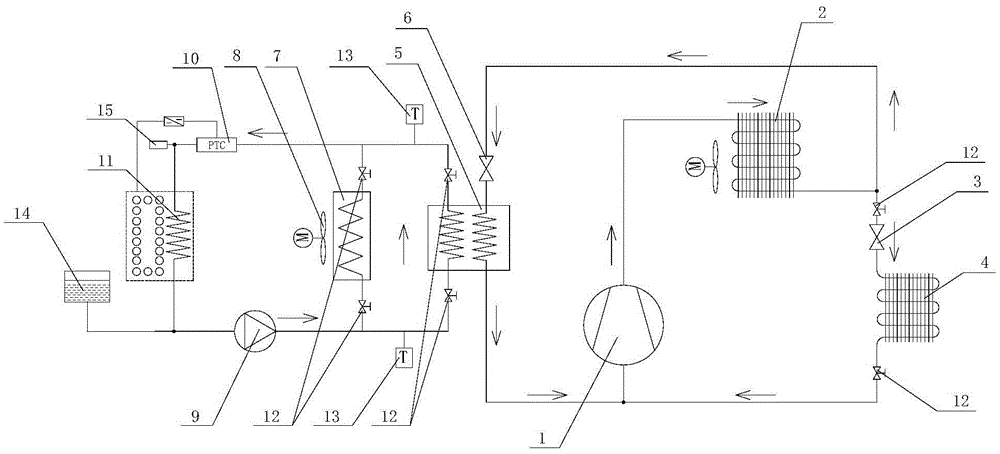

[0033] See figure 2 , vehicle air conditioning system with battery thermal management function, including compressor 1, condenser 2, first expansion valve 3, evaporator 4, plate heat exchanger 5, second expansion valve 6, air-water heat exchanger 7. A fan 8, a water pump 9, an electric heater 10 and a built-in heat exchanger 11 in the battery pack, and the fan is arranged on the air intake side of the air-water heat exchanger. According to the first flow direction of the refrigerant, the outlet of the compressor and the inlet of the condenser, the outlet of the condenser and the inlet of the first expansion valve, the outlet of the first expansion valve and the inlet of the evaporator, and the outlet of the evaporator and the inlet of the compressor The inlets are respectively connected by pipelines to form an air-conditioning refrigeration circulation loop, which is used to cool down the temperature inside the vehicle. According to the second flow direction of the refrigera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com