Automatic drilling frame for instrument panel beam drilling device

A drilling device and instrument panel technology, which is applied in the direction of drilling/drilling equipment, boring/drilling, boring machine/drilling machine parts, etc., can solve the problem that drilling cannot be carried out quickly and stably, and achieve improved drilling Pore efficiency, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

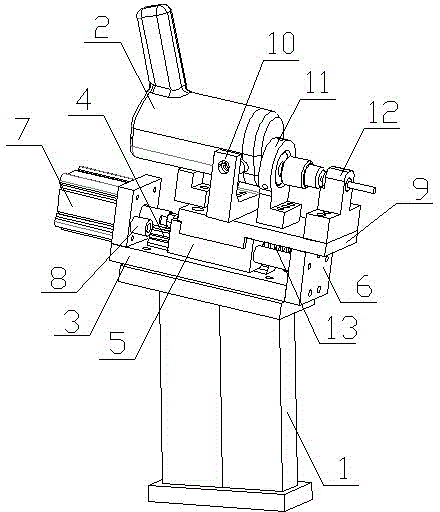

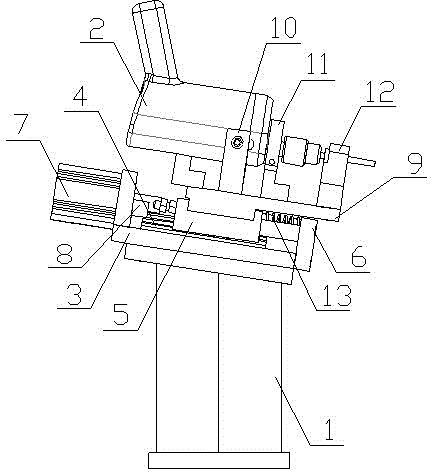

[0017] Example: see figure 2 , image 3 , an automatic drilling frame for an instrument panel beam drilling device, comprising a support frame 1 and an electric drill 2. Described bracing frame 1 top is provided with a rectangular support plate 3, is provided with a slide rail 4 along its length direction on support plate 3, slides and fits a slide block 5 on the described slide rail 4, is respectively provided at the two ends of support plate 3 There is a baffle 6, and two position-limiting columns 8 are arranged between the two ends of the slider 5 and the two baffles 6 respectively. By setting the limit column 8, the position of the electric drill can be effectively controlled during the drilling and withdrawal process, and the drilling transition and withdrawal transition can be avoided, thereby making the drilling faster and more stable.

[0018] An electric drill mounting plate is provided on the slide block 5, and the electric drill 2 is rotationally connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com