Automatic equidistance punching device for metal strip plate

A technology of metal strips and metal plates, applied in driving devices, feeding devices, metal processing, etc., can solve the problems of low drilling efficiency and achieve the effect of improving drilling quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

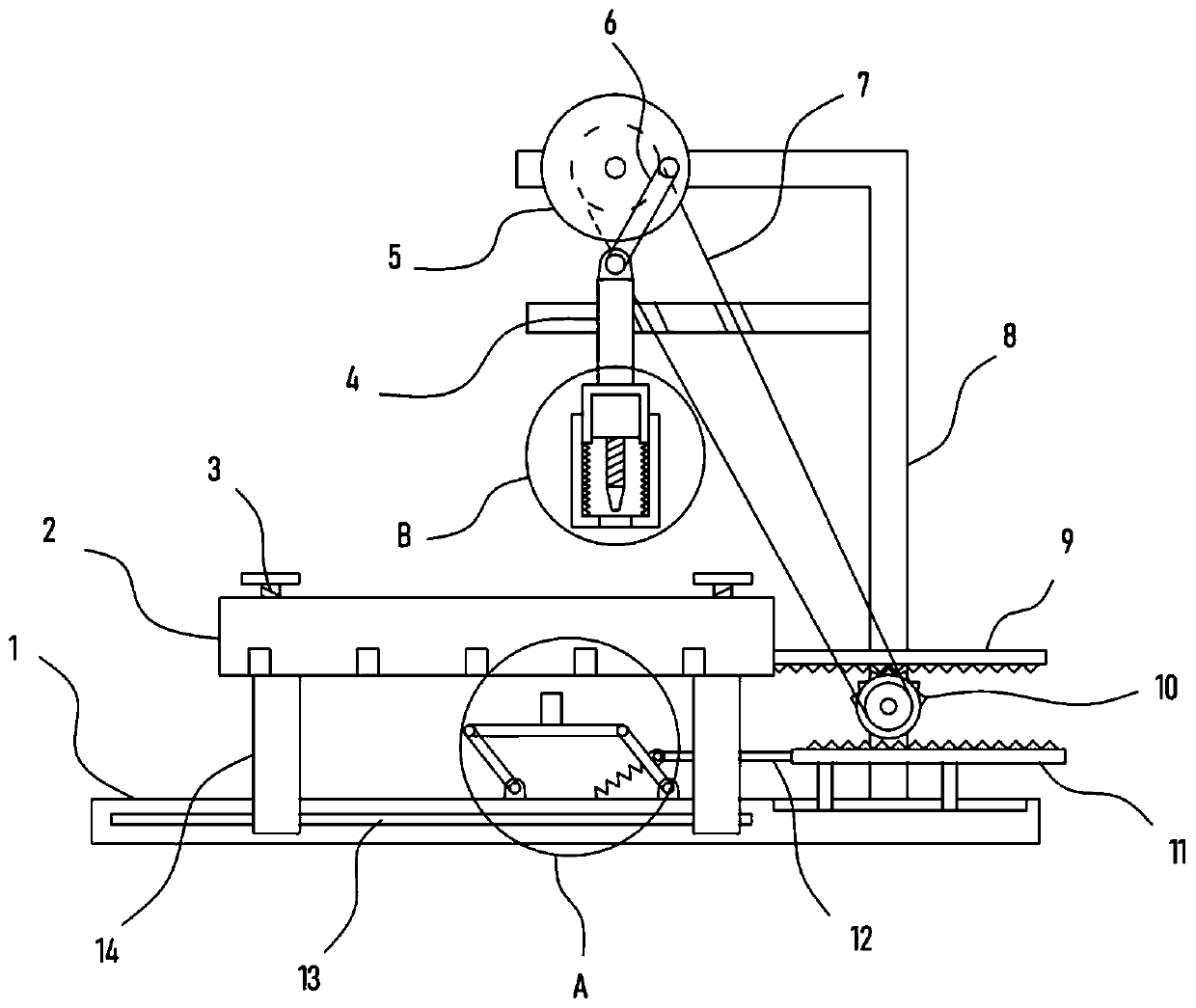

[0023] see Figure 1-5 , an automatic equidistant opening device for metal slats, comprising a base plate 1, a bracket 8 is fixed on the base plate 1, a fixing frame 2 is slidably installed on the bracket 8, and a locking mechanism for clamping metal plate parts is provided on the fixing frame 2 Mechanism, a turntable 5 is installed on the bracket 8, and a lifting mechanism is connected to the turntable 5. The lower end of the lifting mechanism is fixed with a hole assembly for drilling metal plate parts. The incomplete gear 10, the upper side of the incomplete gear 10 is meshed with the rack 19 fixed with the fixed frame 2, the bottom plate 1 is provided with a swing mechanism for intermittently fixing the fixed frame 2, and the swing mechanism includes And the gear rack II11 that is engaged with it.

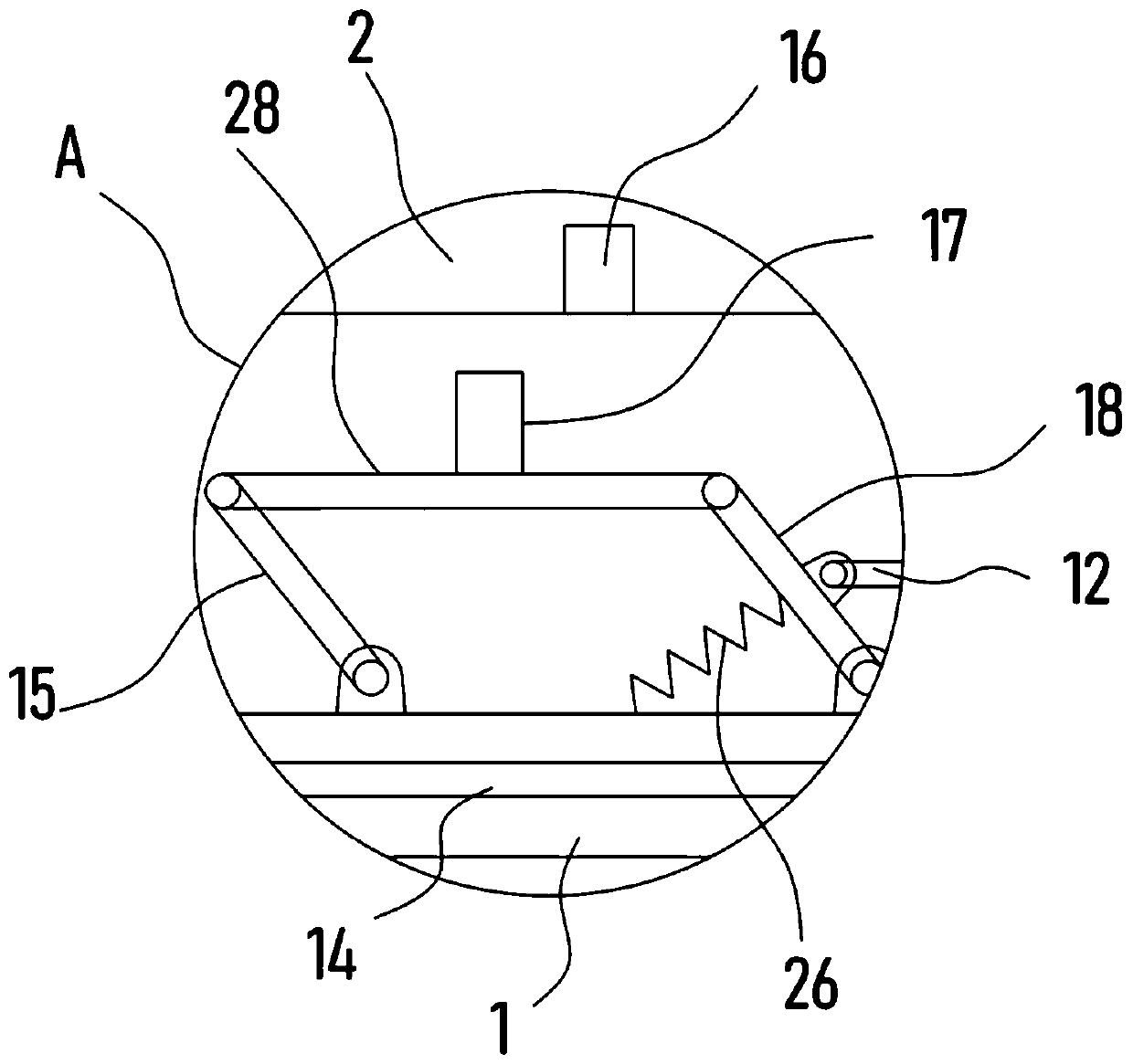

[0024] Before drilling the sheet metal, the sheet metal is locked by a locking mechanism. Specifically, the locking mechanism includes a limiting groove 27 provided on the inn...

Embodiment 2

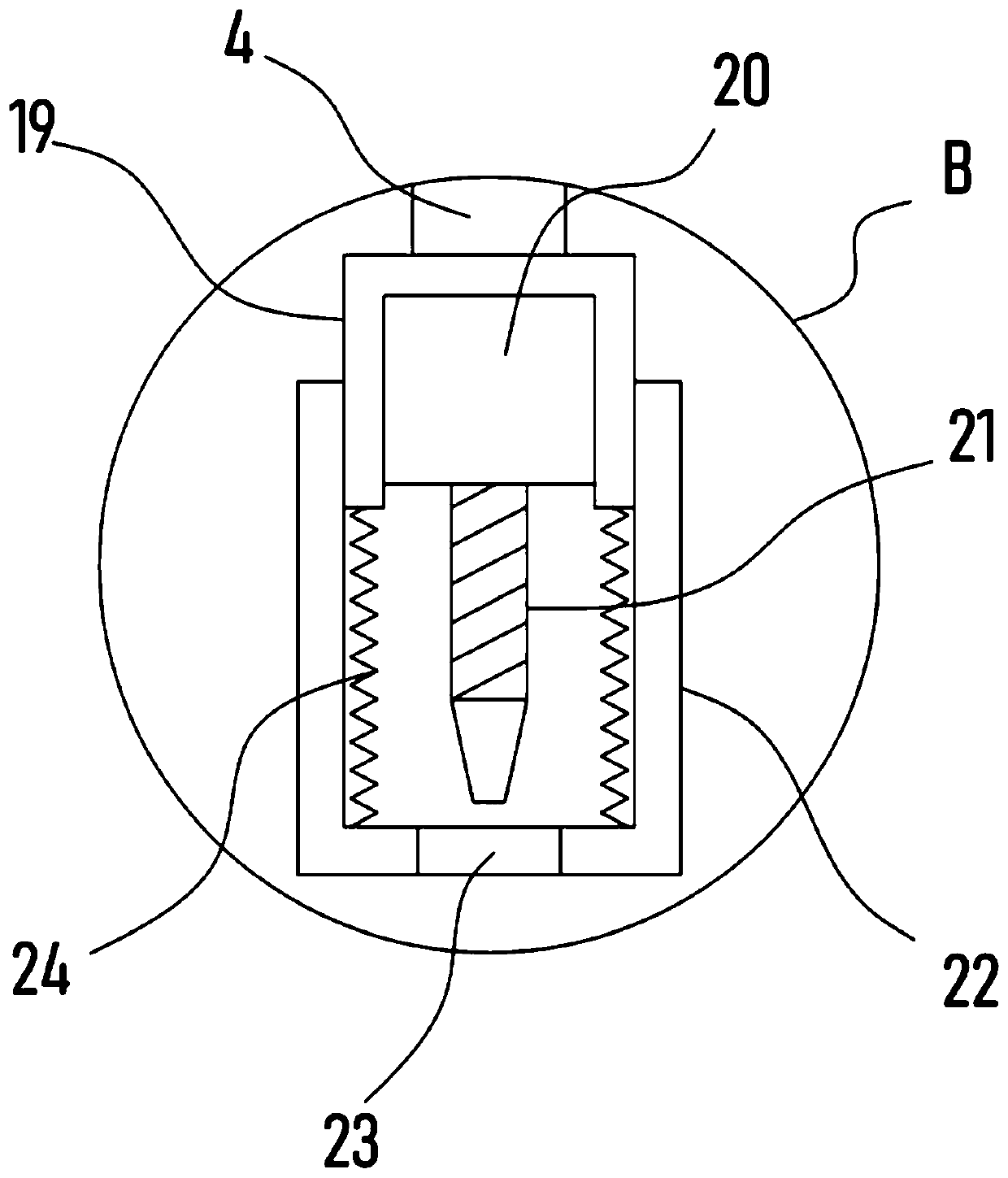

[0029] On the basis of Embodiment 1, in order to improve the stability of the drilling of sheet metal parts and improve the quality of the opening, the opening assembly includes a motor seat 19 fixed on the lower end of the longitudinal slide bar 4, and the motor seat 19 is fixedly connected with a motor 20. The output shaft drive of 20 is connected with the drill bit 21 that is vertically arranged, and the drill bit 21 outer cover is provided with the opening stabilizing mechanism, and the opening stabilizing mechanism comprises the sleeve 22 that is slidably sleeved on the motor base 19, and the sleeve 22 is connected with the motor base 19. A return spring 24 is fixedly connected between the edges, and the bottom of the sleeve 22 is penetrated with an extension hole 23 for the drill bit 21 to pass through.

[0030] When the longitudinal slide bar 4 drives the opening assembly to move down, the sleeve 22 first touches the metal plate, and the return spring 24 is deformed unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com