Hand-held electric hammer uphole drilling device

A drilling device and electric hammer drill technology, applied in the direction of manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problem of not meeting the technical requirements of operators, affecting physical health and work safety, affecting the grasp of drilling quality, etc. problems, to achieve the effect of a large height adjustment range, improve work efficiency, and reduce the impact of dust scattering on human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

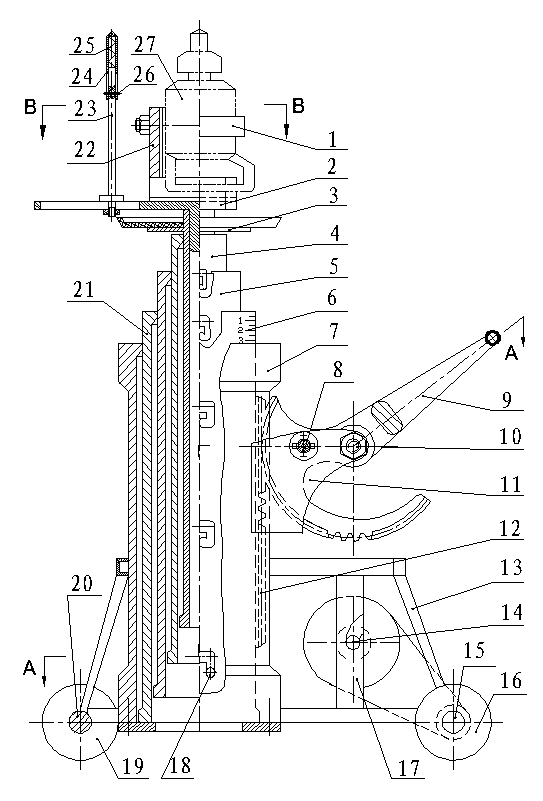

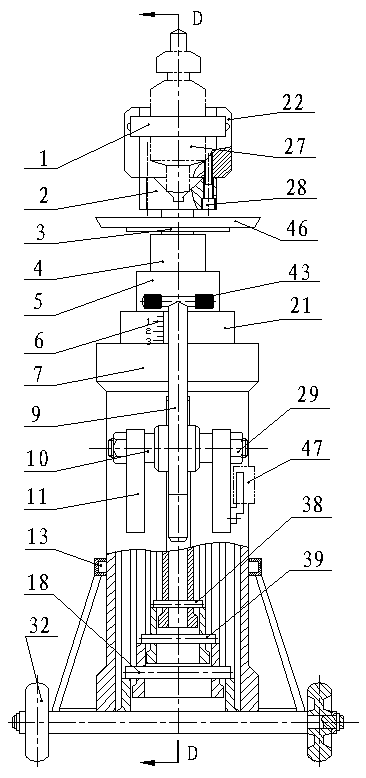

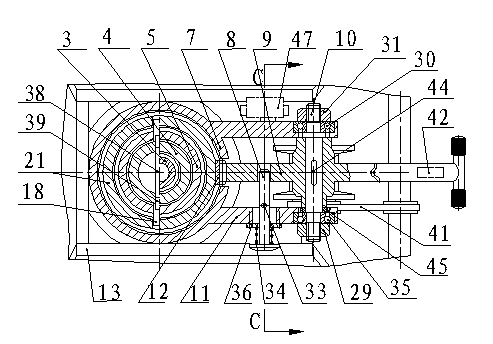

[0027] The technical solution of the present invention will be described below in conjunction with the accompanying drawings.

[0028] Such as Figure 1-5 As shown, the vertical drilling device includes a frame body, a telescopic rod, a connector and a self-drilling feeder. The telescopic rod is installed on the frame body, and the connector is installed on the top of the telescopic rod. On the front side of the lower end of the telescopic rod, the whole constitutes an upward drilling device.

[0029] Wherein, described vehicle frame body comprises vehicle frame 13, front axle 15, rear axle 20, front wheel 16, rear wheel 19, column 17, reel axle 14, belt 41 and the 5th steel pipe 7, and vehicle frame 13 is made of Square steel pipes are welded into a rectangular trapezoidal frame with upper, lower, and lower ends. The lower ends of the vehicle frame 13 are provided with a front axle 15 and a rear axle 20. The front axle 15 is movably connected to the vehicle frame 13. , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com