Multi-part energizer for mechanical seal assembly

a technology of mechanical seals and energizers, which is applied in the direction of sealing/packing, mechanical equipment, and well accessories, etc., can solve the problems of essentially losing the time required to make a round trip for replacing a bit, and affecting the sealing effect of the seal, so as to enhance the effectiveness of the seal, enhance the life of the energizer, and enhance the frictional force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

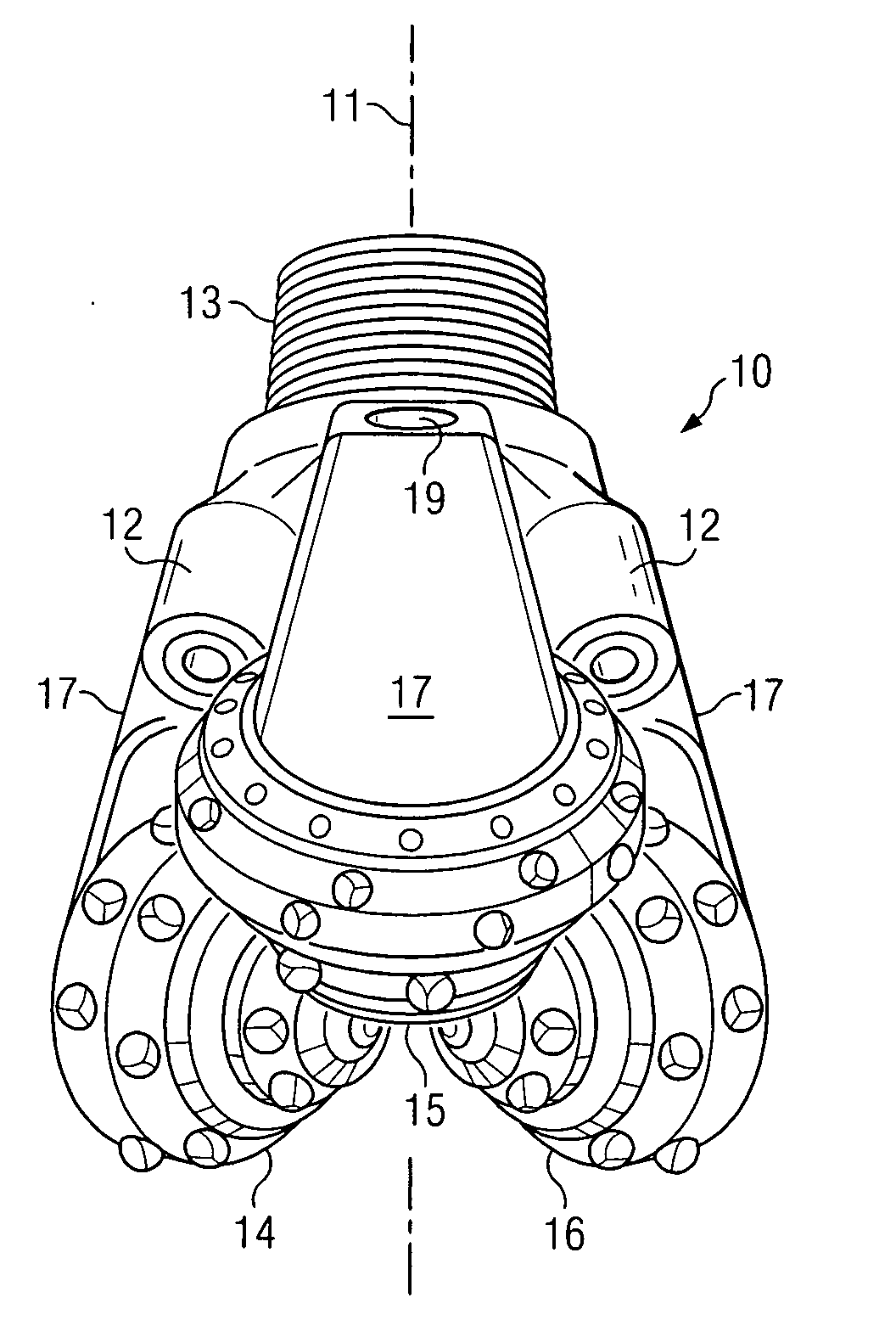

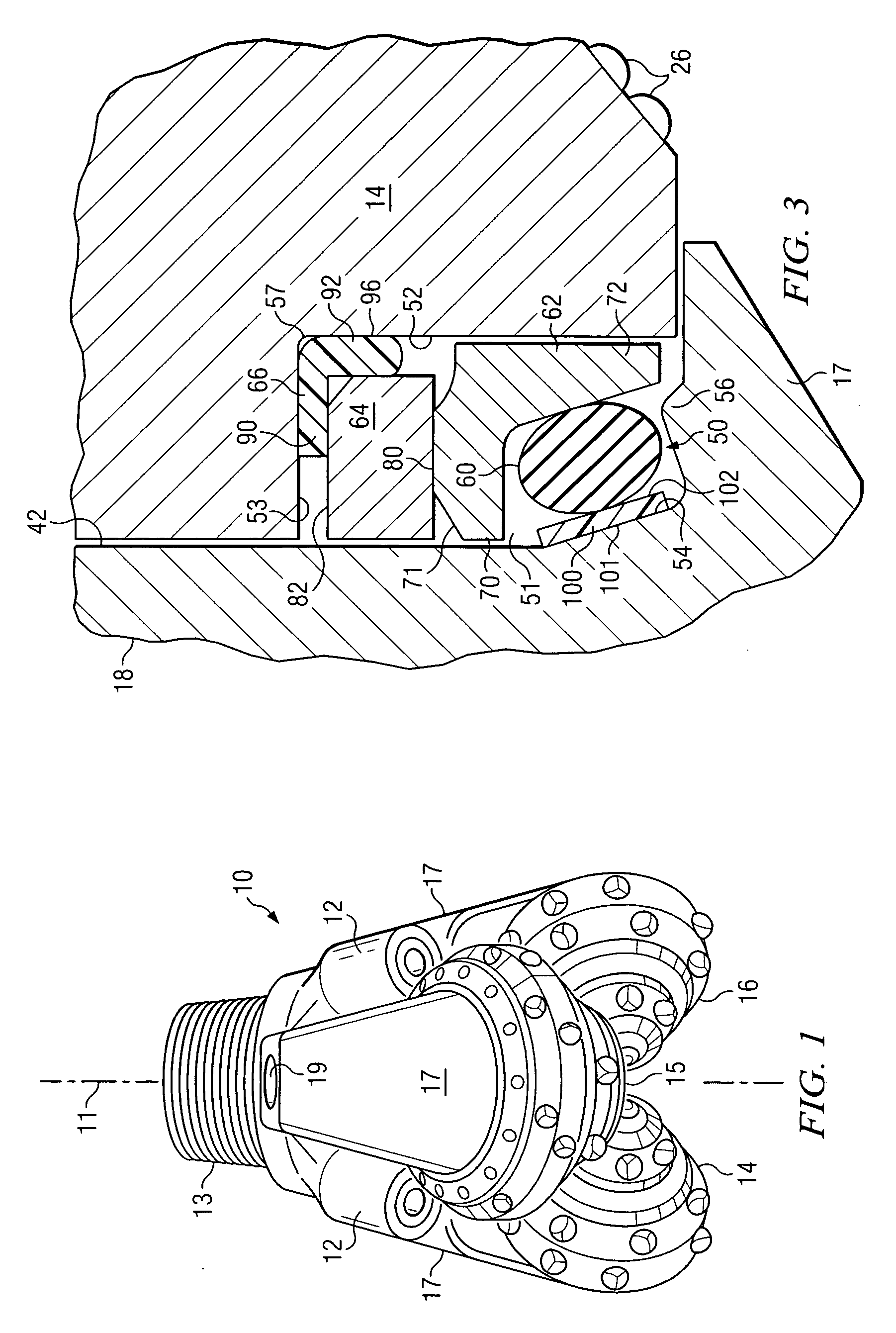

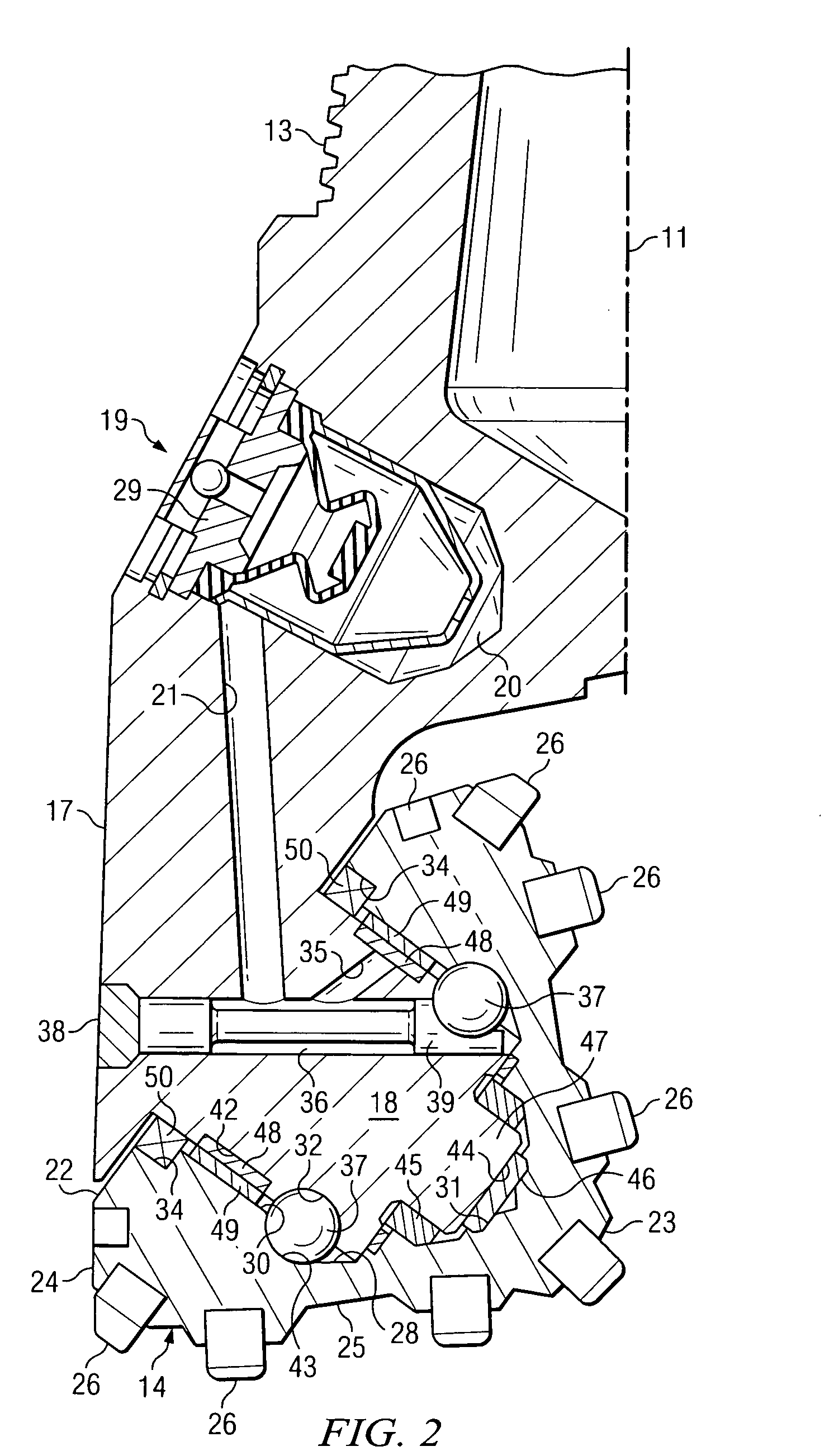

[0019] Described herein is a seal assembly with mechanical seals for dynamically sealing between rotatable members, such as between a rolling cone cutter and a journal shaft of a rock bit. According to at least one embodiment of the invention, a seal assembly for sealing between spaced-apart and opposing surfaces comprises a first resilient ring of a first material, a second resilient ring of a second material that is different from the first material, where the first and second resilient rings engage one another to form a static seal and form an energizer that is disposed between the spaced-apart and opposing surfaces.

[0020] In accordance with another embodiment described herein, a seal assembly for a drill bit includes a bit body having a sealing surface, a substantially rigid ring spaced apart from the bit body and having a static sealing surface facing the sealing surface of the bit body, and a composite energizer disposed between the sealing surface of the bit body and the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com