Electric discharge machine and machining fluid cooling device

A technology of electric discharge machine and cooling device, which is applied in the direction of electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems of poor machining accuracy and no consideration of temperature fluctuation of working fluid, etc., and achieve the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A detailed description will now be given of preferred embodiments of the present invention with reference to the accompanying drawings.

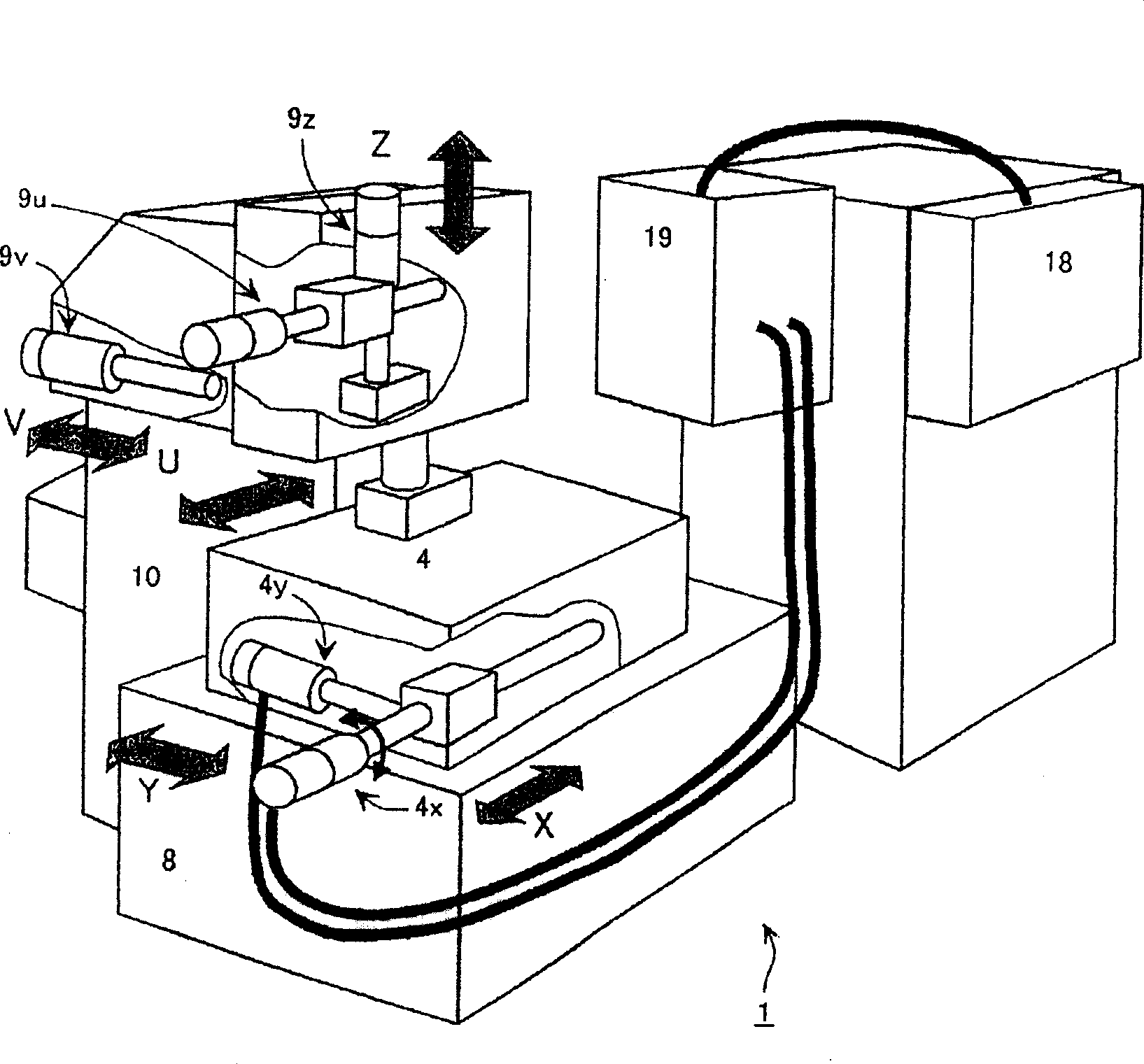

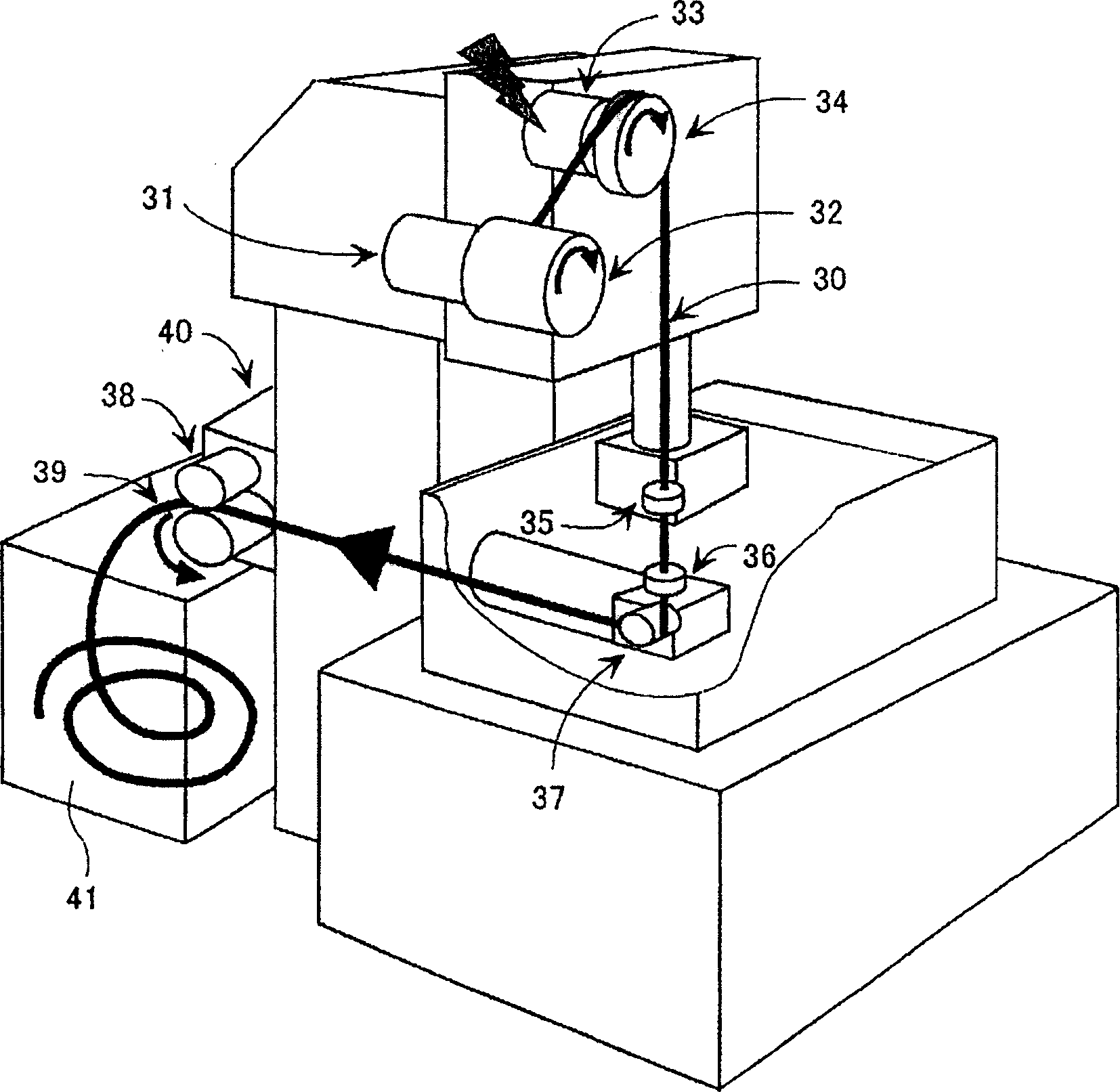

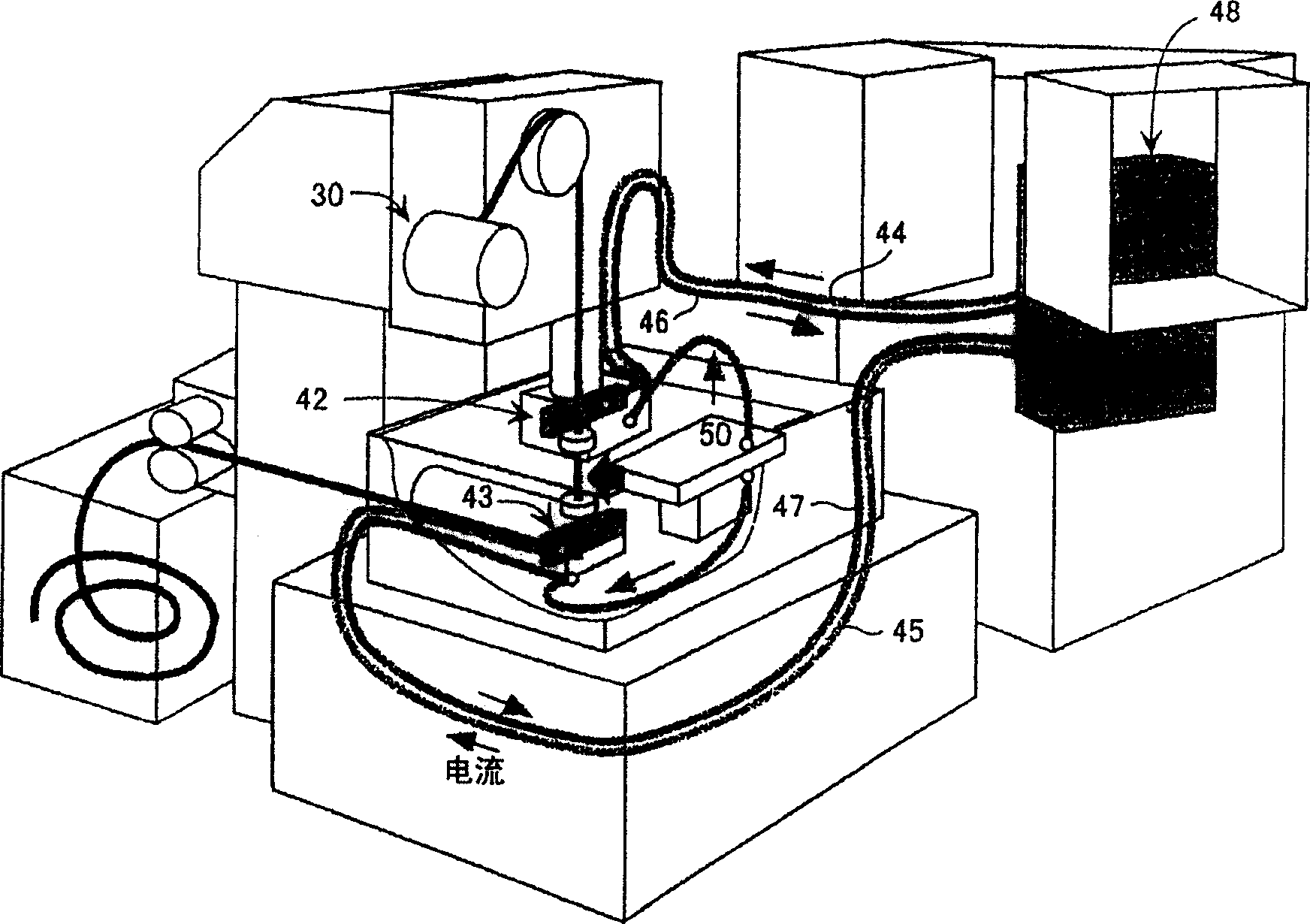

[0039] Figure 1-4 Schematically shows the structure of a discharge and add electrical machine. figure 1 The mechanical structure of the electrical discharge machine is schematically shown. figure 2 A routing system for wire electrodes is schematically shown; image 3 Schematically showing the flow of electric discharge machining current; Figure 4 The flow of the working fluid is schematically shown.

[0040] exist figure 1 Among them, an electrical discharge machine 1 includes a table 4 on which a workpiece is mounted, and a support 10 supporting an upper end guide for guiding a wire electrode. The table 4 is movable in the X and Y axis directions on top of a machine tool 8, and is provided with a driving mechanism 4x and a driving mechanism 4y. The drive mechanism 4x includes a motor and a ball screw for movement in the X di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com