Automatic wood stick drilling device for furniture

A drilling device and wooden rod technology, applied to fixed drilling machines, etc., can solve problems such as low safety and high manpower consumption, and achieve the effects of facilitating the operation process, reducing manpower consumption, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

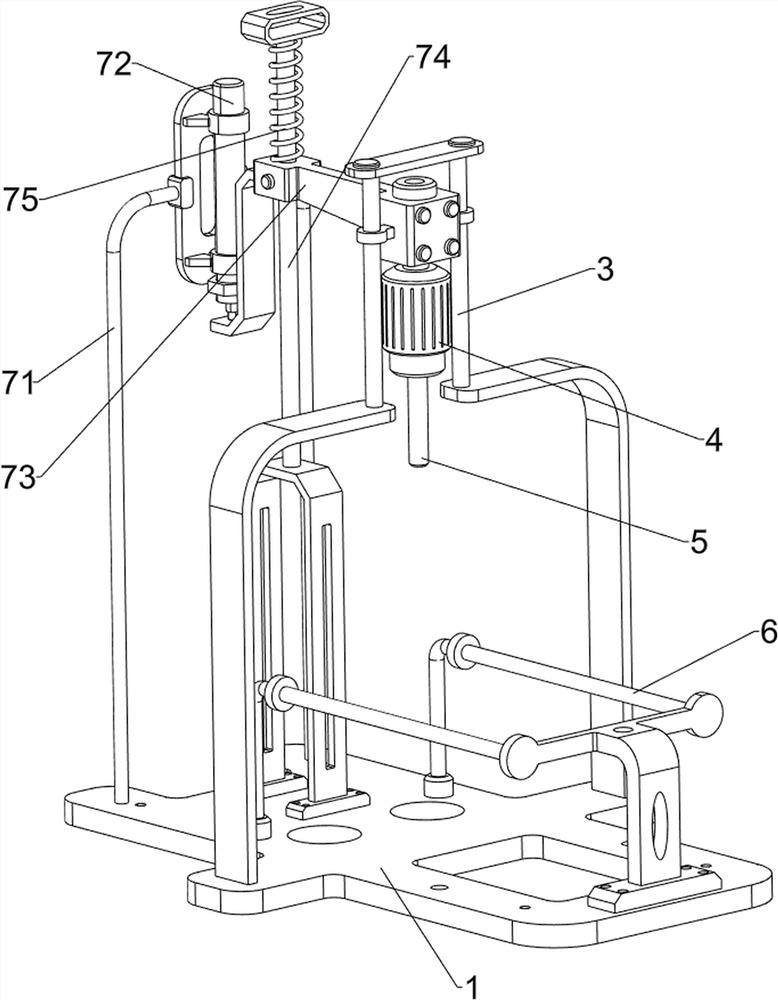

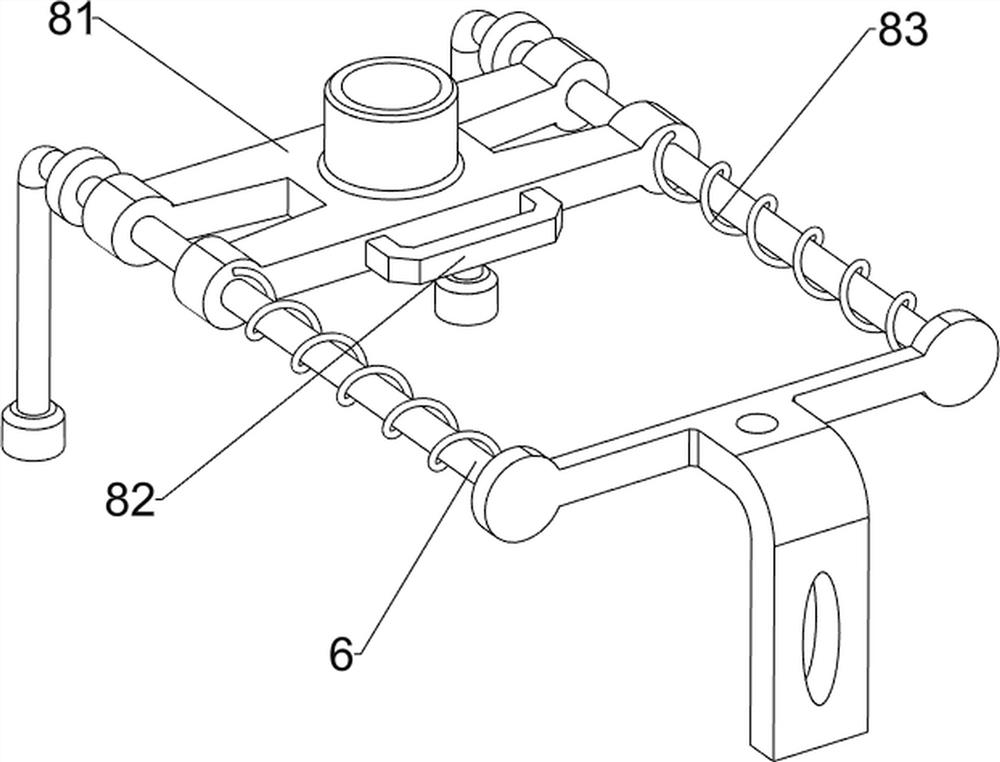

[0075] An automatic drilling device for wooden sticks for furniture, such as figure 1 As shown, it includes a base 1, a pillar 2, a first guide rail 3, an electric drill 4, a drill bit 5, a second guide rail 6, a drilling mechanism 7, a pushing mechanism 8 and a clamping mechanism 9, and the upper side of the base 1 is provided with two Pillar 2, the first guide rail 3 is provided on the upper side of the pillar 2, the drilling mechanism 7 is provided on the upper side of the rear part of the base 1, the drilling mechanism 7 is slidably connected with the first guide rail 3, and the electric drill 4 is arranged on the drilling mechanism 7 , The lower side of the electric drill 4 is provided with a drill bit 5, the upper side of the base 1 is provided with a second guide rail 6, the second guide rail 6 is provided with a pushing mechanism 8, and the pushing mechanism 8 is provided with a clamping mechanism 9.

[0076] When people are going to drill the wooden stick, they first ...

Embodiment 2

[0078] On the basis of Example 1, such as figure 2 , image 3 and Figure 4 As shown, the drilling mechanism 7 includes a first bracket 71, a cylinder 72, a first connecting block 73, a first slide bar 74 and a first spring 75, and the base 1 rear upper side is provided with a first bracket 71, and the first bracket 71 top is equipped with cylinder 72, base 1 rear upper side is provided with first slide bar 74, and first slide bar 74 is provided with the first connecting piece 73 slidingly, and first connecting piece 73 cooperates with the expansion link of cylinder 72, A first spring 75 is wound around the first sliding rod 74 , the first spring 75 is connected with the first sliding rod 74 and the first connection block 73 , and the front part of the first connection block 73 is connected with the electric drill 4 .

[0079] When people are going to drill the wooden stick, they first put the wooden stick into the push mechanism 8, and manually push the push mechanism 8 to...

Embodiment 3

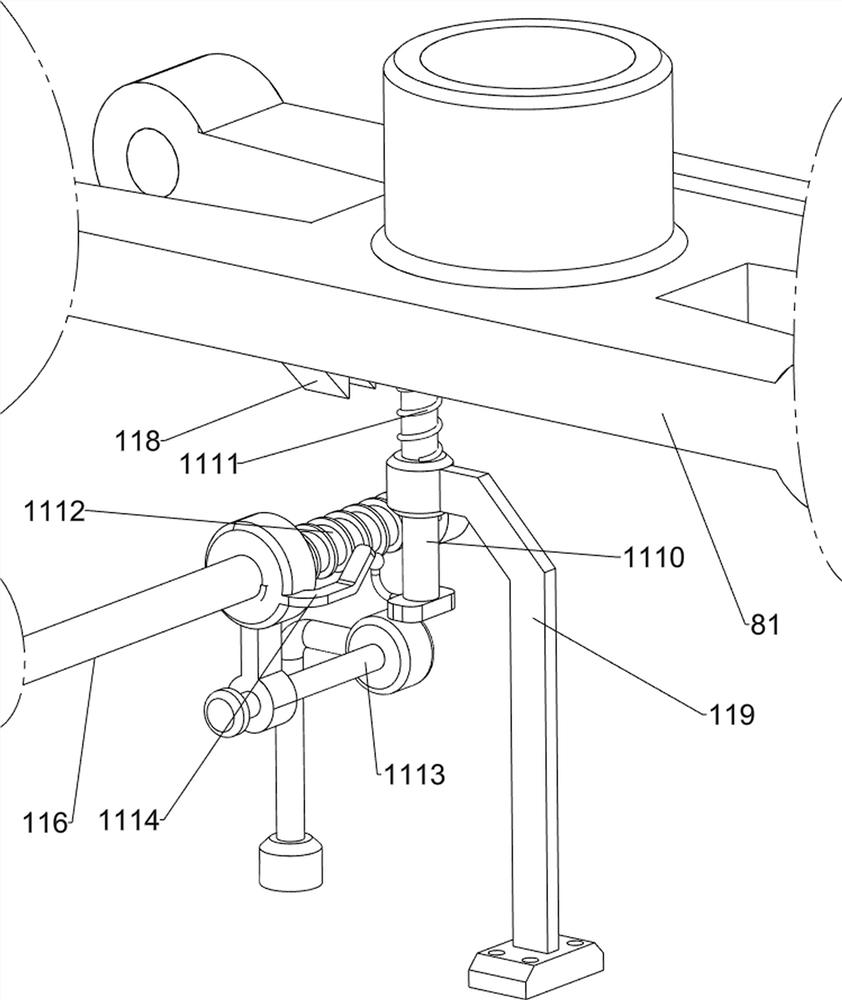

[0085] On the basis of Example 2, such as figure 1 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a swing mechanism 10 is also included, and the swing mechanism 10 includes a second connecting block 101, a connecting rod 102, a third bracket 103, a first rotating shaft 104, a fourth spring 105 and a swing frame 106, and the lower part of the first connecting block 73 The front side is provided with a second connecting block 101, and the left and right sides of the second connecting block 101 are provided with two connecting rods 102, and the front side of the first sliding rod 74 is provided with two third brackets 103, and the outsides of the third bracket 103 are both Rotation type is connected with first rotating shaft 104, and first rotating shaft 104 is all provided with swing frame 106, and swing frame 106 is all matched with connecting rod 102, is wound with fourth spring 105 on first rotating shaft 104, and fourth spring 105 is connected with the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com