Equidistant drilling machine for high-end equipment

An equidistant, drilling mechanism technology, applied in the direction of drilling/drilling equipment, positioning devices, metal processing equipment, etc., can solve the problems of single function and difficulty in realizing equidistant drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

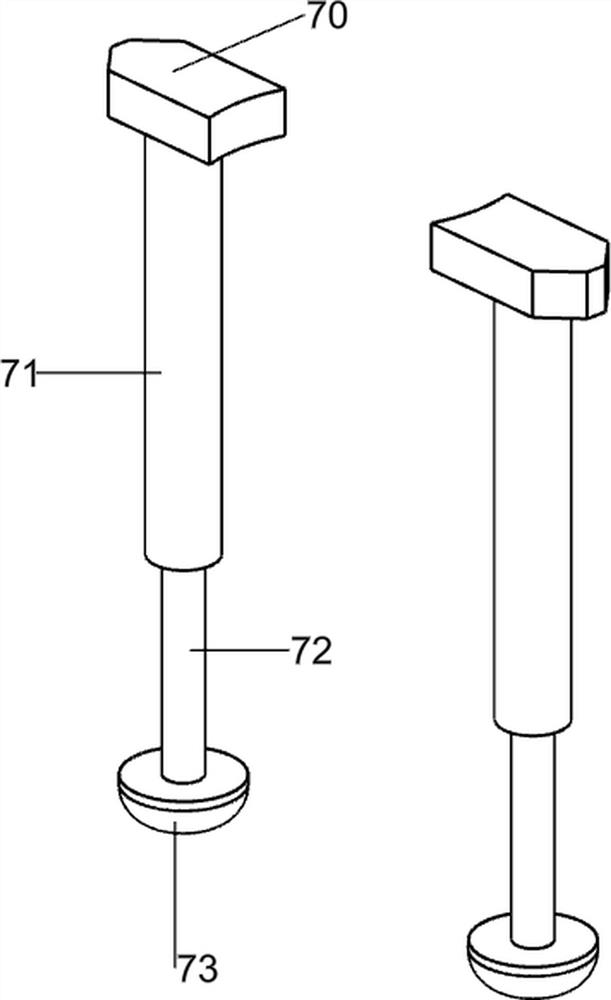

[0065] An equidistant drilling machine for high-end equipment, such as Figure 1-3 As shown, it includes a base 1, a support 2, a placement mechanism 3 and a drilling mechanism 4, the base 1 is provided with a support 2, the support 2 is provided with a placement mechanism 3, and the left side of the base 1 is provided with a drilling mechanism 4.

[0066] The placement mechanism 3 includes a first slide rail 30, a baffle plate 31, a buckle 32 and a bolt 33. The front and rear sides of the top of the bracket 2 are connected with the first slide rail 30, and the first slide rails 30 are slidably connected with a baffle plate. 31 , a buckle 32 is clamped between the right front side of the baffle 31 and the first slide rail 30 , and a bolt 33 is threadedly connected between the buckle 32 and the baffle 31 .

[0067] The drilling mechanism 4 includes a support plate 40, a sliding plate 41, an installation tube 42 and a drill bit 43, and the front and rear sides of the left part o...

Embodiment 2

[0070] On the basis of Example 1, such as Figure 4-8 Shown, comprise lifting mechanism 5, and lifting mechanism 5 comprises fixed plate 50, cylinder 51 and air rod 52, is connected with fixed plate 50 between support plate 40 tops, is provided with cylinder 51 on fixed plate 50, and cylinder 51 bottom is provided with Air rod 52 , the bottom of air rod 52 is connected with installation tube 42 .

[0071] The extension of the control cylinder 51 drives the air rod 52 and the installation cylinder 42 to move downward, and the shortening of the control cylinder 51 drives the air rod 52 and the installation cylinder 42 to move upward and reset.

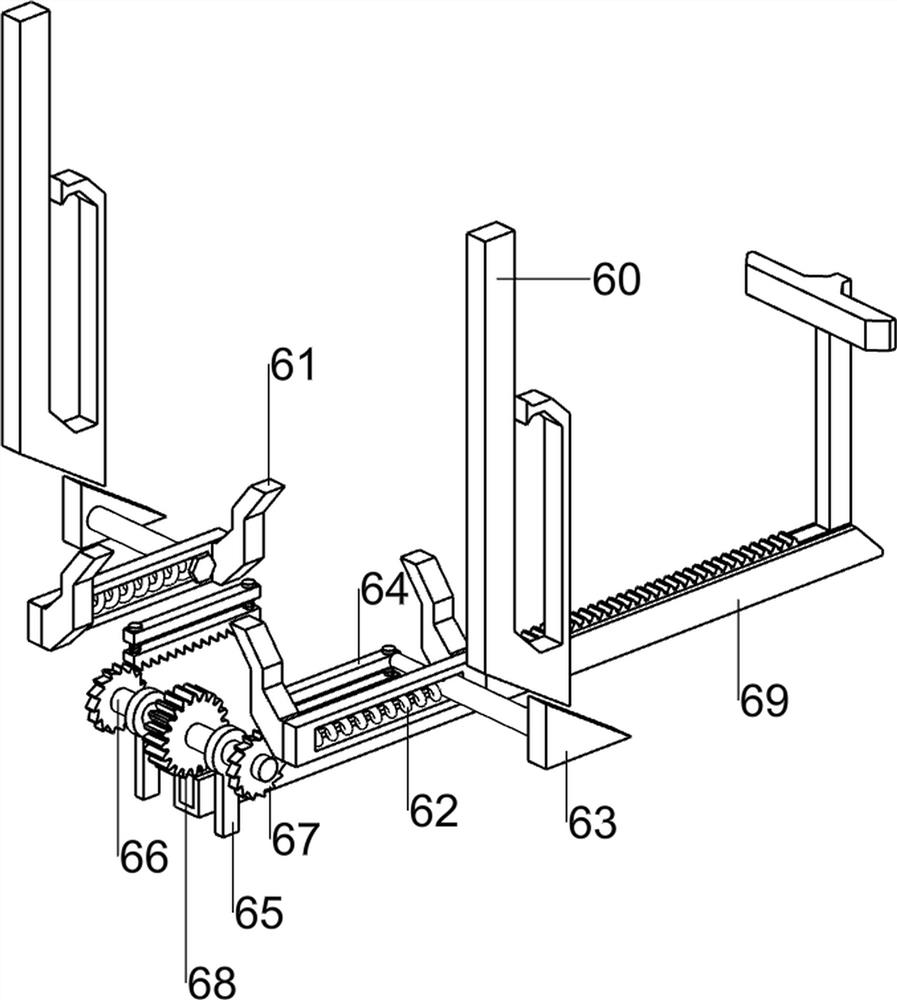

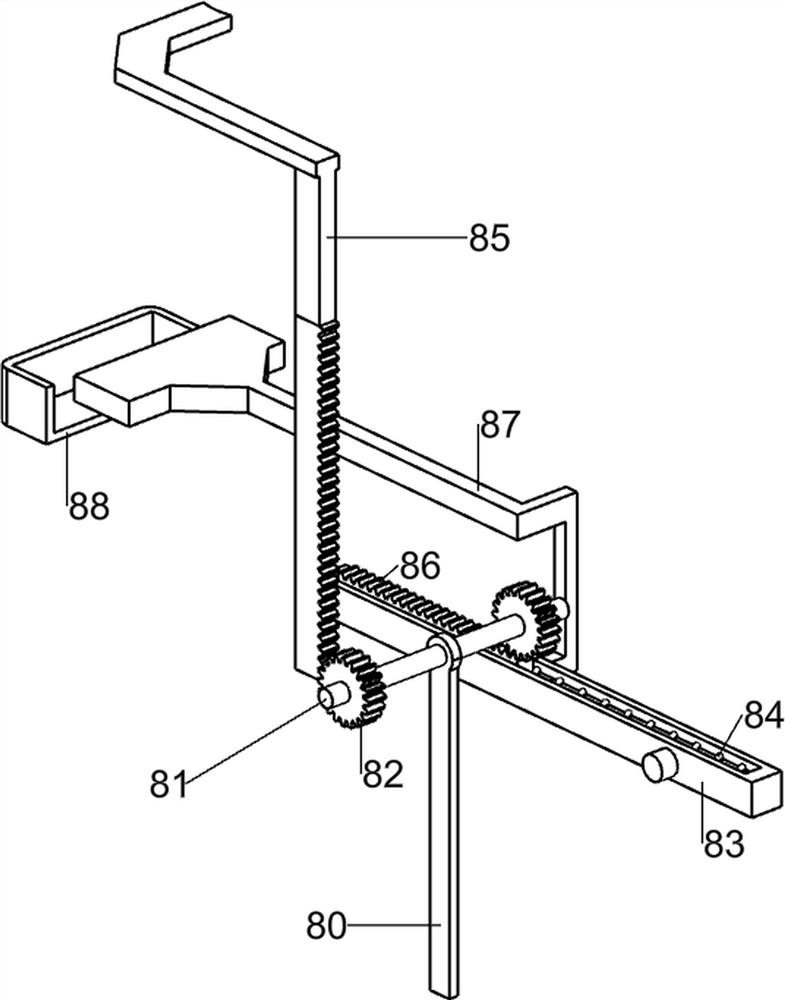

[0072]Also comprise propelling mechanism 6, propelling mechanism 6 comprises lower pressing plate 60, second slide rail 61, first spring 62, wedge block 63, ratchet bar 64, first bearing seat 65, first rotating shaft 66, ratchet 67, the first A gear 68 and a rack push rod 69, the front and rear sides of the sliding plate 41 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com