High-quality conicity-controllable drilling machining device and method

A processing equipment and high-quality technology, applied in metal processing equipment, welding equipment, laser welding equipment and other directions, can solve the problems of complex processing process and inconvenient integration, achieve rapid incident angle adjustment, speed up drilling efficiency, and improve drilling efficiency. The effect of hole quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated below with reference to the accompanying drawings.

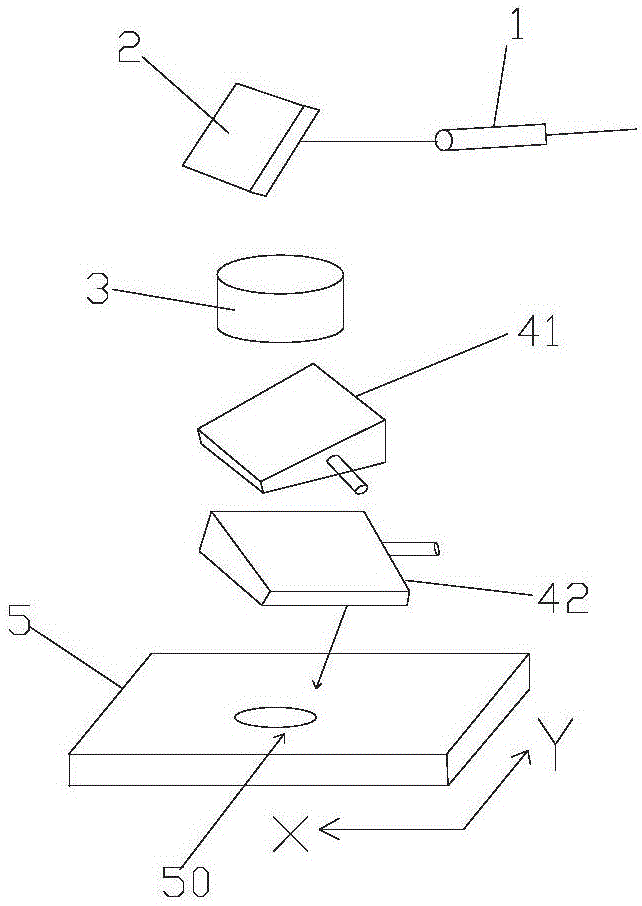

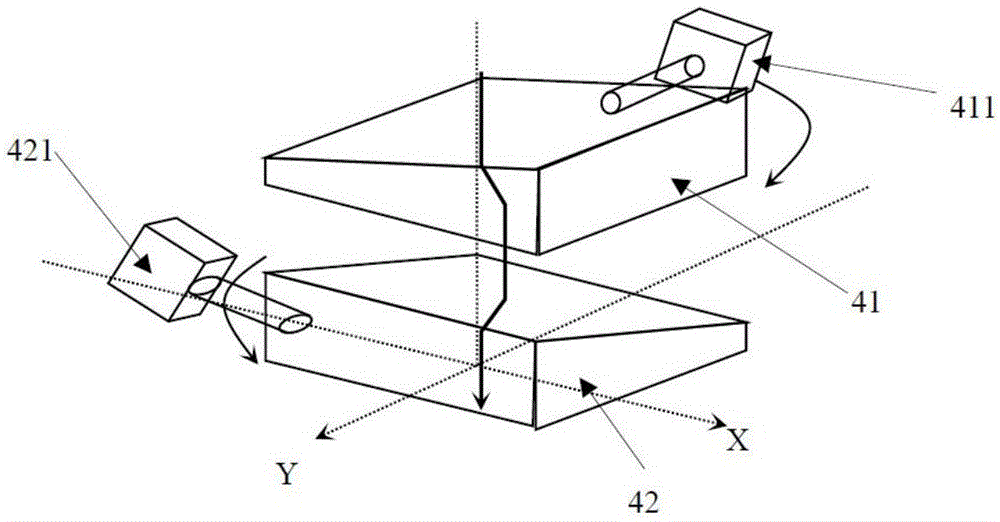

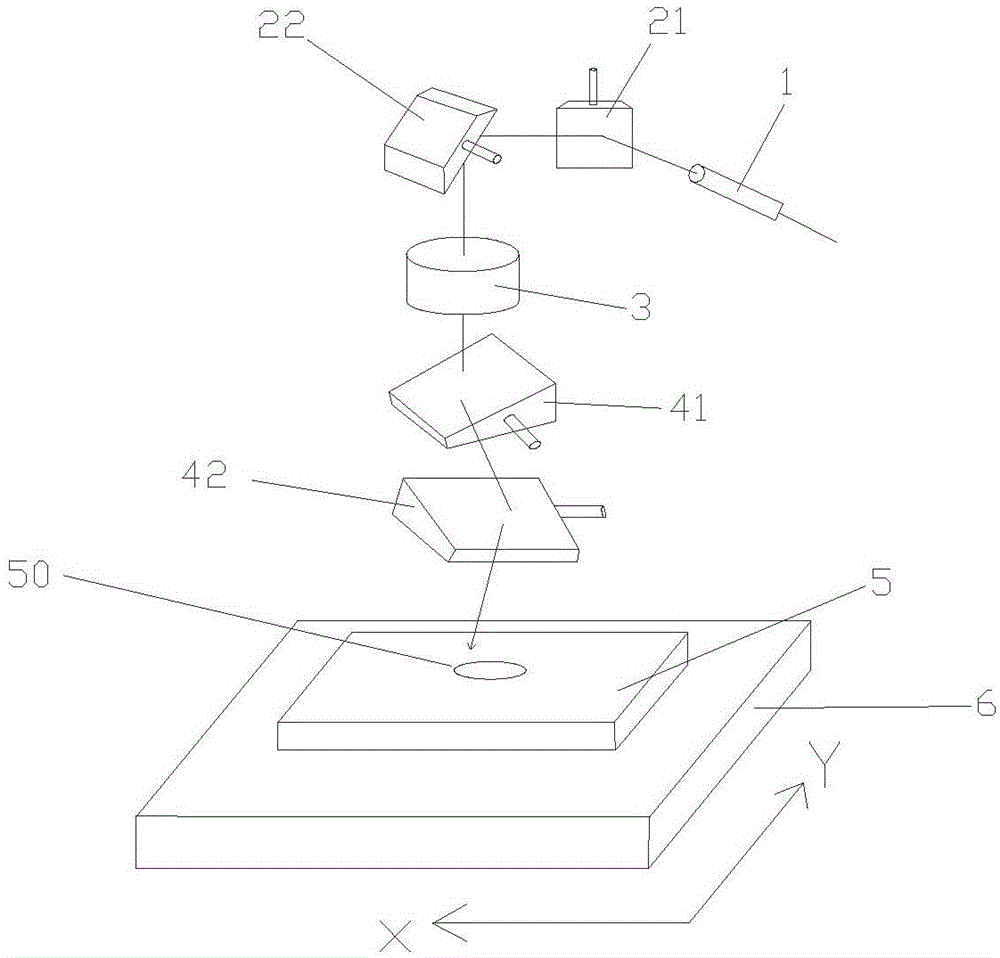

[0026] see figure 1 to attach Figure 5 , a kind of high-quality drilling processing equipment with controllable taper of the present invention has a laser emitting device, which sequentially includes: a beam rotation module 1; a focusing lens 3; a first wedge-shaped optical glass substrate 41; A second wedge-shaped optical glass substrate 42; wherein, the laser light acts on the workpiece to be processed through the beam rotation module 1, the focusing lens 3, the first wedge-shaped optical glass substrate 41 and the second wedge-shaped optical glass substrate 42 in sequence, and the The first wedge-shaped optical glass substrate 41 and the second wedge-shaped optical glass substrate 42 are controlled to rotate the device, so as to change the laser irradiation line, thereby realizing the drilling process.

[0027] Wherein, the beam rotation module adopts self-rotatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com