Edge ring cooling module for semi-conductor manufacture chuck

a cooling module and semi-conductor technology, applied in electrical devices, heat exchange devices, light and heating devices, etc., can solve the problems of high failure probability in wafer processing semiconductor manufacturing progress, inability to cool the above edge ring, etc., to reduce the failure ratio, improve the yield ratio, and effectively cool the edge ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]Hereafter, the invention is described in detail by the attached drawings.

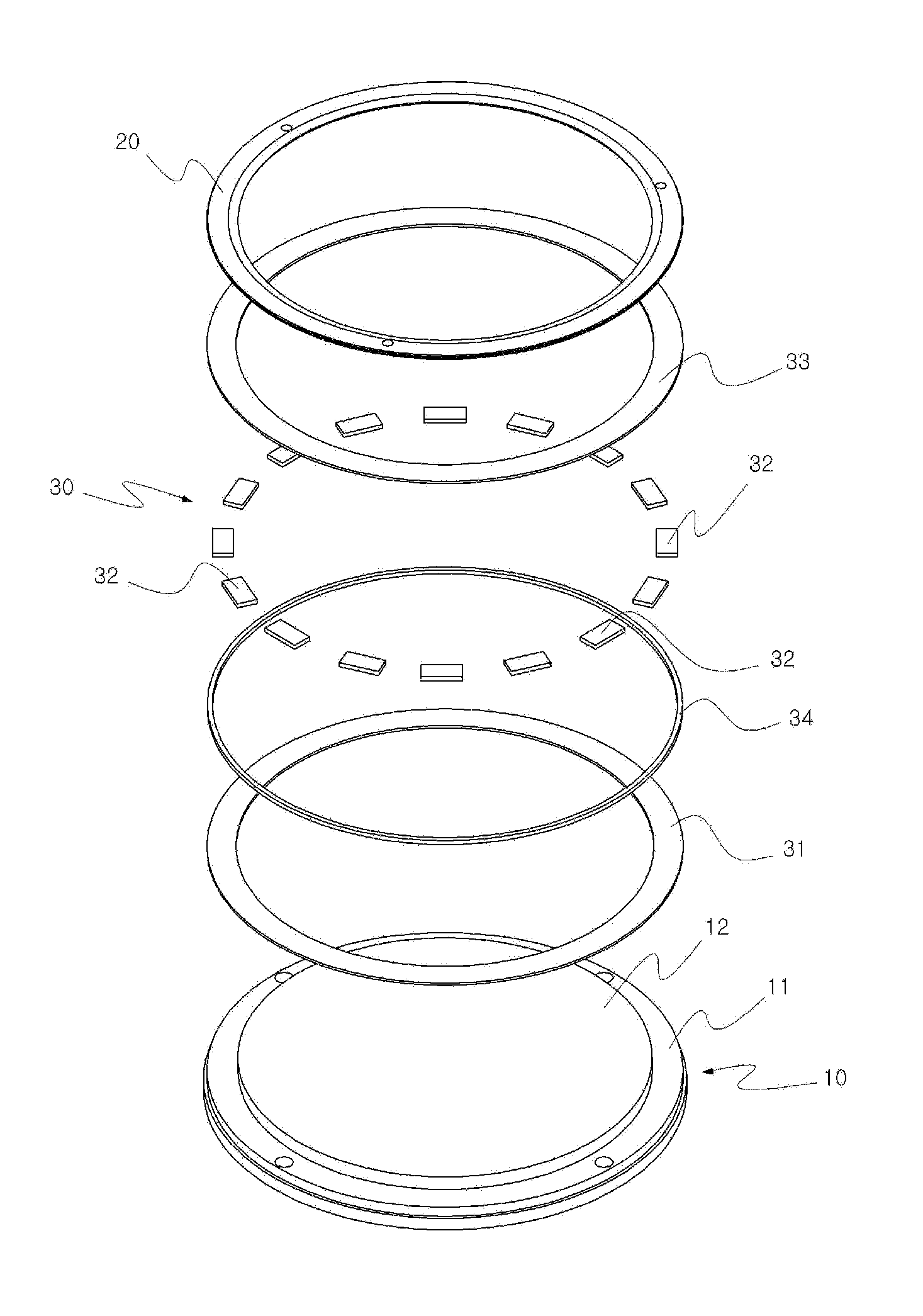

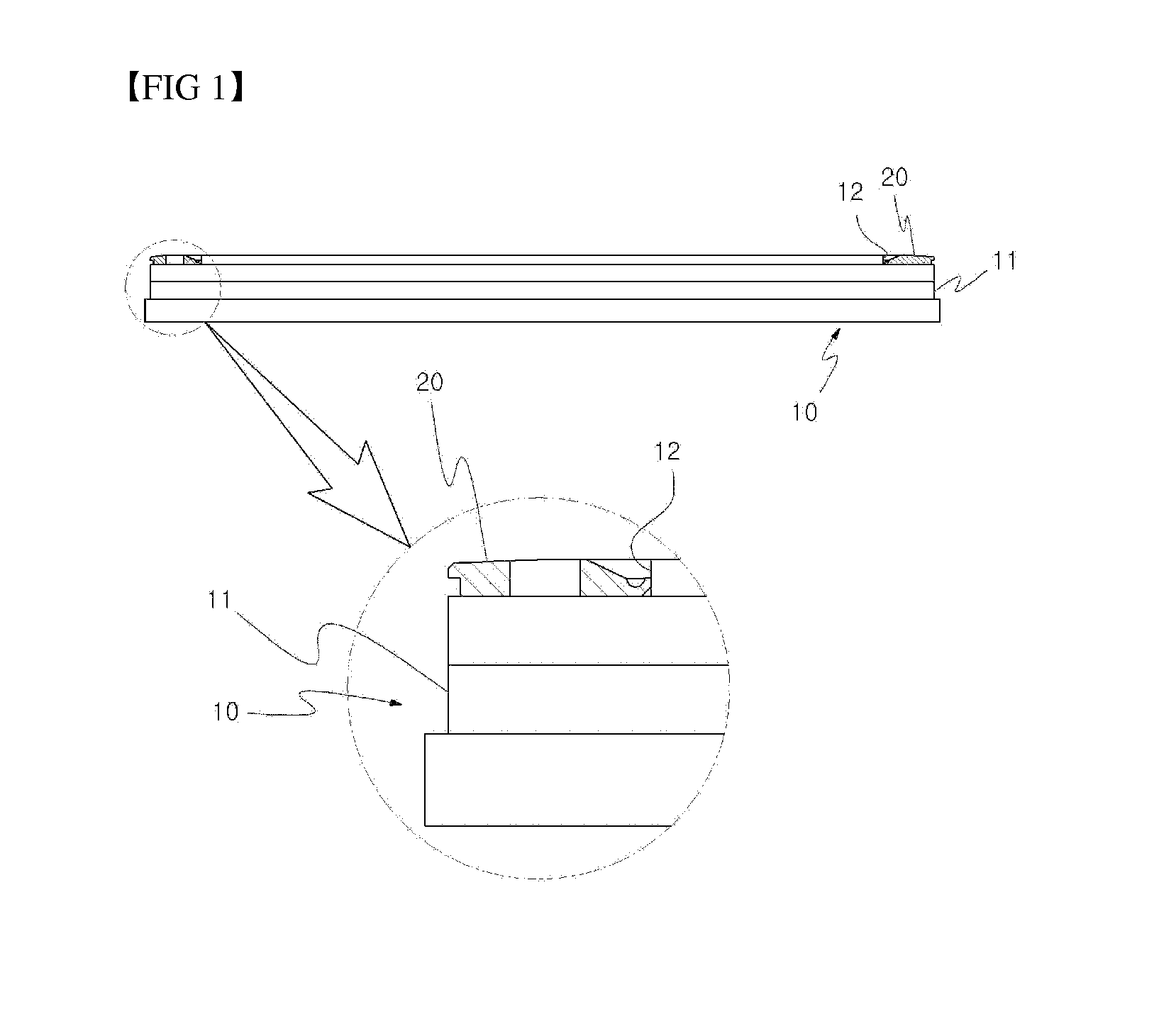

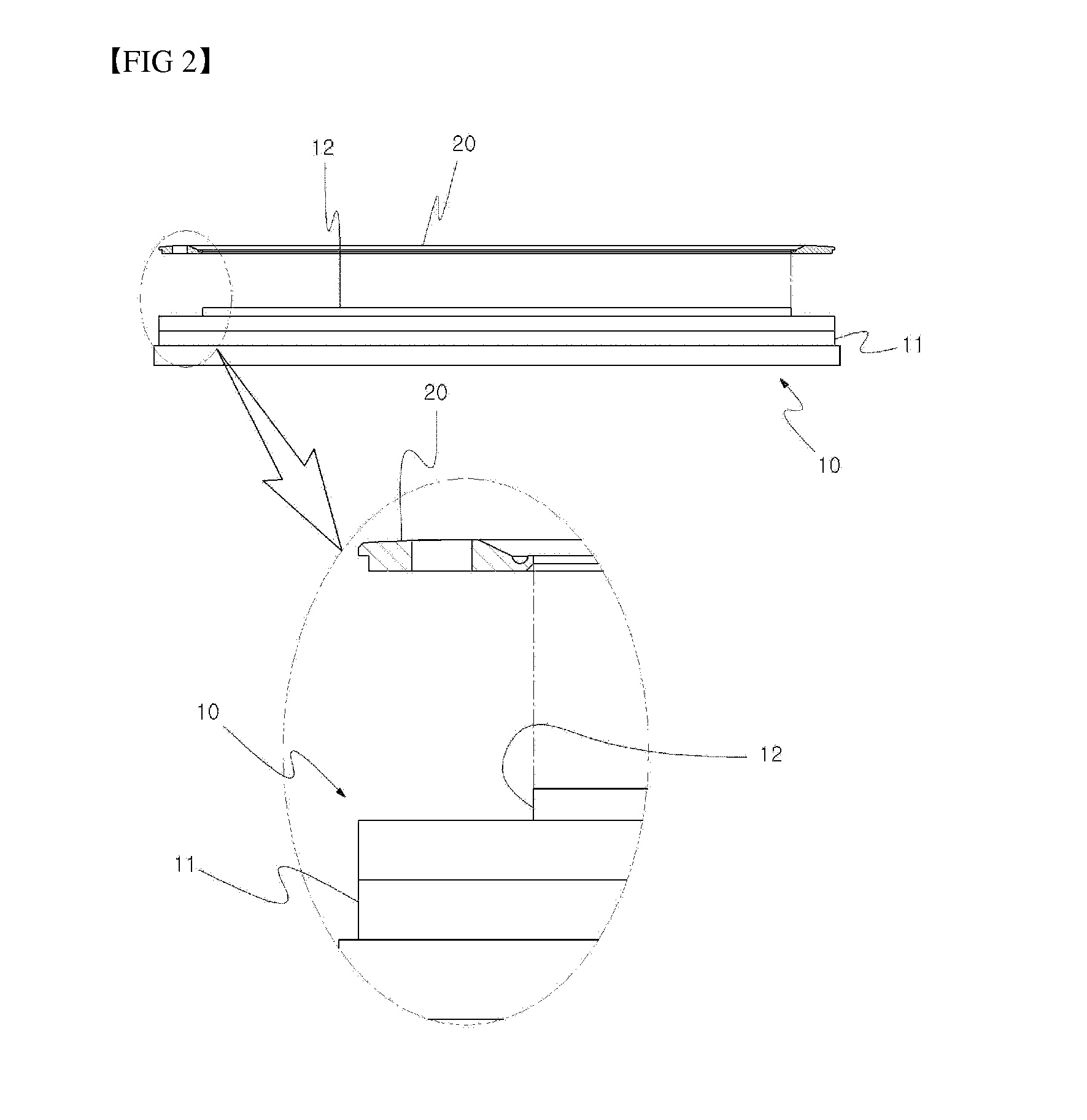

[0022]FIG. 3 or FIG. 5 illustrates the edge ring cooling module for semiconductor manufacturing chuck according to this invention showing ESC Claim example to fix wafer using static electricity.

[0023]In the same way as before, the above ESC consists of chuck body (10), composed of disc-shaped large-diameter portion (11) and small-diameter portion (12) upwardly projected from top center of the above large-diameter portion (11) to form a disc shape of smaller diameter compared to the above large-diameter portion (11), and edge ring (20) inserted to the outside of the above small-diameter portion (12).

[0024]Then electrostatic generator and cooling device are furnished to the above chuck body (10), not shown in the drawings, to generate static electricity to the above chuck body (10), fix the wafer on top of the chuck body and effectively cool the chuck body (10) heated by plasma in the semiconductor manufact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com