Drill head for a deep hole drilling tool for BTA deep hole drilling, and deep hole drilling tool

A technology for deep hole drilling and drill bits, which is applied in the direction of drilling/drilling equipment, drilling tool accessories, manufacturing tools, etc. It can solve the problems of drilling quality impact, frequent tool replacement, no tool life, etc., and achieve the trend of vibration Minimum, increased tool life, and improved drilling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

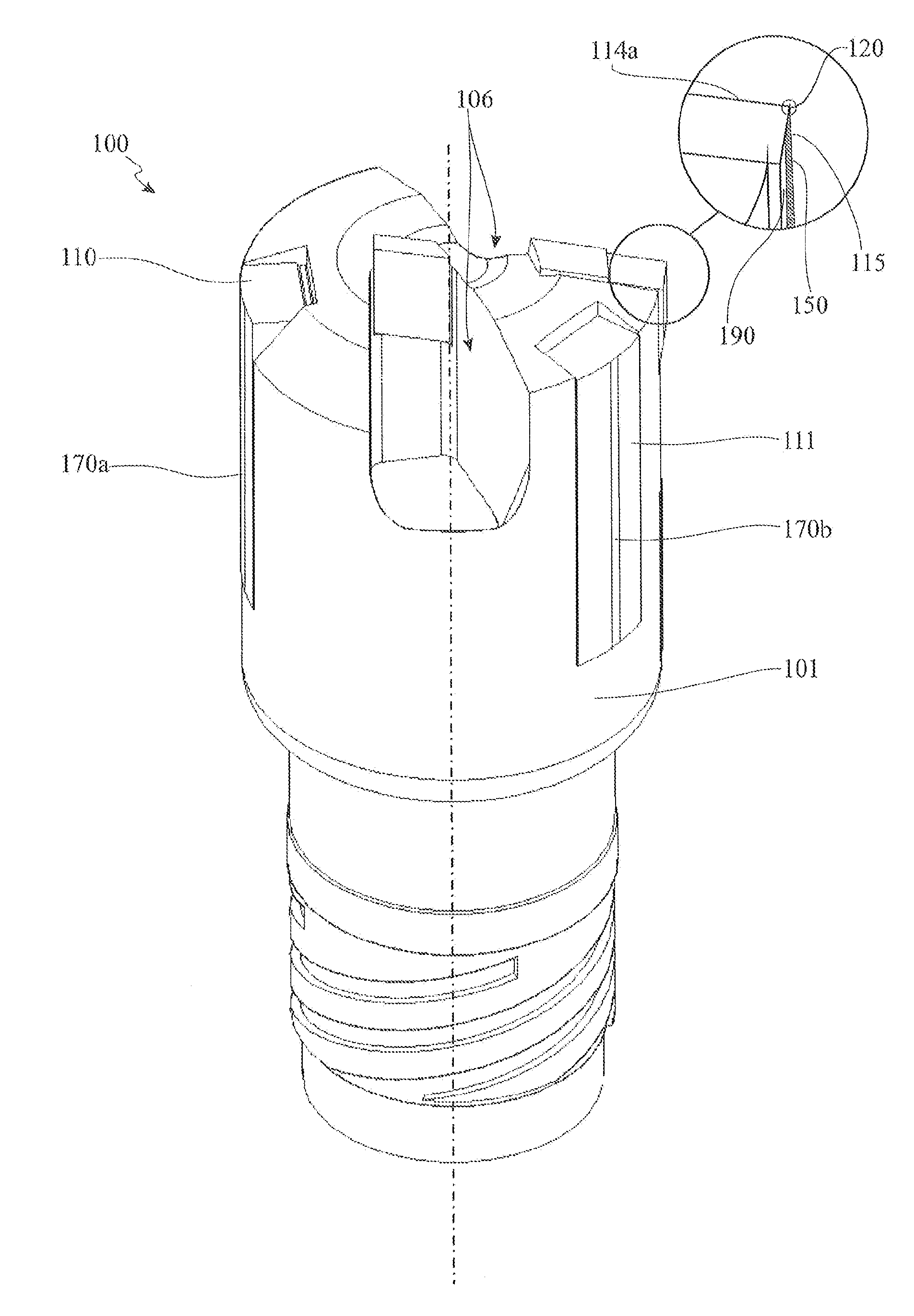

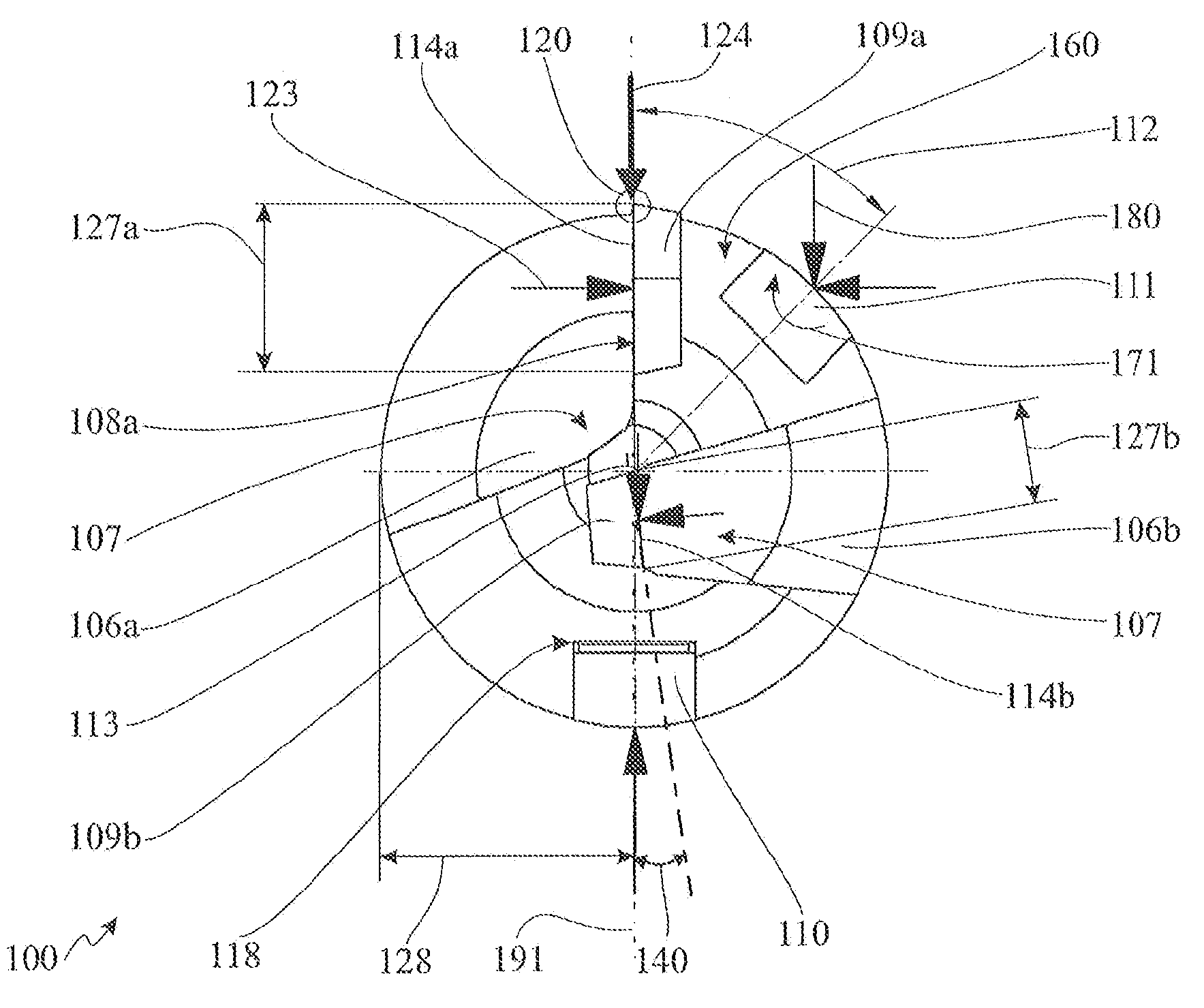

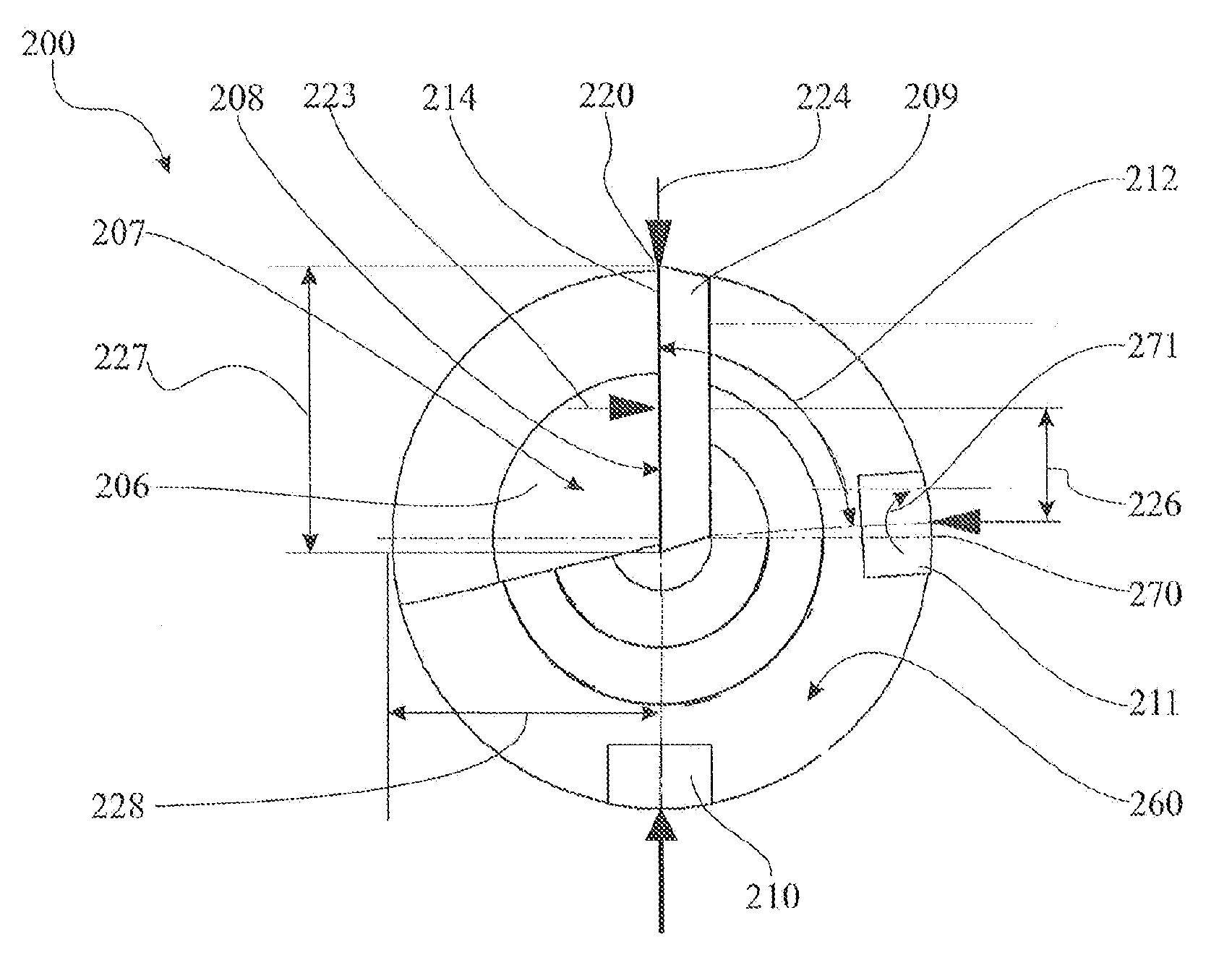

[0045] figure 1 An exemplary embodiment of a drill 100 with a cutting edge 109 which is divided into two partial cutting edges 109a and 109b is shown in perspective. The drill bit 100 shown has a substantially cylindrical drill body 101 , which is rotatable about an axis of rotation 113 and has a drilling region 102 , and a shank region 103 . The shank region 103 is designed to be connected to a drill pipe not shown here. For the exemplary embodiment shown, special connecting threads 104 are provided to connect the drill bit 100 to the drill pipe. It may be a conventional single start or four thread connecting thread for BTA drill bits. In the case of very small drilling diameters in the range of approximately 7 mm to 12 mm, the drill bit can even be incorporated directly into the drill pipe. For large deep hole drilling tools, the bit can also be flanged.

[0046] The cutting edge 109 is arranged on the drilling side 160 of the drill body 101 , wherein the two partial cut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com