Construction method for highway to pass through coal seam goaf

A technology of expressway and construction method, which is applied in the direction of mining equipment, earthwork drilling, filling, etc., can solve the problems that there is no construction technology in the goaf, and it is difficult to ensure the construction quality in the goaf, so as to avoid poor hole quality, Avoid untimely correction and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

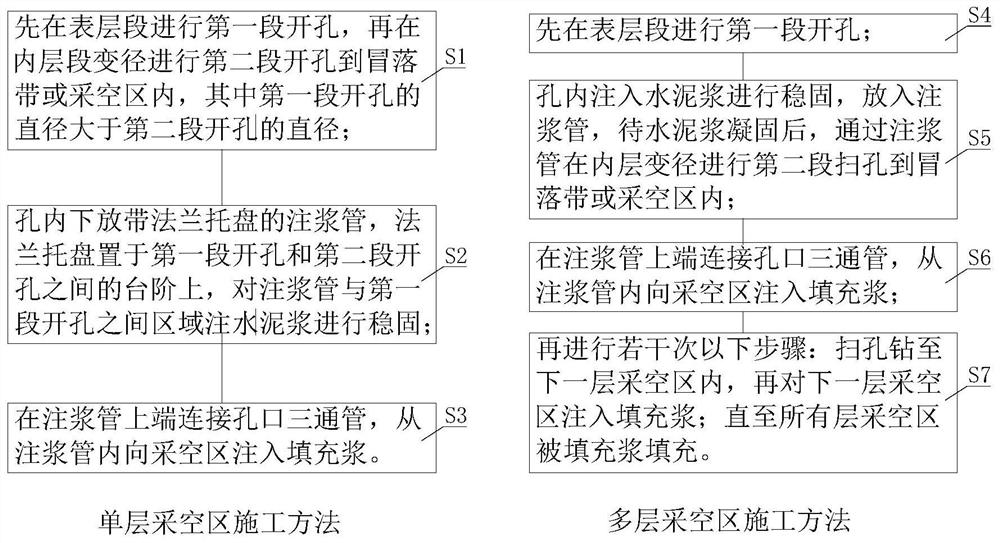

Method used

Image

Examples

Embodiment 1

[0070] Goaf 1 has 249,000 meters of drilling holes, the depth of the holes ranges from 101m to 205m, and the grouting volume is 197,000 cubic meters. Goaf 1 is treated by drilling and grouting. Drilling uses 220 down-the-hole drilling rig or XY-4 geological drilling rig, and grouting uses 250 and 350 mud pumps.

[0071] 1. Construction technology and requirements

[0072] 1.1 fixed point

[0073] The grouting hole shall be measured and set out on the spot by GPS or total station. For the general grouting hole, the actual hole position shall not deviate from the design position by 0.5m. When the borehole cannot be placed in the designed position because of the influence of the terrain, the boreholes that can be in place around it should be constructed first, and then adjusted according to the situation of the goaf 1 exposed by drilling.

[0074] 1.2 Hole forming process and technical requirements

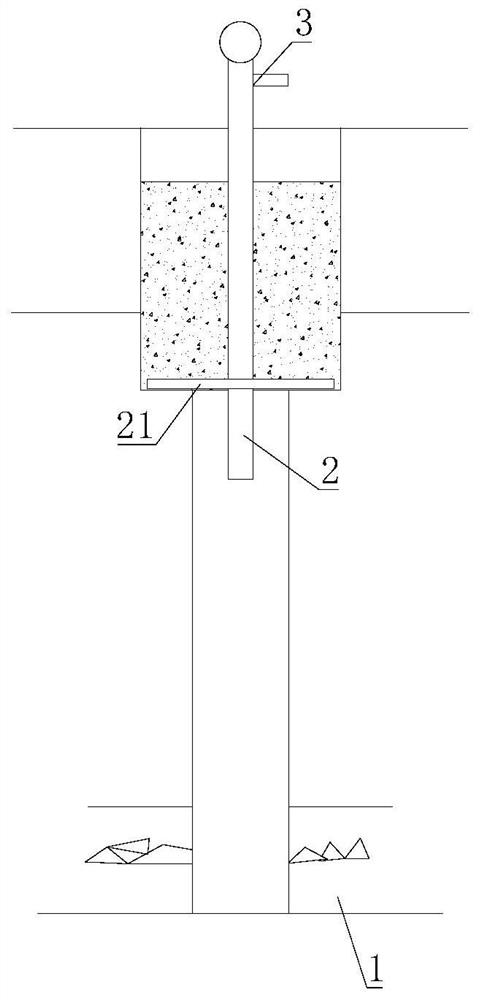

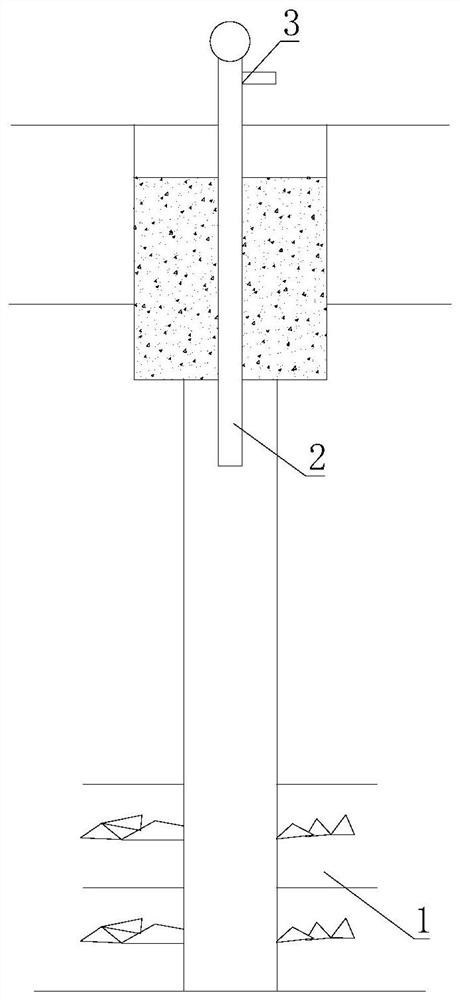

[0075] (1) Hole forming and casting orifice pipe

[0076] For the single-la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com