Low-temperature compact twinge equipment utilizing CO2 rapid cooling

A technology of rapid cooling and low-temperature impact, which is applied to heating appliances for treatment, cooling appliances for treatment, contraceptives, etc., which can solve the problems of difficult maintenance of equipment and low service life of gas nozzles, and achieve equipment automation. High efficiency, long service life, and low cost of product use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

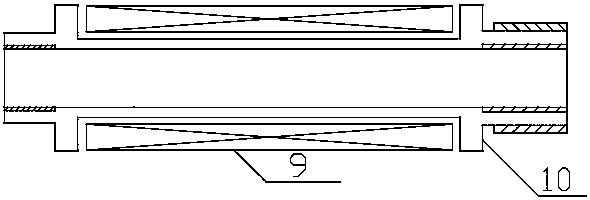

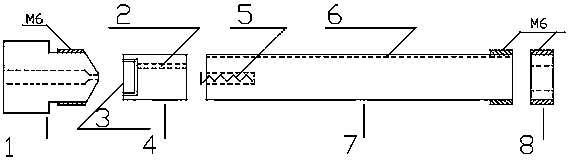

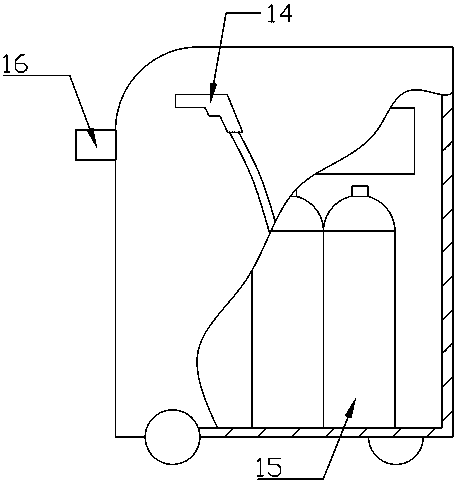

[0031] A low-temperature impact labor pain device that uses CO2 to rapidly cool down, see Figure 1 to Figure 4 , The carbon dioxide cylinder is set in the instrument shell, its outlet is connected to the jet pipe, the other end of the jet pipe is installed with a spray head, and the spray head is installed in the spray gun; the controller is installed in the instrument shell, and the controller is installed on the instrument shell. The connected touch LCD panel; the spray head is a rotary valve body 10, the valve body 10 is covered with an electromagnetic coil connected to the power supply element circuit, and the valve body 10 is coaxially equipped with an adjustment rod 7 and a piston 4 in turn. And the vaporization refrigeration cabin 1, the outer diameter of the adjustment rod 7 and the piston 4 is smaller than the inner hole diameter of the spray head to form a carbon dioxide liquid flow channel, one end of the spring 5 is connected to the adjustment rod, and the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com