House building engineering column top steel bar drilling and planting auxiliary device

A technology of construction engineering and auxiliary devices, which is applied in the field of housing construction, and can solve problems such as multiple operating points, falling from heights, and high physical exertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

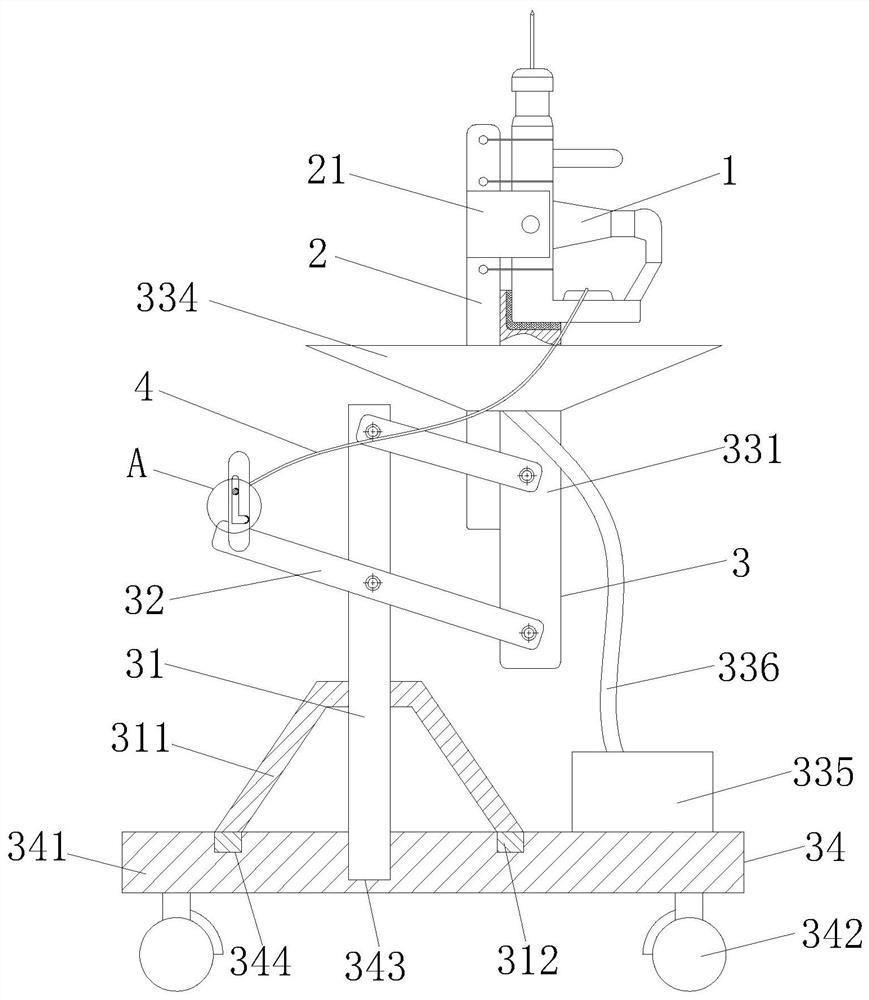

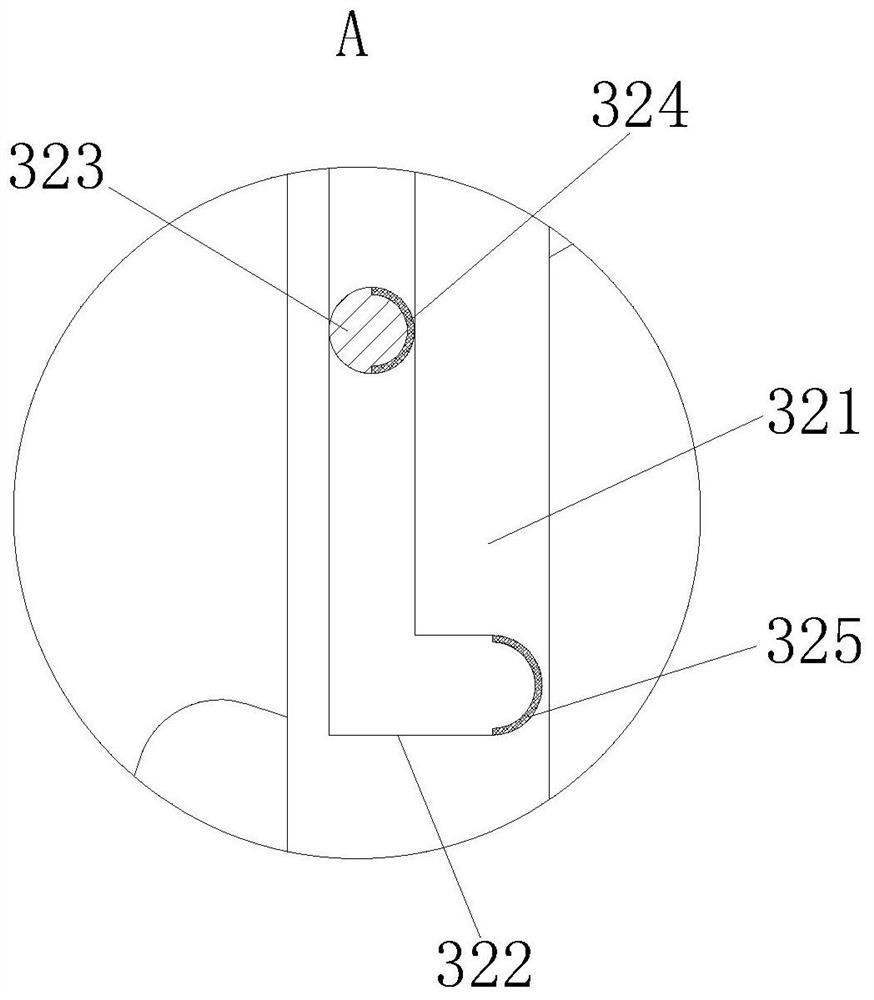

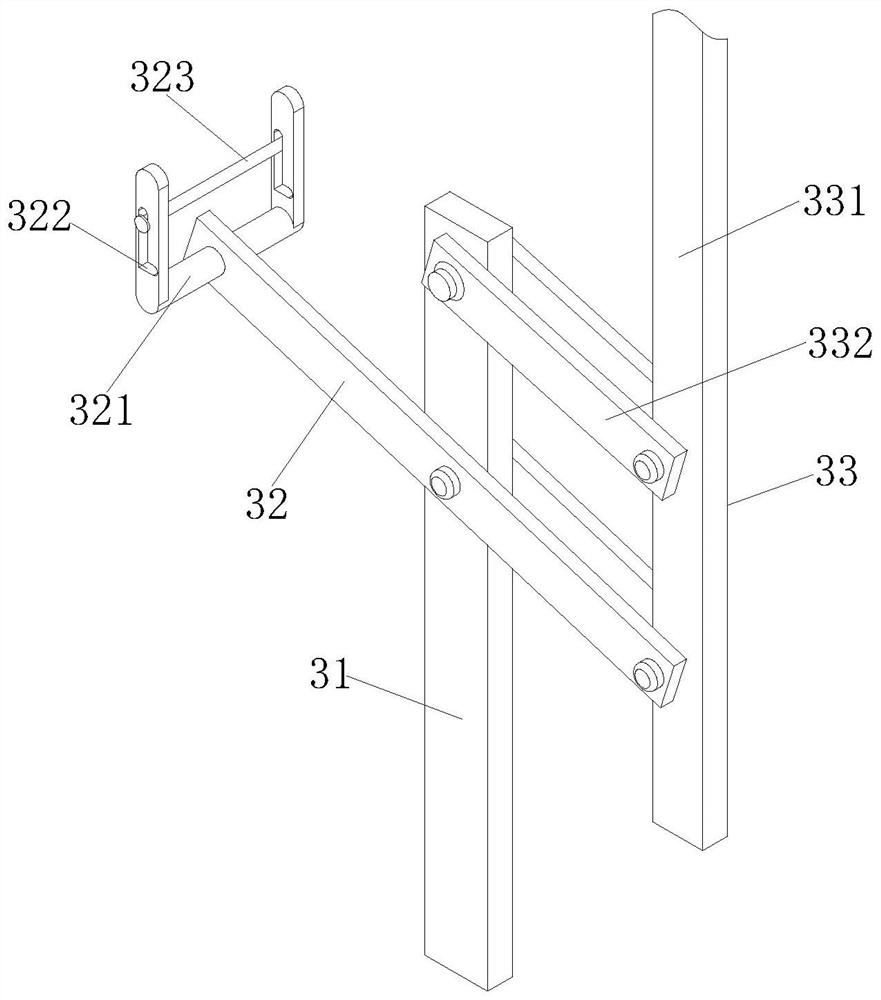

[0029] see Figure 1-6 As shown, an auxiliary device for drilling and planting steel bars at the top of a house construction project includes a drilling machine body 1, a fixed rod 2, a support assembly 3 and a pull rope 4; the fixed rod 2 is fixed on the support assembly 3 on the side wall; the drilling machine body 1 is arranged on the top of the support assembly 3, and the drilling machine body 1 is affixed to the fixing rod 2 through iron wire; the stay rope 4 passes through the drilling machine body 1, and the stay rope 4 ends partly wound on the support assembly 3; the support assembly 3 includes a column 31, a handle bar 32 and a lifting mechanism 33; a pair of the handle bars 32 are connected to the outer side wall of the column 31 by rotating pins, and are respectively located on the column 31 opposite On the two side walls of the side wall; the lifting mechanism 33 is arranged on the outer side wall of the column 31, and the lifting mechanism 33 is connected with the...

Embodiment 2

[0040] see Figure 7 As shown in Comparative Example 1, as another embodiment of the present invention, an anti-slip gasket 241 is fixedly attached to the side wall of the splint 24; the material of the anti-slip gasket 241 is rubber; The anti-slip gasket 241 is fixedly connected on the side wall of 24 to increase the friction force between the splint 24 and the contact surface of the drilling machine body 1, so that the fixing effect of the splint 24 is better.

[0041] Working principle: When drilling and planting steel bars, the drilling machine body 1 is placed in the groove 333 on the top of the dowel bar 331, and the rubber pad 337 on the inner wall of the groove 333 starts the drilling machine body 1 Buffer protection function, when the drilling machine body 1 is stuck between the two baffles 21, the threaded rod 23 is rotated, the threaded rod 23 and the threaded hole 22 are threadedly matched, and the splint 24 is gradually approached during the rotation of the thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com