Drilling device used before tripod supporting rod tapping

A drilling device and support rod technology, applied in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve problems such as position deviation and tripod fixation, and achieve the effect of easy cleaning and avoiding random flying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

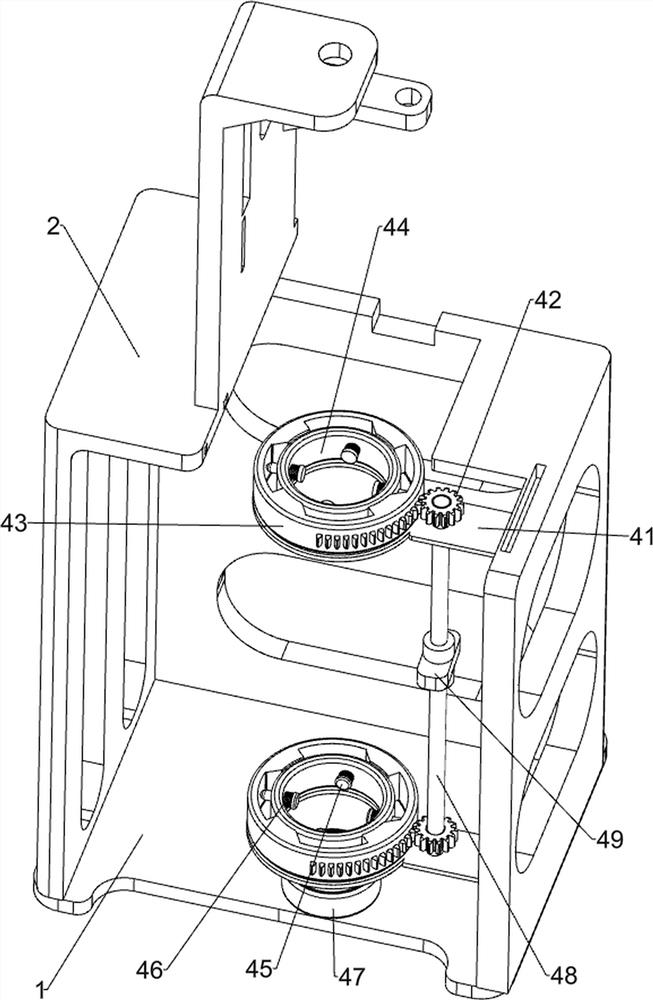

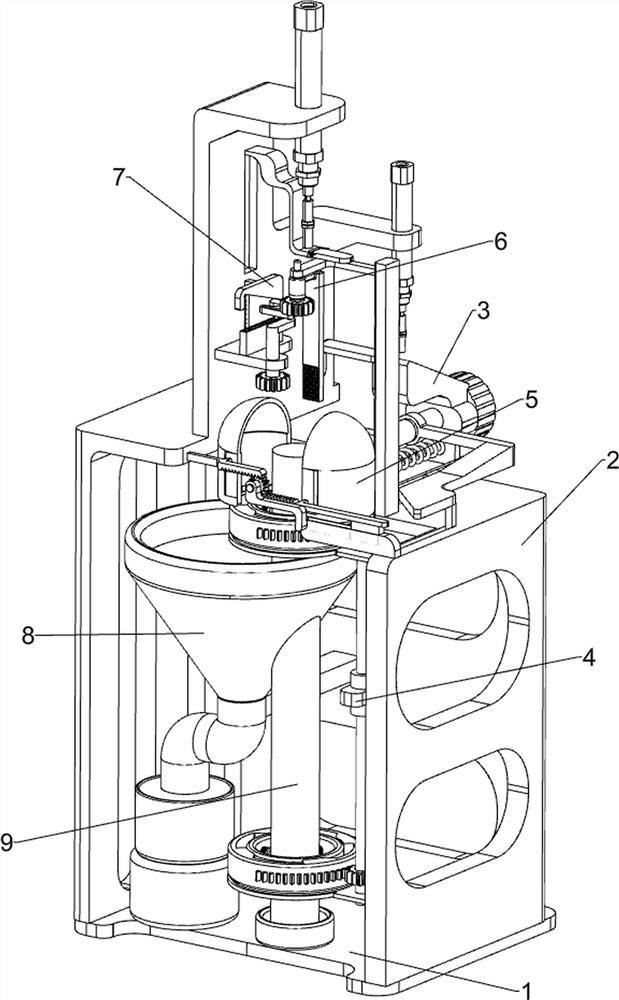

[0024] A drilling device for tripod support rod before tapping, refer to figure 1 As shown, it includes a bottom plate 1, a first support frame 2, a drilling mechanism 3, a fixing mechanism 4 and a protection mechanism 5. The top of the bottom plate 1 is provided with a first support frame 2, and the first support frame 2 is provided with a drilling mechanism 3. A fixing mechanism 4 is provided on the first support frame 2, and a protection mechanism 5 is provided between the top of the first support frame 2 and the parts of the drilling mechanism 3.

[0025] refer to figure 2 As shown, the drilling mechanism 3 includes a first cylinder 31, a first special-shaped block 32, a high-speed drilling machine 33, a first slotted fixed block 34 and a first return spring 35, and the rear side of the top of the first support frame 2 is provided with The first cylinder 31, the first support frame 2 top rear side is provided with the first slotted fixed block 34, and the sliding type on...

Embodiment 2

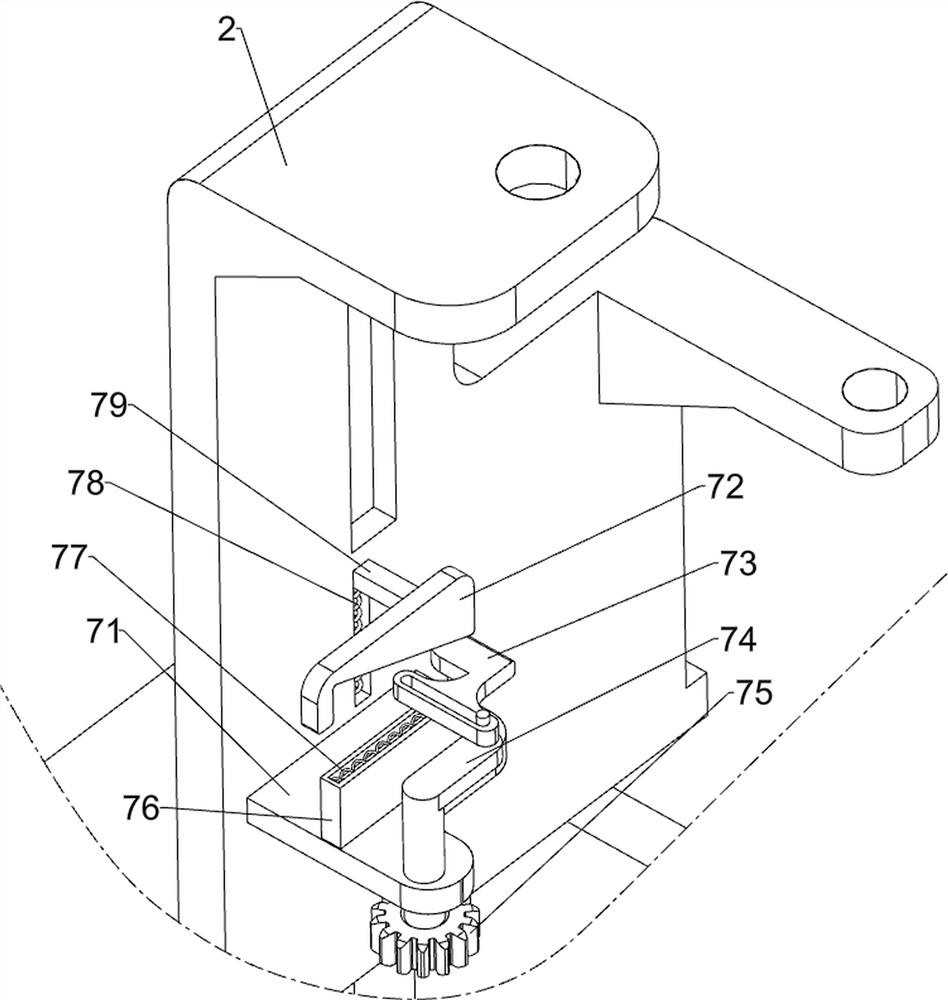

[0030] On the basis of embodiment 1, refer to Figure 5 As shown, it also includes a deburring mechanism 6, and the deburring mechanism 6 includes a second cylinder 61, a second special-shaped block 62, a first baffle plate 63, a torsion spring 64, a fixed plate 65, a second fixed rod 66, a third Gear 67, the fourth return spring 68, the second baffle plate 69 and file 610, the first support frame 2 top is provided with the second cylinder 61, the first support frame 2 upper left sliding type is provided with the second special-shaped block 62, the second The special-shaped block 62 links to each other with the second cylinder 61 telescopic rods, the second special-shaped block 62 right side rotation type is provided with the first baffle plate 63, is connected with the torsion spring 64 between the first baffle plate 63 and the second special-shaped block 62, the third The upper side of the support frame 510 is slidably provided with a fixed plate 65, and a fourth return spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com