Batch drilling device for PVC boards

A drilling device and plate batch technology, applied in metal processing and other directions, can solve the problems of low drilling efficiency, easy arm soreness, and need for a long time, and achieve the effect of improving drilling efficiency and facilitating drilling work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

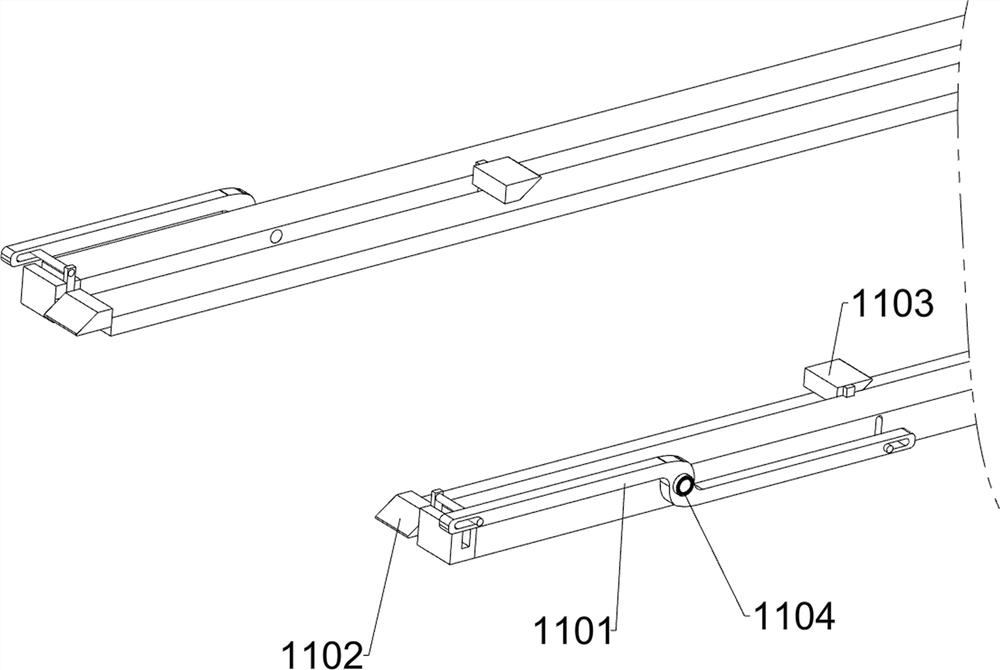

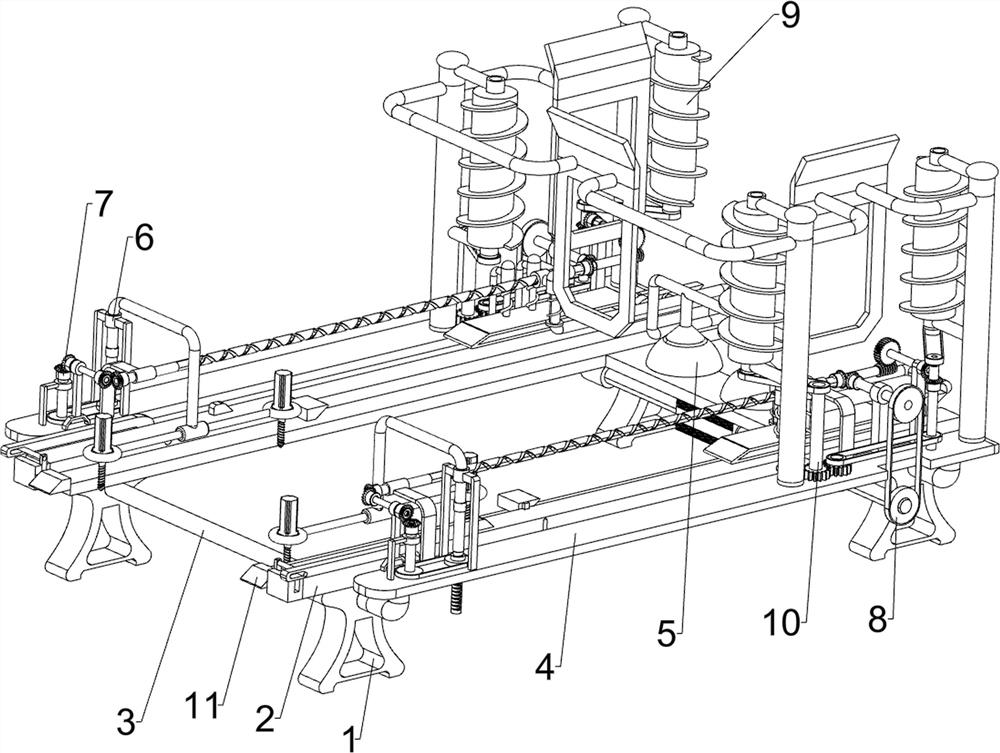

[0027] A kind of PVC board batch drilling device, such as Figure 1-2 As shown, it includes a support foot 1, a slide rail 2, a support rod 3, a feeding plate 4, a feeding mechanism 5 and a drilling mechanism 6. The bottom of the slide rail 2 is symmetrically connected with four support feet 1, and the left two support feet 1 There is a support rod 3 connected between them, and there are two material setting plates 4 symmetrically connected between the support rod 3 and the right leg 1. A feeding mechanism 5 is installed between the material setting plate 4 and the slide rail 2. On the material setting plate 4 Drilling mechanism 6 is installed.

[0028] The feeding mechanism 5 includes a first twist rod 51, a first carriage 52, a first compression spring 53, a suction cup 54, a first wedge 55, a second wedge 56, a first fixing frame 57, a third wedge 58, The second compression spring 59 and the fourth wedge block 510, the top of the material setting plate 4 is rotatably conne...

Embodiment 2

[0032] On the basis of Example 1, such as Figure 1-2 As shown, the first transmission mechanism 7 is also included, and the first transmission mechanism 7 includes a first rotating shaft 71, a first bevel gear set 72, a second rotating shaft 73, a second bevel gear set 74, a second twist rod 75 and a second rotating shaft 75. A belt transmission group 76, the left side of the top of the material plate 4 is rotationally connected with a first rotating shaft 71, the first rotating shaft 71 is located on the left side of the second fixed frame 61, and the first rotating shaft 71 is connected with the first twist rod 51. The first bevel gear set 72, the left side of the top of the material plate 4 is rotationally connected with a second rotating shaft 73, the second rotating shaft 73 is located on the outside of the first rotating shaft 71, and a second rotating shaft 73 is connected with the first rotating shaft 71. The bevel gear set 74, the left part of the material plate 4 is...

Embodiment 3

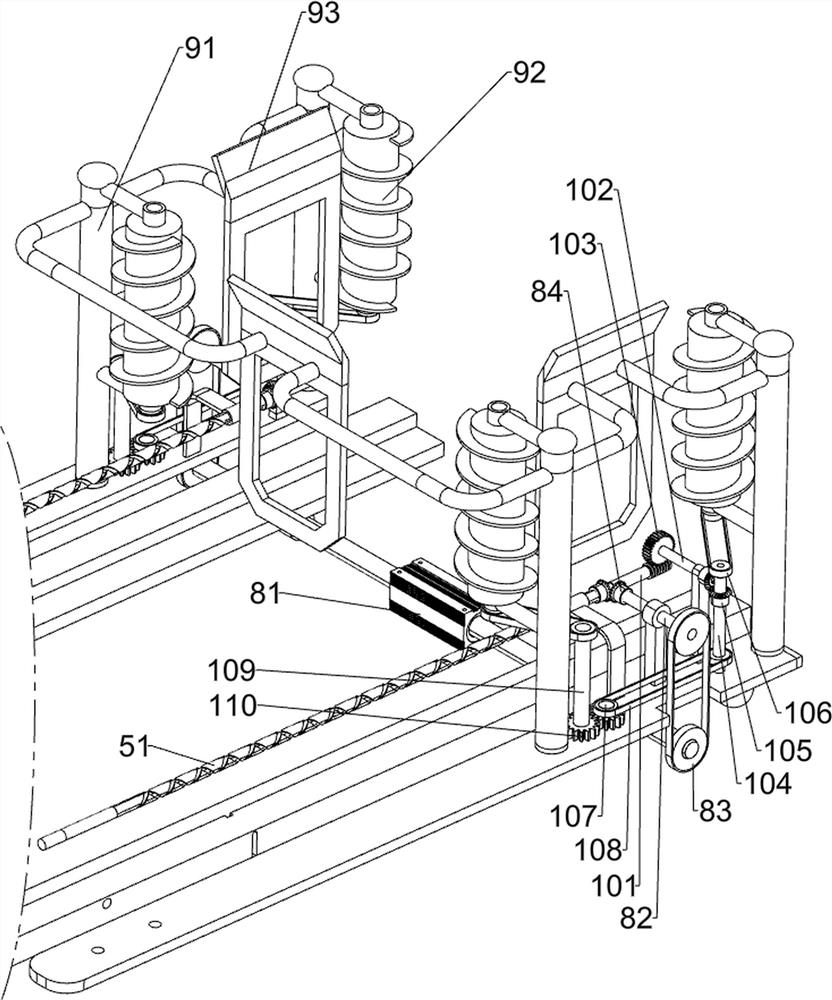

[0036] On the basis of Example 2, such as figure 1 and image 3 Shown, also include unloading mechanism 9, unloading mechanism 9 includes support 91, unloading bar 92 and baffle plate 93, two brackets 91 are connected on the right side of stock plate 4 top, on the bracket 91 rotary type is connected with the bottom Baffles 93 are connected between the material rods 92 and the adjacent brackets 91 .

[0037] Also includes a second transmission mechanism 10, the second transmission mechanism 10 includes a worm 101, a fourth shaft 102, a turbine 103, a fifth shaft 104, a fifth bevel gear set 105, a flat belt 106, a sixth shaft 107, a third Belt transmission group 108, the seventh rotating shaft 109 and the opposite gear group 110, the right end of the first twist rod 51 is connected with a worm 101, the right side of the top of the material plate 4 is rotationally connected with a fourth rotating shaft 102, and the fourth rotating shaft 102 is located on the bracket 91, the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com