Heat exchanger and associated method

a technology of heat exchanger and heat exchanger, which is applied in the direction of lighting and heating apparatus, tubular elements, and stationary conduit assemblies, etc., can solve the problems of high temperature process that requires expensive brazing equipment and complex process control, and still a relatively expensive and heavy oil cooler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following description of various aspects of the invention is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses. The present teachings are applicable, but are not limited to, the area of cooling of transmission oil and / or engine oil in automotive applications. The present teachings are, for example, also applicable to diverse areas such as railways, ships, aircraft, machine tool, power generation equipment and others.

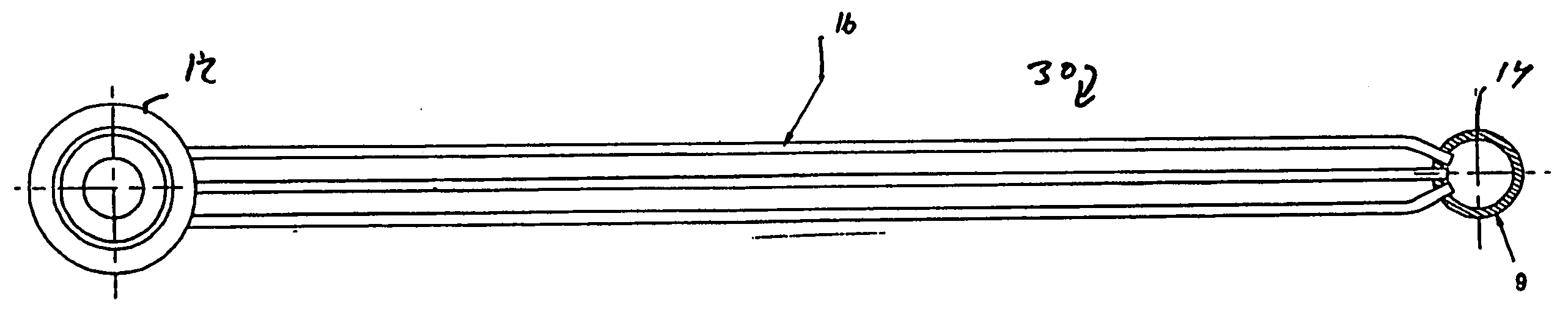

[0043] Referring to FIG. 5, an exemplary heat exchanger, such as for example, an oil cooler, is illustrated and identified at reference character 10 according to an aspect of the present teachings. The heat exchanger 10 is shown to generally include first and second end tanks 12 and 14. The end tanks 12 and 14 can be round or circular in shape. The end tanks 12 and 14 can be connected by a plurality of heat transfer tubes 16. In the exemplary illustration of FIG. 5, the heat exchanger 10 is shown to include ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com