Swing clamp for pipe numerical control drilling machine

A technology of CNC drilling machines and clamps, which is applied in the direction of clamping, metal processing machinery parts, supports, etc., can solve the problems of poor hole processing quality, damage to equipment and pipe fittings, etc., and achieve the effect of improving drilling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

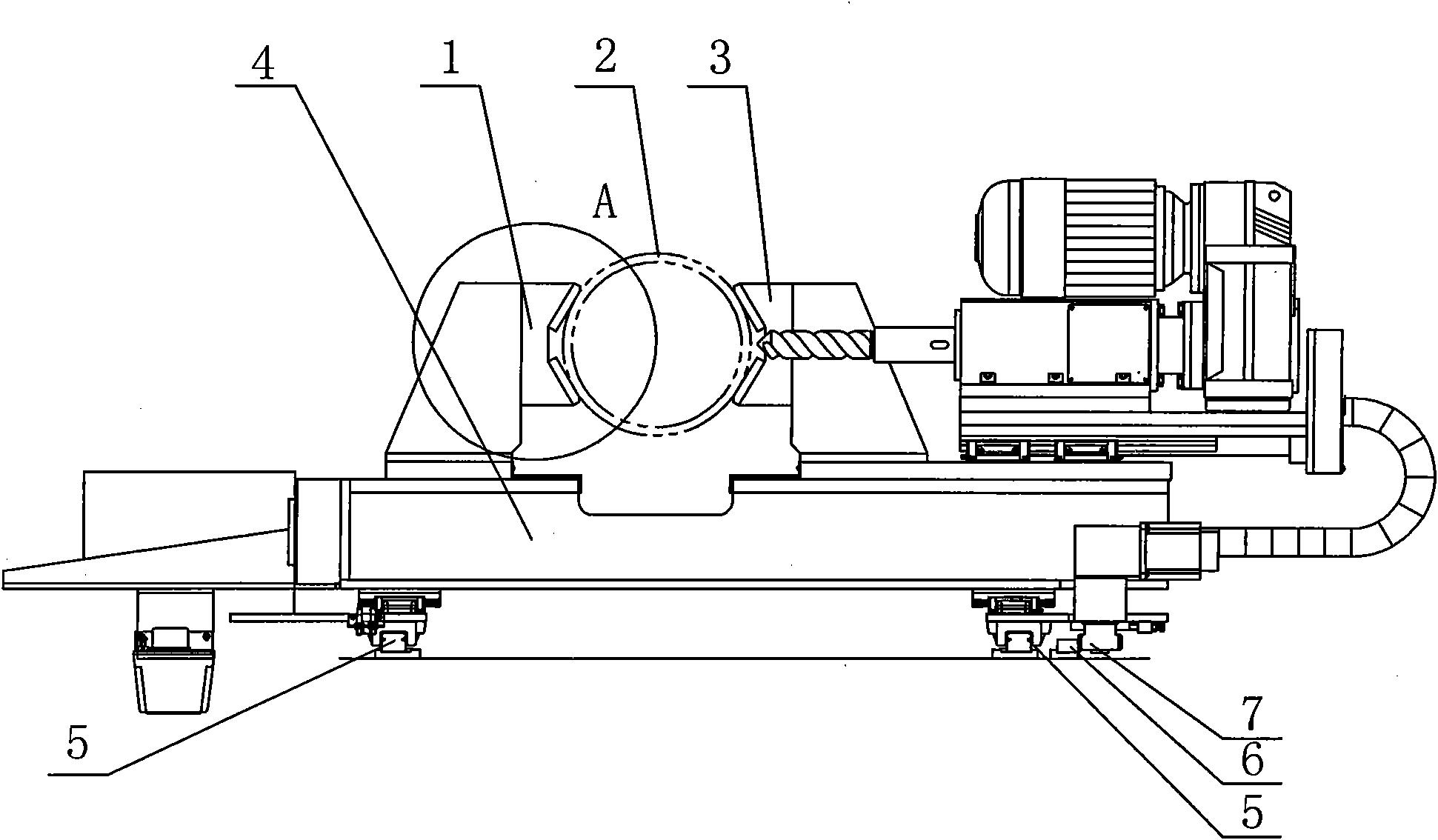

[0010] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

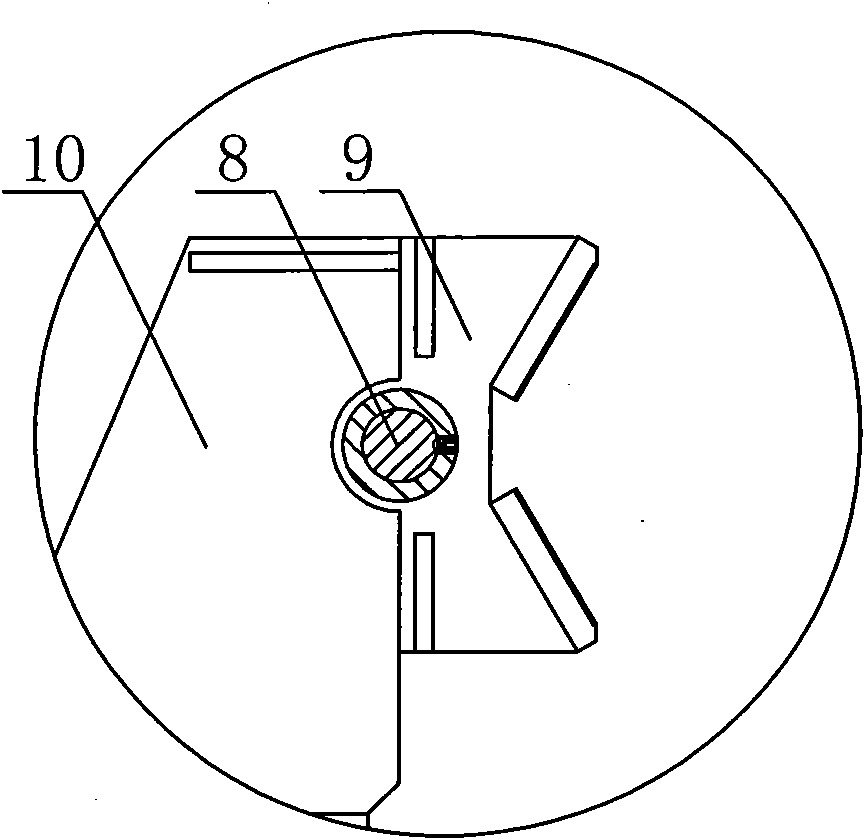

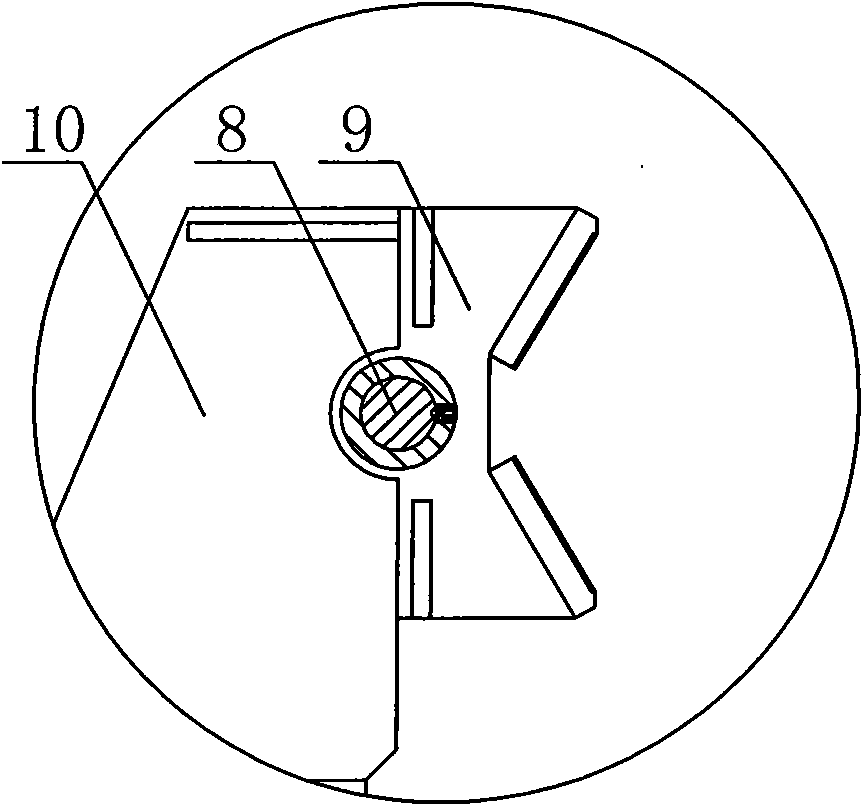

[0011] Such as figure 2 As shown, the V-shaped clamp 9 provided on the top of the first clamping block 1 and the second clamping block 3 of the present invention is an independent part. One side of the clamp 9 is provided with a V-shaped notch, and the middle part of the other side is provided with a pivot hole. , through the pin shaft 8 and the clamping block base 10 pivot connection, it can swing and rotate around the pin shaft 8 at a certain angle, so that when clamping, it can make self-adaptive and flexible adjustments according to the shape of the outer wall surface of the clamped pipe, and more Effectively and stably clamp the circular section to prevent the rigid structure from being self-adaptive and thus unable to effectively clamp or damage the pipe fittings due to rigid clamping.

[0012] The above description is an explanati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com