Rotating member, housing, bearing, gearbox, rotating machine, shaft structure, and surface treatment method

A technology of rotating parts and chassis, applied in the direction of machines/engines, mechanical equipment, bearing components, etc., can solve problems such as wear and frequent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

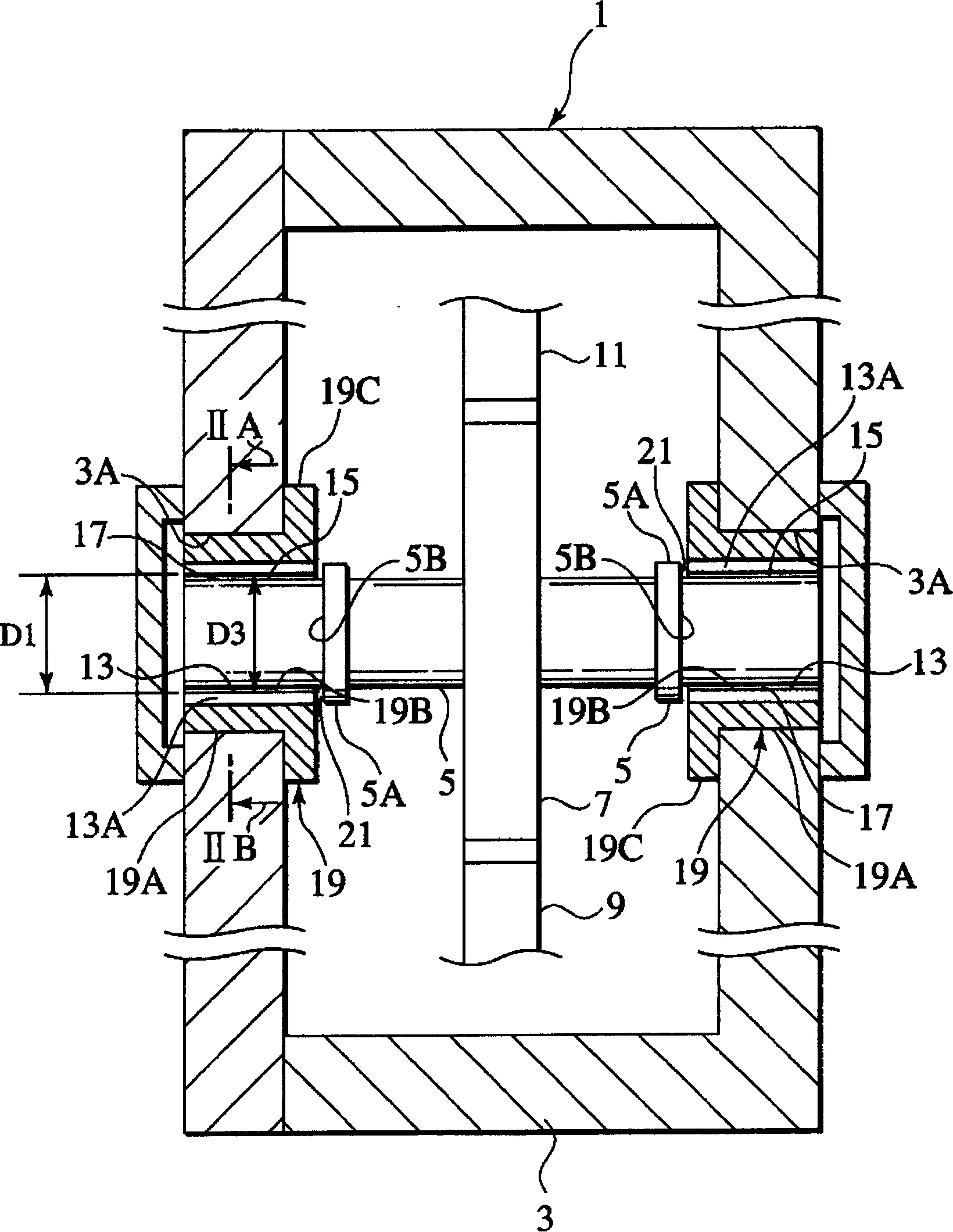

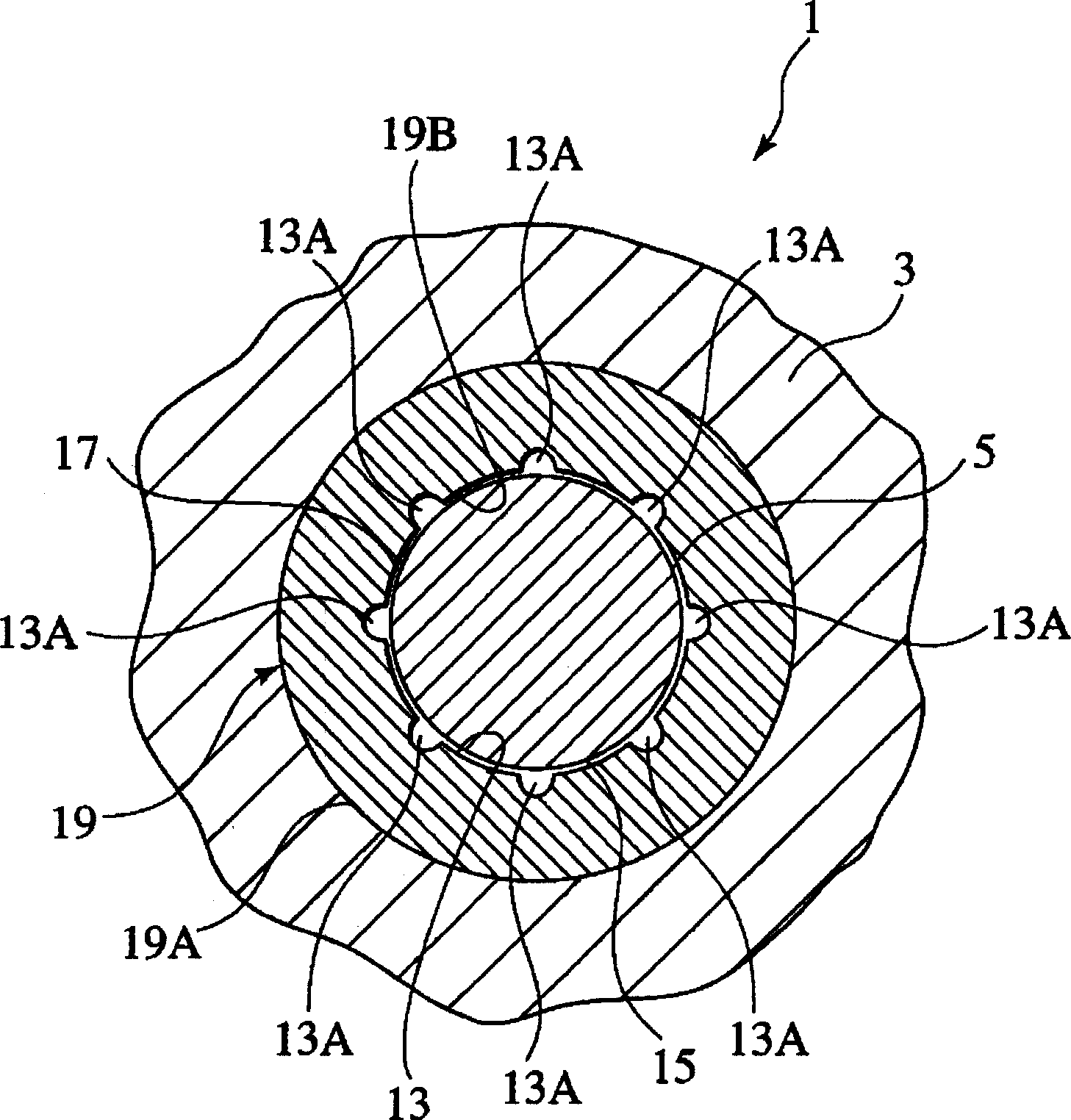

[0034] figure 1 Shown is a schematic cross-sectional view of an accessory, a driving device, and a gear box related to the first embodiment of the present invention. figure 2 shown figure 1 The IIA-IIB section view.

[0035] Parts·Driver·Gear Box (hereinafter referred to as Gear Box) 1 is a gearbox driven by the turbine shaft of the gas turbine, and is used to drive the parts (generator, hydraulic pump, etc.) of the gas turbine.

[0036] The accessory, the driving device, and the gear box 1 are provided with a case 3 supported by the engine case of the gas turbine outside the case. In addition, the engine case is formed in a cylindrical shape so as to form a compressor or a turbine gas flow path inside.

[0037] Inside the housing 3 , a conductive cylindrical rotating member 5 is provided rotatably with respect to the housing 3 . A gear 7 is integrally provided at an intermediate portion in the longitudinal direction of the rotating member 5 . Gears 9 and 11 that are r...

Embodiment 2

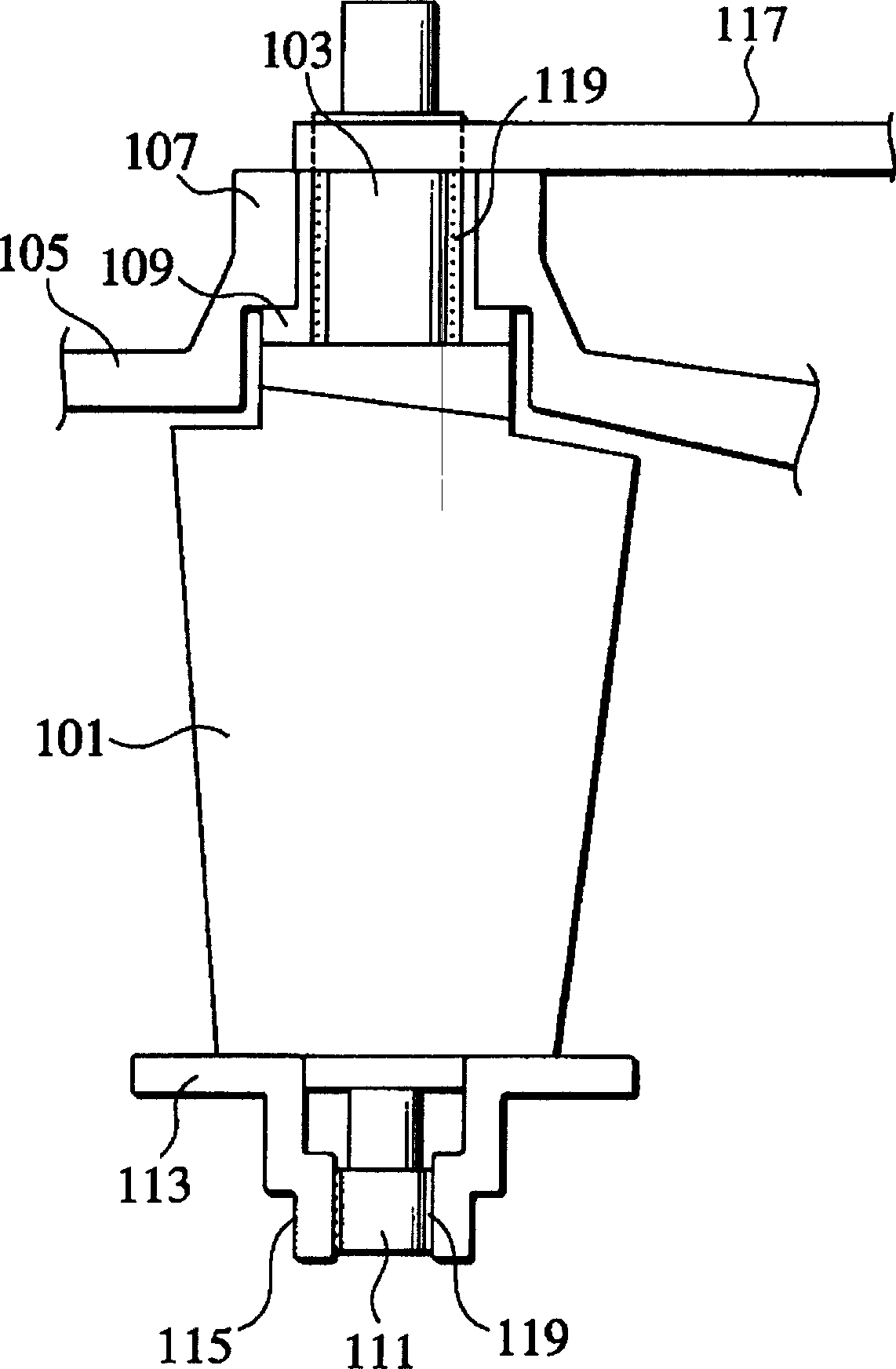

[0072] A second embodiment of the present invention, that is, a case where the present invention is implemented on a variable stator vane provided in a compressor of a gas turbine, will be described below using the drawings. In the axial flow compressor of the gas turbine, the installation angle of the inlet guide inner vane and the first few sets of stator blades is changed, so that the corresponding angle of the moving sub-blade can be adjusted to a suitable value as much as possible.

[0073] Such as image 3 As shown, the variable stator vane (variable vane) 101 that can change the installation angle is placed in the annular air flow path of the axial flow compressor of the gas turbine, in the peripheral direction between the moving sub-blade rows (not shown). at intervals ( image 3 Only one of these configurations is shown in , and the shaft portion 103 on the outer end side of the variable stator vane 101 is rotatably supported by a bushing 109 at a hole edge 107 provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com