Device and method capable of reducing interlayer burrs during making holes for aircraft assembly

An aircraft assembly and interlayer technology, which is applied in the direction of manufacturing tools, portable drilling rigs, drilling/drilling equipment, etc., can solve the problems of complex hole making process and poor effect, achieve reasonable device structure, reduce the workload of hole making, and improve The effect of drilling efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

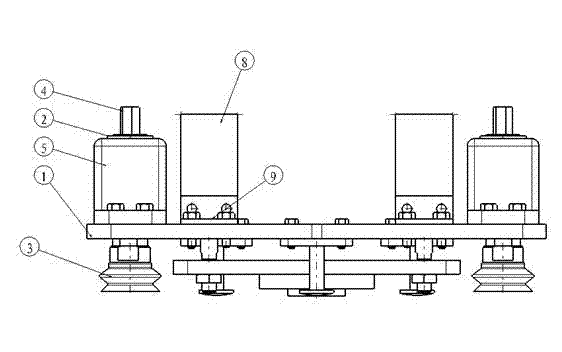

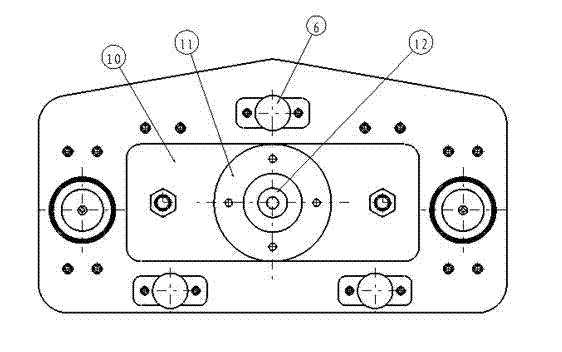

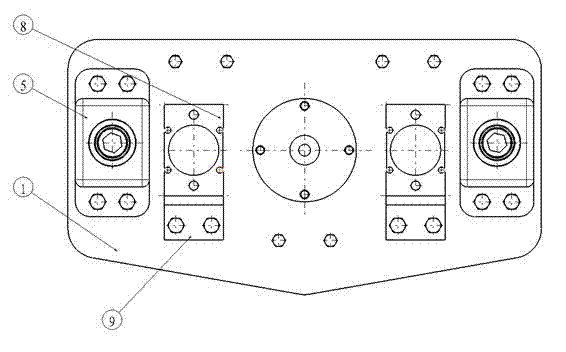

[0039] Such as Figure 1-4 shown.

[0040] A device capable of reducing interlayer burrs during aircraft assembly hole making, which includes a main frame plate 1, a spherical joint bearing 2, a vacuum suction cup 3, a suction cup connecting shaft 4, an auxiliary mounting frame 5, a positioning shaft 6, and a limit rubber ring 7 , cylinder 8, cylinder auxiliary mounting plate 9, pressure foot frame 10, pressure foot 11 and drill riveting sleeve 12, such as figure 1 As shown, the vacuum chucks 3 (the number is at least two) are balanced and fixedly arranged on the main frame plate 1, so that the main frame plate 1 can be fixed on the machined surface of the aircraft through the suction force of the vacuum chucks 3, The vacuum suction cup 3 can be connected with the vacuum generating device through the trachea so that the suction cup foot can generate the required suction force, and the adjustment of the vacuum degree of the vacuum generating device can realize the adjustment o...

Embodiment 2

[0044] A kind of method that can reduce interlayer burr when aircraft assembly makes hole it comprises the following steps:

[0045] Step 1: Place and position the device of Example 1 on the surface of the product;

[0046] Step 2: Fix the device of Example 1 on the surface of the aircraft product by controlling the suction cup in turn. At this time, the arc-shaped end faces of the three positioning shafts are in contact with the surface of the aircraft product. The arc-shaped ends of the positioning shafts are covered with rubber, allowing a certain amount The elasticity, so there will be no excessive pressure on the surface of the aircraft product to cause deformation. At this time, the centroid axis of the triangle formed by the three positioning axes coincides with the surface normal of the aircraft product in the working area, that is, the normal alignment of the pressure foot is completed.

[0047] Step 3: Control the pressure switch of the cylinder so that the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com