Novel PDC drill bit with combination teeth

A drill bit and a new type of technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of accelerating bit wear and blunting, reducing drilling efficiency and drilling cost, increasing centralizer and drill string wear, etc. The effect of increasing ROP and bit life, extending bit life and reducing drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

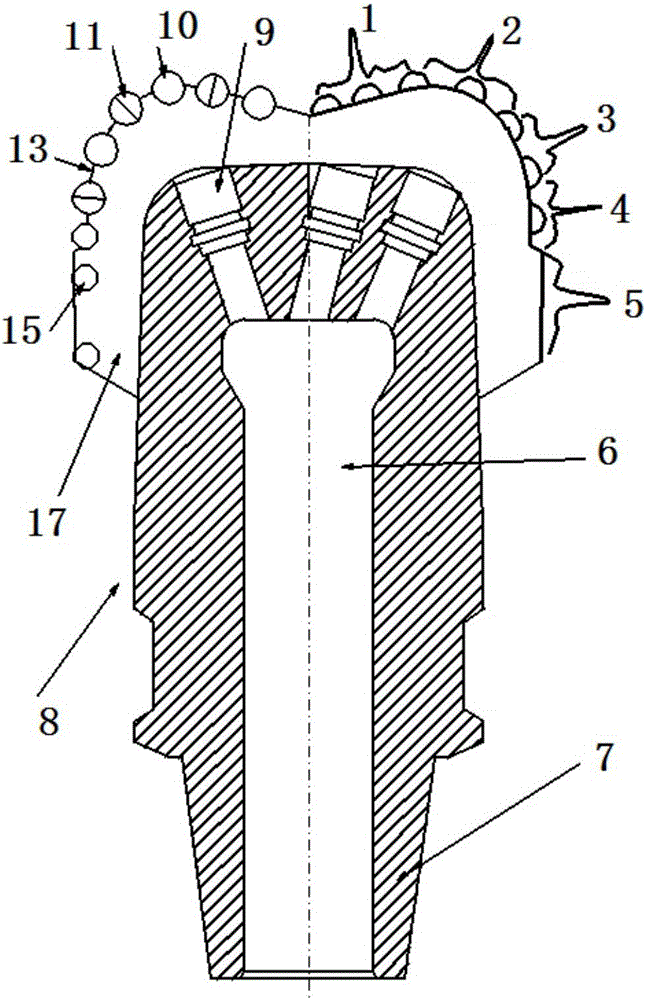

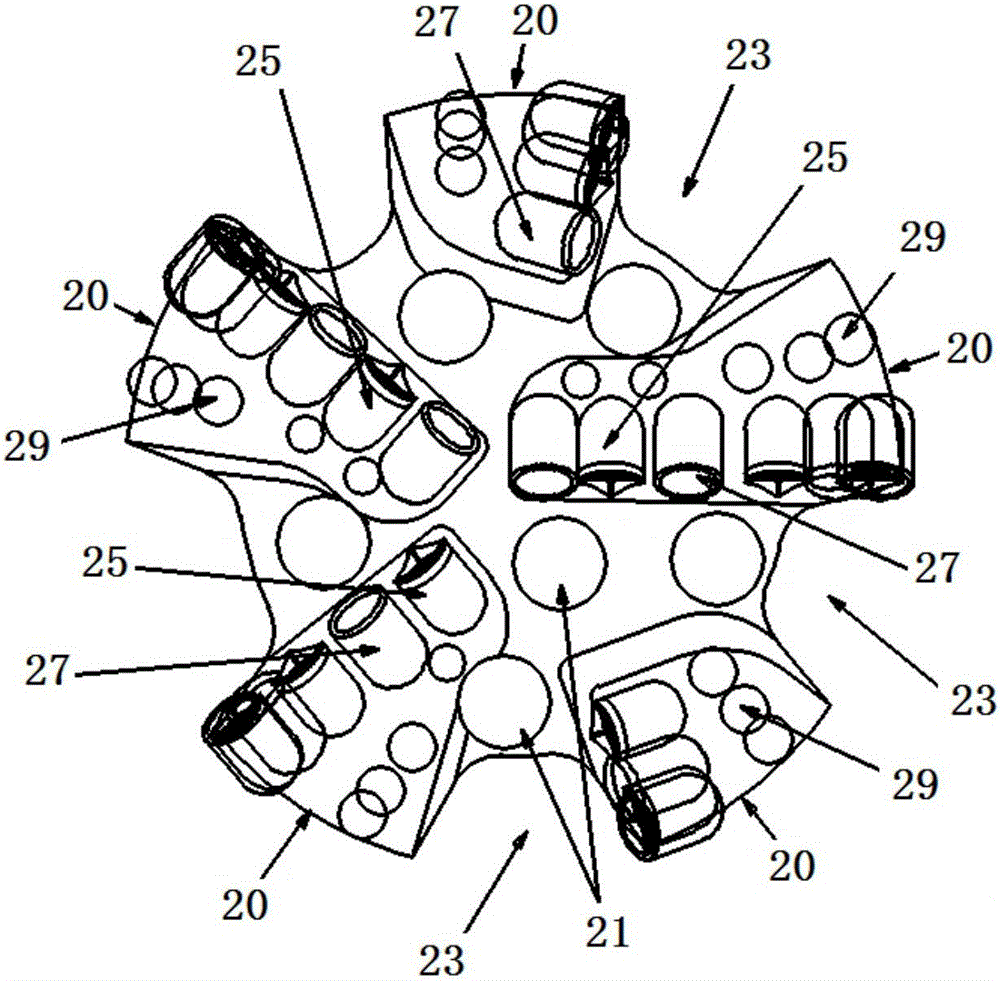

[0046] like figure 1 and figure 2 As shown, the drill bit body 8 includes a plurality of scrapers 20, including at least one scraper 20, whose front teeth are made up of disc shear teeth 27 and ridge-shaped shear teeth 25; on the same scraper 20, disc shear teeth 27 and The ridge-shaped shearing teeth 25 are distributed at intervals, that is, a disc shearing tooth 27 is distributed followed by a slice of ridge-shaped shearing teeth 25 and this process is repeated...; the disc shearing teeth 27 and the ridge-shaped shearing teeth 25 are all distributed on the The inner cone 1, the nose 2, the outer cone 3, the shoulder 4 and the gage block 5 of the outline of the scraper 20; the rear row of teeth of the scraper 20 includes at least one kind of limit tooth 29, and the limit tooth 29 is a spherical cylindrical tooth . There is a back rake angle (refer to Figure 11 ), the value of the back tilt angle varies between 5° and 30°; the installation method of the stop tooth 29 on t...

Embodiment 2

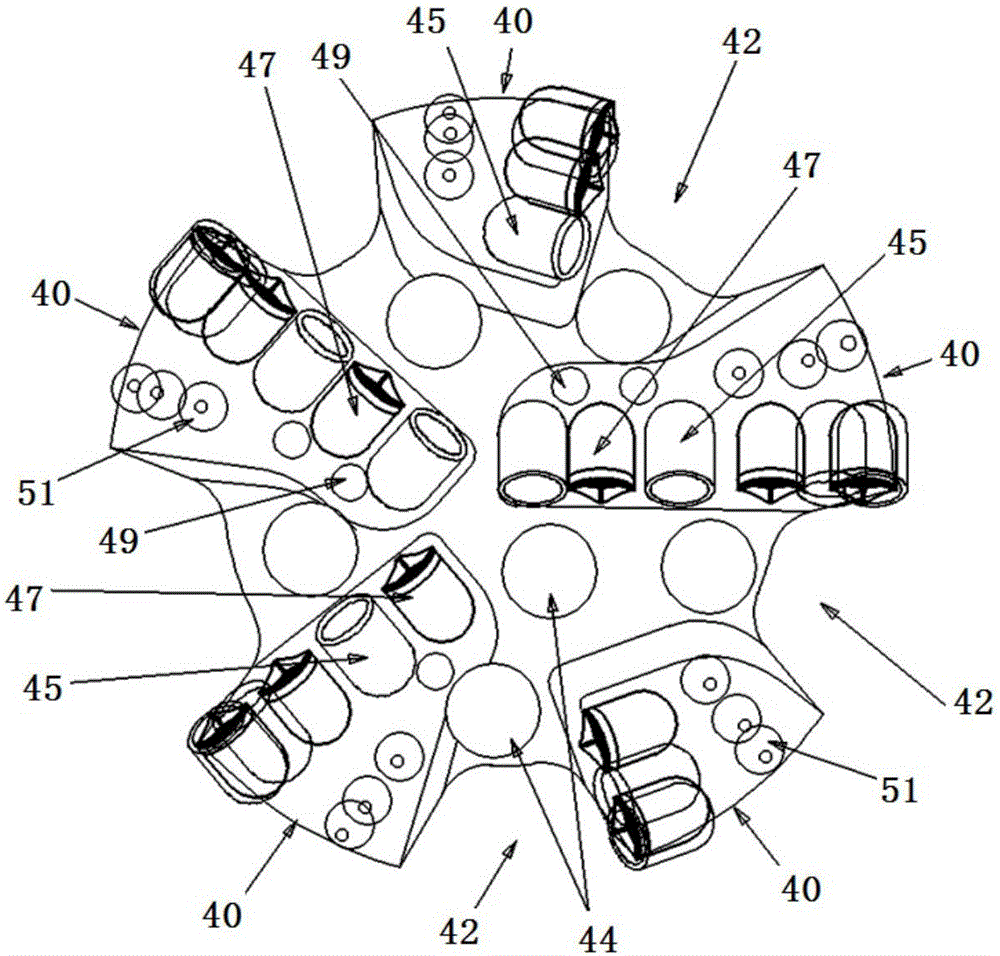

[0048] like figure 1 and image 3 As shown, a plurality of scrapers 40 are included on the drill bit body 8, at least one scraper 40 is included. Distributed at intervals with the ridge-shaped shearing teeth 47, that is, a disc shearing tooth is distributed next to a slice of ridge-shaped shearing teeth and repeats this process...; the disc shearing teeth 45 and the ridge-shaped shearing teeth 47 are all distributed on the scraper blade The inner cone 1, the nose 2, the outer cone 3, the shoulder 4 and the gauge block 5 of the outline of 40, the rear teeth of the scraper 40 include two kinds of limit teeth, and the two kinds of limit teeth are spherical cylindrical teeth 49 and tapered cylindrical teeth 51. The spherical cylindrical teeth 49 are distributed on the inner cone 1 and the nose 2 of the contour of the scraper 40 ; the tapered cylindrical teeth 51 are distributed on the nose 2 , the outer cone 3 and the shoulder 4 of the contour of the scraper 40 . As another mod...

Embodiment 3

[0050] like figure 1 and Figure 4 As shown, a plurality of scrapers 60 are included on the drill bit body 8, at least one scraper 60 is included. Distributed at intervals with the ridge-shaped shearing teeth 68, that is, a disc shearing tooth is then distributed with a slice of ridge-shaped shearing teeth and repeats this process...; the disc shearing teeth 66 are distributed on the inner cone 1, Nose 2, outer cone 3, shoulder 4 and gauge block 5; ridge shearing teeth 68 are distributed on the inner cone 1, nose 2, outer cone 3, shoulder 4 of the contour of the scraper 60; the scraper 60 The back row of teeth includes the back row of disc cutting teeth 70 and ridge cutting teeth 72, and the two kinds of teeth are alternately arranged on the nose 2, outer cone 3, and shoulder 4 of the scraper 60 profile; the back row of the scraper 60 The teeth also include spacer teeth, and the spacer teeth are ball-end cylindrical teeth 74 and are distributed on the inner cone 1 and nose 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com