Laser drilling and drilled-hole filling system and method

A laser drilling and filling system technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of small size, inability to achieve optical components, and inability to adjust the rotation angle of high-speed rotating beams, etc. problem, to achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

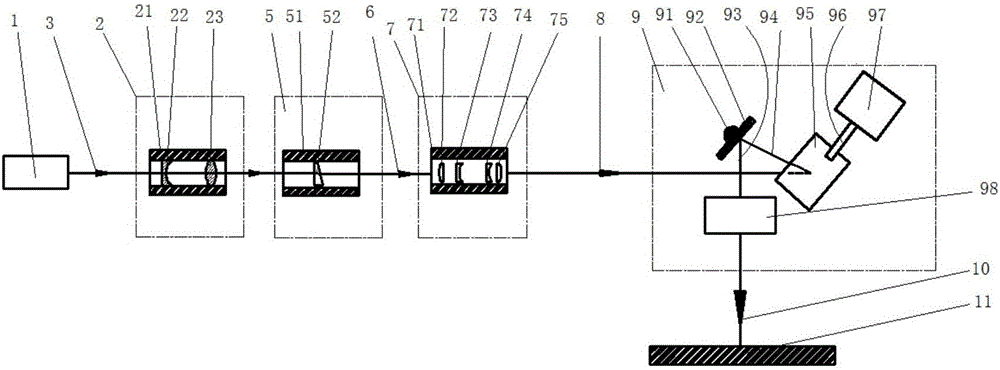

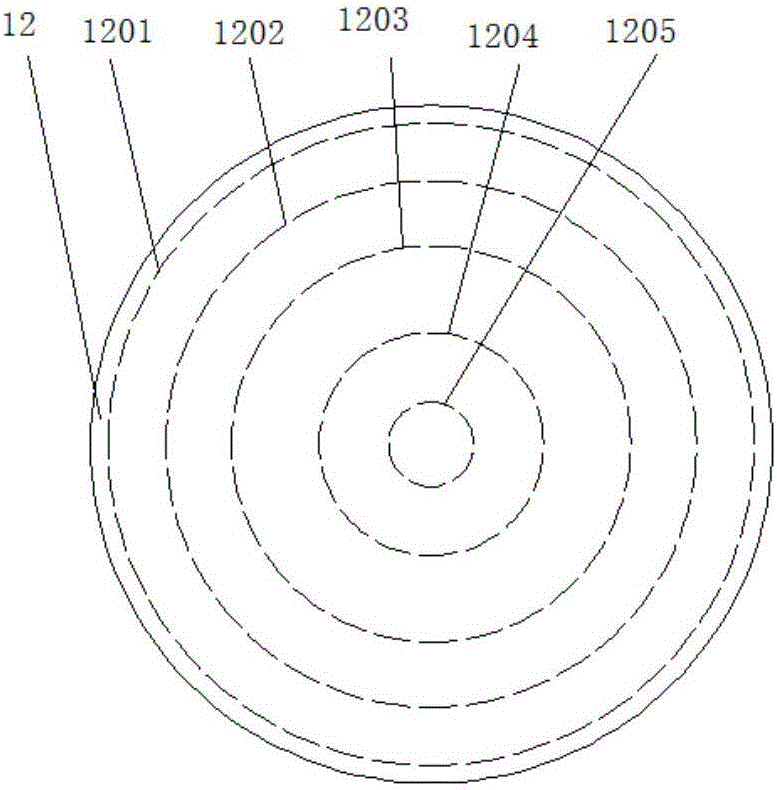

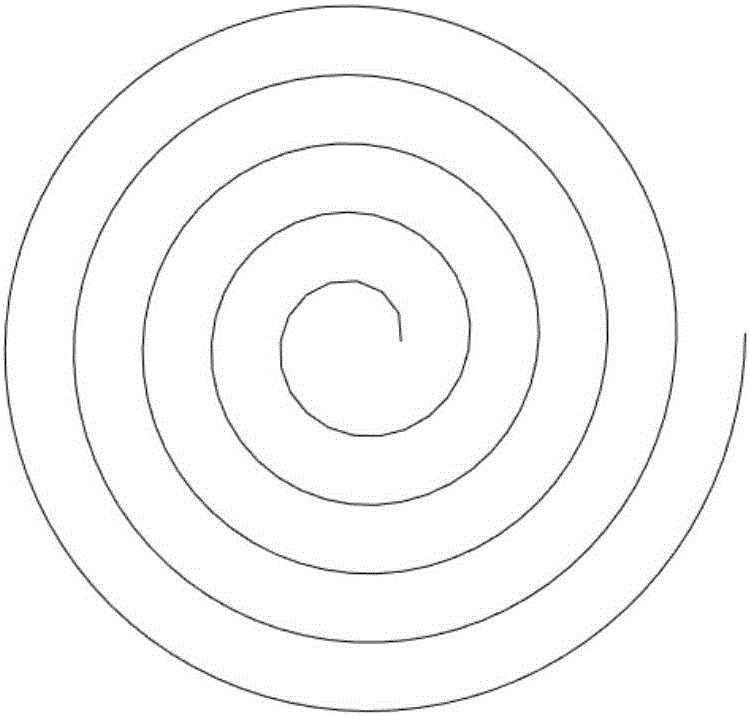

[0055] Embodiment 1. A silicon wafer laser drilling system. Combine below Figure 1-Figure 4 This embodiment will be described in detail.

[0056] see figure 1 , a silicon wafer laser drilling system in this embodiment includes a laser light source module 1, an incident beam rotation movement module 5, an adjustable beam rotation angle compression ratio module 7, and a laser focusing and focus switching module 9;

[0057] The laser light source module 1 is used to generate an incident light beam 3, which is incident on the incident light beam rotation movement module 5;

[0058] The incident light beam rotation movement module 5 is used for rotationally modulating the incident light beam 3 to output a rotating light beam to form a first light beam 6 that rotates around the optical axis of the incident light beam 3, and the first light beam 6 is incident on the The beam rotation angle compression magnification adjustable module 7, wherein the full angle of rotation of the fi...

Embodiment 2

[0077] Embodiment 2. A laser drilling system for low temperature co-fired ceramics.

[0078] The laser drilling system of this embodiment is as Figure 5 As shown, in addition to the module in the above-mentioned embodiment 1, it also includes a beam expansion magnification compensation module 2, the laser light source module 1 emits an exit laser beam 4, the exit laser beam 4 enters the beam expansion magnification compensation module 2, and outputs an incident beam 3 .

[0079] Different from Embodiment 1, a beam expansion magnification compensation module 2 is provided before the incident beam rotation movement module 5; when the beam rotation angle compression magnification adjustable module 7 compresses the rotation angle of the first beam 6 at a large , the beam expansion magnification compensation module 2 performs small-magnification beam expansion on the exit laser beam 4, or, when the beam rotation angle compression magnification adjustable module 7 performs small-m...

Embodiment 3

[0084] Embodiment 3, a laser drilling and drilling filling method.

[0085] see Figure 6 , the borehole filling method provided in this embodiment includes the following steps:

[0086] S1, the incident beam generated by the laser light source module enters the incident beam rotation movement module;

[0087] S2, the incident light beam rotation movement module rotates and modulates the incident light beam to output a rotating light beam to form a first light beam that rotates around the optical axis of the incident light beam, and the first light beam enters the beam rotation angle compression magnification adjustable module , wherein the full angle of rotation of the optical axis of the first light beam is less than 30 milliradians;

[0088] S3, the beam rotation angle compression magnification adjustable module expands the first beam and compresses the spatial rotation angle of the first beam, outputs the second beam with a compressed rotation angle and enters the laser ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com