Wood board drilling equipment

A technology for drilling equipment and wood boards, which can be applied to fixed drilling machines and other directions, can solve problems such as drilling, and achieve the effects of increasing usage rate, good pressing effect and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

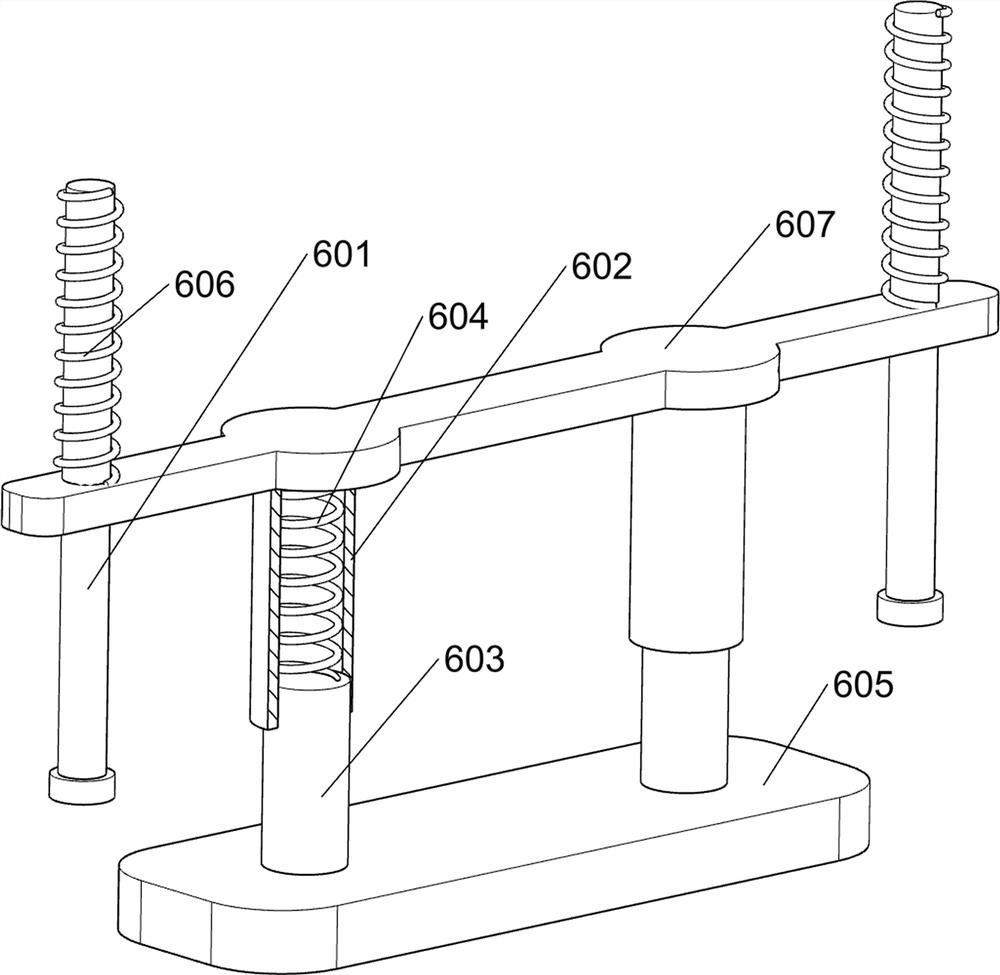

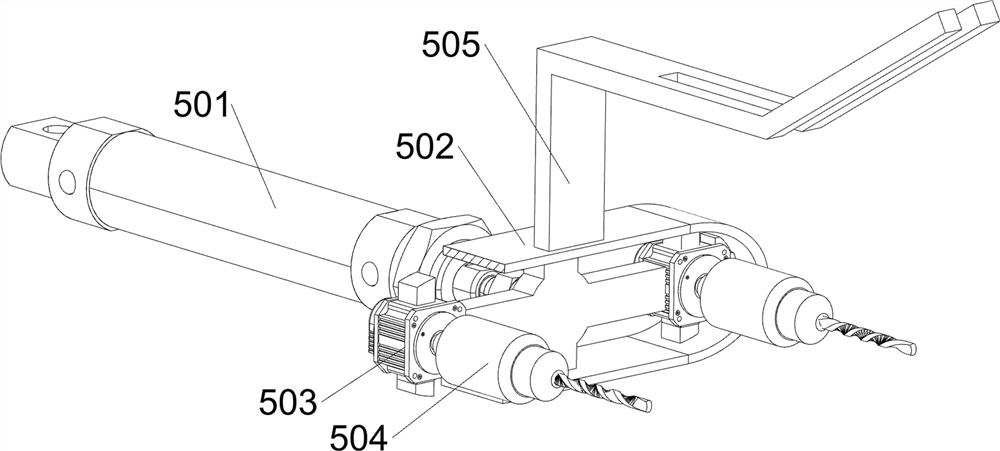

[0027] A device for drilling holes in wood, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, it includes a base 1, a bracket 2, a workbench 3, a drill bit 4, a drive assembly 5 and a pressing assembly 6, the top right side of the base 1 is symmetrically provided with a bracket 2, the top right side of the base 1 is provided with a workbench 3, and the base 1. A driving assembly 5 is provided on the left side of the top, and a drill bit 4 is arranged symmetrically on the driving assembly 5. A pressing assembly 6 is provided on the right side of the upper part of the workbench 3. The driving assembly 5 cooperates with the pressing assembly 6.

[0028] When people need to drill a plank, they place the plank on the workbench 3, then start the drive assembly 5, and under the action of the drive assembly 5, the drill bit 4 is driven to drill the plank, while the pressing assembly 6 pairs The planks are compressed, which can make it easier for the planks to carry o...

Embodiment 2

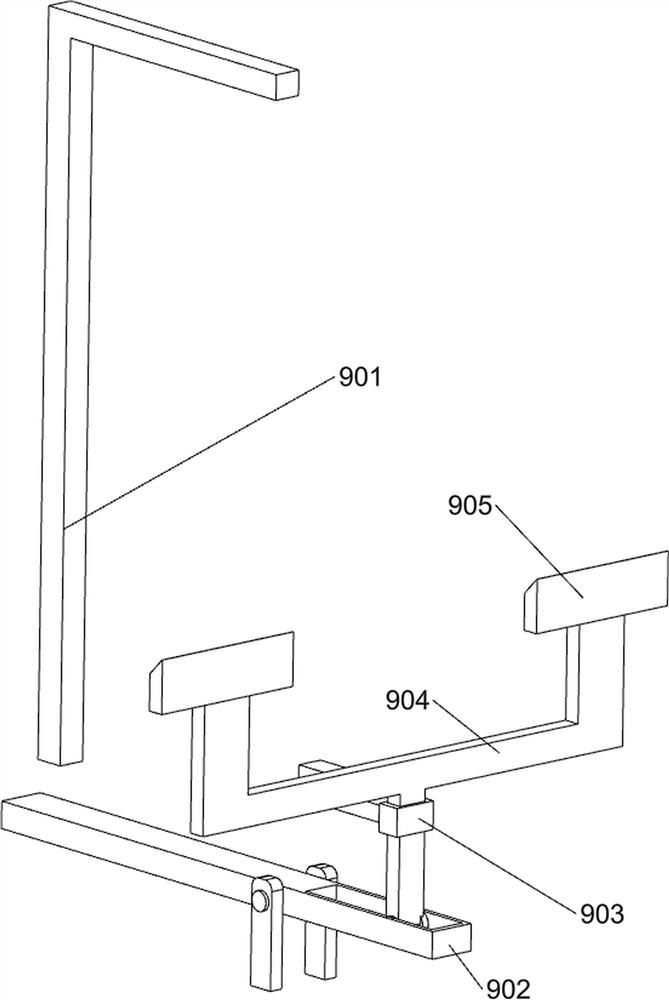

[0033] On the basis of Example 1, such as figure 2 , Figure 5 , Image 6 with Figure 7 As shown, a feed assembly 7 is also included, and the feed assembly 7 includes a first rack 701, a rotating shaft 702, a gear 703, a first guide groove 704, a push rod 705, a second rack 706, and a second guide rod 707, feed frame 708 and the 3rd spring 709, support sleeve 502 front and rear sides are provided with first tooth bar 701, and workbench 3 upper left side symmetrical rotation type is provided with rotating shaft 702, is all provided with gear 703 on rotating shaft 702, gear 703 are all meshed with the first rack 701, and the inner side of the upper part of the bracket 2 is provided with a first guide groove 704, between the first guide grooves 704, a pusher rod 705 is slidingly provided, and the bottom of the pusher rod 705 is symmetrically provided with a fixed block, The two ends on the left side of the push rod 705 are provided with a second rack 706, and the second rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com