Patents

Literature

55results about How to "Convenient drilling work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

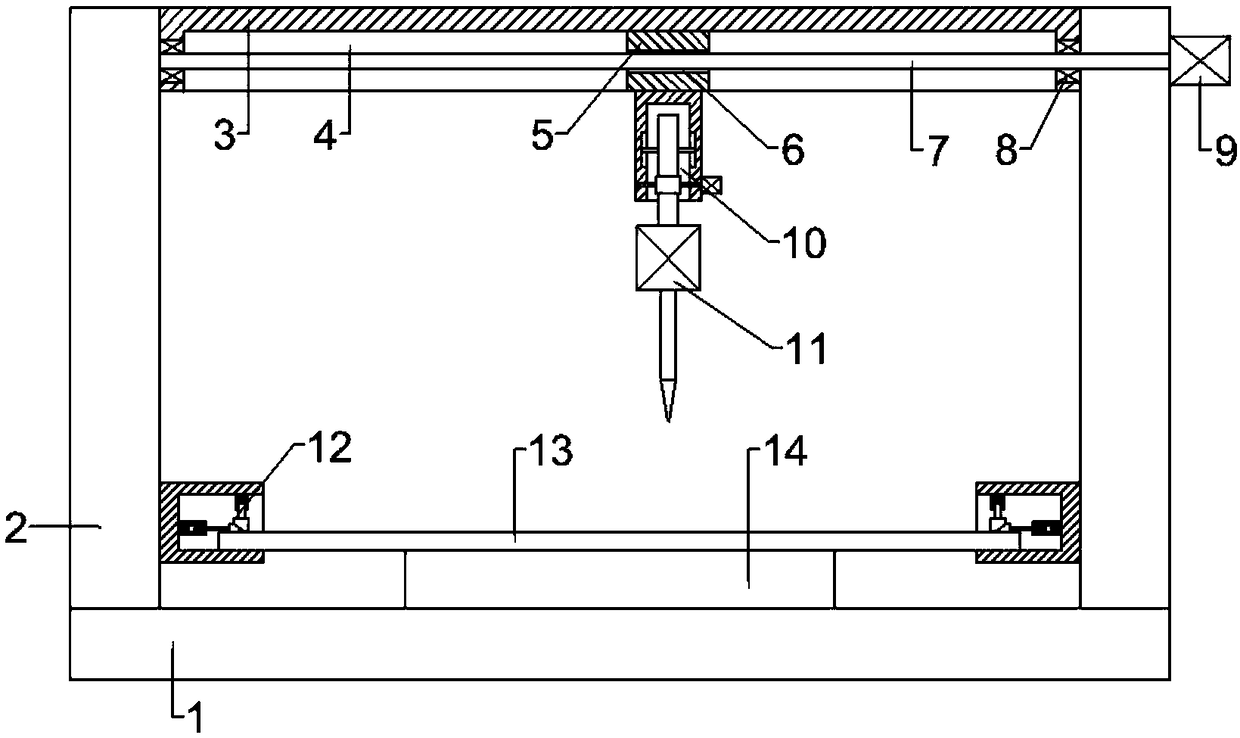

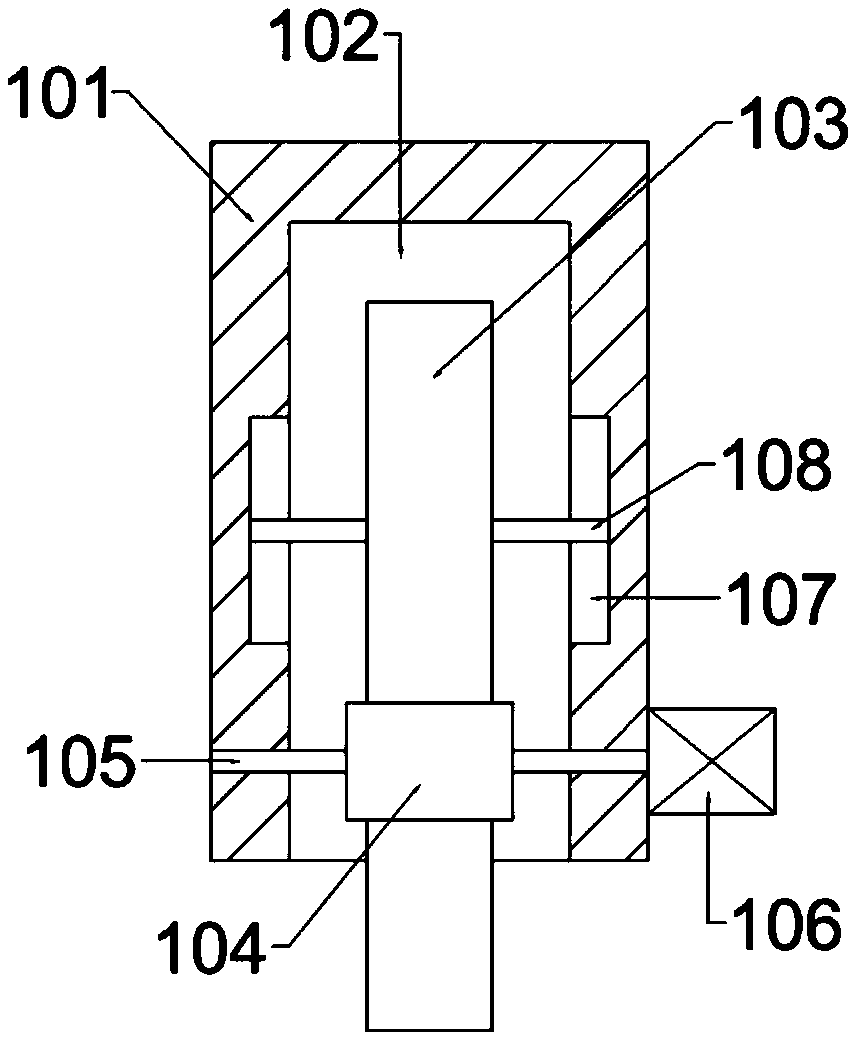

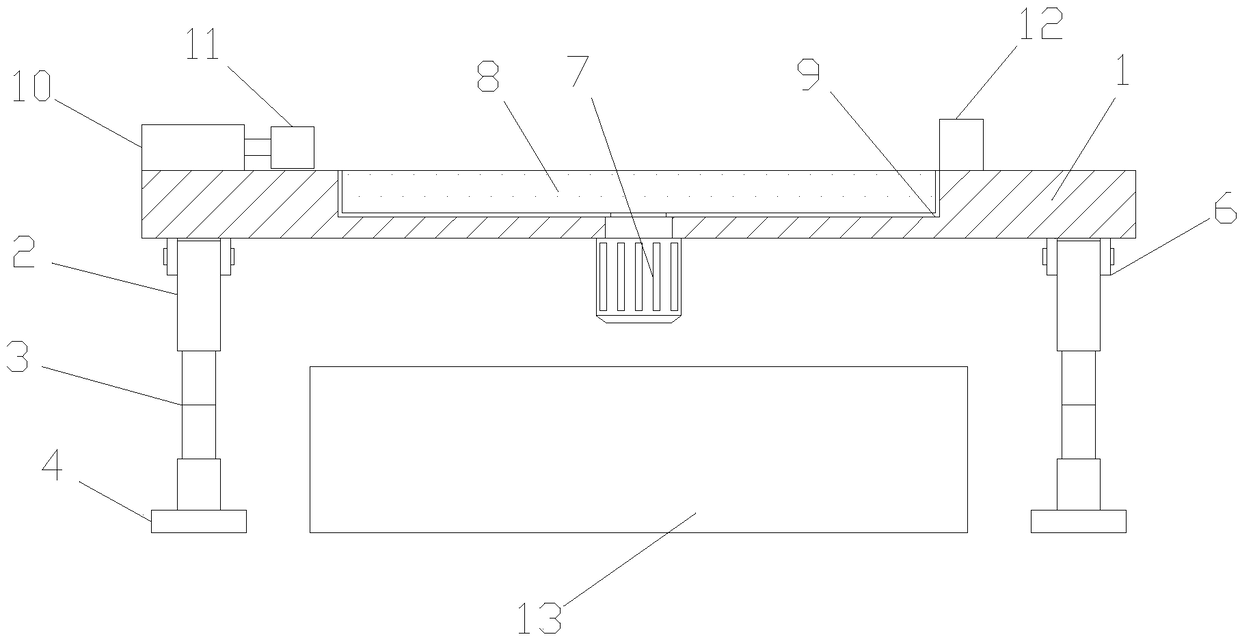

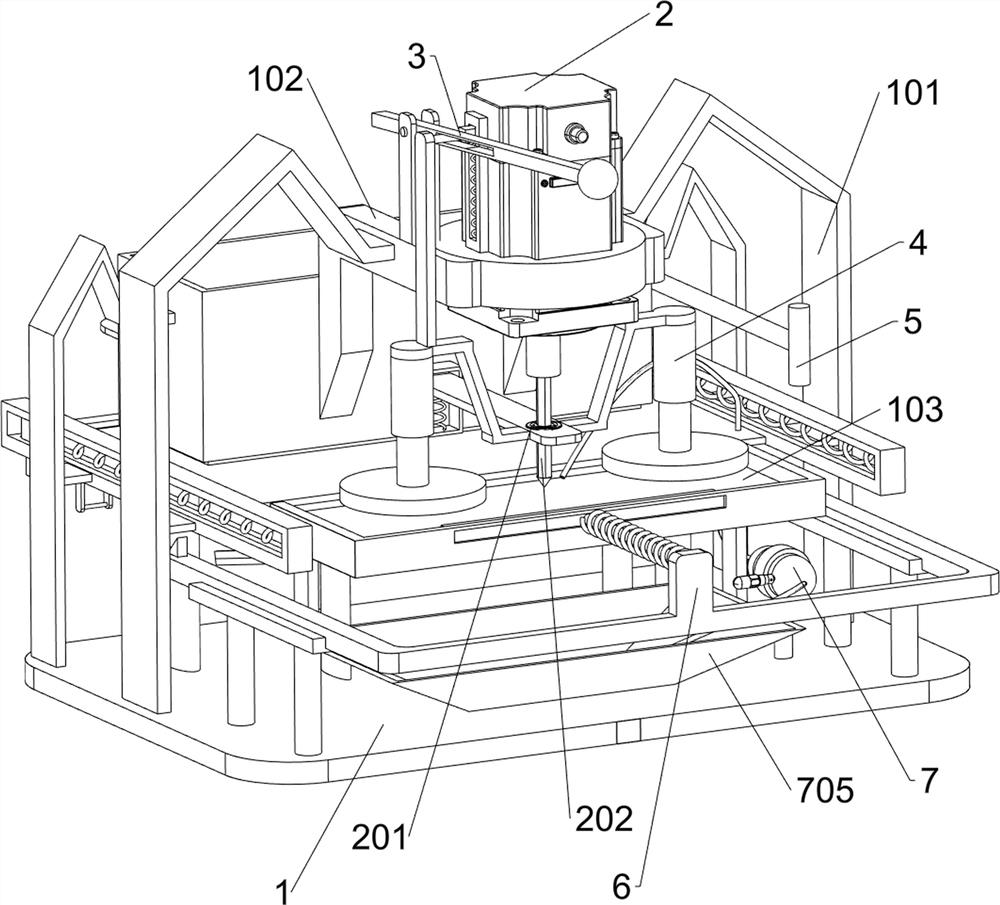

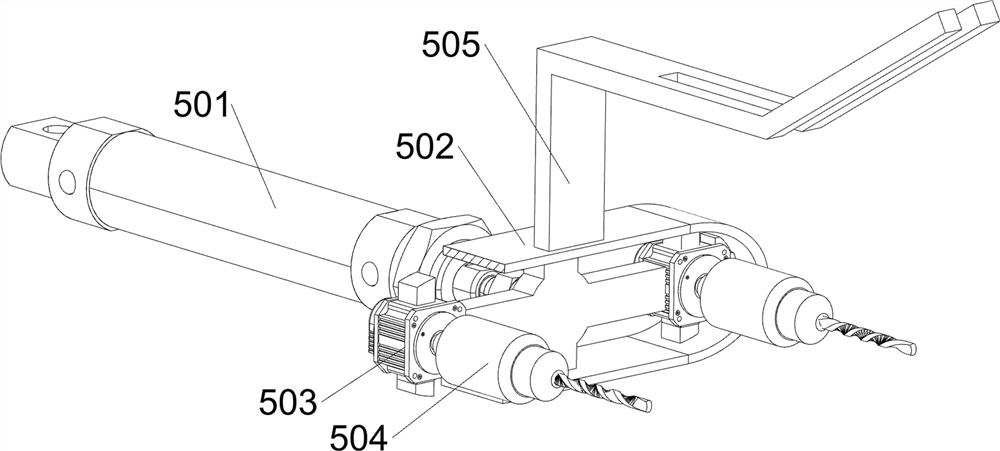

Drilling device applied to graphite mold production

InactiveCN105414599ASolving Drilling ProblemsStrong targetingWorkpiecesTurning toolsElectric machineryReducer

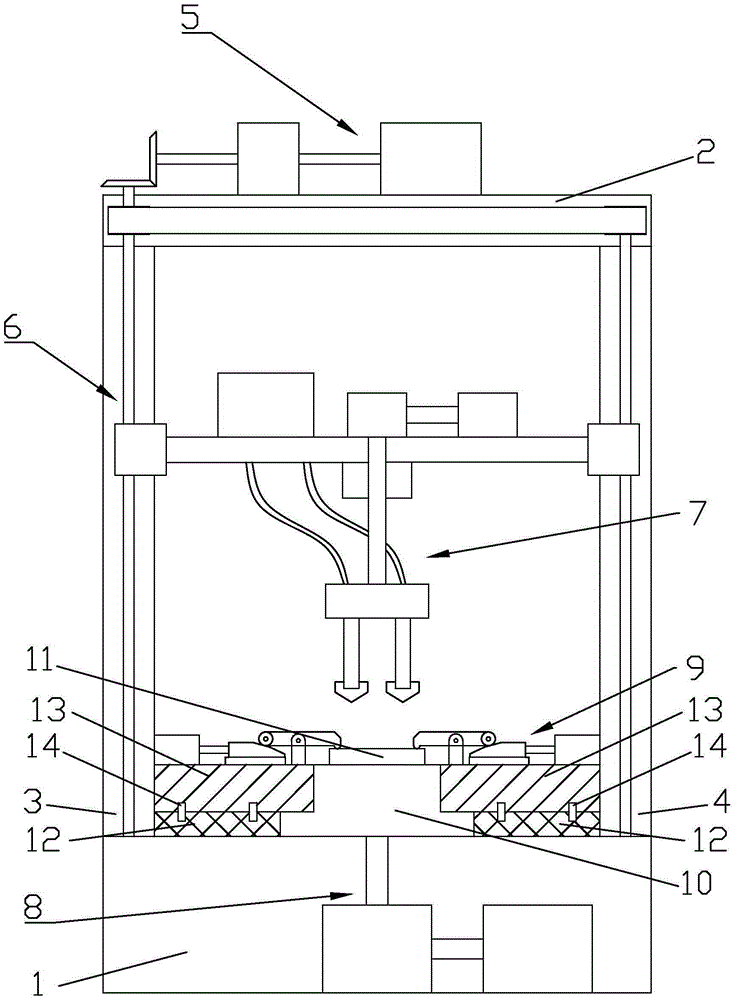

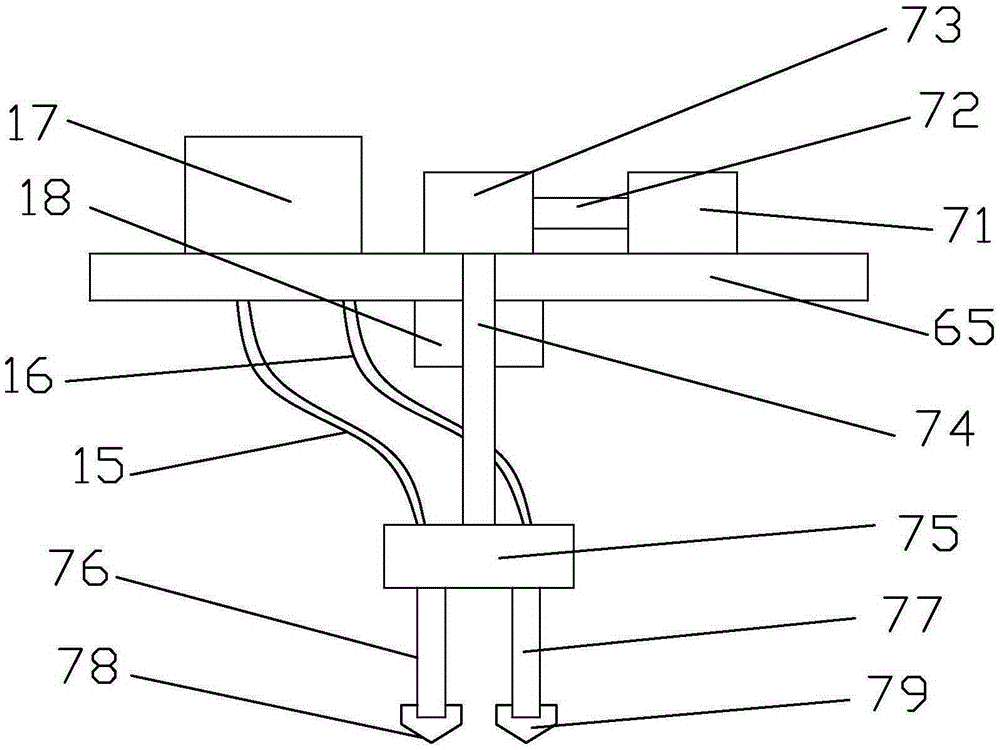

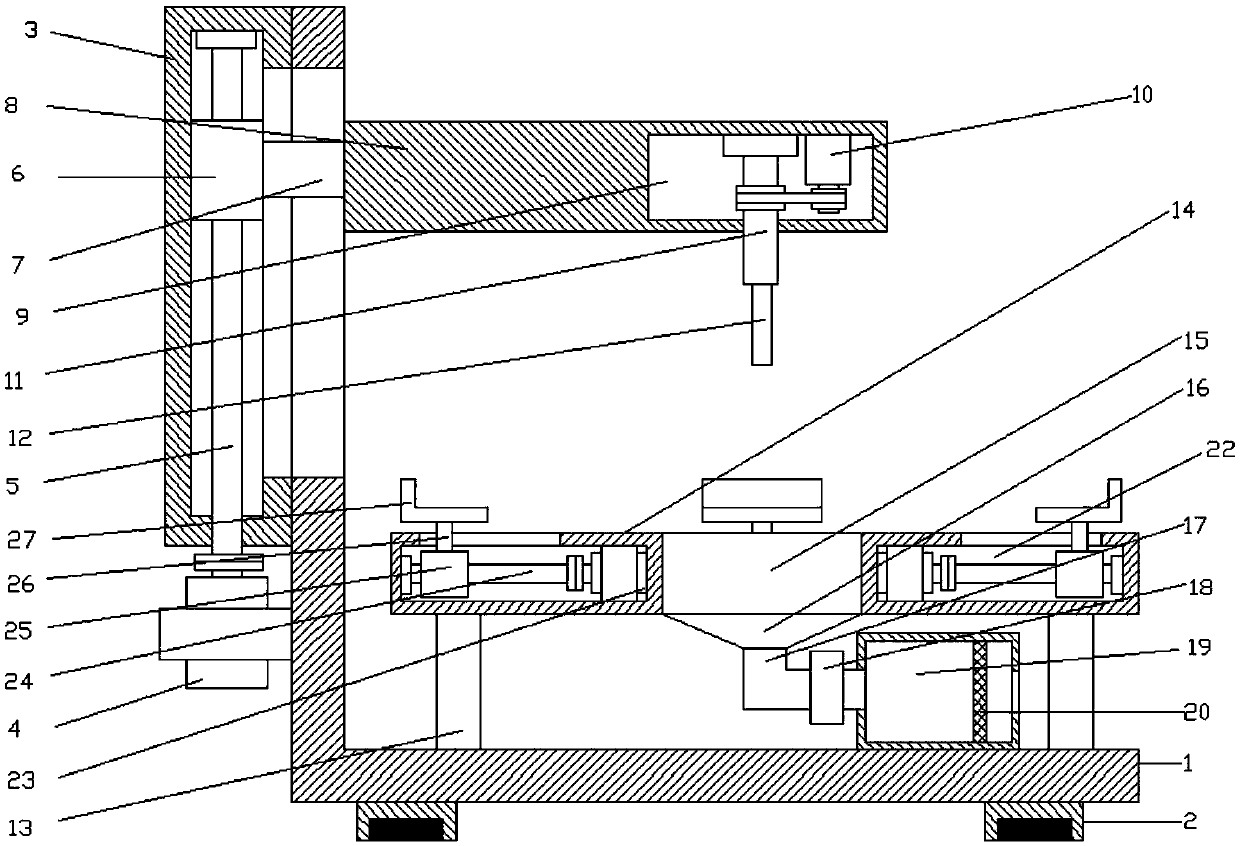

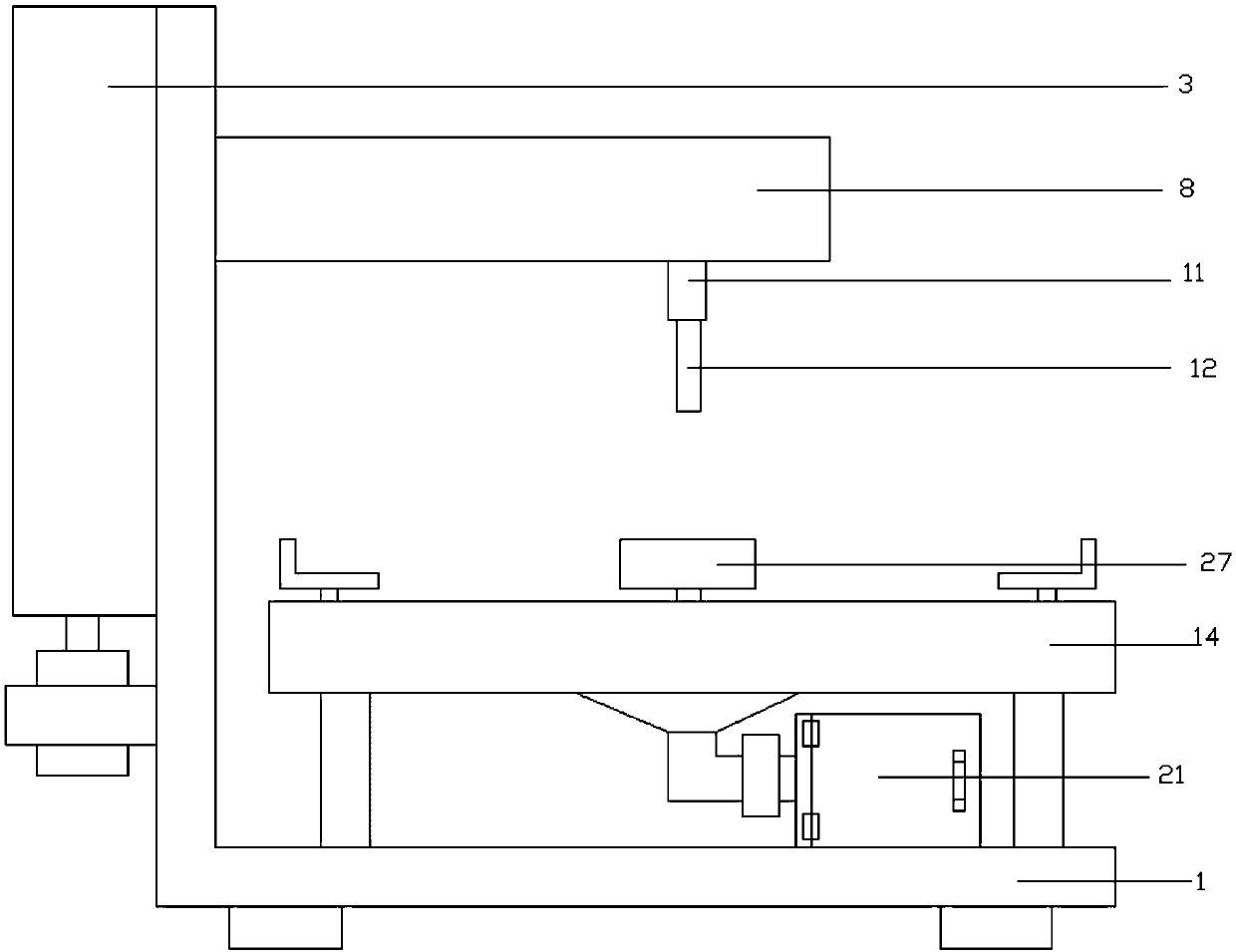

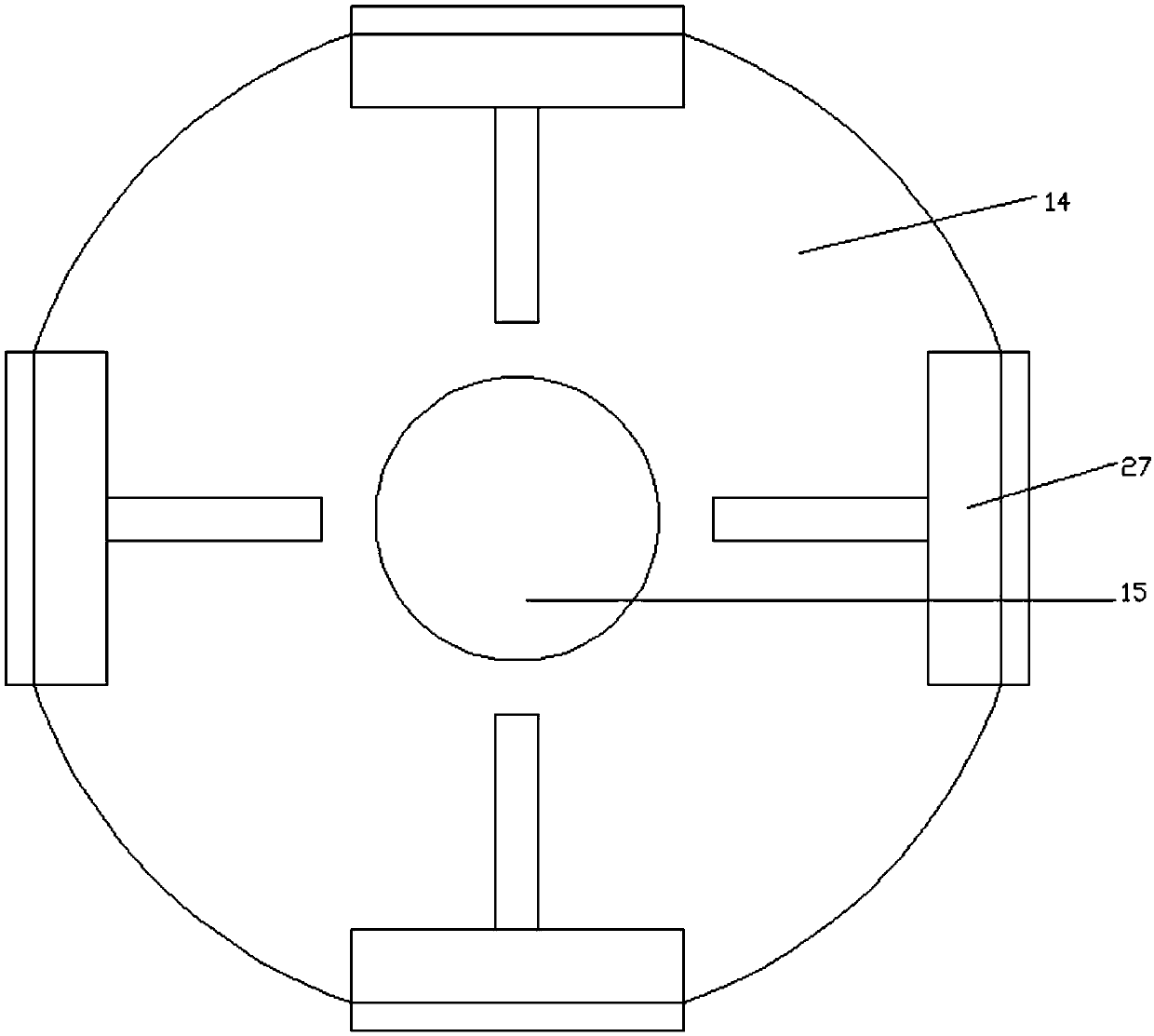

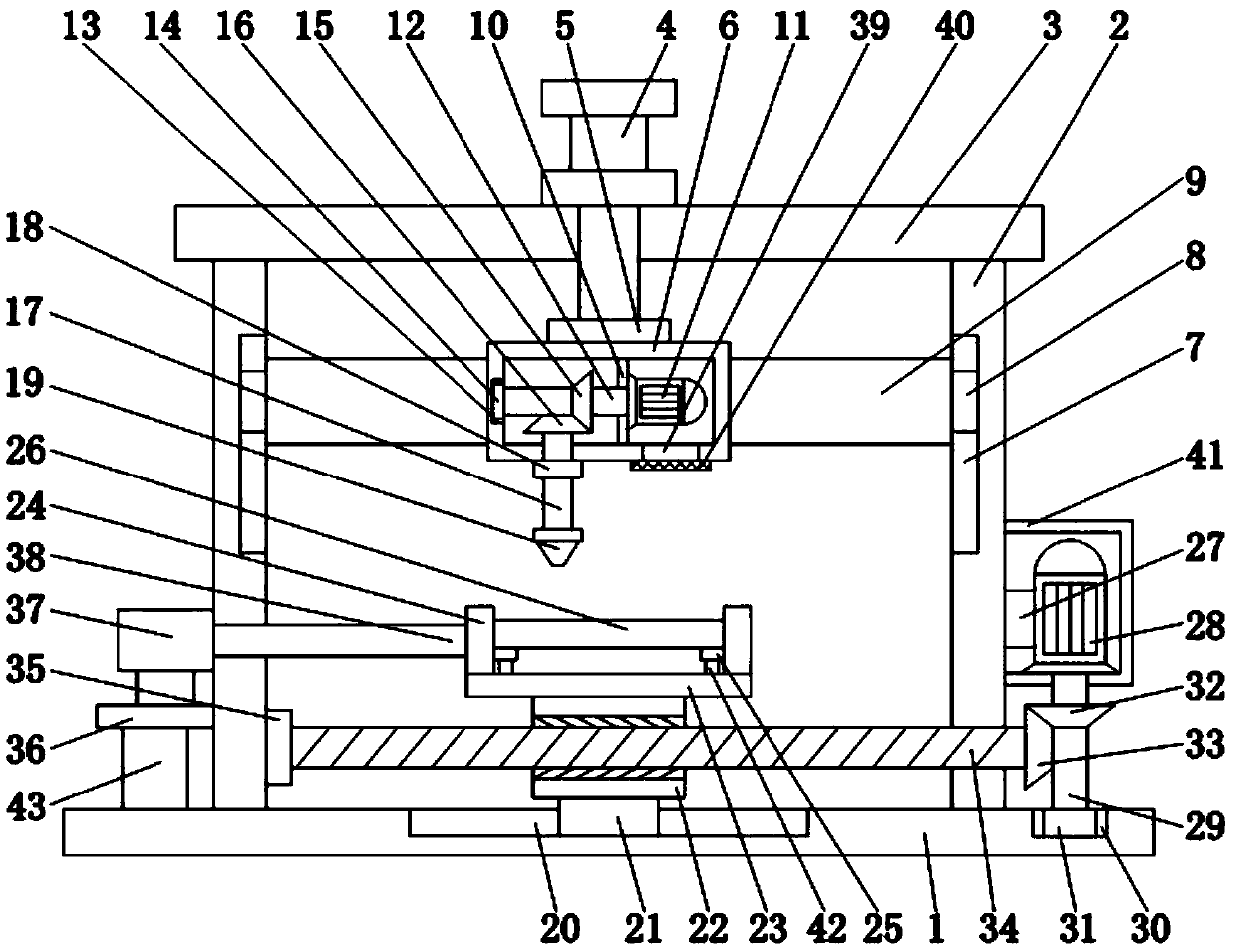

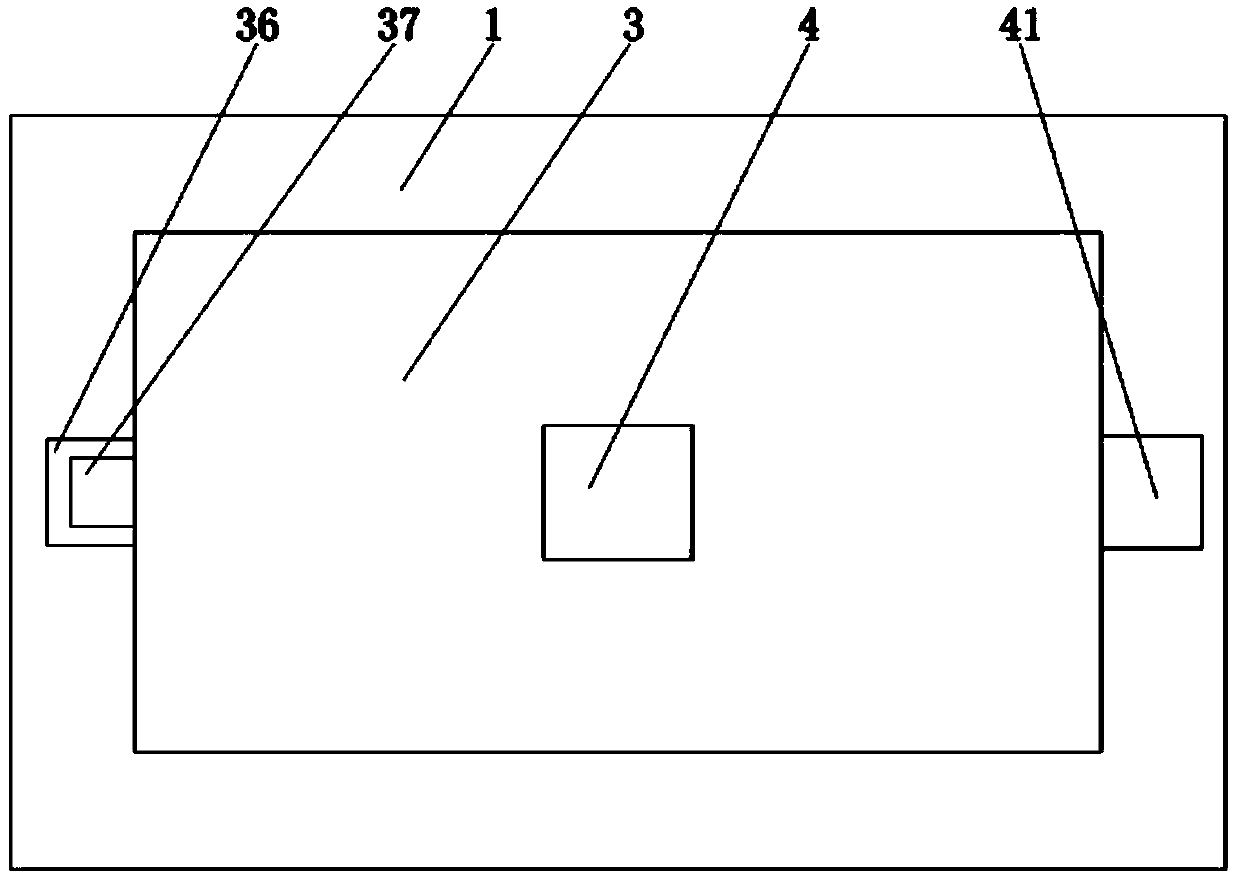

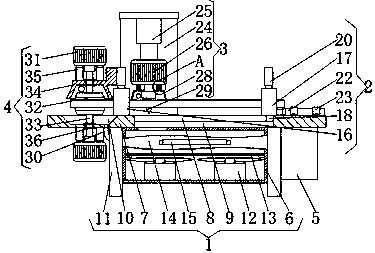

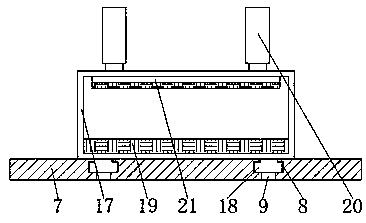

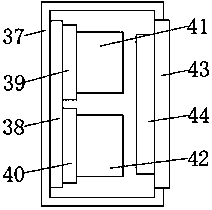

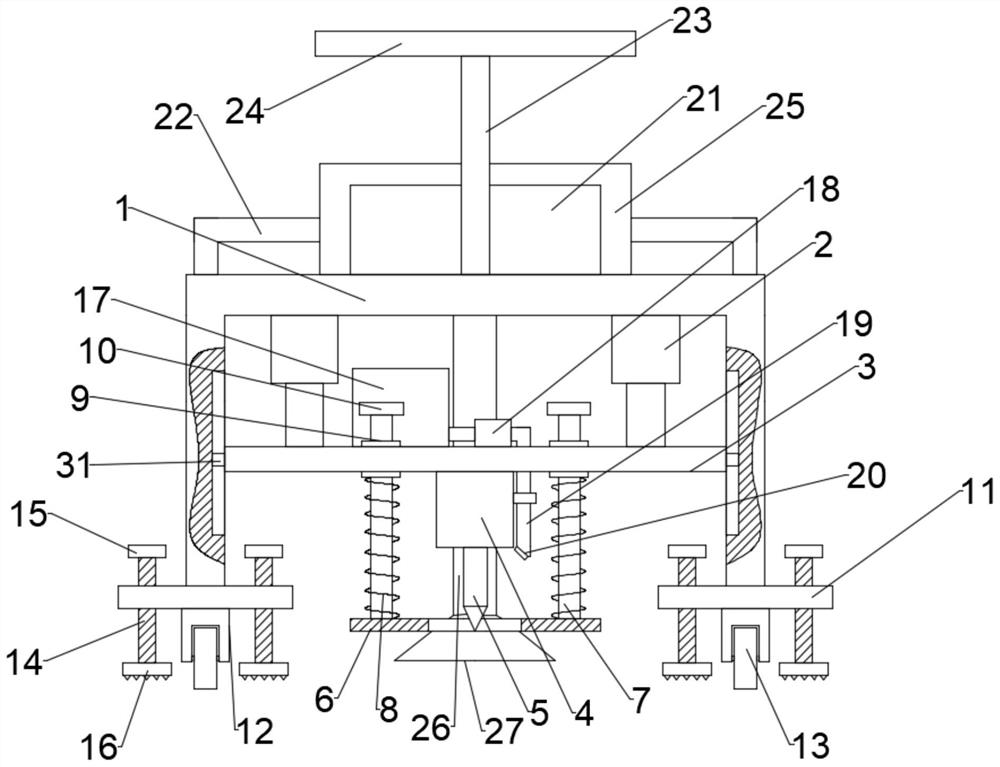

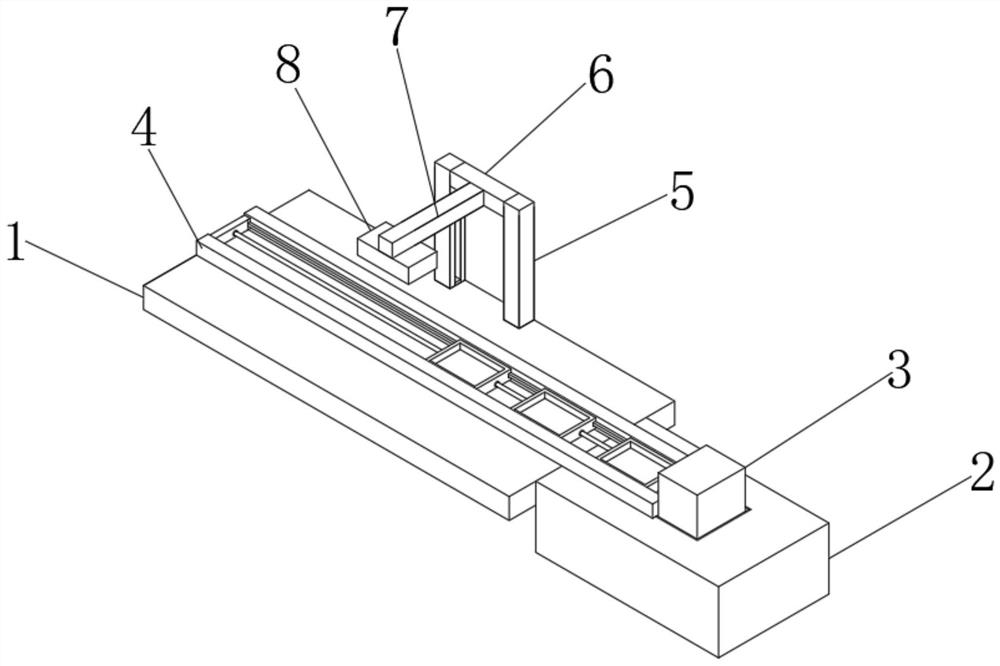

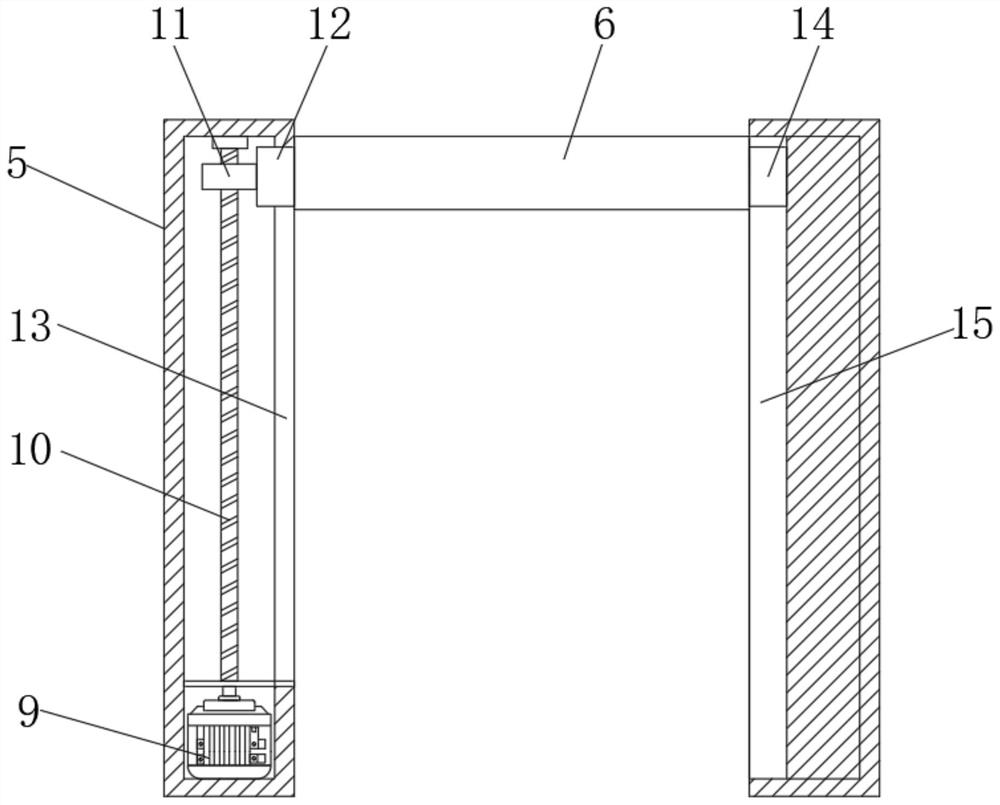

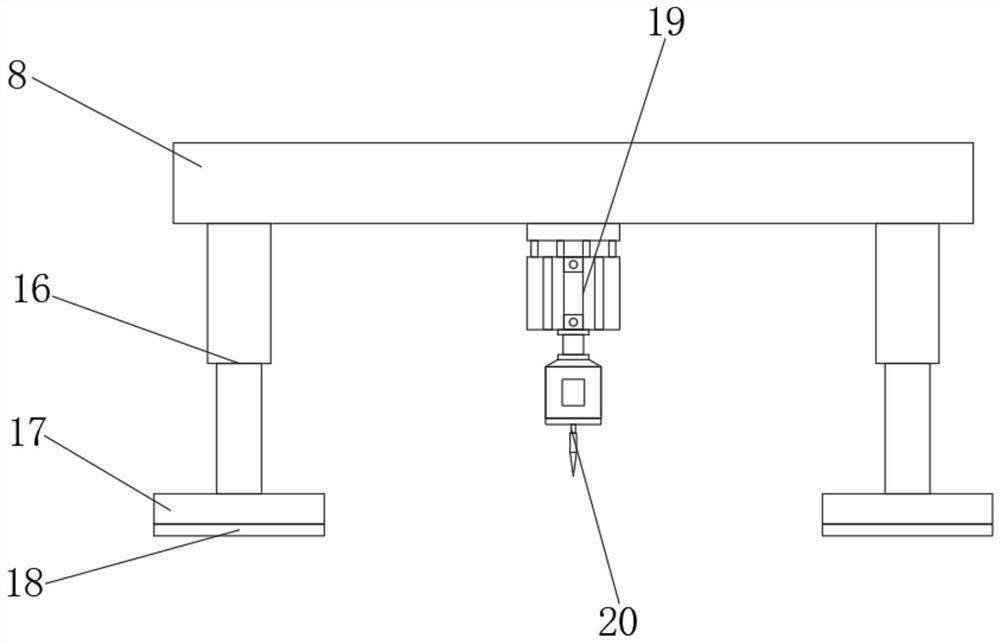

The invention discloses a drilling device applied to graphite mold production. The drilling device comprises a frame and a drilling table; drilling longitudinal frames and a drilling transverse frame are arranged on the frame; the drilling longitudinal frames are positioned at the two sides of the frame; the drilling transverse frame is positioned between the drilling longitudinal frames, and is provided with a lifting driving mechanism and a lifting mechanism; the lifting mechanism includes lifting platforms and lifting lead screws; the lifting lead screws are mounted in the drilling longitudinal frames, and are connected with lifting lead screw connecting bases; the lifting lead screw connecting bases are connected with the lifting platforms; drilling mechanisms are arranged on the lifting platforms, and include drilling motors and drilling lead screws; the drilling motors are connected with drilling motor output shafts; the drilling motor output shafts are connected with drilling speed reducers; the drilling speed reducers are connected with the drilling lead screws; the drilling lead screws are connected with drilling bases; and the drilling bases are connected with drill rods. The machine is simple in structure, strong in pertinency, precise in positioning and excellent in drilling effect, and preferably solves the drilling problem in the graphite mold production.

Owner:SHENGZHOU SIGMA TECH

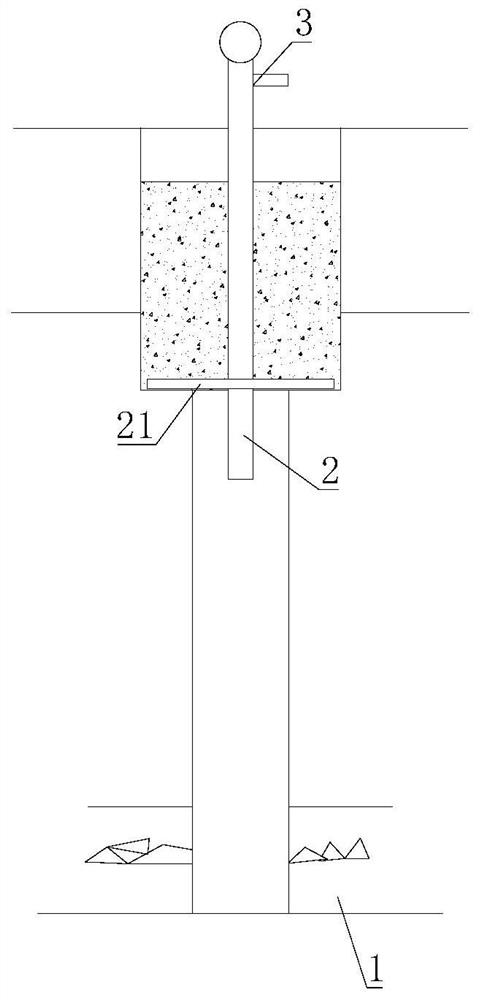

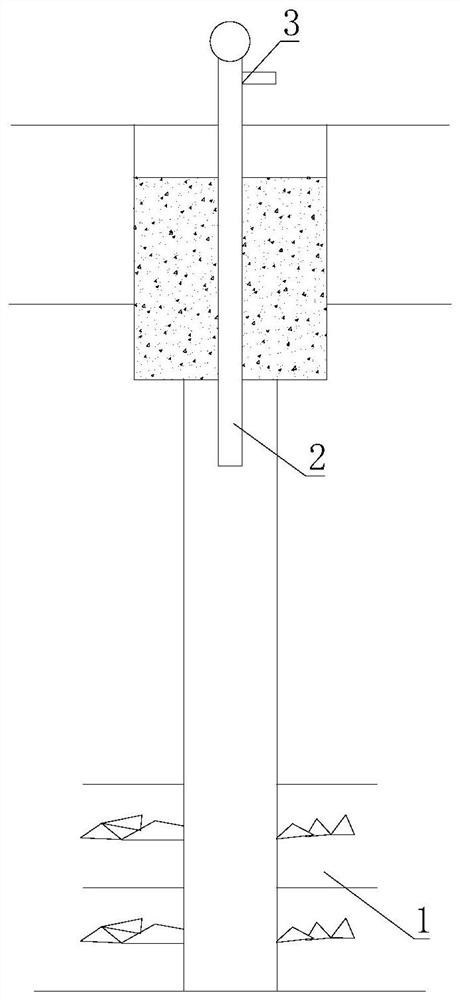

Construction method for highway to pass through coal seam goaf

InactiveCN111997685AEnsure stabilityImprove construction efficiencyDrilling rodsDirectional drillingArchitectural engineeringCement slurry

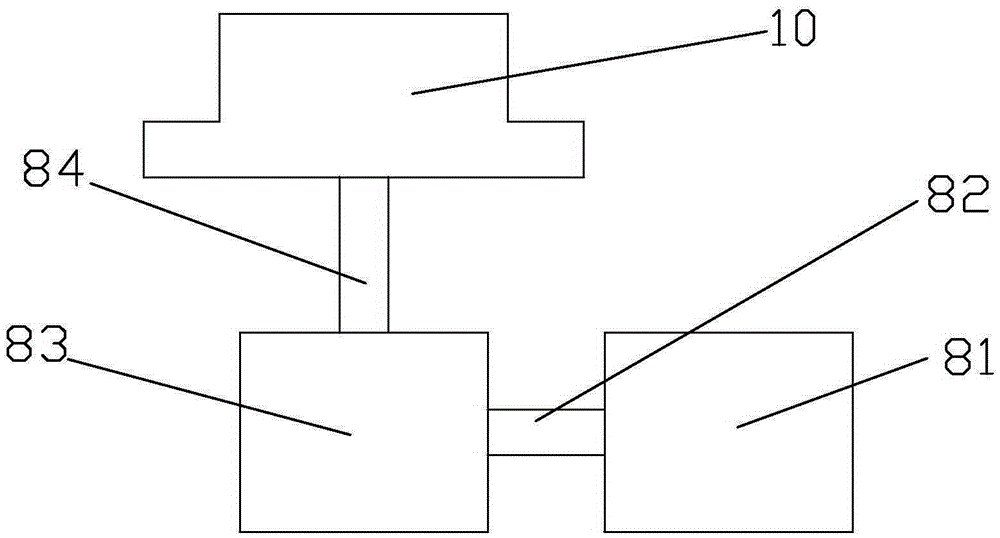

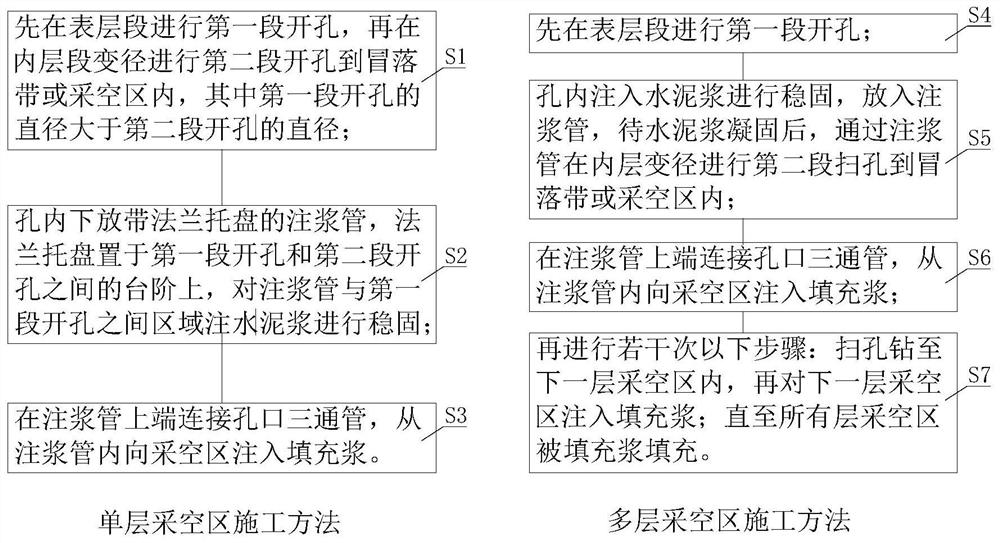

The invention belongs to the technical field of highway construction, and particularly relates to a construction method for a highway to pass through a coal seam goaf. The method includes the following steps that S1, first-section perforating is carried out on a surface section and then second-section perforating is carried out; S2, a grouting pipe with a flange is laid down, and cement slurry isinjected for stabilization; S3, filling slurry is injected to the goaf from the interior of the grouting pipe; as for a multi-layer goaf, S4, first-section perforating is carried out on a surface section; S5, cement slurry is injected into a hole for stabilization, the grouting pipe is laid down, and the hole is cleaned to a caving zone or the interior of the goaf; S6, filling slurry is injected;and S7, the following steps are sequentially carried out that the hole is drilled to a goaf in a next layer, and then filling slurry is injected into the goaf in the next layer. The construction method for the highway to pass through the coal seam goaf improves the construction efficiency of the single-layer goaf and improves the construction quality of the multi-layer goaf.

Owner:NO 3 ENG COMPANY OF CHINA RAILWAY NO 8 ENG GRP +1

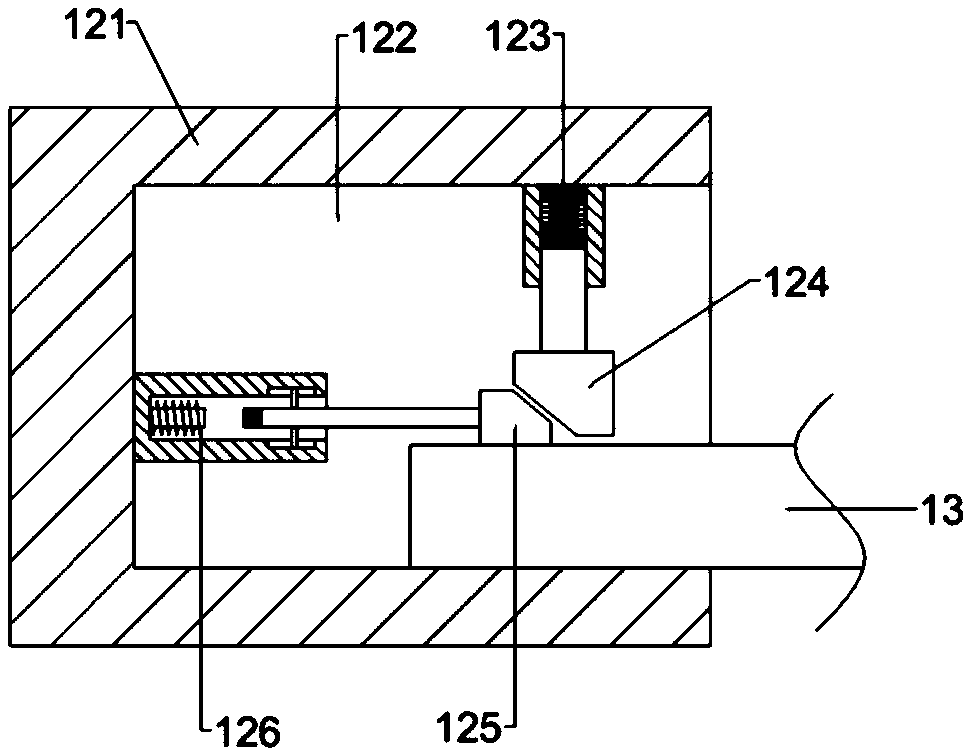

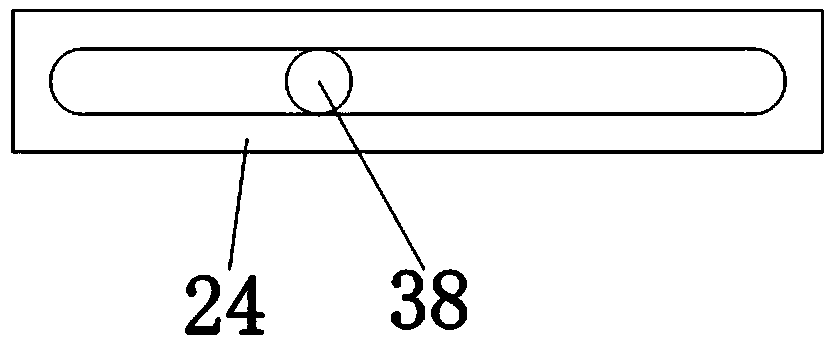

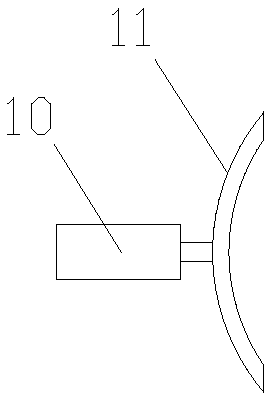

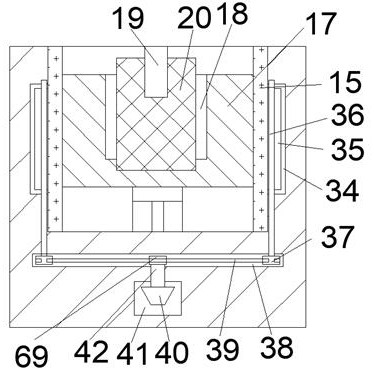

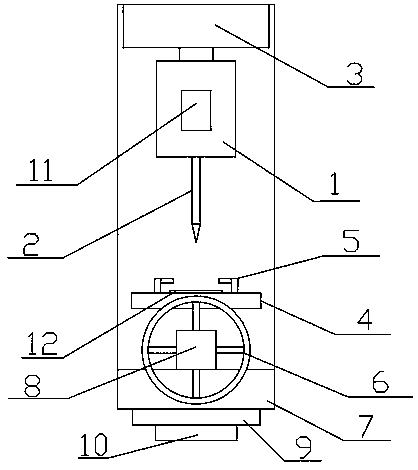

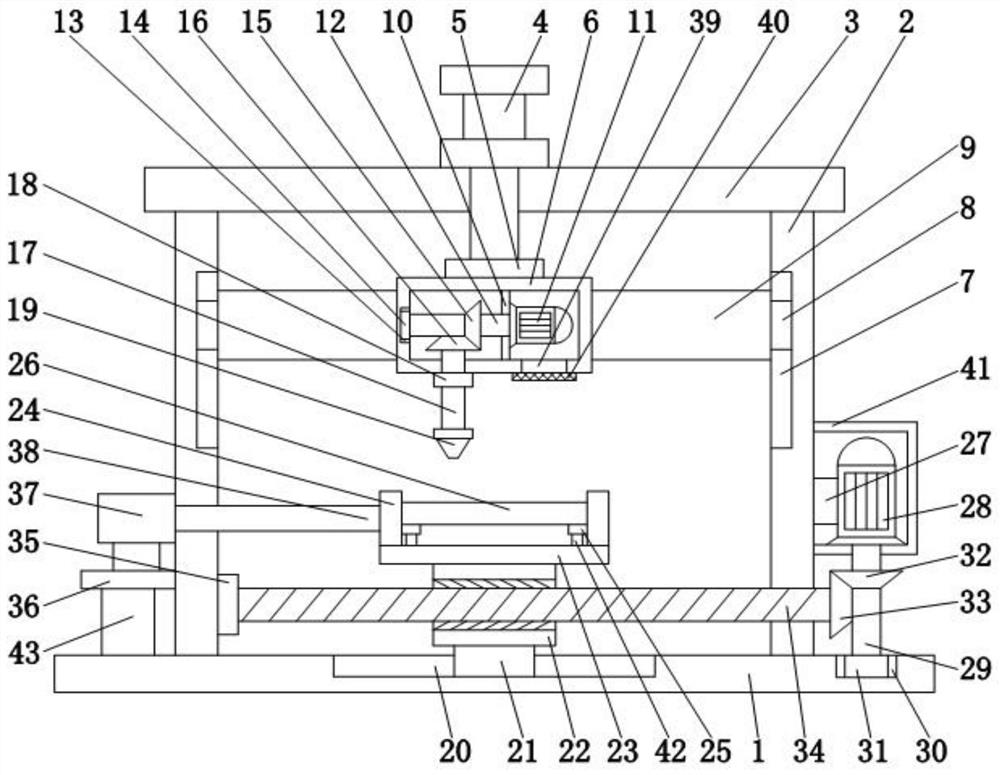

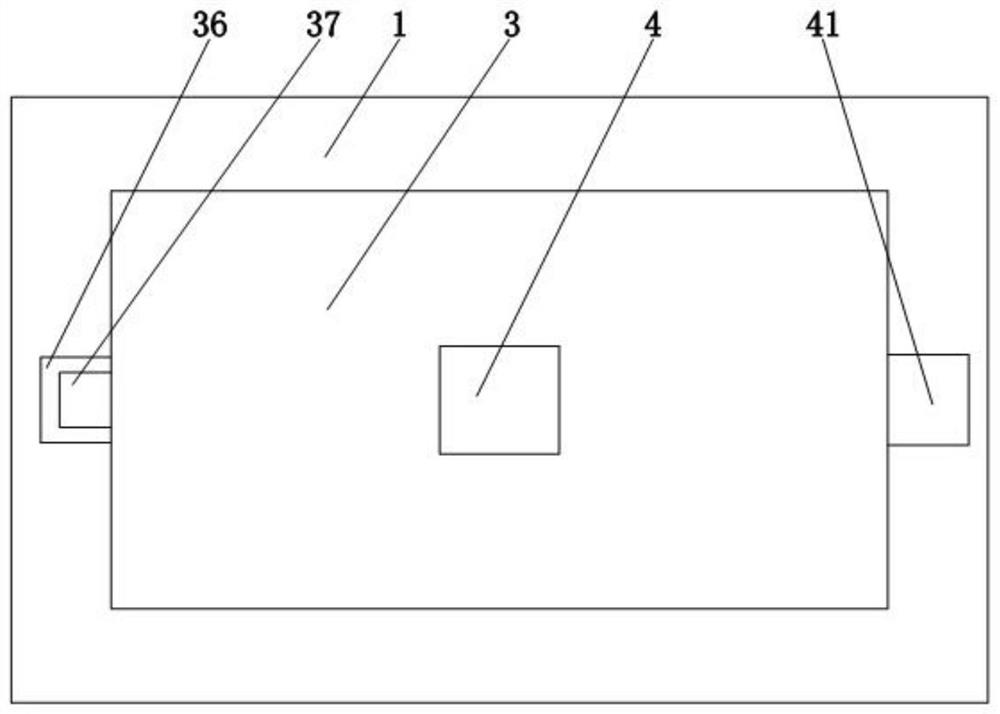

Mold drilling equipment having shift prevention function

InactiveCN108856796AConvenient drilling workAchieve releaseFeeding apparatusLarge fixed membersBlock matchScrew thread

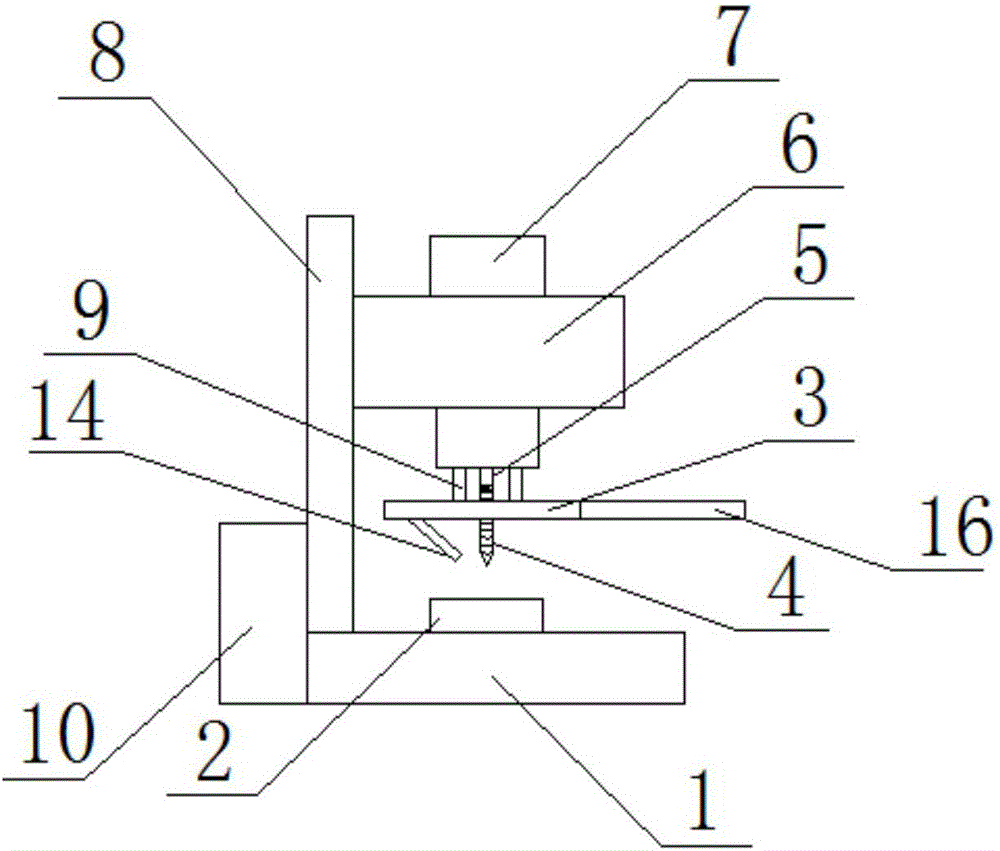

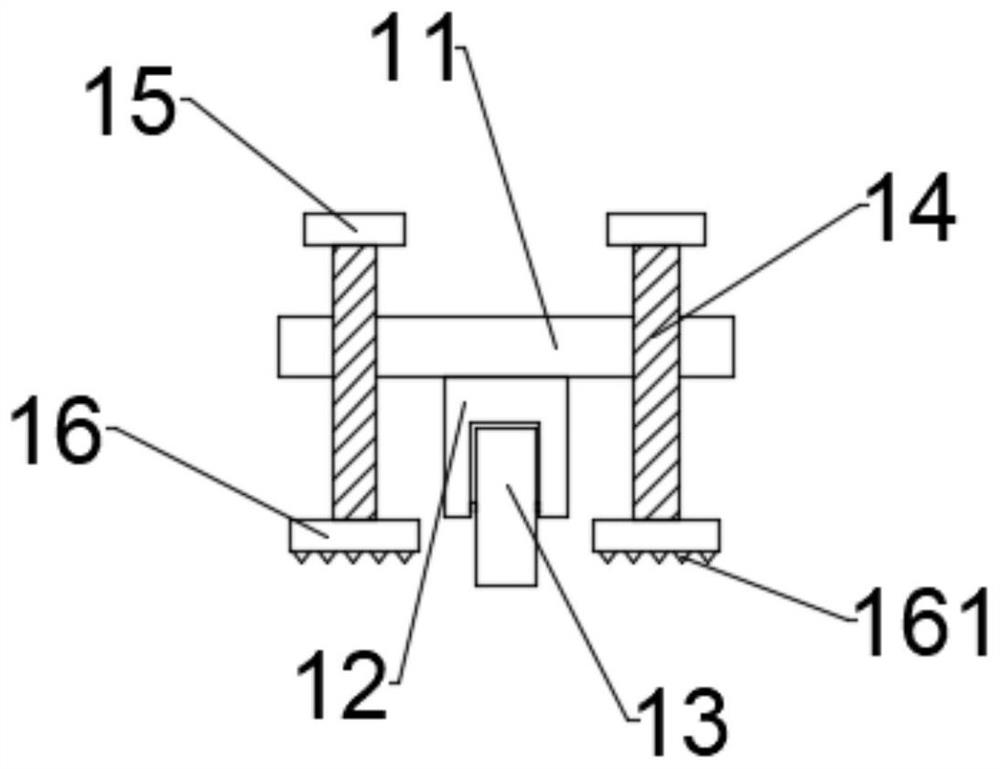

The invention discloses mold drilling equipment having the shift prevention function. The mold drilling equipment comprises a base. Two support plates are fixedly and symmetrically connected to the upper side of the base. A mounting plate is fixedly connected to the top ends of the two support plates and provided with a moving groove, wherein an opening of the moving groove faces downwards. A moving block is arranged in the moving groove and provided with a horizontal threaded through hole. A horizontal threaded rod is connected into the horizontal threaded through hole in a threaded manner. The two ends of the horizontal threaded rod are arranged at the two ends of the mounting plate in an erected manner. The mold drilling equipment has the beneficial effects that a motor output shaft drives the threaded rod to rotate, and the moving block matched with the threaded rod moves in the moving groove, so that a drilling machine is driven to move; the drilling work can be conducted at different positions on a mold conveniently; by means of locating devices, first inclined blocks move downwards to clamp the mold; and after machining is ended, second inclined blocks are driven by loosening devices to move away from the support plates, and the second inclined blocks enable the first inclined blocks to move upwards, so that loosening of the mold is achieved.

Owner:邢思义

Drilling device for abrasion-resisting building material machining

InactiveCN109014290AEasy to adjustImprove practicalityMaintainance and safety accessoriesBoring/drilling machinesMaterials processingWear resistance

The invention discloses a drilling device for abrasion-resisting building material machining. The drilling device comprises a drilling machine body with the bottom provided with a fixing base. An airblowing device is arranged on one side of the drilling machine body, and a dust collecting device is arranged on the other side of the drilling machine body. Damping wheels are fixedly arranged on thelower surface of the fixing base. A stand column is fixedly arranged at the rear side position of the upper surface of the fixing base, and a sliding rail is vertically arranged on the front surfaceof the stand column. The drilling device is scientific and reasonable in structure and convenient to operate; through the action of a lifting air cylinder, a worktable can be driven to slide on the sliding rail up and down, accordingly, height adjustment of the worktable is achieved, an operator can conveniently conduct height adjustment according to the actual usage requirement, convenience is provided for users, and the practicability of the drilling device is improved; and through sliding grooves, a movable worktable top can slide on the workbench, left-right adjustment of the movable worktable top is achieved, drilling work can be conveniently conducted, and the work efficiency is improved to a certain degree.

Owner:WUHU HUANGSHANSONG IND FLOOR NEW MATERIAL CO LTD

Efficient drilling equipment for building construction

InactiveCN109514283AEasy to useEasy to collectLarge fixed membersPositioning apparatusArchitectural engineeringExhaust pipe

The invention discloses efficient drilling equipment for building construction. The efficient drilling equipment for building construction comprises an L-shaped support plate, a sliding groove is formed in the left side of the L-shaped support plate, a first motor is arranged on the lower side of the sliding groove, a first screw rod is arranged on the upper side of the first motor, a first sliding block is arranged on the first screw rod, a connecting rod is arranged on the right side of the first sliding block, a supporting plate is arranged on the right side of the connecting rod, a connecting cavity is formed inside the support plate, a second motor is arranged at the right end of the connecting cavity, a bit connecting seat is arranged on the left side of the second motor, supportinglegs are arranged at four corners of the upper side of the L-shaped support plate, a connecting exhaust pipe is arrange on the upper sides of the supporting legs, an impurity storage box is arranged on the right side of the exhaust pipe, a sliding groove is formed in the periphery of the outer side of an opening, a third motor is arranged at the inner end inside the sliding groove, a second screwrod is arranged on the outer side of the third motor, a second sliding block is arranged on the second screw rod, a supporting rod is arranged on the upper side of the second sliding block, and an L-shaped clamping plate is arranged on the upper side of the supporting rod. According to the efficient drilling equipment for building construction, continuous drilling of the equipment is effectively facilitated, impurity storage of drilling is convenient, and thus using of people is convenient.

Owner:广西东创智能科技有限公司

Drilling machine

InactiveCN105855985AStop splashProtection securityMetal working apparatusMaintainance and safety accessoriesWorkbenchDrilling machines

The invention discloses a drilling machine, comprising: a workbench (1), a drilling mechanism, a support rod (8), a telescopic rod (9) and a protective cover (3), and the support rod (8) is vertically arranged on the workbench ( 1) on the upper surface, the drilling mechanism is arranged on the support rod (8), and the drilling mechanism can slide along the length direction of the support rod (8), the telescopic rod (9) is vertically arranged, and the telescopic rod (9) One end is fixed on the lower surface of the drilling mechanism, the other end is connected with the upper surface of the protective cover (3), the lower surface of the protective cover (3) is recessed inwardly to form a cavity (12), and the upper surface of the protective cover (3) is vertically A first through hole (11) matched with the drilling mechanism is provided. The drilling machine overcomes the prior art. The drilling machine does not have a corresponding debris handling vertical structure, and the debris generated splashes around, which not only increases the cleaning workload of the user, but also has poor safety, which poses a threat to the safety of the user. Certainly threatening issues.

Owner:YINFENG CASTING WUHU CO LTD

Steel structure drilling device convenient to use

ActiveCN109570550AReduce labor intensityReduce drilling errorsPositioning apparatusBoring/drilling componentsDrill bitUltimate tensile strength

The invention discloses a steel structure drilling device convenient to use. The steel structure drilling device comprises a bottom plate, the left side and the right side of the top of the bottom plate are both fixedly connected with supporting plates, the tops of the two supporting plates are fixedly connected through a top plate, the top of the top plate is fixedly connected with an air cylinder, and the bottom end of the air cylinder penetrates through the top plate and extends to the exterior of the top plate. According to the steel structure drilling device convenient to use, through mutual cooperation of the air cylinder, a drilling motor, a drilling rotating shaft, a first gear, a second gear, a rotating shaft, a second bearing, a drill bit, a threaded block, an adjusting motor, anadjusting rotating shaft, a third bearing, a third gear, a fourth gear, a threaded rotating shaft, a fourth bearing, a horizontal-moving motor and a strip-shaped gear groove, the problem of inconvenient use of a common steel structure drilling device is solved, when a plurality of drilled holes are formed in a steel structure, an automatic adjustment mode is adopted, the drilling position is convenient to adjust, the labor intensity of workers is lowered, the drilling error is reduced, and great convenience is brought to drilling work.

Owner:湖南常德辰馨科技发展有限公司

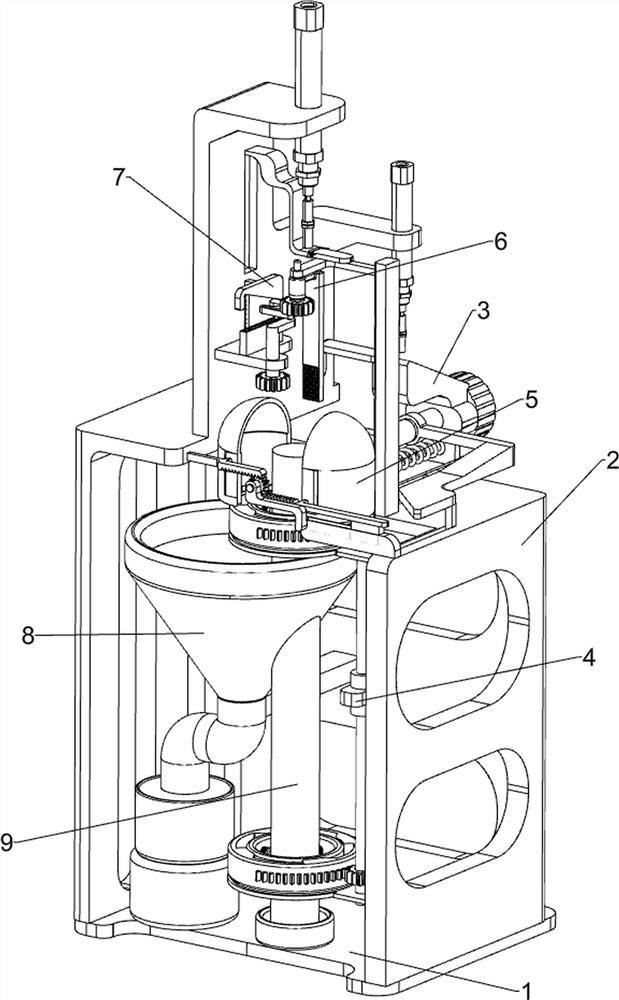

Drilling device for industrial automation

InactiveCN110711873AReduce labor intensityAvoid flying aroundWork clamping meansPositioning apparatusThermodynamicsDust control

The invention discloses a drilling device for industrial automation. The drilling device for the industrial automation comprises a bottom plate, a frame body, a control box, a collection box, a drilling mechanism, a clamping mechanism and a dust removal mechanism, wherein the frame body is installed at the top of the bottom plate, and the control box is installed at the top of the frame body. Thedrilling device for the industrial automation controls the drilling mechanism, the drilling mechanism and the dust removal mechanism through the control box, and performs drilling work for workpiecesby adopting an automatic mode, and compared with manual operation, the drilling device for the industrial automation reduces labor intensity of workers, reduces manual cost, and improves production efficiency. By arranging the clamping mechanism, when the drilling device for the industrial automation processes the workpieces of different quantities or different sizes, clamp customization is not needed, and therefore not only is cost input reduced, but also manual work is not needed for fixing the workpieces, labor intensity is reduced, and work efficiency is improved. The drilling device for the industrial automation can prevent chippings generated in drilling from flying apart in all directions, prevents potential safety hazard from being caused, and brings great convenience to drilling work.

Owner:XIAN YONGXIN TECH CO LTD

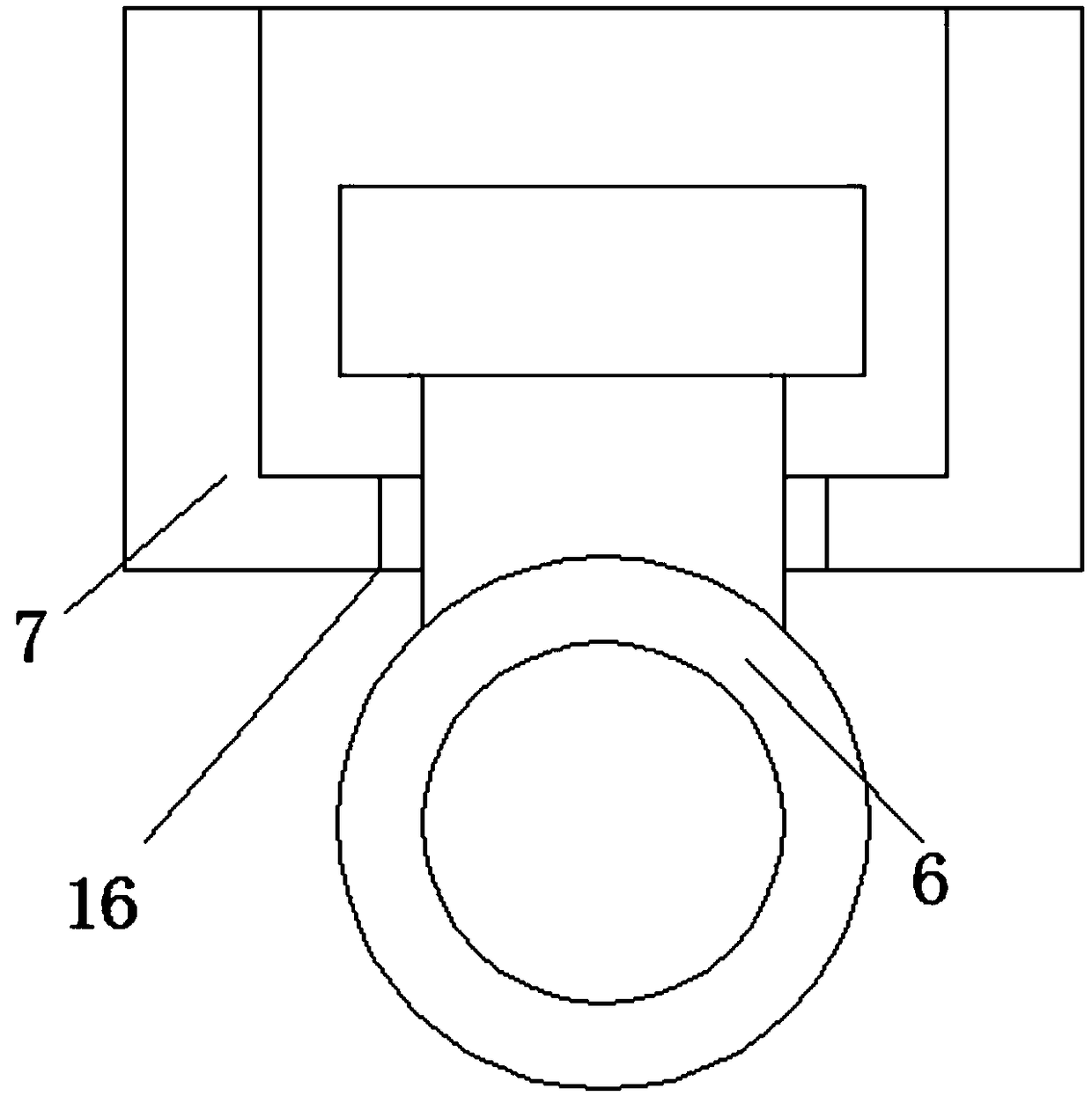

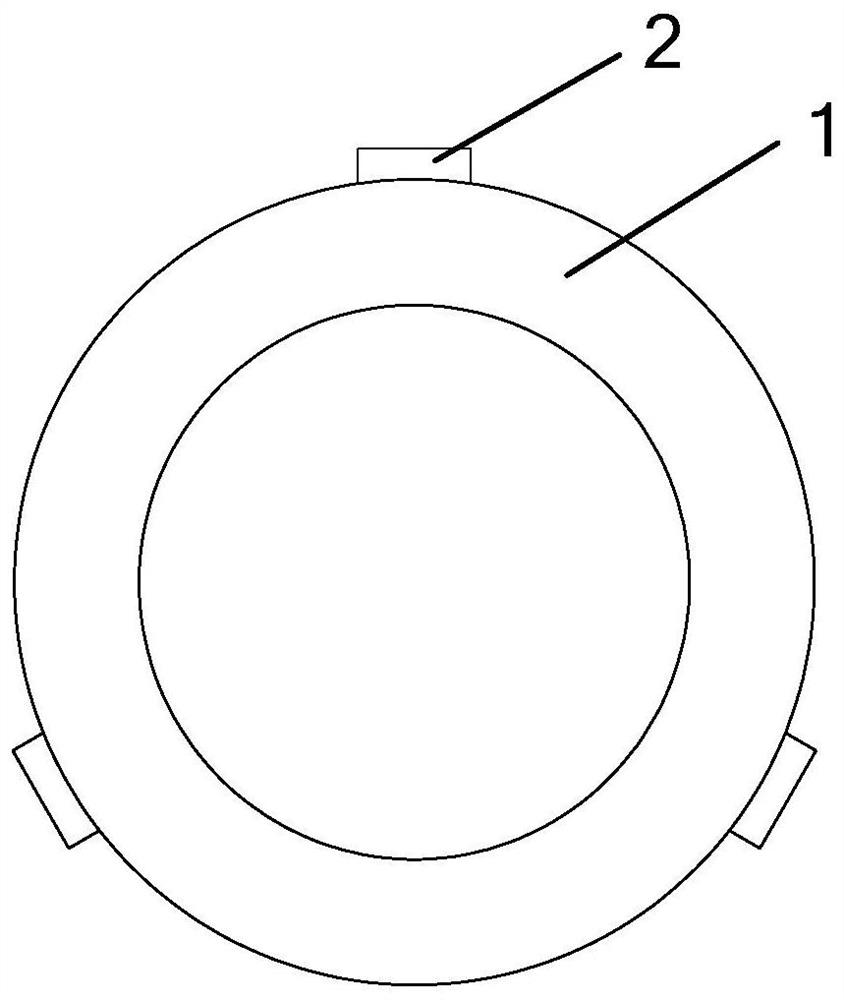

Locating and adjusting device for drilling automobile wheel hub

InactiveCN108406390AEasy to processSave human effortMetal working apparatusPositioning apparatusEngineeringCoupling

The invention discloses a locating and adjusting device for drilling an automobile wheel hub. The locating and adjusting device comprises a workbench, a first supporting leg and a second supporting leg are separately and movably connected to the front side and the rear side of the workbench through connecting pins, an electric push rod is arrange on the first supporting leg, and a cushion plate isarranged at the bottom of the first supporting leg. A cushion plate is further movably connected to the bottom of the second supporting leg through a connecting pin. A motor is arranged in the middleposition of the bottom of the workbench, and an output shaft of the motor penetrates through the workbench through a coupling and is connected with a rotary table. A first clamping block is connectedto the top of the left side of the workbench through an air cylinder, a second clamping block is fixedly installed to the position, located on one side of the rotary table, of the right side of the workbench, a material receiving slot is formed in the bottom of the rear side of the workbench, and a mesh plate is obliquely arranged in the material receiving slot. The locating and adjusting devicefor drilling the automobile wheel hub facilitates the drilling operation of automobile wheel hub, facilitates the drilling work of inclined position, facilitates the processing and saves manpower.

Owner:芜湖市新海域智能科技有限公司

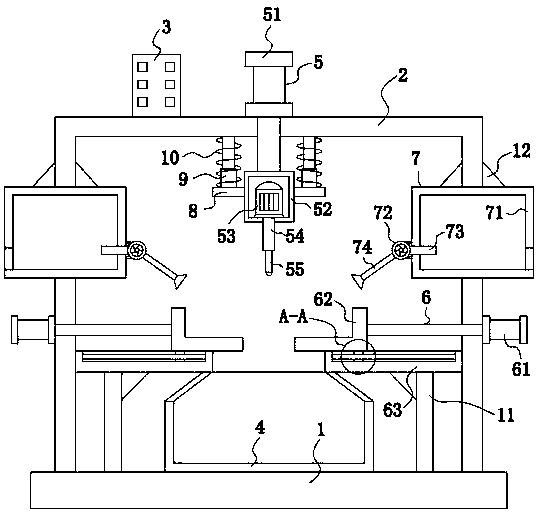

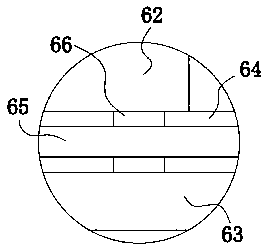

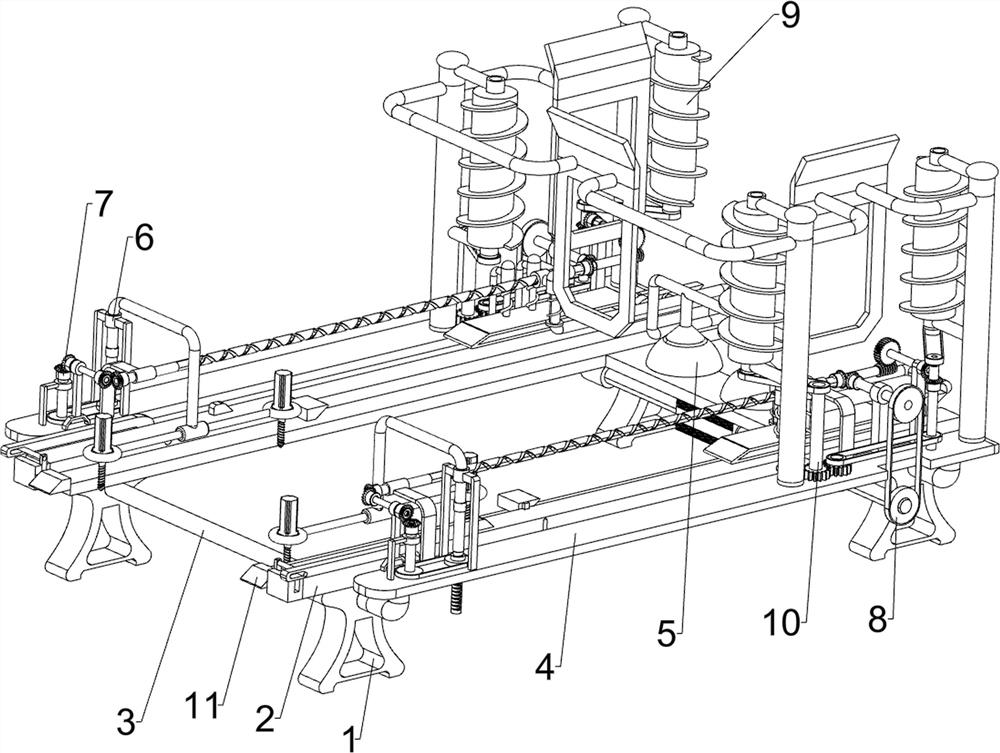

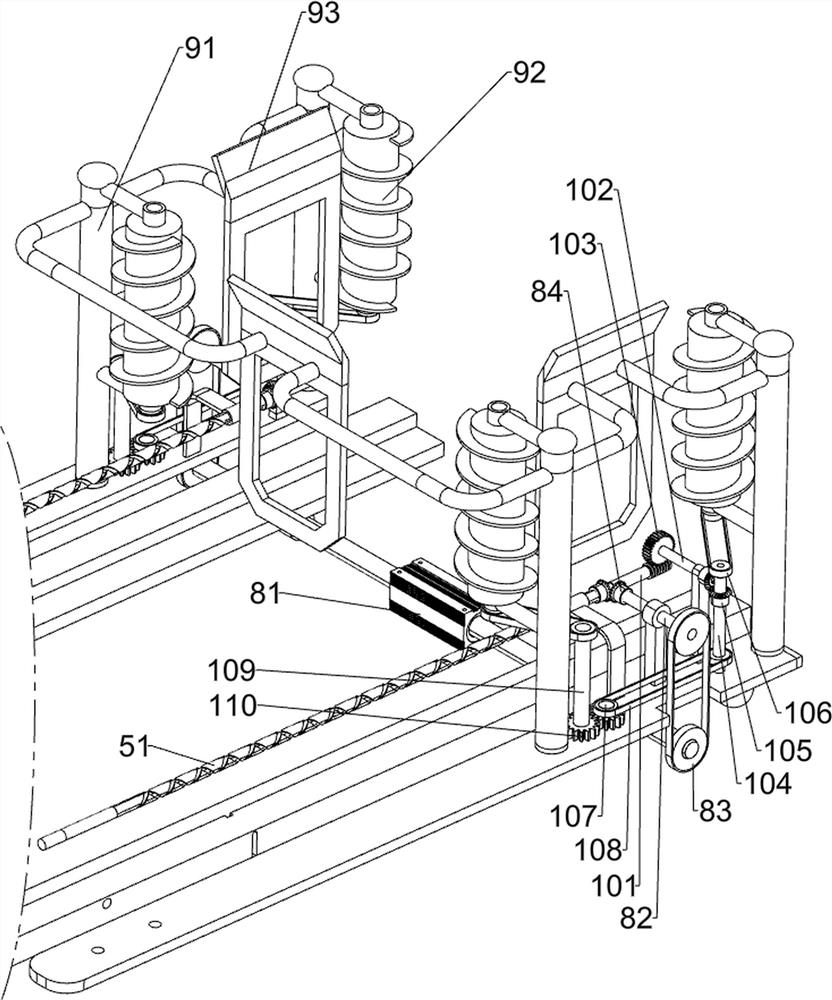

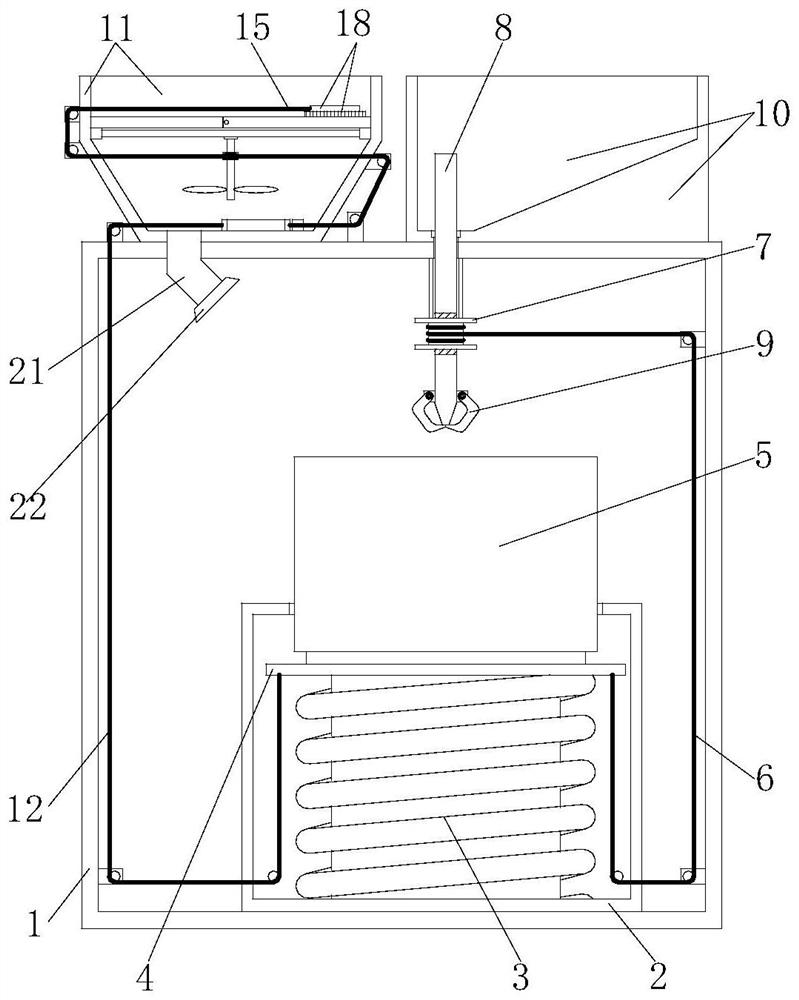

Part drilling device for new energy automobile production

ActiveCN112828340AAccelerateImprove work efficiencyFeeding apparatusPositioning apparatusPhysicsDrill hole

The invention relates to a drilling device, in particular to a part drilling device for new energy automobile production. The part drilling device for new energy automobile production aims at achieving the technical effects that the cooling speed is high, and the chipping cleaning function is achieved. According to the technical scheme, the part drilling device for new energy automobile production comprises a base, M-shaped frames, first special-shaped frames, a workbench, a servo motor and the like, the M-shaped frames are arranged on the left side and the right side of the top of the base, the M-shaped frames are also arranged on the left portion and the right portion of the rear side of the top of the base, the first special-shaped frames are arranged on the inner sides of the M-shaped frames on the front side, the workbench is arranged on the front side of the top of the base, a round hole is formed in the workbench, and the servo motor is arranged between the first special-shaped frames. A pressing assembly is driven to move downwards under the action of a downward pressing assembly, so that the automobile parts on the workbench of the pressing assembly are pressed.

Owner:淄博宝来霖机械铸造有限公司

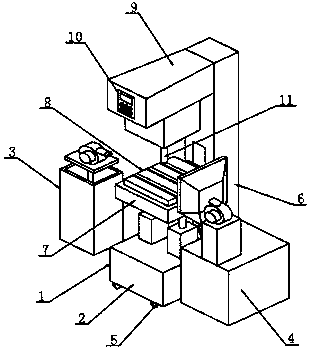

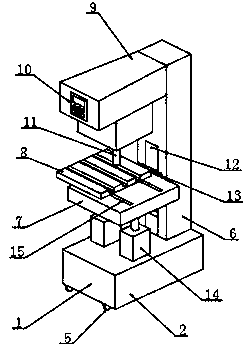

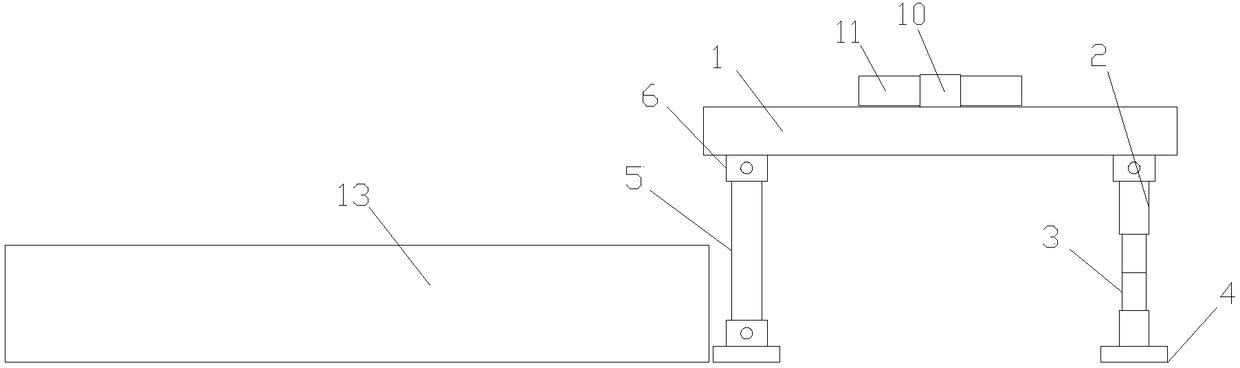

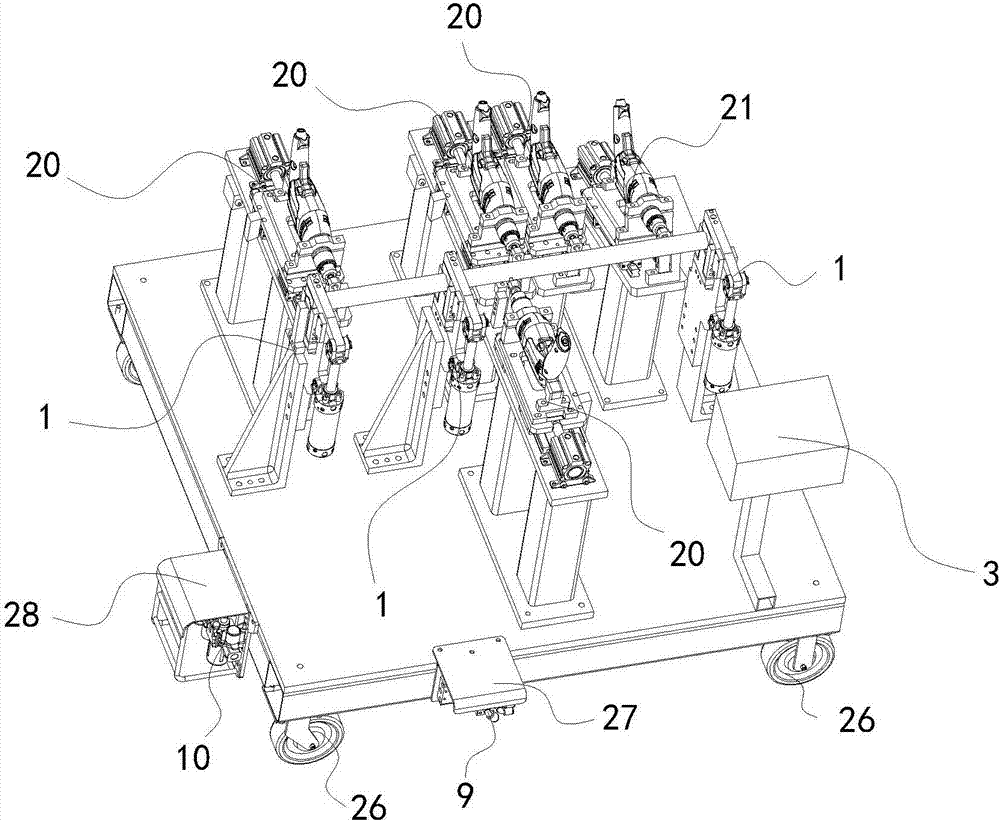

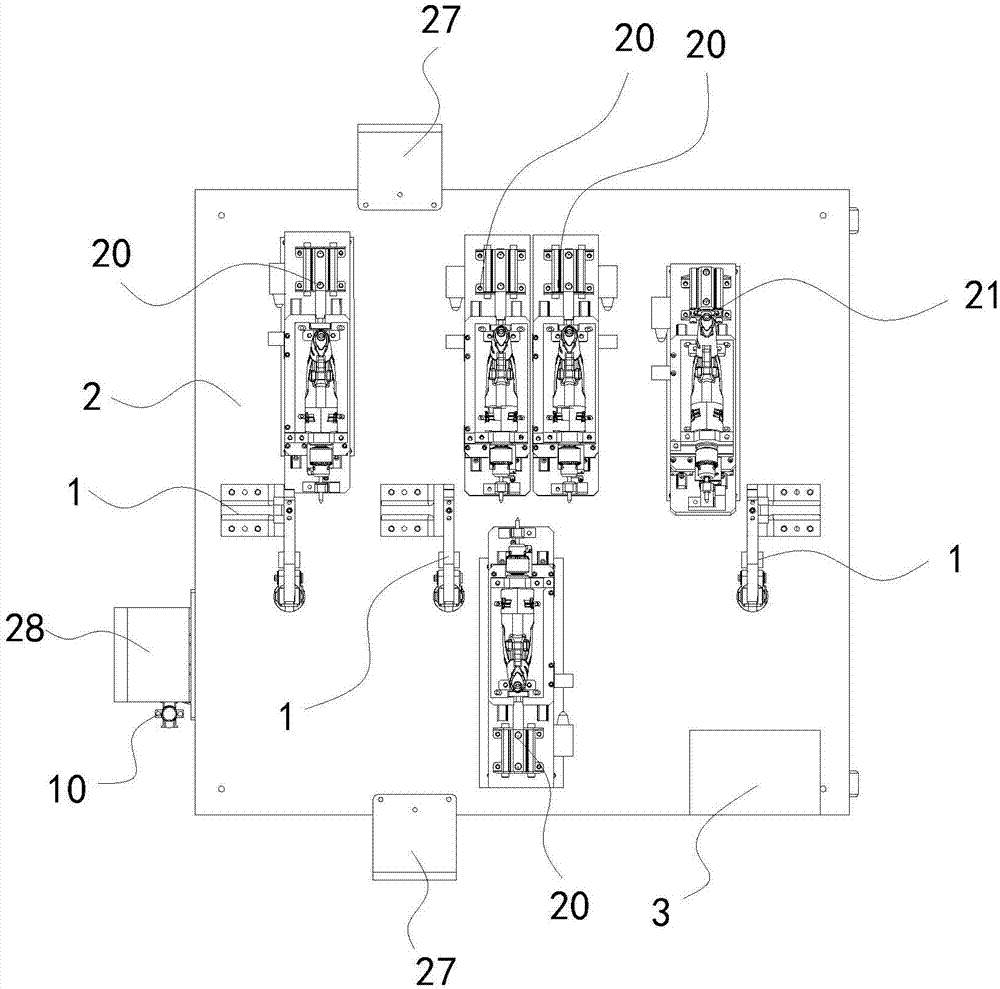

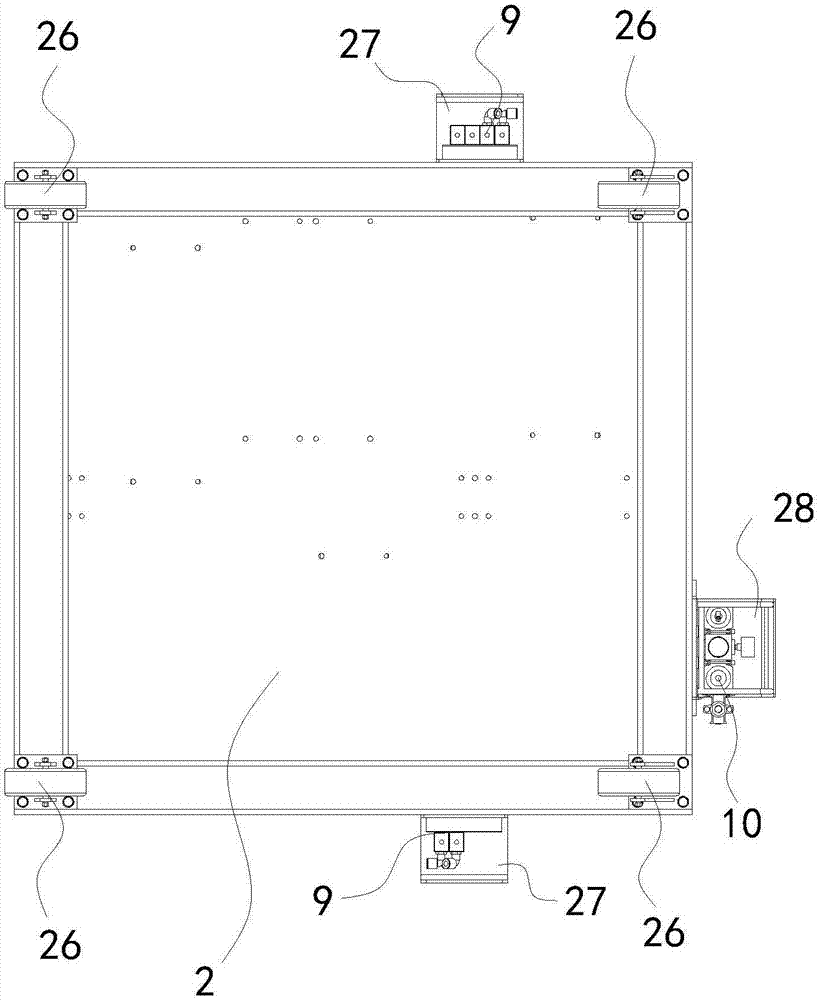

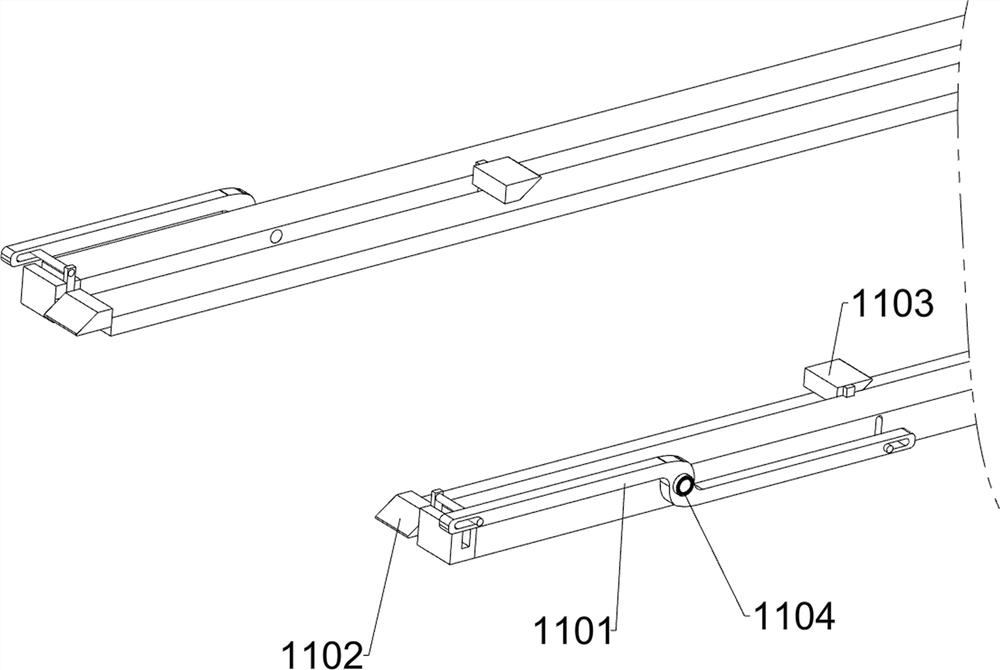

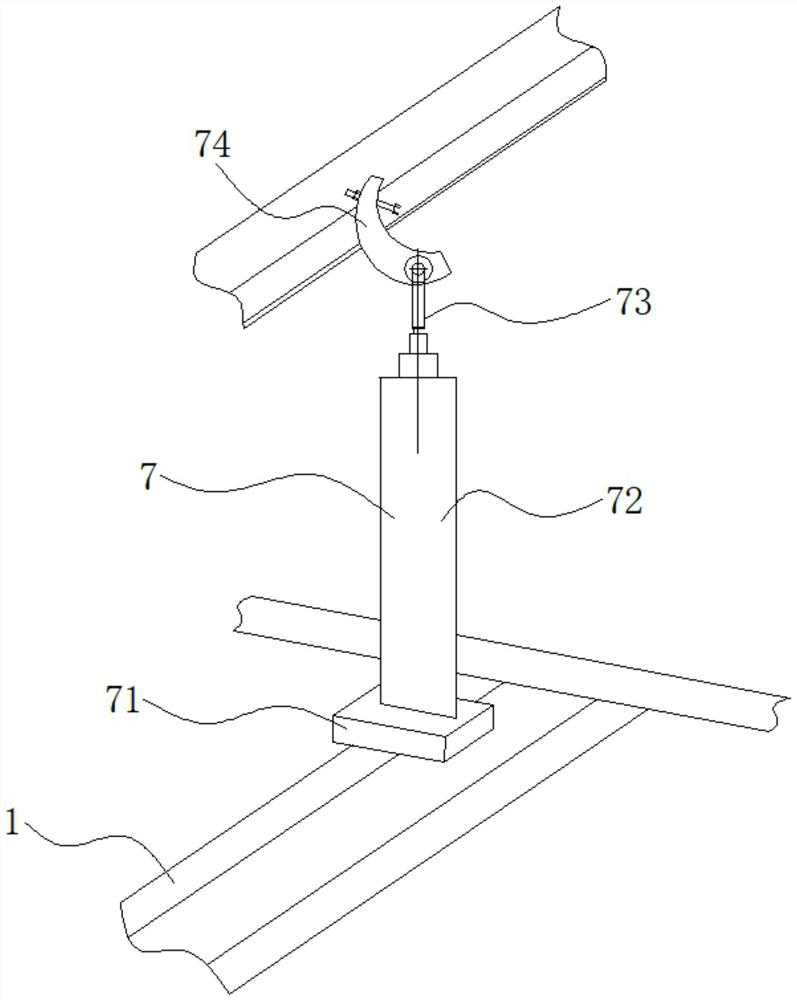

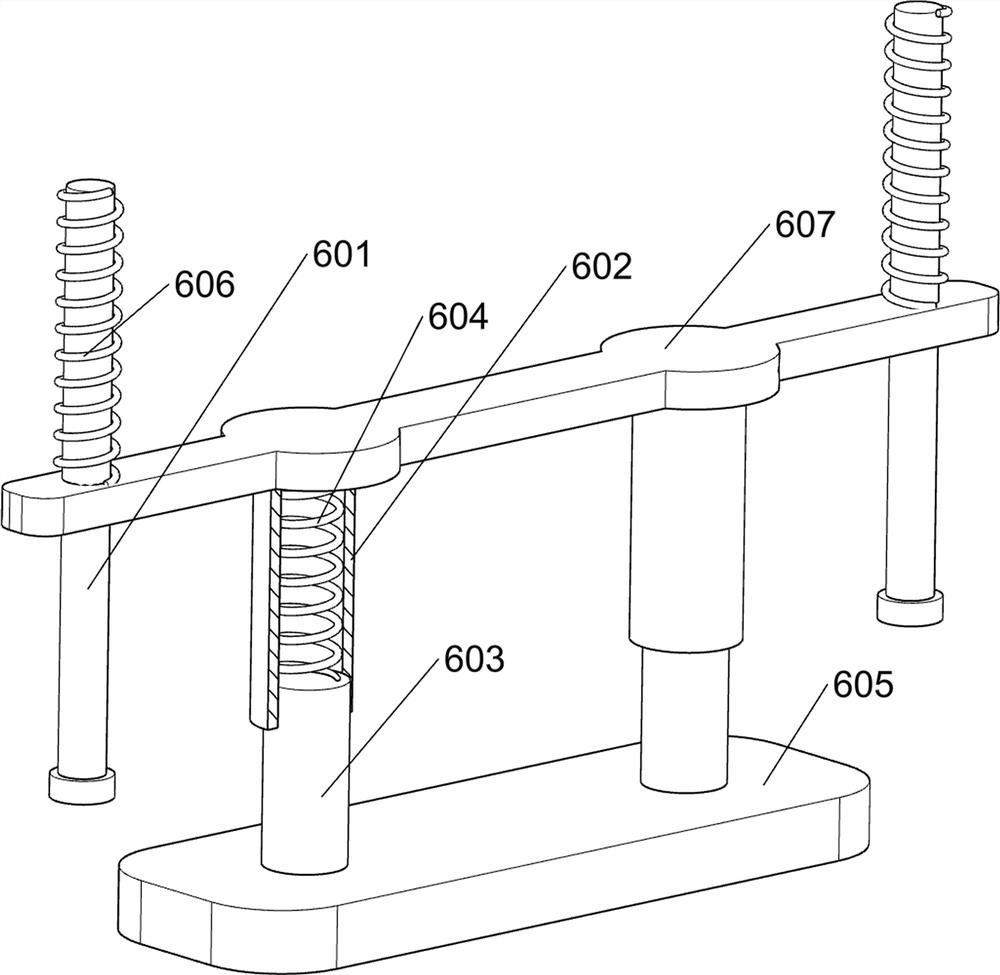

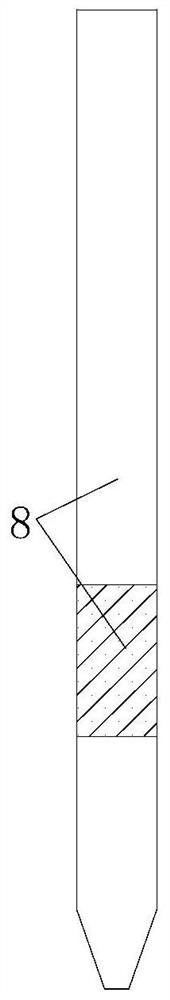

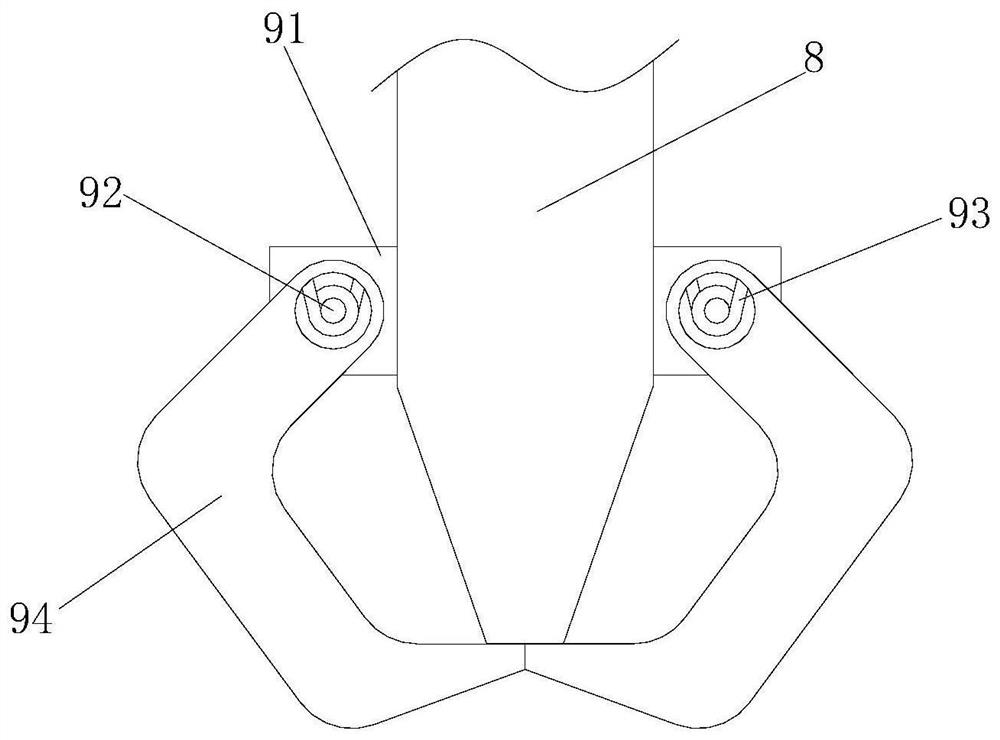

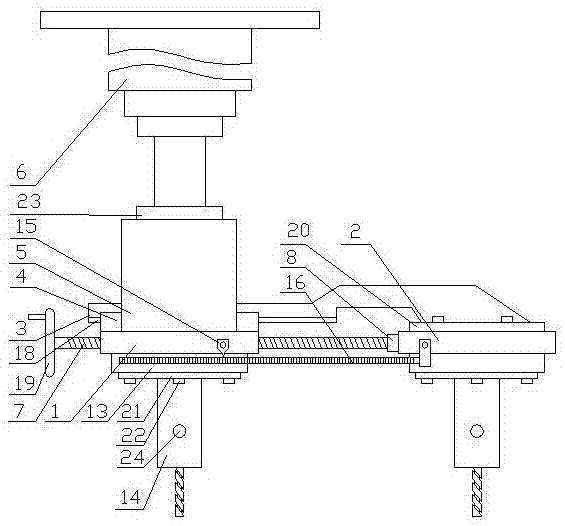

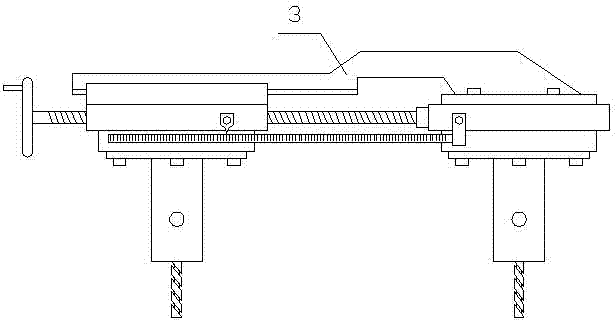

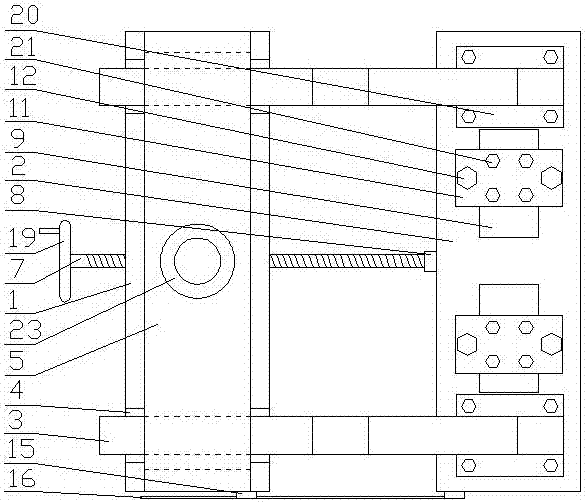

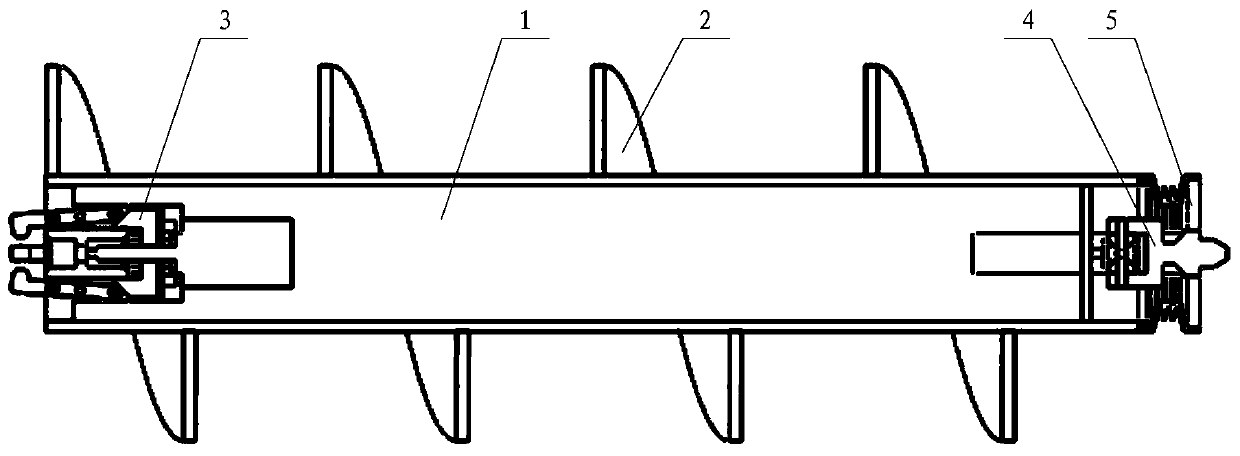

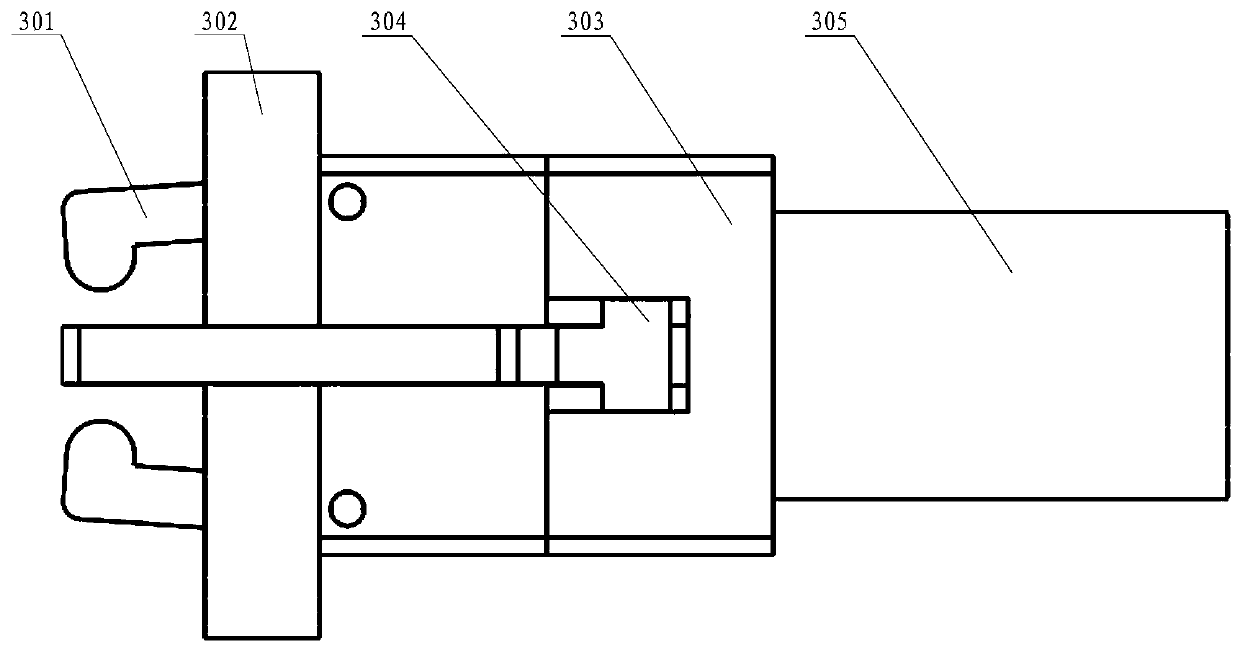

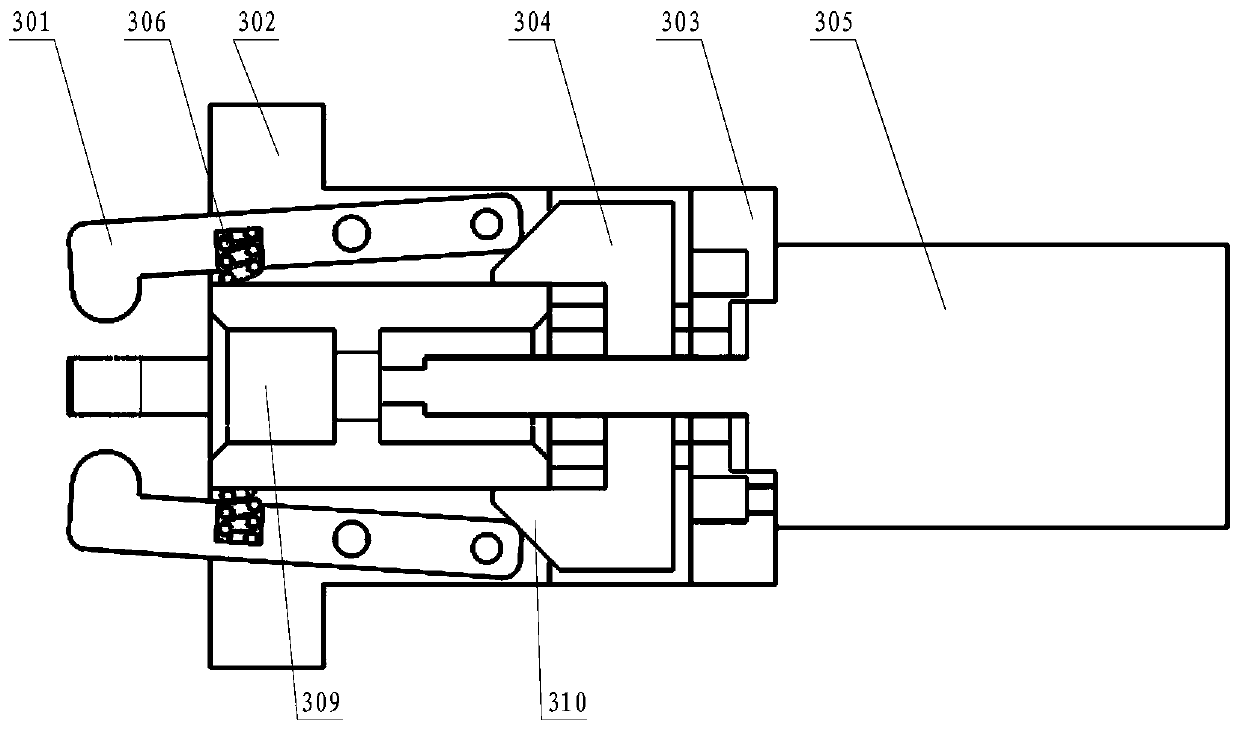

Device for drilling tubular beam

PendingCN107984438AIncrease productivitySimple structureWork benchesBoring/drilling machinesBiomedical engineeringDrill hole

The invention relates to the technical field of main tubular beam drilling tools of an automobile instrument panel, in particular to a device for drilling a tubular beam. The device comprises a plurality of drilling mechanisms, a plurality of tubular beam clamping mechanisms and a base, and each drilling mechanism comprises a support base and a drilling tool used for drilling the tubular beam andconnected to the upper end of the support base; each tubular beam clamping mechanism comprises footstand used for supporting the tubular beam, and a pressing component used for clamping the tubular beam; the pressing component is connected to the upper end of the footstand; the drilling mechanisms are arranged on the both sides or one side of the tubular beam clamping mechanisms; the support baseand the footstand are both connected to the upper surface of the base separately; and the base is provided with a switch control box used for controlling the operation of the drilling mechanisms and the tubular beam clamping mechanisms. According to the device provided by the invention, the production efficiency of main tubular beams of the automobile instrument panel is improved greatly, and thedevice has the advantages of simple structure, low cost, good processing effect and manpower saving.

Owner:重庆能正机械有限公司

Drilling machining equipment

InactiveCN109531173AImprove work efficiencyImprove processing efficiencyOther manufacturing equipments/toolsMaintainance and safety accessoriesEngineeringPulp and paper industry

The invention discloses drilling machining equipment. The equipment comprises a dust suction mechanism, wherein a clamp is arranged at the top of the dust suction mechanism, the rear end of the left side of the top of the dust suction mechanism is fixedly connected with a drilling mechanism, a grinding mechanism is fixedly connected to the part, on the left side of the drilling mechanism, of the top of the dust suction mechanism, and a controller is fixedly connected to the right side of the bottom of the dust suction mechanism. According to the equipment, the dust suction mechanism, the clamp, the drilling mechanism, the grinding mechanism and the controller are cooperatively used, a material can be mechanically drilled, so that time and labor are saved, and working efficiency is greatlyimproved; in addition, waste scraps can be adsorbed in the drilling process, so that great convenience is brought to drilling work; a hole can be subjected to burr grinding after the hole is drilled,so that machining efficiency is greatly improved; by arranging through holes, the waste scraps in the inner cavity of a sliding groove can be adsorbed, so that sliding work can be better ensured.

Owner:许益安

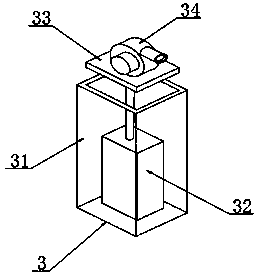

Well drilling device for mining

The invention provides a well drilling device for mining. The well drilling device comprises a moving base. A lifting box is welded and fixed to the upper end of the moving base and has a hollow circular iron box; two lifting motors are fixedly installed at the upper end inside the lifting box by bolt connection and are distributed on the inner walls of the left side and the right side of the upper end of the lifting box symmetrically; and a conveyor belt sleeves the lower end of the lifting box in rotation manner. The outer side of a threaded sliding plate is arranged inside a limiting framein a sliding manner; and a connection hole is formed in the connection part. A mounting plate is arranged at the upper space inside the lifting box in a sliding manner; two fixation blocks are installed at the lower end of the mounting plate and are distributed at the left side and the lower side of the lower end surface of the mounting plate symmetrically; and a lifting plate is fixed and weldedto the lower ends of the fixation blocks. Two rollers are arranged and are installed inside chutes in a sliding manner. The well drilling device having a simple structure is convenient to operate; andthe drilling work is completed efficiently and rapidly. The well drilling device is worthy of popularization and use.

Owner:宛兴友

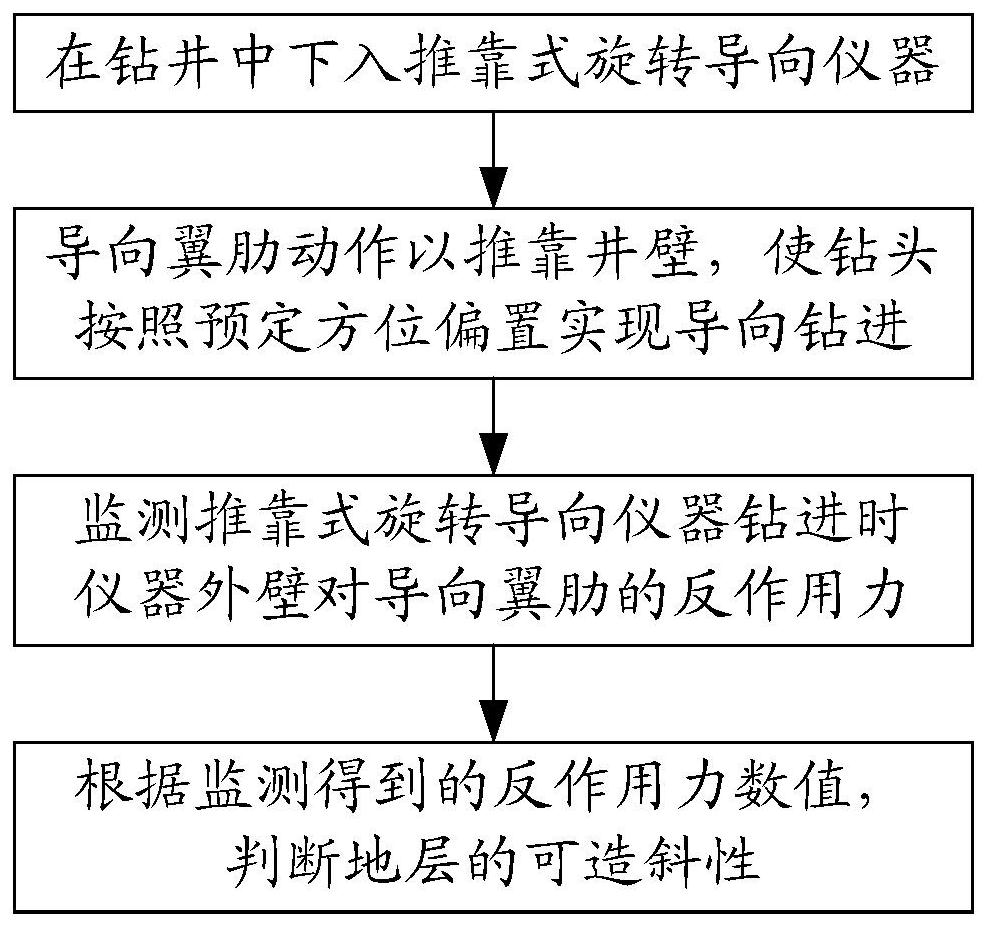

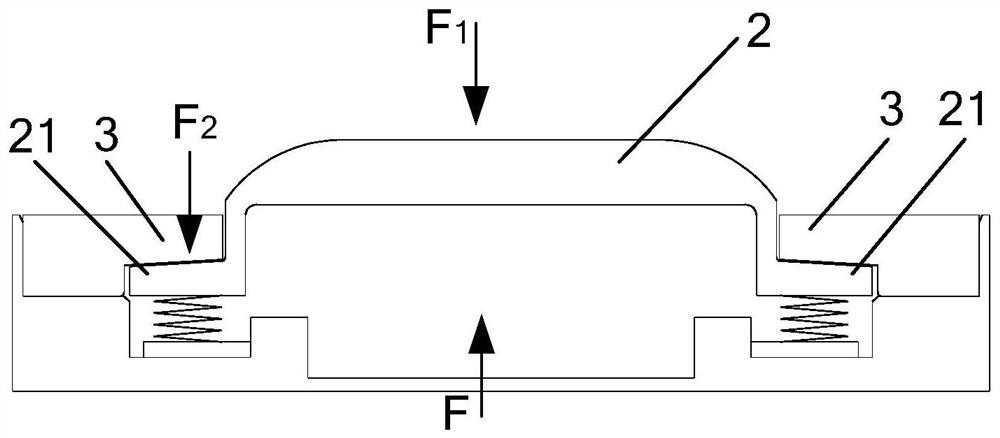

Stratum deflecting property evaluation method

PendingCN111691879AThe evaluation method is simple and reliableAvoid job failuresBorehole/well accessoriesClimate change adaptationEngineeringDrill bit

The embodiment of the invention provides a stratum deflecting property evaluation method. The evaluation method comprises the following steps that a pushing type rotary guiding instrument is put intoa well; a guiding rib of the pushing type rotary guiding instrument moves to push against the well wall, and a drill bit is deflected in the preset direction to achieve guided drilling; the reactive force of the outer wall of the instrument to the guiding rib is monitored when the pushing type rotary guiding instrument drills; and according to reactive force value obtained through monitoring, thedeflecting property of stratum is judged. By means of the stratum deflecting property evaluation method provided by the embodiment of the invention, the deflecting property of stratum can be measuredand evaluated conveniently and rapidly, and subsequent well drilling operation is facilitated.

Owner:CHINA OILFIELD SERVICES

Batch drilling device for PVC boards

ActiveCN113001669ADrilling automaticImprove drilling efficiencyMetal working apparatusMechanical engineeringPetroleum engineering

Owner:上海京宁环保科技有限公司

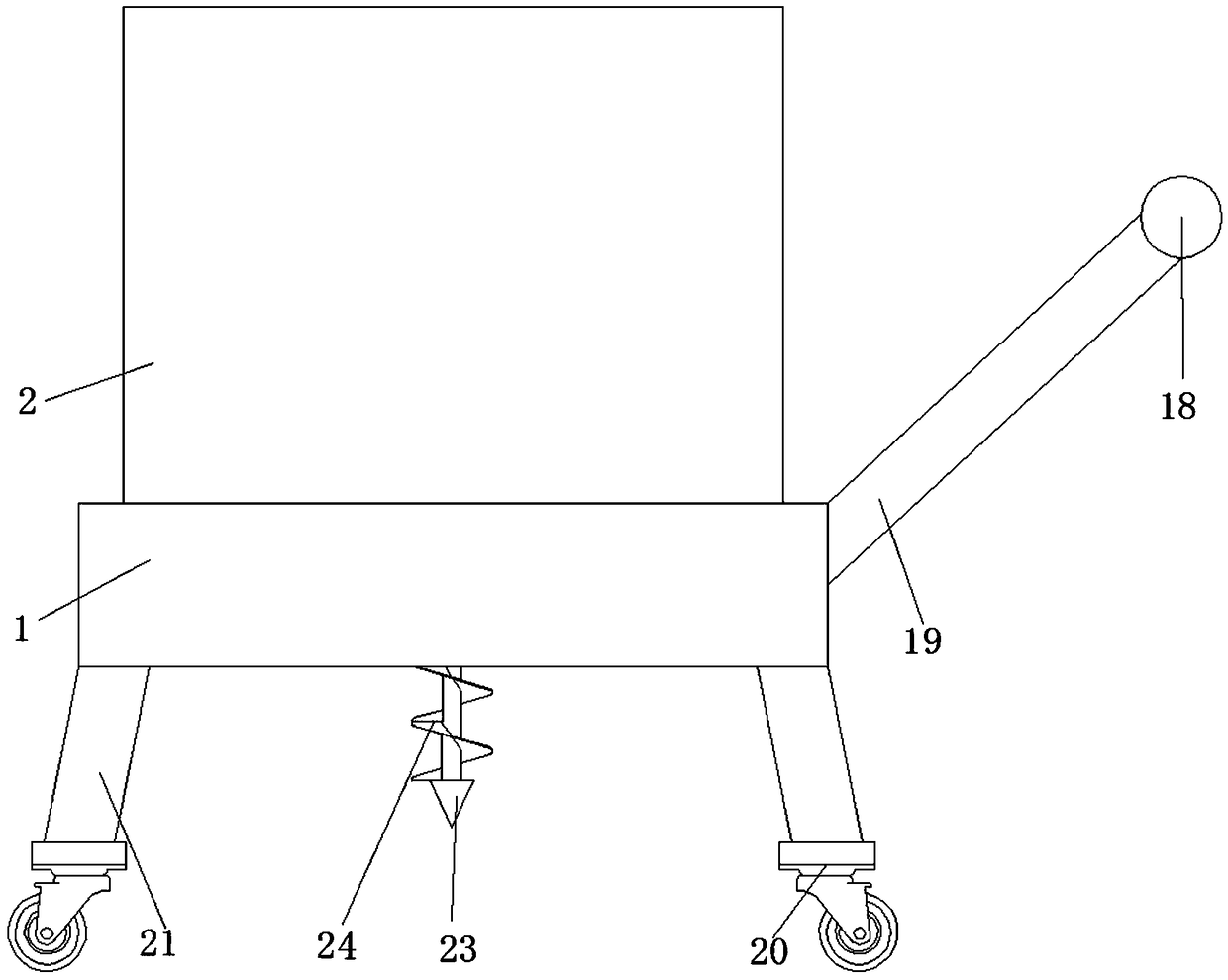

Movable drilling device for ground construction

InactiveCN112431551AEasy vertical drillingConvenient drilling workEarth drilling toolsDrilling machines and methodsElectric machineryEngineering

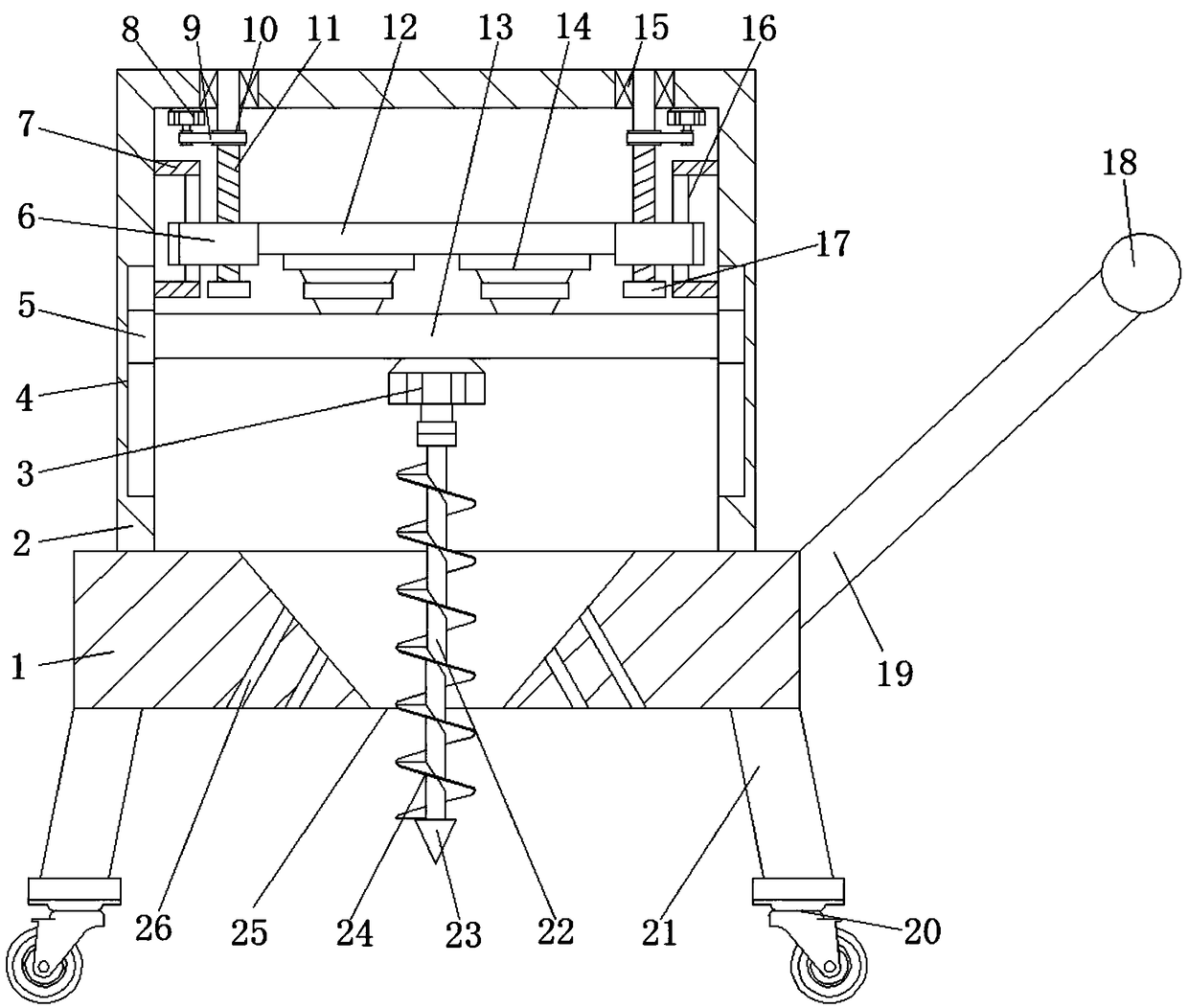

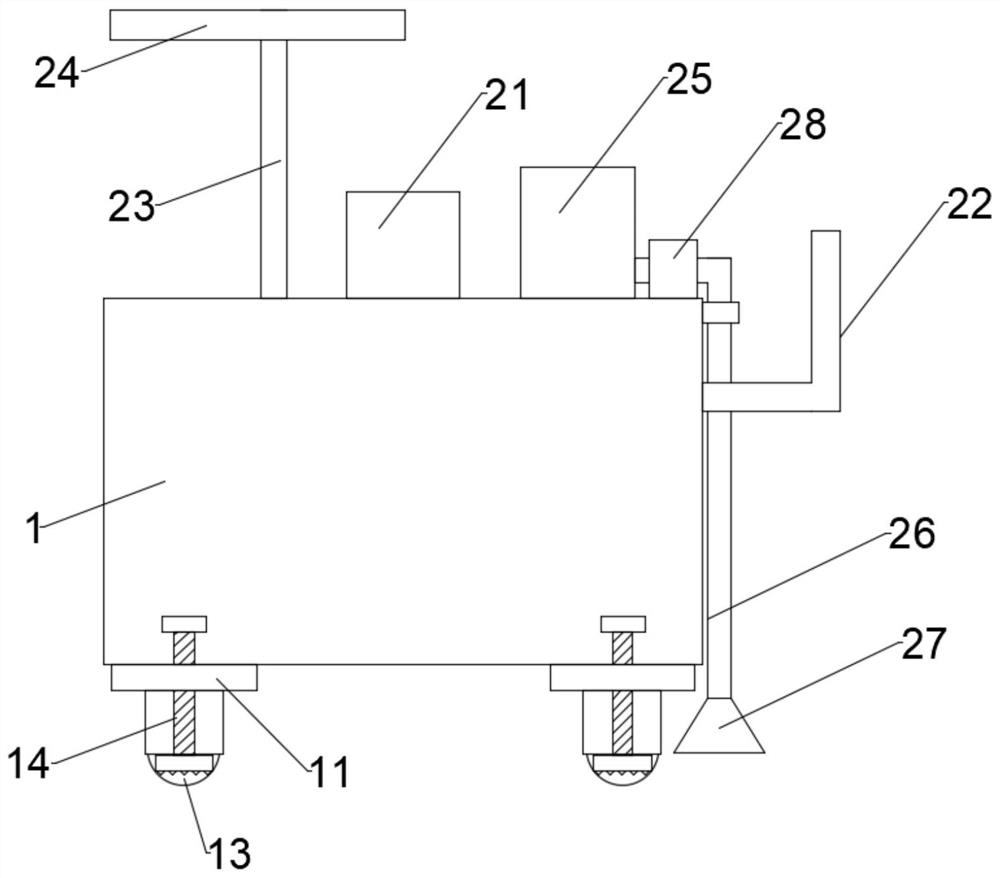

The invention discloses a movable drilling device for ground construction. The movable drilling device comprises a left square bracket-shaped mounting frame, wherein electric push rods are mounted atthe inner top of the left square bracket-shaped mounting frame, a movable plate is mounted at the movable ends of the electric push rods, two sides of the movable plate are in sliding fit with the inner wall of the left square bracket-shaped mounting frame, a motor is mounted at the lower end of the movable plate, a drill bit is installed at the output end of the motor, four moving rods are slidably connected to the moving plate, stop blocks are fixed to the upper ends of the four moving rods, a supporting plate is connected to the lower ends of the four moving rods, a through hole is formed in the supporting plate, the drill bit is arranged above the through hole, and springs connected to the outer sides of the moving rods in a sleeving mode are fixed between the moving plate and the supporting plate. According to the movable drilling device, the whole device is stably supported through the supporting plate and the springs between the supporting plate and the moving plate, the drill bit can vertically drill into the ground conveniently, and therefore inconvenience caused by manual drilling is avoided.

Owner:陶寿松

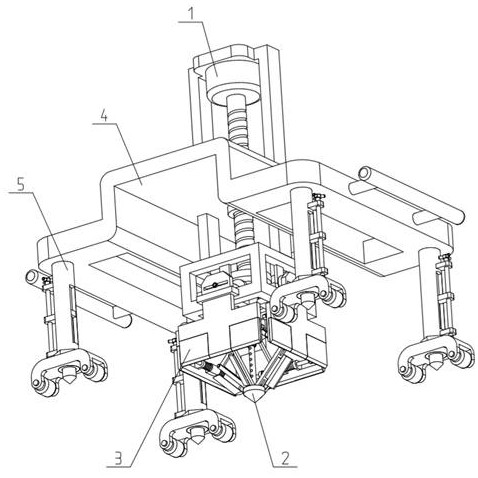

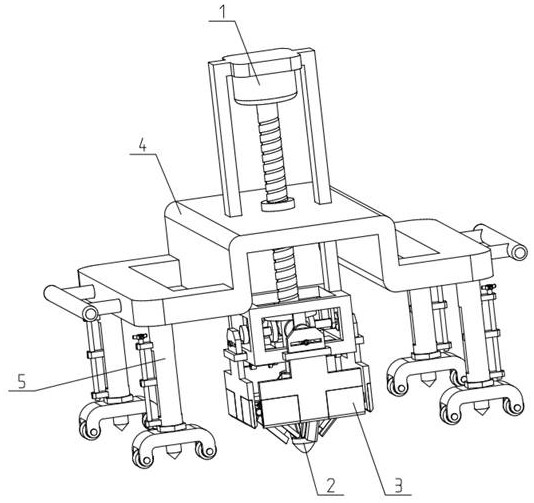

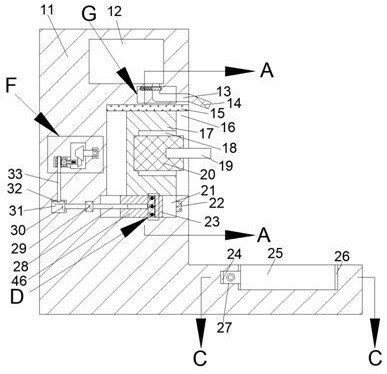

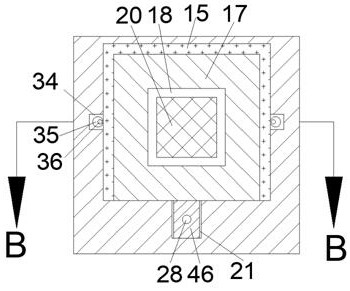

Building construction foundation drilling equipment

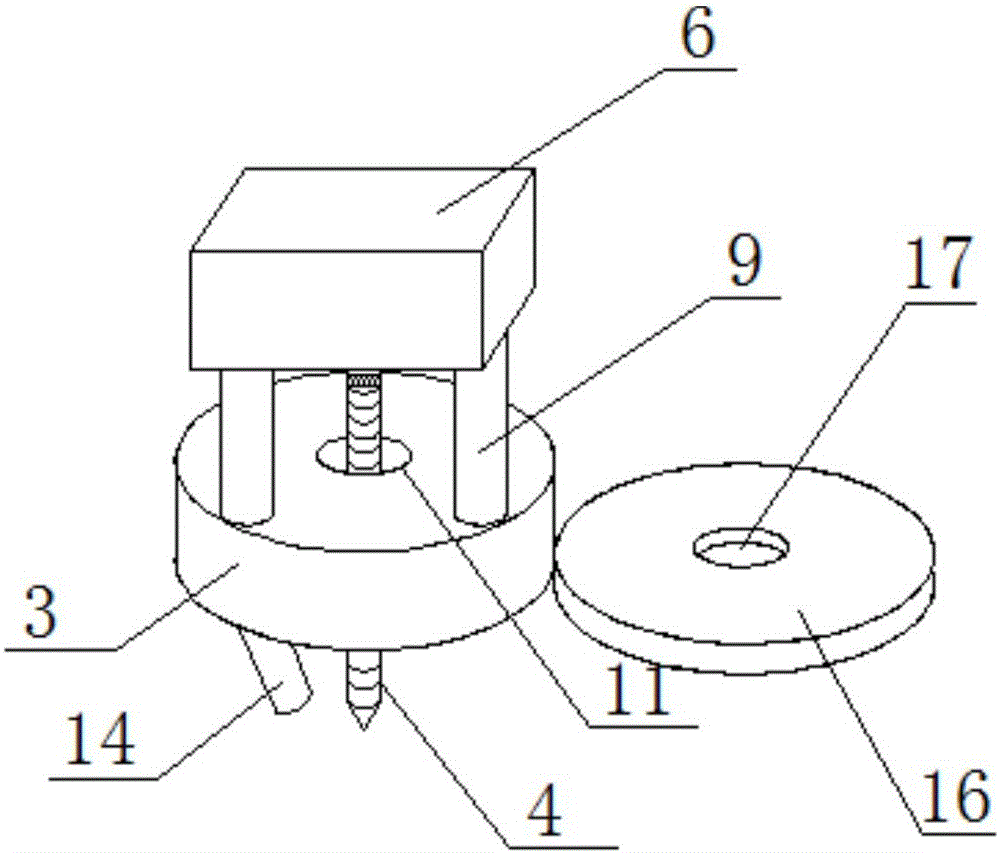

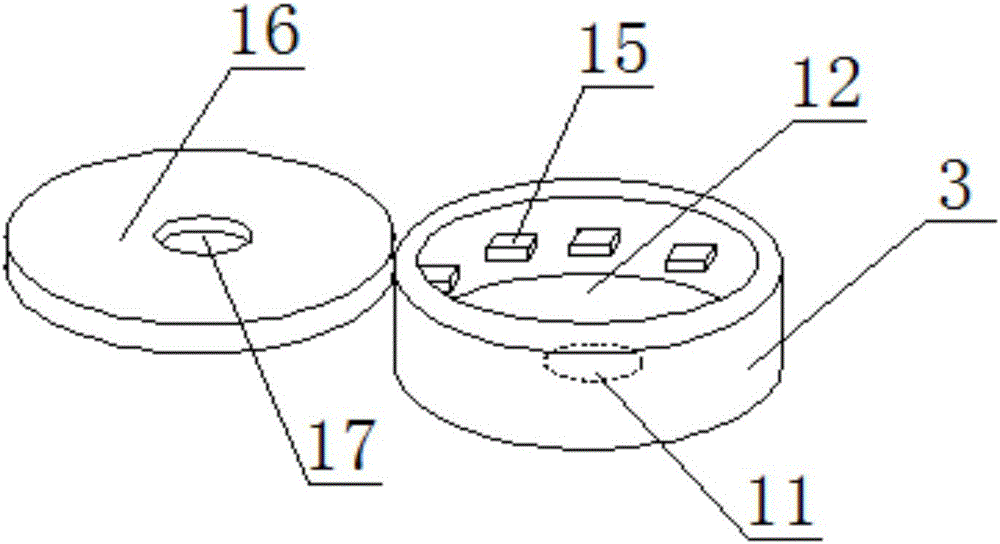

InactiveCN111963051AConvenient drilling workConvenient punching workEarth drilling toolsDrill bitsPunchingMolding machine

The invention relates to the technical field of building construction equipment, in particular to building construction foundation drilling equipment which comprises a drilling driving mechanism, a round hole drill bit mechanism, a square hole forming mechanism, a rack and supporting column mechanisms. The middle of the drilling driving mechanism is connected to the middle of the rack. The lower end of the drilling driving mechanism is fixedly connected with the round hole drill bit mechanism; the drilling driving mechanism is in transmission connection with the square hole forming mechanism;the lower end of the drilling driving mechanism is detachably connected with the square hole forming mechanism; the round hole drill bit mechanism is located on the inner side of the square hole forming mechanism. The four corners of the bottom end of the rack are each fixedly connected with one supporting column mechanism. By means of the building construction foundation drilling equipment, roundhole punching work can be conducted on a foundation, square hole punching work can also be conducted, and different piling requirements are met.

Owner:广州易鑫软件科技有限公司

Electric drill broken drill bit dismounting equipment

InactiveCN112453747AImprove drilling efficiencyConvenient drilling workWelding/cutting auxillary devicesAuxillary welding devicesPhysicsEngineering

The invention discloses electric drill broken drill bit dismounting equipment. The equipment comprises an L-shaped dismounting machine body, a clamping cavity with an upward opening is formed in the dismounting machine body, clamping plates which are symmetrical in the front-back direction and can move in the front-back direction are arranged in the clamping cavity, the center of the distance between the clamping plates at the front side and the rear side is the symmetrical center, and a clamping connecting cavity is formed in the left wall of the clamping cavity in a communication manner. After a broken drill bit is welded and fixed through welding, subsequent drill taking work is facilitated, and then the broken drill bit is separated from the clamping position of an electric drill to acertain degree through slight vibration; then, a lubricant is added in the process of pulling the drill bit leftwards, so that a clamping device of the electric drill is protected, meanwhile, the drill taking efficiency is improved, meanwhile, left-right reciprocating vibration is conducted when the drill bit is pulled leftwards, meanwhile, the frequency of front-back vibration is increased, and the drill taking efficiency of the whole device is improved; and meanwhile, the electric drill is maintained and protected to a certain extent.

Owner:福州堡徐翁科技有限公司

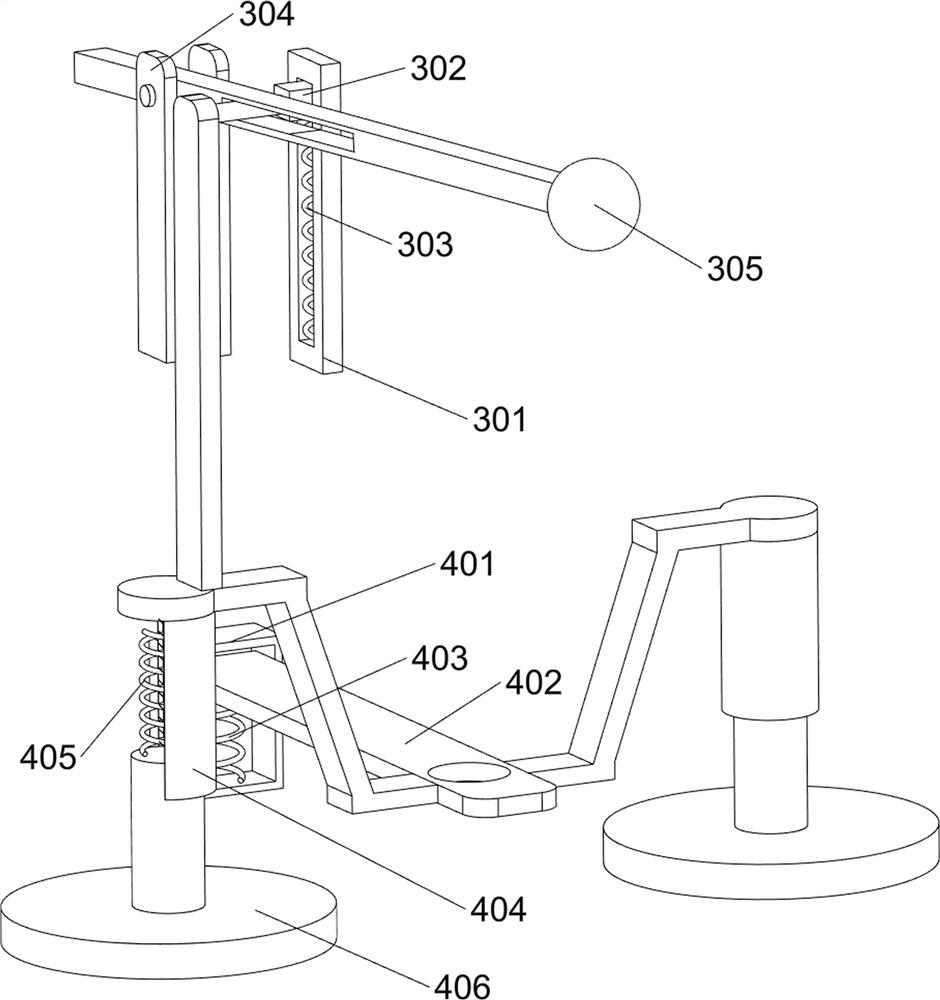

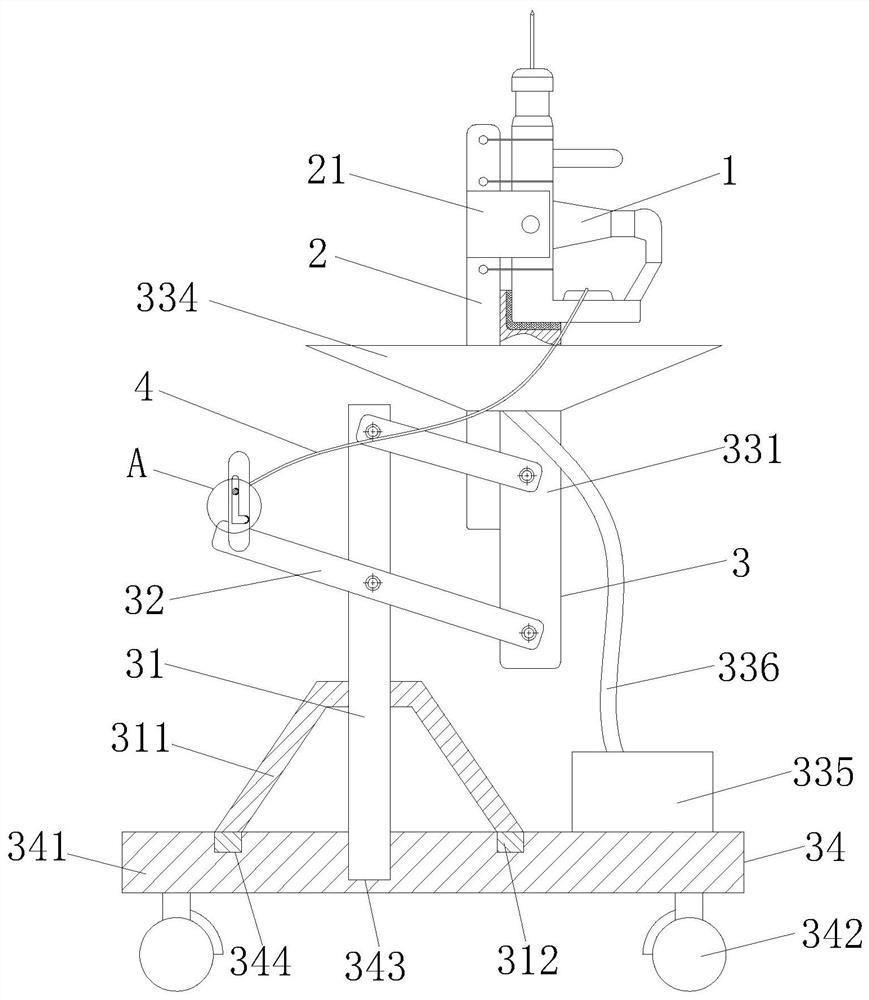

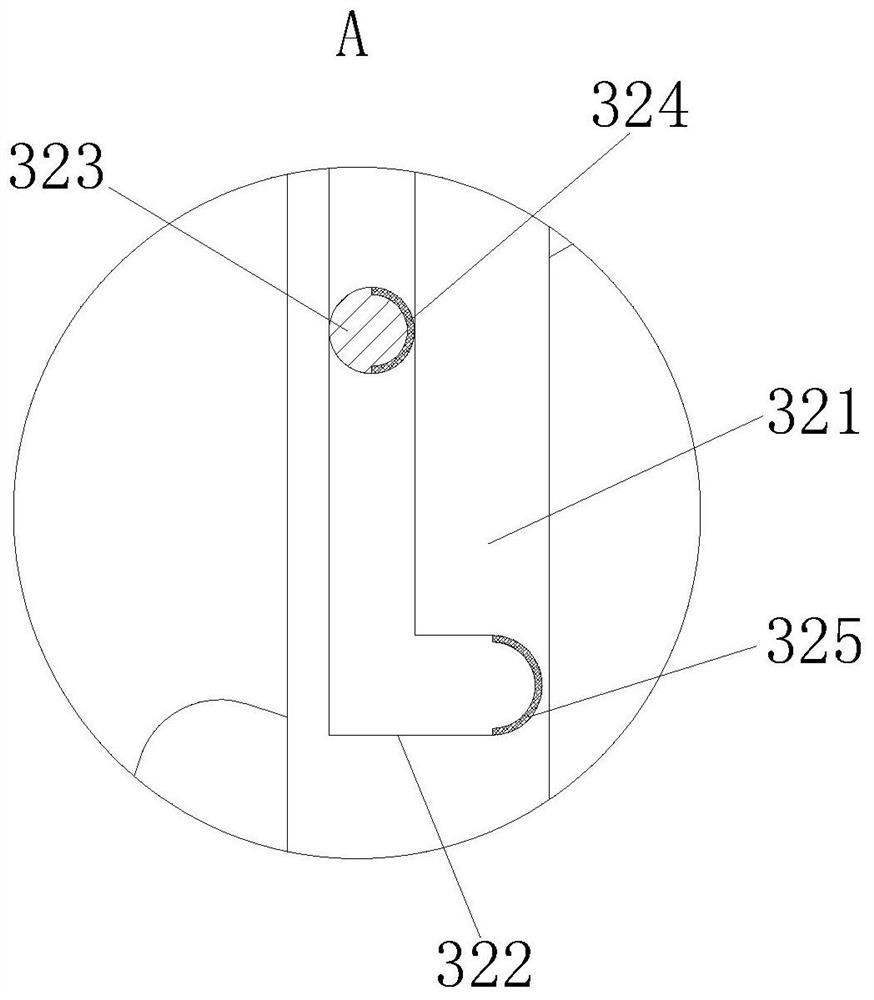

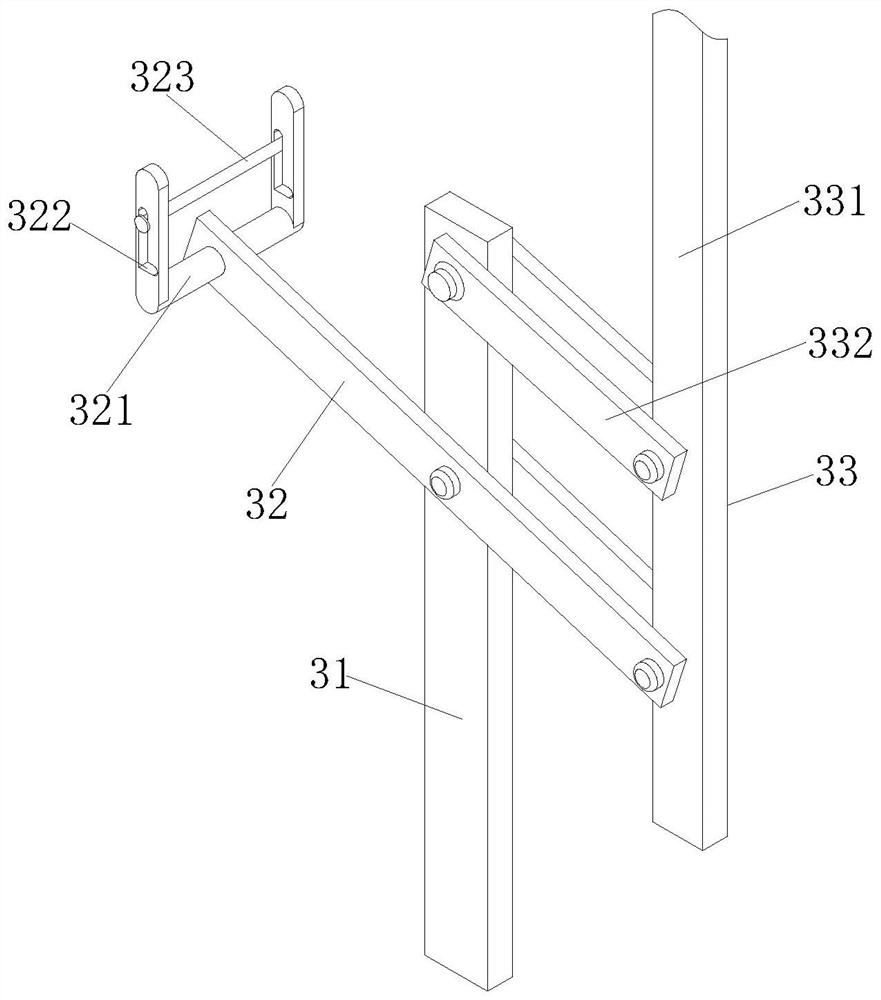

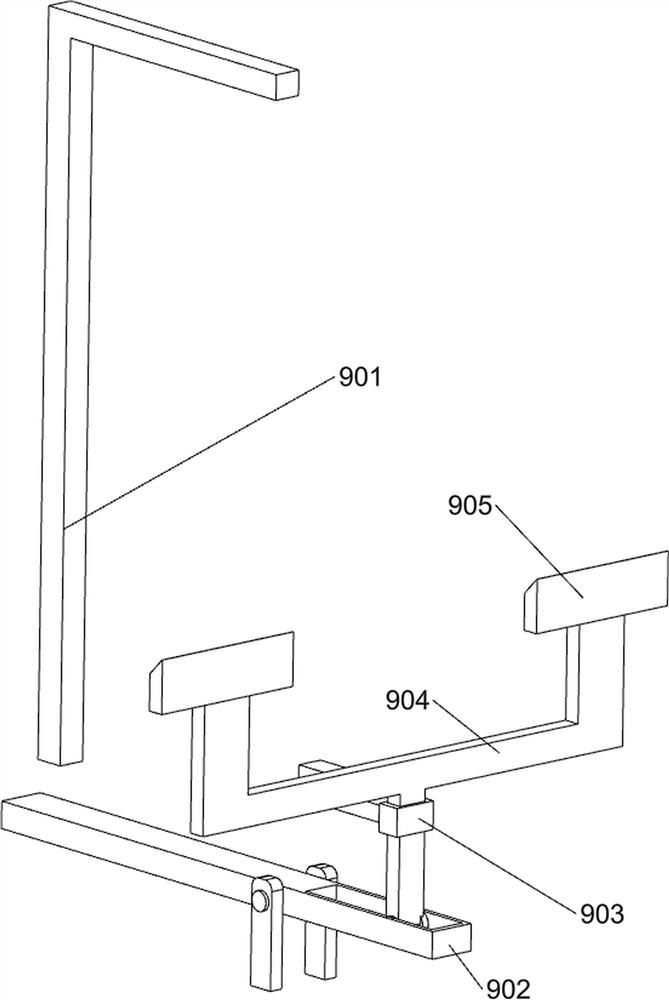

House building engineering column top steel bar drilling and planting auxiliary device

PendingCN113320023AImprove securityConvenient drilling workWorking accessoriesStone-like material working toolsAgricultural engineeringHouse building

The invention belongs to the technical field of house building, and particularly relates to a house building engineering column top steel bar drilling and planting auxiliary device. The device comprises a drilling machine body, a fixing rod, a supporting assembly and a pull rope, wherein the fixing rod is fixedly connected to the side wall of the supporting assembly, the drilling machine body is arranged on the top of the supporting assembly, the end part of the pull rope is wound on the supporting assembly, the supporting assembly comprises a stand column, handle rods and a lifting mechanism, the pair of handle rods are rotationally connected to the outer side wall of the stand column by means of rotating pins and located on the two opposite side walls of the stand column correspondingly, the lifting mechanism is arranged on the outer side wall of the stand column, and the lifting mechanism is rotationally connected with the handle rods by means of rotating pins. According to the device, the drilling machine body is driven by the lifting mechanism to ascend, so that steel bar planting and drilling work is conducted, a high-altitude falling phenomenon caused by manually carrying a ladder or erecting a platform is avoided, and the safety of the drilling work is improved.

Owner:THE FIFTH ENG CO LTD OF CHINA RAILWAY NO 10 ENG GRP

High-strength high-plasticity aluminum alloy extruded section

InactiveCN108655770AImprove drilling accuracyAdapt to punching requirementsPositioning apparatusMetal-working holdersDrill bitAluminium alloy

The invention provides a high-strength high-plasticity aluminum alloy extruded section. The high-strength high-plasticity aluminum alloy extruded section is characterized in that the high-strength high-plasticity aluminum alloy extruded section is perforated by a multi-angle perforating device; the multi-angle perforating device comprises a perforating machine, a drill bit is arranged at the lowerend of the perforating machine, a lifting cylinder is arranged at the upper end of the perforating machine, an aluminum section containing plate is arranged below the drill bit, and mounting bucklesare arranged on the aluminum section containing plate; and an aluminum section is fixed by the mounting buckles, a circular bracket is arranged at the lower end of the aluminum section containing plate, a base is arranged on the circular bracket, and a rotating motor is arranged on the base. According to the high-strength high-plasticity aluminum alloy extruded section, the aluminum section is fixed on the aluminum section containing plate by the mounting buckles, and the circular bracket is adjusted by the rotating motor, so that the angle of the aluminum section containing plate is adjusted,perforating work in different directions is facilitated, the perforating requirements of aluminum sections in irregular shapes are met, the aluminum section is fixed by a magnetic strip in an assisted fixing manner, and the perforating accuracy is improved.

Owner:HAIAN HUADA ALUMINUM SECTION

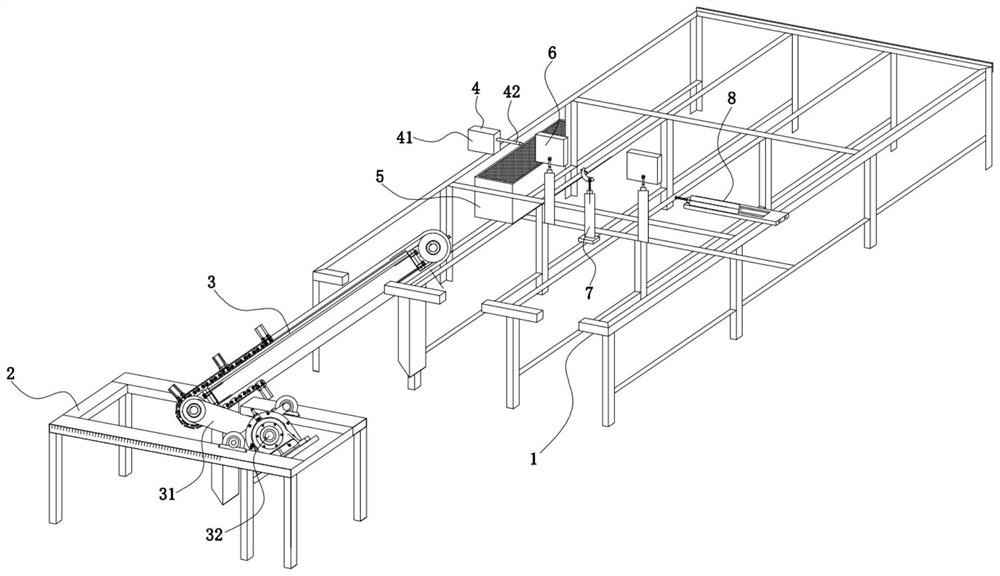

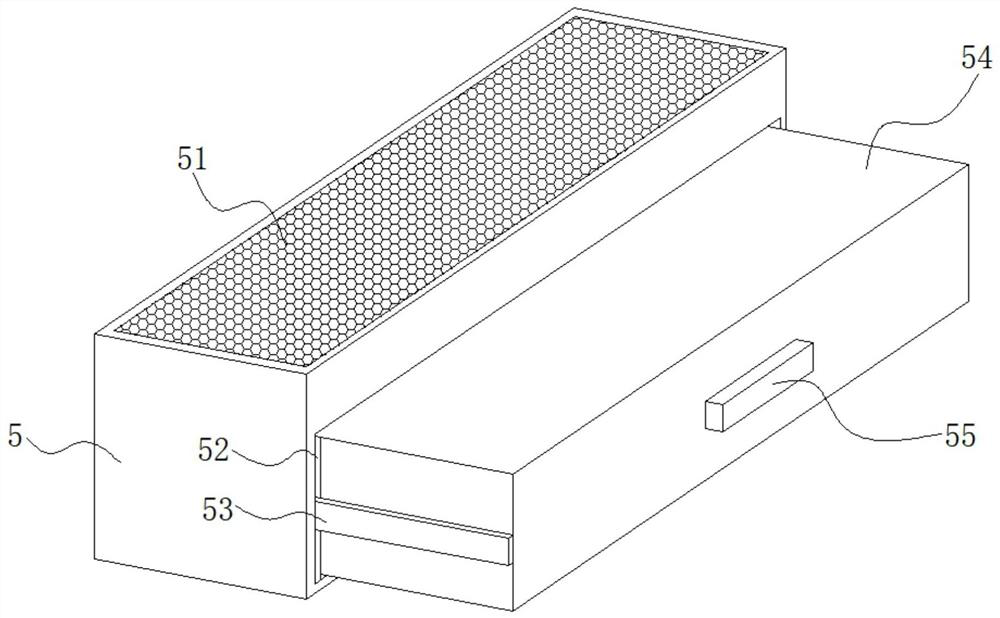

Clamping and drilling mechanism for bar material

InactiveCN113290268AEasy to handleNot easy to polluteMetal working apparatusMaintainance and safety accessoriesThermodynamicsMaterials processing

The invention discloses a clamping and drilling mechanism for a bar material, and relates to the technical field of bar material processing. The clamping and drilling mechanism comprises a drilling material frame, a fixing frame, a conveying belt, a drilling mechanism, a collecting box, a lifting positioning baffle mechanism, an overturning and clamping device and a horizontal positioning device, wherein the conveying belt used for conveying the bar material is arranged between the drilling material frame and the fixing frame, the drilling mechanism used for drilling, the lifting positioning baffle mechanism, the overturning and clamping device and the horizontal positioning device are sequentially arranged on the drilling material frame from left to right, and the collecting box used for collecting waste scraps is arranged under the drilling mechanism. According to the clamping and drilling mechanism for the bar material, when the drilling mechanism is used for drilling the bar material, the generated waste scraps fall into a collecting drawer through a filter screen, waste materials generated by drilling the bar material are collected in time, and the clamping and drilling mechanism has the advantages of being beneficial to clamping and drilling of the bar material, collecting and treatment of the waste materials and improving of the working efficiency, and thus, the problem that the use effect is common in traditional bar material drilling processing is solved.

Owner:重庆欣天利智能重工有限公司

Wood board drilling equipment

ActiveCN113771141AConvenient drilling workDrilling work is stableStationary drilling machinesWood plankWorkbench

The invention relates to drilling equipment, and especially relates to wood board drilling equipment. The technical problem of the invention is to provide the wood board drilling equipment which is accurate in drilling and has a pressing function. The technical implementation scheme of the invention is as follows: the wood board drilling equipment comprises a base, supports, a workbench, a driving assembly, drill bits and a pressing assembly, wherein the supports are symmetrically arranged at one side of the top of the base; the workbench is arranged at one side of the top of the base; the driving assembly is arranged at the other side of the top of the base; the drill bits are symmetrically arranged on the driving assembly; and the pressing assembly is arranged at one side of the workbench, and the driving assembly is cooperated with the pressing assembly. According to the invention, under the action of the driving assembly, the drill bits are driven to drill a wood board, meanwhile, the wood board is pressed by the pressing assembly, the wood board can be more conveniently drilled, a good pressing effect of the pressing assembly is achieved, the wood board can be more stably drilled, and high drilling precision is achieved.

Owner:吉屋(青岛)家居有限公司

Plant cuttage transplanting device for research of agricultural science

InactiveCN112438143AConvenient drilling workReduce consumptionManure treatmentSelf-acting watering devicesAgricultural engineeringAgricultural science

The invention discloses a plant cuttage transplanting device for research of agricultural science. The plant cuttage transplanting device comprises a frame body, a cultivating basin, fan blades and spray heads. A fixed block is fixedly mounted on the inner wall of the lower end of the frame body, a telescopic spring is fixedly mounted in the fixed block, a placing platform is fixed to the top endof the telescopic spring, and the cultivating basin is arranged on the surface of the placing platform. According to the plant cuttage transplanting device for research of agricultural science, when the cultivating basin filled with a proper amount of soil is placed on the placing platform, the cultivating basin pushes the placing platform to slide downward due to the total weight of the cultivating basin, so that the placing platform drives a first connecting line to loosen, and a junction box is reset automatically to rotate through a scroll spring inside, and therefore, the junction box drives a connecting pipe in threaded connection to descend. Thus, it is convenient to drive a cuttage mechanism to perforate soil by the connecting pipe. As the soil is perforated by means of gravity ofthe cultivating basin, the energy consumption is reduced effectively.

Owner:绍兴市米莉农业科技有限公司

Batched drilling equipment for mechanical machining

ActiveCN107322032AAvoid mobilityAvoid parts problemsLarge fixed membersBoring/drilling machinesEngineeringDrill

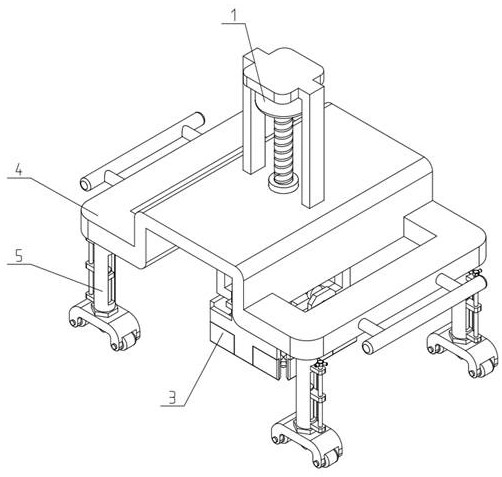

The invention discloses batched drilling equipment for mechanical machining. The batched drilling equipment comprises a device main frame and a movement frame, the top of the movement frame is detachably connected with a guide frame, a guide seat is welded to the device main frame, and the guide seat is matched with the guide frame; the upper portion of the device main frame is connected with a connection frame in a welded manner, and the upper portion of the connection frame is detachably connected with an ascending and descending oil cylinder; the middle of the device main frame is provided with an adjustment screw in a penetrated manner, and the end of the adjustment screw rod is matched with the movement frame through a bearing; the device main frame and the movement frame are both provided with through sliding chutes, the sliding chutes are internally provided with sliding blocks in a sliding fit manner, the tops of the sliding blocks are detachably connected with top plates, the two sides of each top plate are both provided with pressing bolts in a penetrated manner, the bottoms of the sliding blocks are connected with bottom plates in a welded manner, and the lower portions of the bottom plates are detachably connected with electric drills. By means of the batched drilling equipment for mechanical machining, multiple holes can be machined simultaneously, drilling efficiency is high, and when batched drilling of the same components is performed, production efficiency can be improved remarkably.

Owner:宁国市四方精工机械有限公司

Preparation method of high-strength heat-resistant oil field well cementation rubber plug

The invention discloses a preparation method of a high-strength heat-resistant oil field well cementation rubber plug. The oil field well cementation rubber plug is prepared from, by weight, 20-30 parts of 65-mesh rubber powder, 12-15 parts of butadiene styrene rubber, 10-30 parts of silica gel, 15-25 parts of silica powder, 5-8 parts of floating beads, 3-10 parts of argil, 12-15 parts of calcium carbonate, 1-3 parts of white carbon black, 1-5 parts of an anti-aging agent, 1.5-4 parts of an anti-scorching agent, 2-6 parts of a plasticizing agent and 3-9 parts of a softening agent. The overall strength, high temperature resistance and heat resistance of the rubber plug can be greatly improved, the adsorption capacity, acid and alkali resisting and corrosion resisting capacity, high temperature resistance, mechanical strength, insulating property, heat stability and chemical stability of the rubber plug can be greatly improved, steel tubes for oil field well cementation can be protected and prevented from being damaged by external factors, and thus smooth oil field well cementation can be promoted.

Owner:枣阳市恒泰化工有限公司

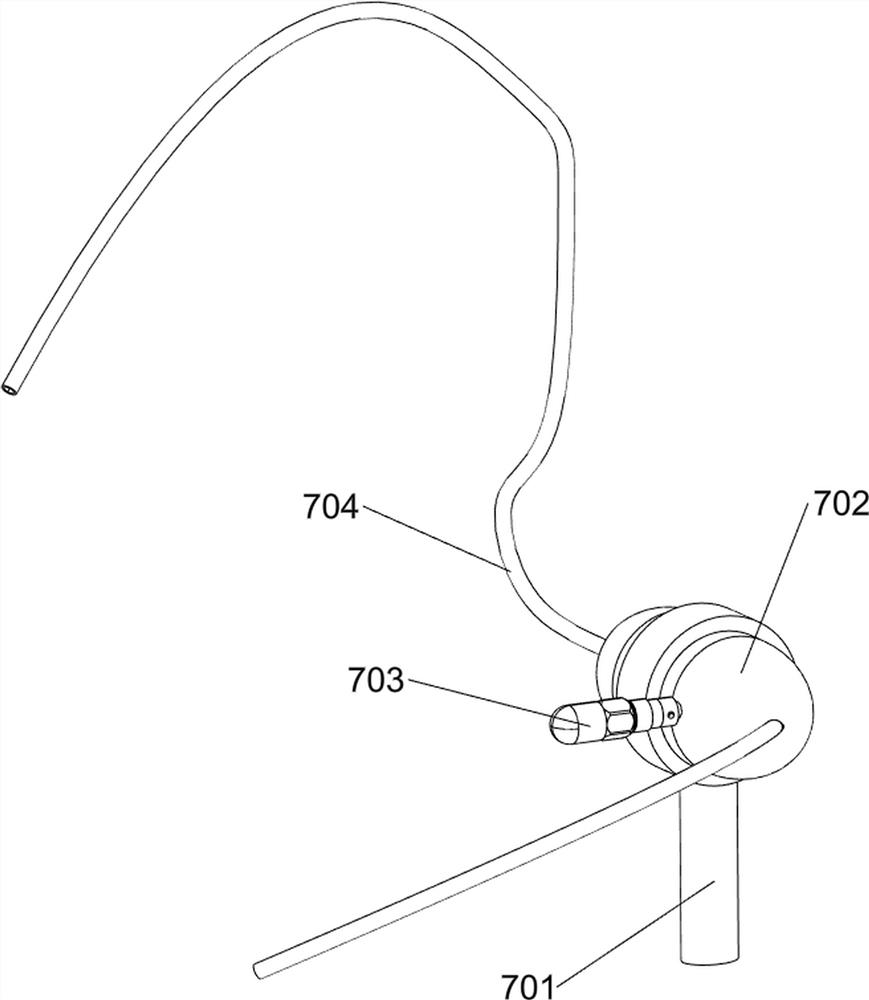

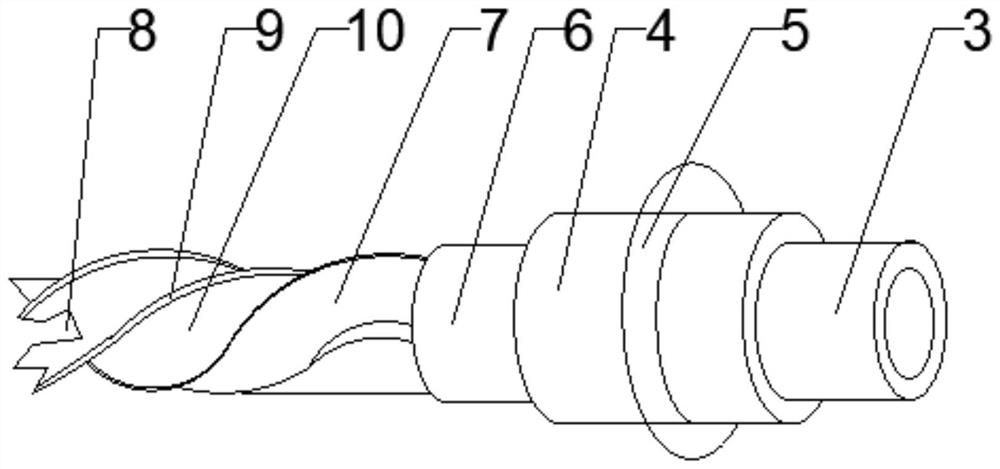

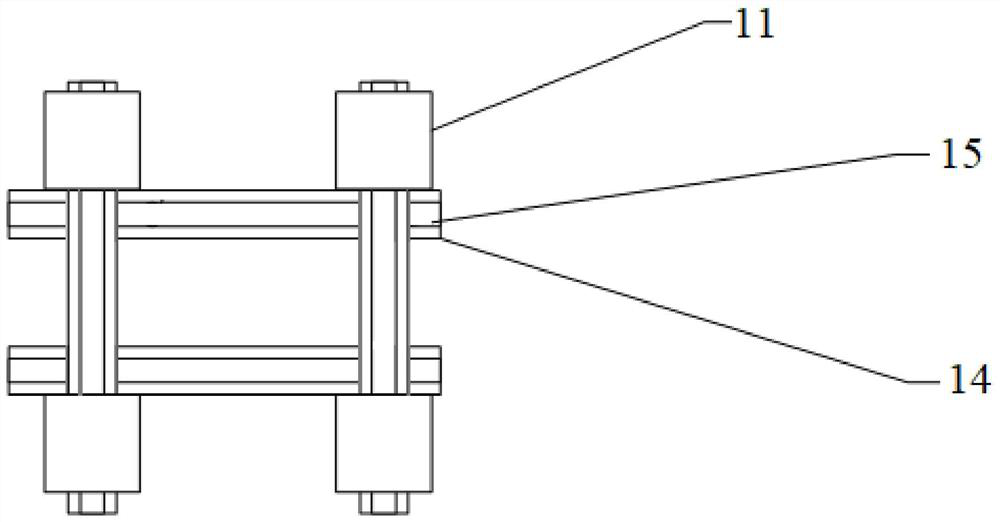

Drill pipe device for mine

PendingCN110454097AEffective length adjustmentConvenient drilling workDrilling rodsGas removalTime changesPetroleum engineering

The invention relates to coal mining equipment, in particular to a drill pipe device for a mine. The drill pipe device includes a drill pipe body, blades, connecting ends and deflection ends, whereinthe outer surface of the drill pipe body is provided with the blades, two ends of the drill pipe body are correspondingly connected with the connecting ends and the deflection ends, and a plurality ofdrill pipe devices for the mine are connected in series through the connecting ends and the deflection ends. According to the drill pipe device for the mine, series connection is realized through themultiple drill pipe devices for the mine, the connection of different numbers of the drill pipe devices for the mine can effectively adjust the length of a whole drill pipe so as to adapt to requirements of the drill pipe length under different environments; and the deflection ends of the drill pipe devices for the mine can be used for realizing the real-time change of a whole drilling path, anddrilling work under complex environments is facilitated.

Owner:山西汾西中兴煤业有限责任公司

Efficient punching equipment for power panel machining and punching method for power panel machining

PendingCN113977695AConvenient drilling workImprove drilling efficiencyMetal working apparatusPunchingElectric machinery

The invention discloses efficient punching equipment for power panel machining and a punching method for power panel machining. The efficient punching equipment comprises an operation table and a base; the operation table is fixedly connected to one side of the base; a motor shell is fixedly connected to the top end of the base; a drilling mechanism is arranged at the top end of the operation table; the drilling mechanism comprises stand columns, a transverse rod, a supporting rod and a drilling plate; the two stand columns are fixedly connected to the two sides of the top end of the operation table respectively; the transverse rod is arranged between the two stand columns; the supporting rod is fixedly connected to the outer side of the transverse rod; and the drilling plate is fixedly connected to the bottom end of the supporting rod. According to the efficient punching equipment for power panel machining and the punching method for power panel machining, a first motor, a first threaded rod, a first threaded sleeve, a first sliding block and the transverse rod are adopted, the other side of the transverse rod is fixedly connected with a second sliding block, and the second sliding block is slidably connected to the inner side of a second sliding groove; and through the above arrangement, the transverse rod is effectively driven to move up and down, that is, the drilling plate is driven to move up and down, and thus, the flexibility of the equipment is improved, and manual operation is reduced.

Owner:惠州市立华五金电子有限公司

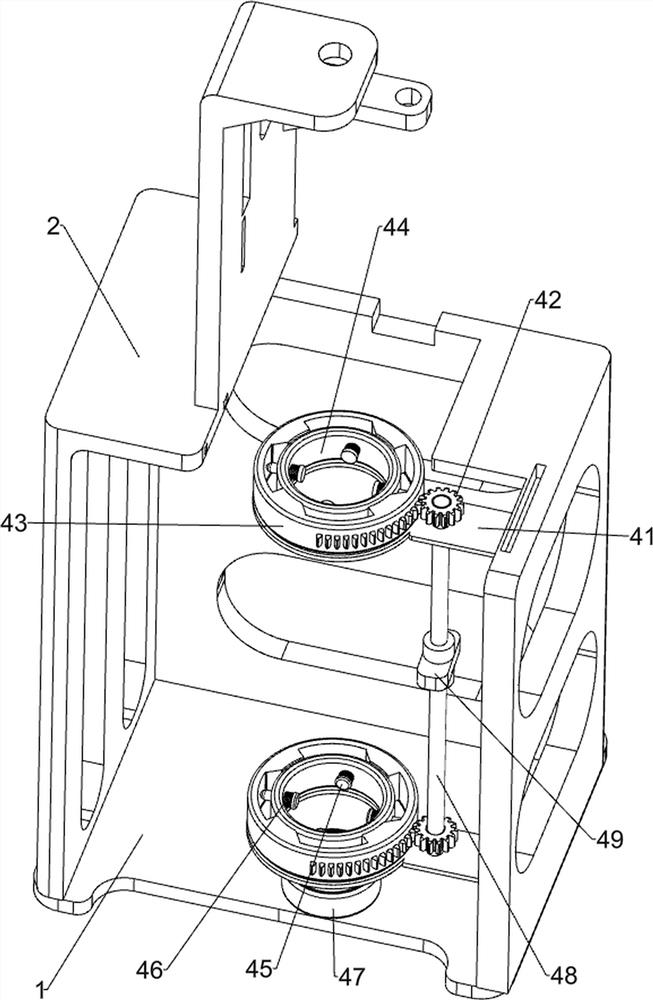

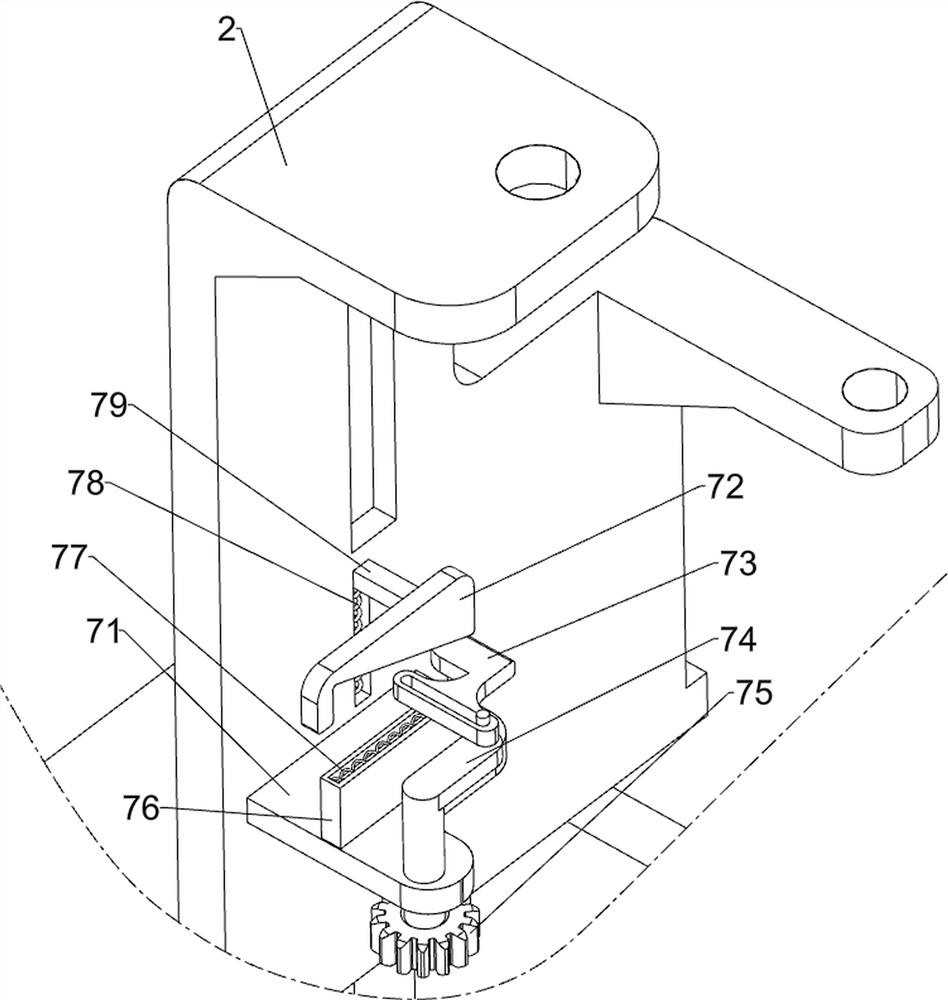

A switch cabinet opening system

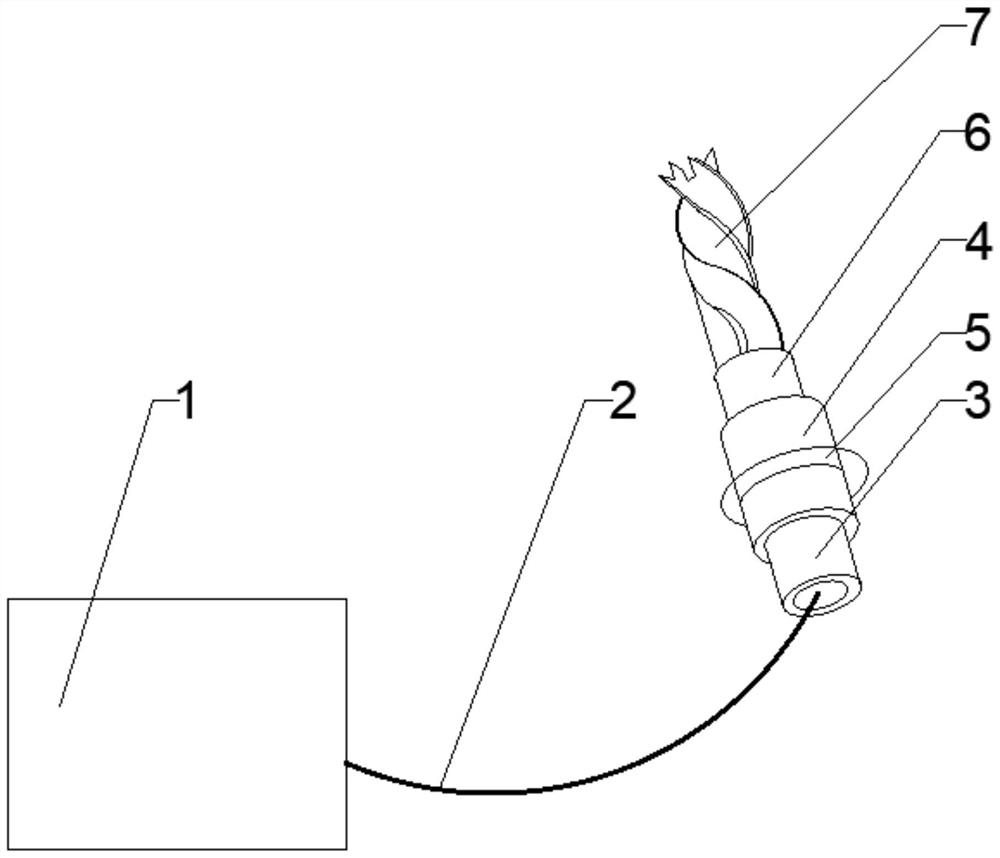

ActiveCN112355370BHigh precisionSmooth chip removalMilling cuttersMilling equipment detailsMilling cutterEngineering

The invention belongs to the technical field of switch cabinets, and in particular relates to a switch cabinet drilling tool and mold and a hole drilling system. The hole-opening tool includes an electric rotating machine, the electric rotating machine is connected with a chuck through a wire, the chuck is connected with a fixed rod, the fixed rod is connected with a rotating head, and the rotating head is connected with a milling cutter, and the surface of the milling cutter is coated with nano-metal paint; the hole-opening mold includes adsorption magnets and The fixed piece fixed by the adsorption magnet, and the fixed piece is provided with a groove; the hole opening system includes a hole cutting tool and a hole punching die. The hole-opening tool has smooth chip removal and low cutting resistance, which can prevent the milling cutter from breaking. The surface of the milling cutter is coated with nano-metal paint, which improves the rigidity of the milling cutter; the switch cabinet hole-opening die facilitates hole-opening work and improves the drilling The opening system is simple and convenient, and can achieve low vibration and spark-free opening of the switch cabinet, avoiding accidents and improving the efficiency of opening.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO SHOUGUANG POWER SUPPLY CO +1

Drilling device used before tripod supporting rod tapping

PendingCN114226800AAvoid flyingEasy to cleanPositioning apparatusMaintainance and safety accessoriesPhysicsDrill hole

The invention relates to a drilling device, in particular to a drilling device used before tripod supporting rod tapping. Aiming at the defects in the prior art, the invention provides the drilling device for the tripod supporting rod before tapping, which can fix the tripod during drilling. According to the technical scheme, the drilling device used before tripod supporting rod tapping comprises a bottom plate, a first supporting frame, a drilling mechanism, a fixing mechanism and a protection mechanism, the first supporting frame is arranged at the top of the bottom plate, the drilling mechanism is arranged on the first supporting frame, the fixing mechanism is arranged on the first supporting frame, and the protection mechanism is arranged at the top of the first supporting frame. And the tripod supporting rod can be fixed through the arranged fixing mechanism, so that drilling work is facilitated.

Owner:敖宁红

An easy-to-use steel structure drilling device

ActiveCN109570550BEasy to useEasy to adjustPositioning apparatusBoring/drilling componentsGear wheelClassical mechanics

The invention discloses a steel structure drilling device convenient to use. The steel structure drilling device comprises a bottom plate, the left side and the right side of the top of the bottom plate are both fixedly connected with supporting plates, the tops of the two supporting plates are fixedly connected through a top plate, the top of the top plate is fixedly connected with an air cylinder, and the bottom end of the air cylinder penetrates through the top plate and extends to the exterior of the top plate. According to the steel structure drilling device convenient to use, through mutual cooperation of the air cylinder, a drilling motor, a drilling rotating shaft, a first gear, a second gear, a rotating shaft, a second bearing, a drill bit, a threaded block, an adjusting motor, anadjusting rotating shaft, a third bearing, a third gear, a fourth gear, a threaded rotating shaft, a fourth bearing, a horizontal-moving motor and a strip-shaped gear groove, the problem of inconvenient use of a common steel structure drilling device is solved, when a plurality of drilled holes are formed in a steel structure, an automatic adjustment mode is adopted, the drilling position is convenient to adjust, the labor intensity of workers is lowered, the drilling error is reduced, and great convenience is brought to drilling work.

Owner:湖南常德辰馨科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com