a drilling tool assembly

A drilling tool assembly and dynamic drilling tool technology, which is applied in the direction of drill pipe, drill pipe, earthwork drilling and production, etc., can solve the problems that cannot meet the requirements of high wellbore anti-deviation and fast development, and the effect of anti-deviation and fast drilling is poor, and achieve well Good eye quality, improved anti-slant effect, and high ROP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

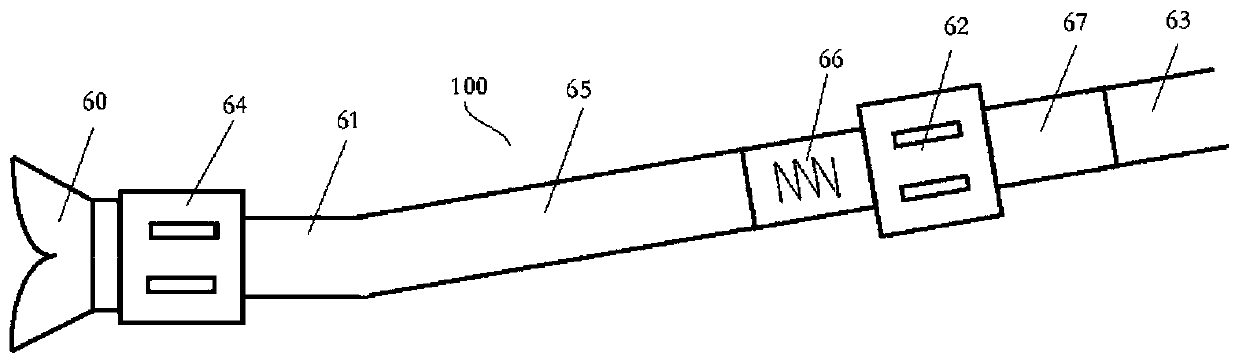

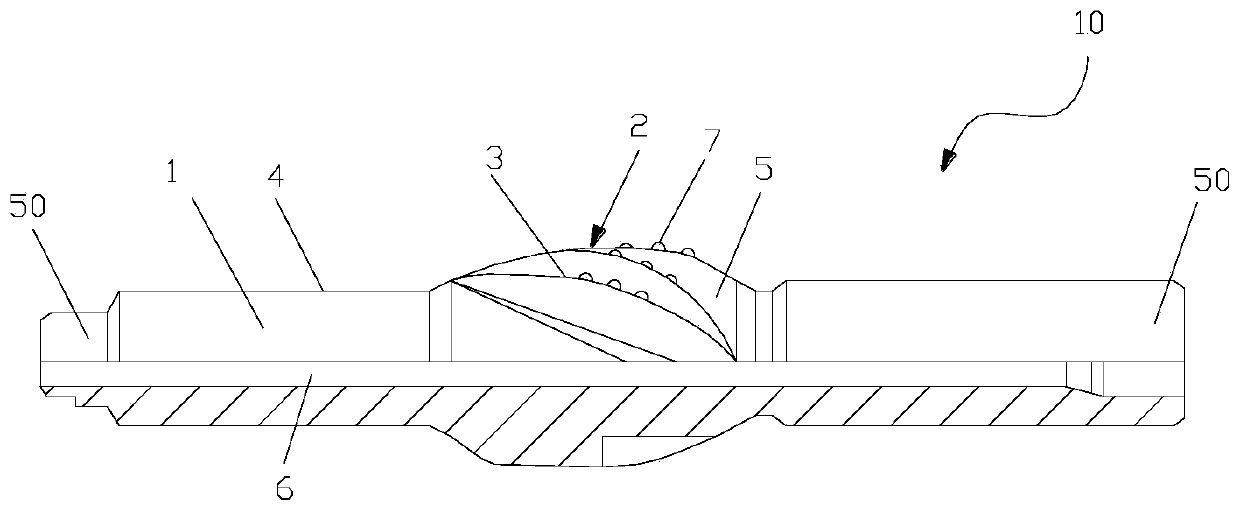

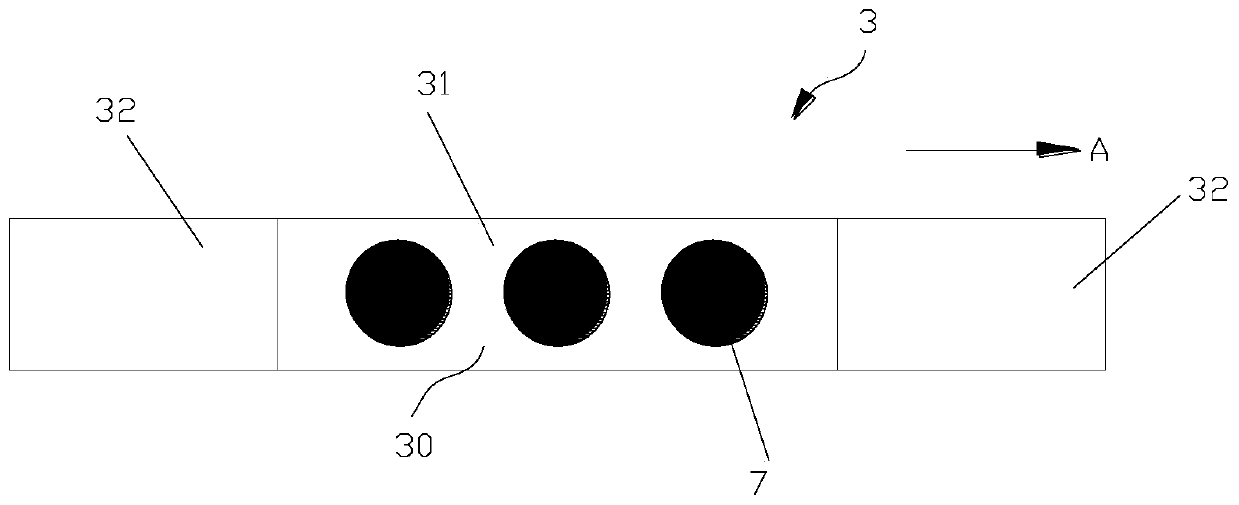

[0031] figure 1 A drill tool assembly 100 according to one embodiment of the invention is shown. like figure 1 As shown, the drill tool assembly 100 includes a drill bit 60 , a motorized drill 61 , a first stabilizer 62 and a drill collar 63 . Wherein, the power drilling tool 61 is arranged above the drill bit 60 and is configured as a power drilling tool 61 capable of providing a descending force, so as to transmit the ground input torque and rotational speed to the drill bit 60, and can output additional torque and rotational speed to the drill bit 60. The drill bit 60, the power drill 61 can improve the anti-slant effect. The first stabilizer 62 is disposed above the power drilling tool 61 to provide pendulum force and enhance the stability of the drilling tool assembly 100 . At the same time, the cooperation of the first stabilizer 62 and the power drilling tool 61 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com