Texturing of the seal surface for a roller cone rock bit

A sealing surface and surface structure technology, which is applied to the sealing of drill bits, engines, earthwork drilling, etc., can solve the problems of journal bearing scratches, wear, and seizure, and achieve the effect of reducing friction and prolonging the life of drill bits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

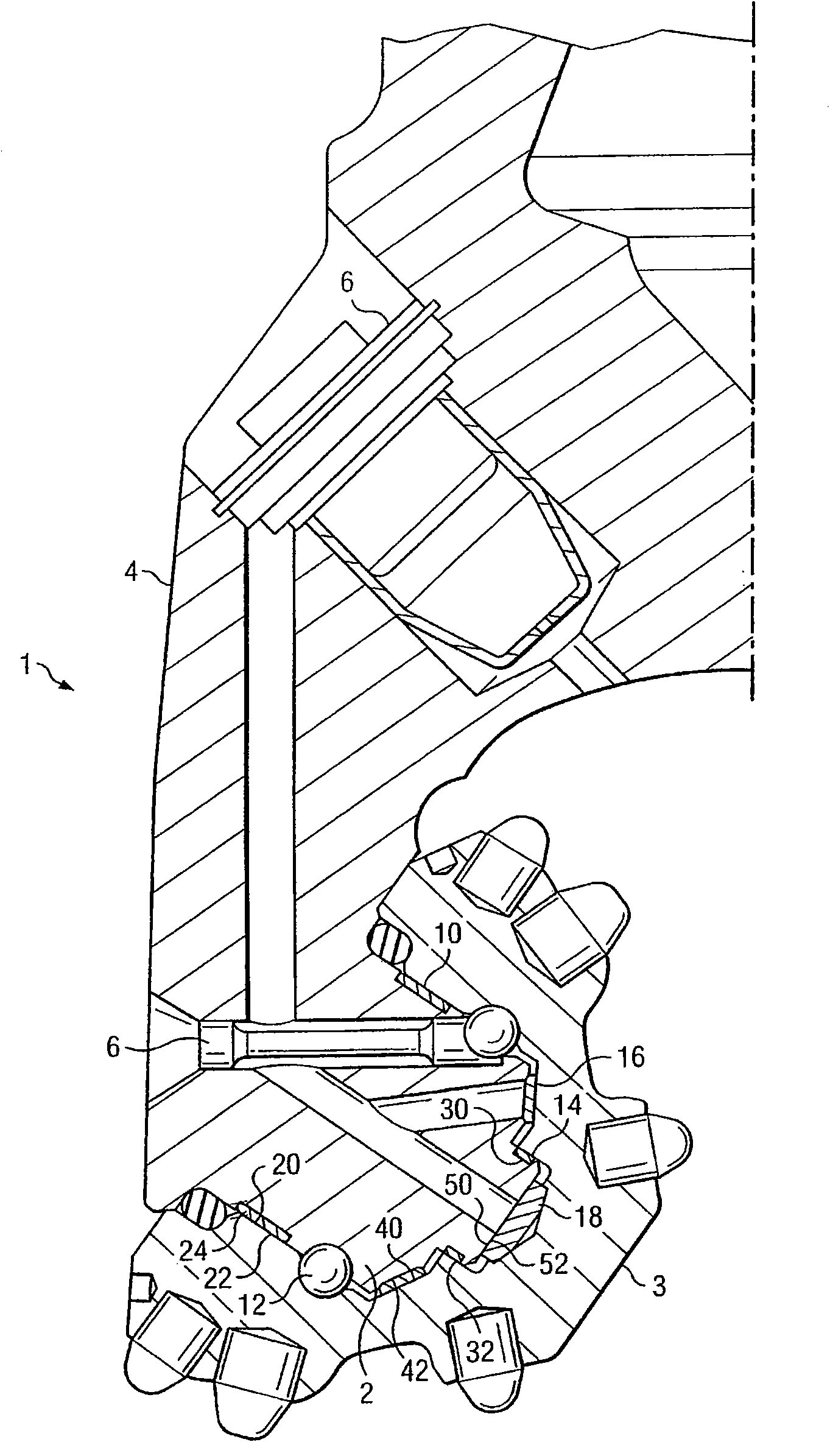

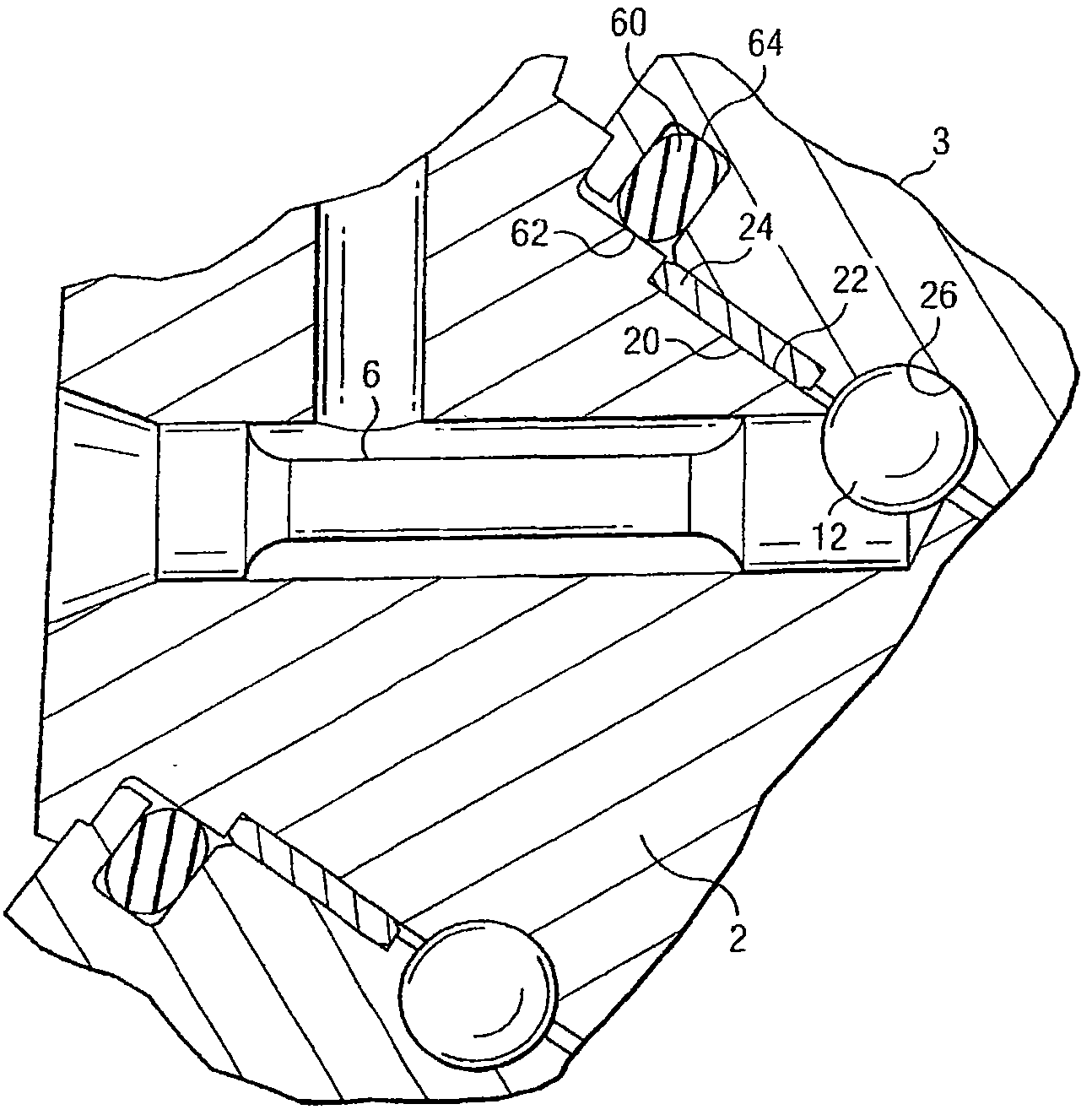

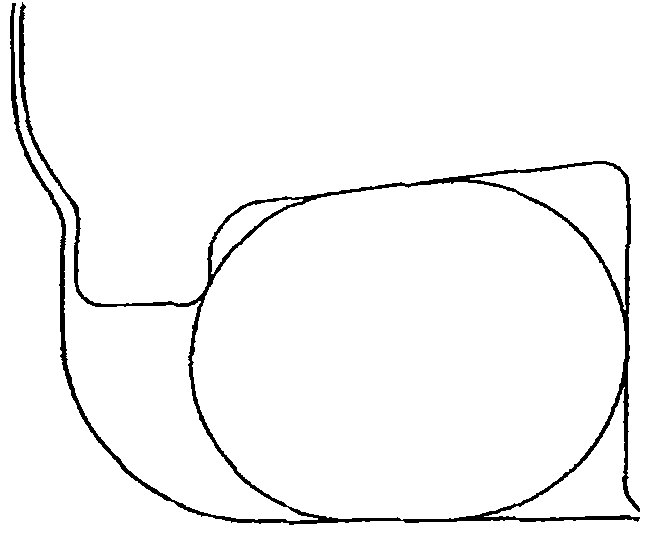

[0044] Surface texturing is used to modify the topography of one or more surfaces (radial, conical or cylindrical or otherwise) of a sealing system and / or bearing system of a roller cone bit. The surface texture creates a dimpled surface that retains additional lubricant that is beneficial in reducing friction at the interface and in the region of mixed lubrication. At least for the bearing surface, the surface coverage of the dimpled formation should exceed a minimum of 60%, more preferably between 70-90%, and even more preferably approach or reach approximately 100%. For sealing surfaces, a lighter shot peening (5-60%) can be applied.

[0045] Refer to Figure 1 and figure 2 , the textured surface in a sealing system to which surface texture is applied preferably includes any surface that has sliding contact with the sealing ring 60 when the cone rotates. This will include one or more surfaces of the gland 64 . More specifically, it will include at least the sealing hub 62...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com