Protector for rock bit seals

a technology of protecting and sealing the rock bit, which is applied in the direction of machines/engines, mechanical equipment, cutting machines, etc., can solve the problems of secondary sealing taking up precious space, wear and leakage,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

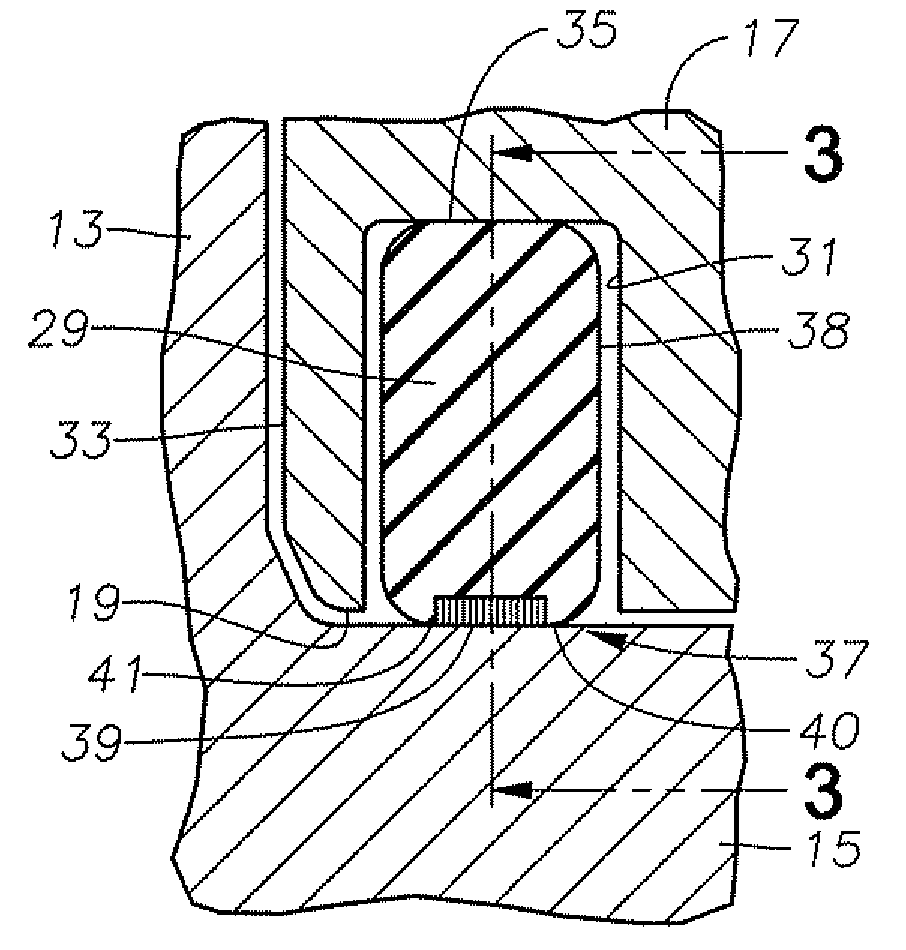

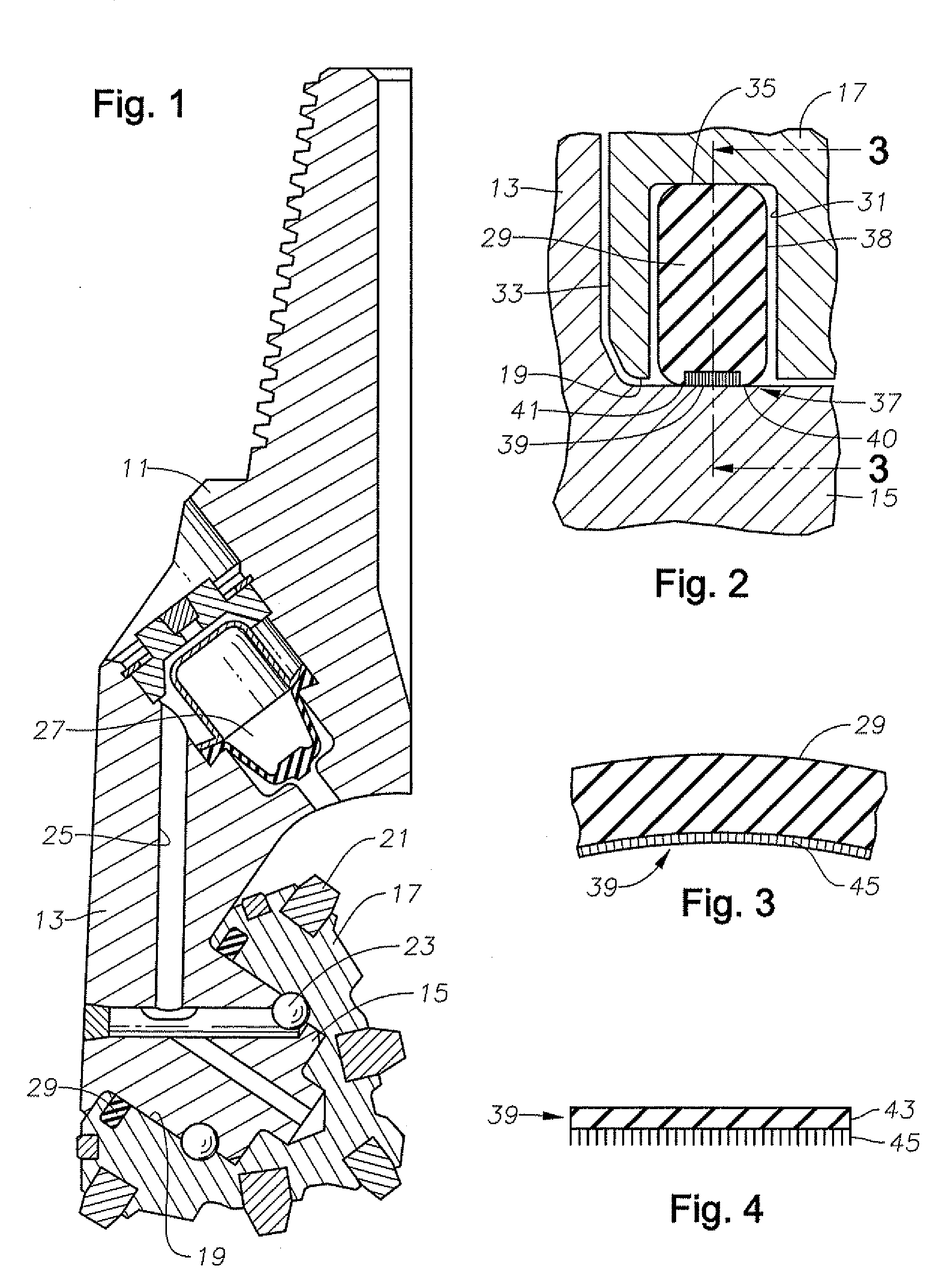

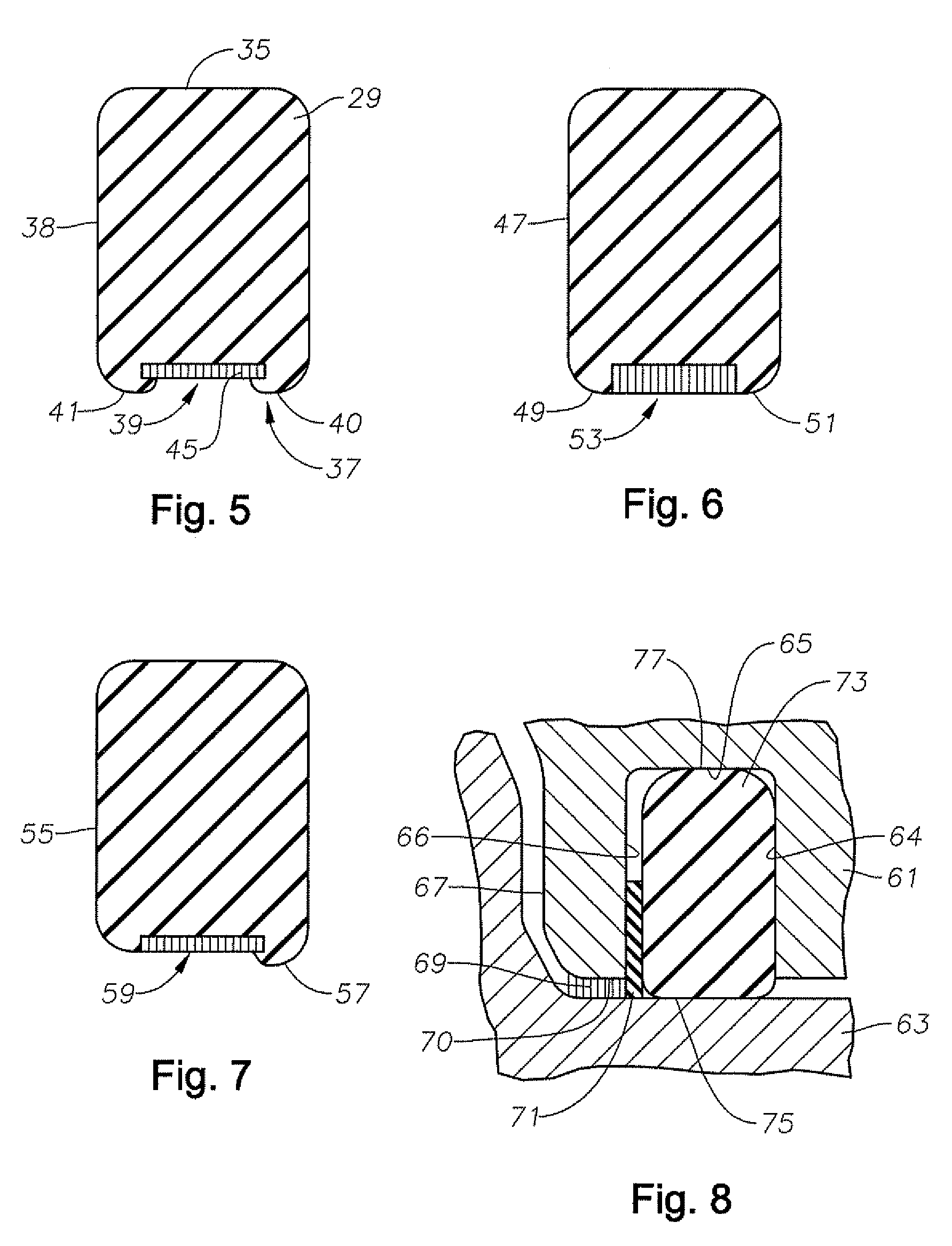

[0019]Referring to FIG. 1, the bit has a bit body 11 with at least one bit leg 13, and preferably three. A bearing pin 15 depends downward and forward from each bit leg 13 toward the bit axis of rotation. A cone 17 has a cavity 19 that slides over bearing pin 15, allowing cone 17 to rotate relative to bearing pin 15. Cone 17 has a plurality of cutting elements 21 on its exterior. Cutting elements 21 may be tungsten carbide inserts pressed into mating holes, or cutting elements 21 may comprise teeth integrally machined from the body of cone 17. Cone 17 is held on bearing pin 15 by a locking element, which in this embodiment comprises a plurality of balls 23 located in mating annular grooves of bearing pin 15 in cone cavity 19.

[0020]A lubricant passage 25 extends through each bit leg 13 from a compensator 27 to the bearing spaces within cavity 19. A seal 29 seals lubricant within the bearing spaces. Compensator 27 reduces the pressure differential across seal 29, which is exposed to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com