Environmental-friendly water-based cutting fluid

A cutting fluid, water-based technology, used in the petroleum industry, lubricating compositions, etc., to achieve outstanding anti-corruption ability, outstanding hard water resistance, and prevention of discoloration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

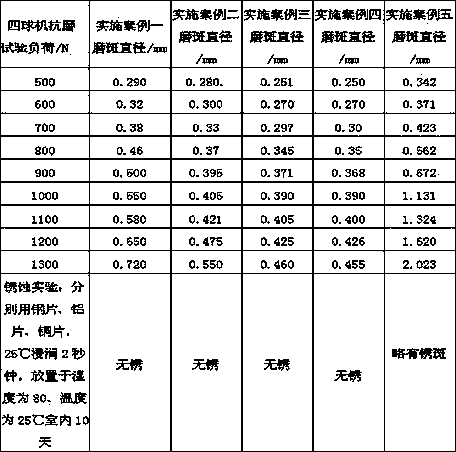

Examples

Embodiment 1

[0042] Embodiment 1: A kind of novel green environmental protection water-based synthetic cutting fluid, is made up of following weight components

[0043] Water-based base fluid 64.6%,

[0044] Oleamide 15%,

[0045] Acid Oleoyl Phosphate 2.0%,

[0046] N-Methylmorpholine 5%,

[0047] Calcium Dimerate 8%,

[0048] Tolyltriazole 1.0%,

[0049] Hexahydrotriazine 1.2%,

[0050] Defoamer 0.2%,

[0051] Methyltrimethoxysilane 2.0%,

[0052] Gamma-Glycidoxypropyltrimethoxysilane 1.0%,

[0053] After mixing the above raw materials, use triethanolamine to adjust the pH value to 8.4-9.0.

Embodiment example 2

[0054] Implementation case 2: A new type of green and environmentally friendly water-based synthetic cutting fluid, which is characterized by: consisting of the following weight components

[0055] Water-based base fluid 67.7%,

[0056] Ricinamide 13%,

[0057] Oleoyl Acid Phosphate 2.2%,

[0058] Triethanolamine 2.5%,

[0059] Aluminum Dimer Acid 9%,

[0060] Benzotriazole 1.1%,

[0061] Hexahydrotriazine 1.1%,

[0062] Defoamer 0.1%,

[0063] Sodium Metaborate 1.8%,

[0064]N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane 1.5%.

[0065] After mixing the above raw materials, use triethanolamine to adjust the pH value to 8.4-9.0.

Embodiment example 3

[0066] Implementation case 3: A new type of green and environmentally friendly water-based synthetic cutting fluid, which is characterized by: consisting of the following weight components

[0067] Water-based base fluid 62.1%,

[0068] Sodium alkylbenzene sulfonate + sodium fatty alcohol sulfate (mass ratio 1:3) 16%,

[0069] Acid Oleoyl Phosphate 1.8%,

[0070] Boric acid 3.7%,

[0071] Zinc Dimerate 11%,

[0072] Tolutriazole: imidazoline (mass ratio 3:2) 0.5%,

[0073] Isothiazolinone 0.9%,

[0074] Defoamer 0.2%,

[0075] Methyltrimethoxysilane 2.5%,

[0076] Gamma-methacryloxypropyltrimethoxysilane 1.3%.

[0077] After mixing the above raw materials, use triethanolamine to adjust the pH value to 8.4-9.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com