Methods for identifying compounds useful for producing heavy oils from underground reservoirs

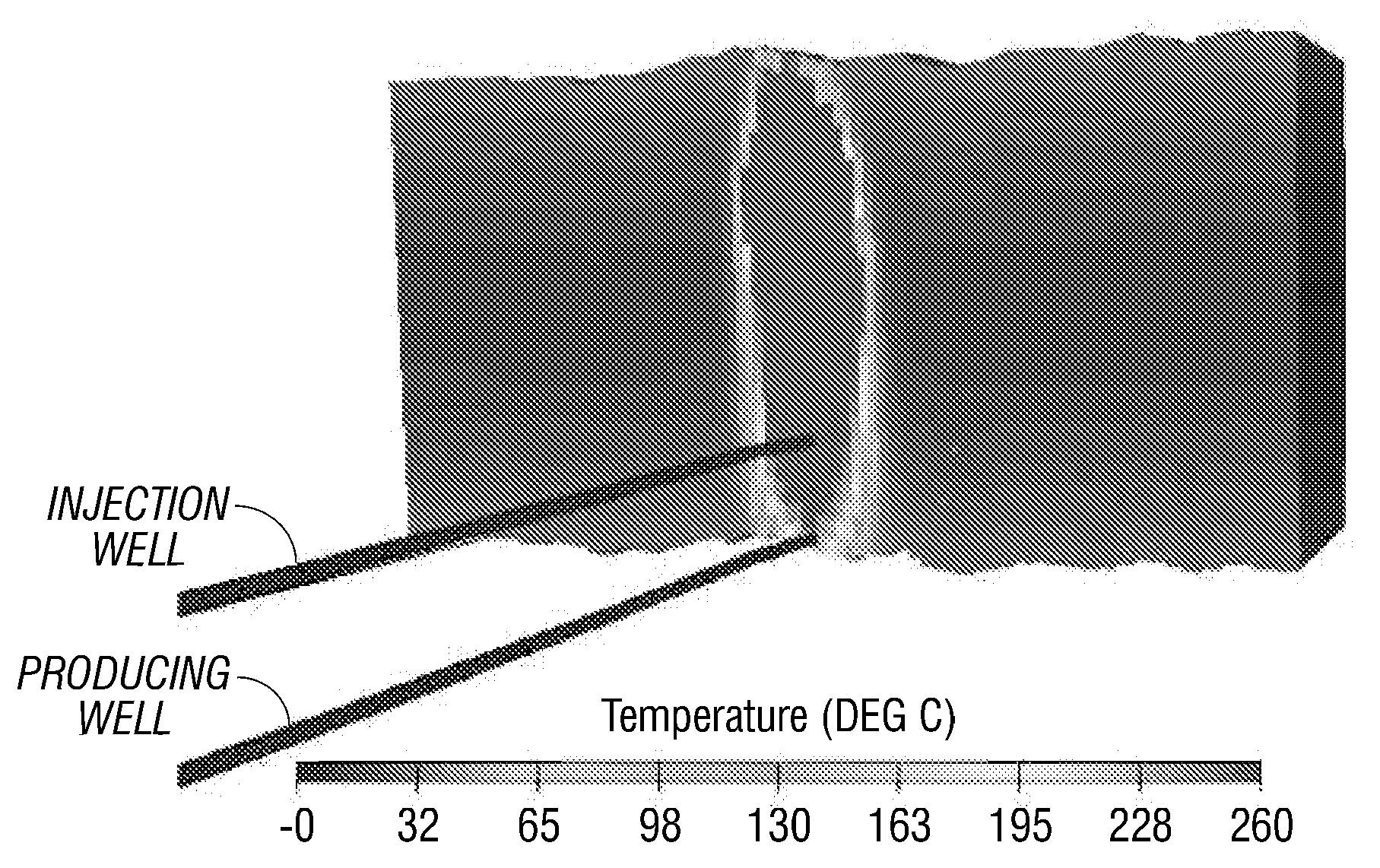

a technology for underground reservoirs and heavy oils, applied in the direction of survey, instruments, borehole/well accessories, etc., can solve the problems of requiring significant time and energy consumption to recover all contained oil, and affecting the recovery of heavy oils, so as to facilitate the development of chemicals, improve physicochemical properties, and increase the efficiency of heavy oil removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Improve the Thermal Stability of Surfactants Useful in SAGD Applications

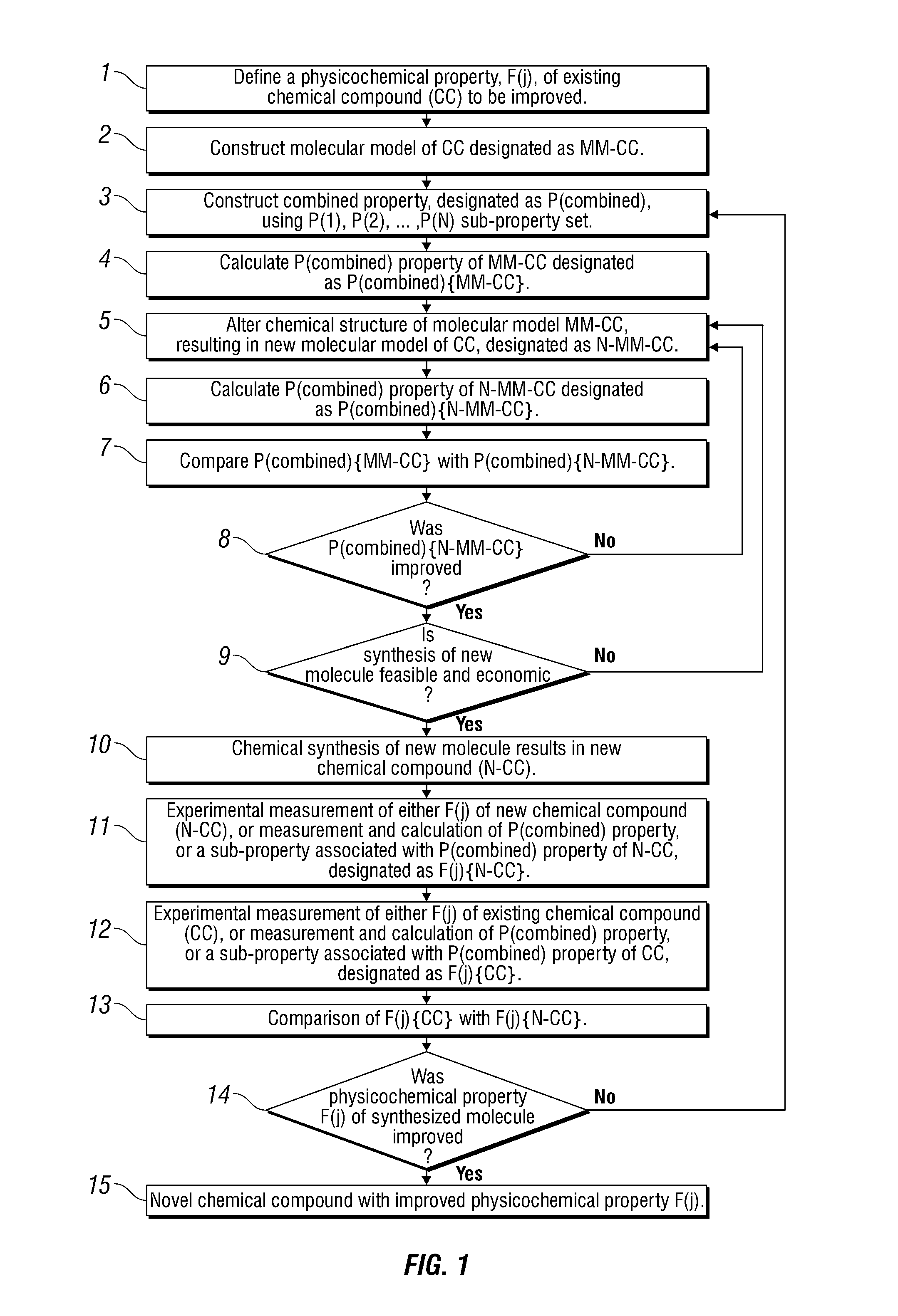

[0048]1) Define a physicochemical property. F(j), of existing chemical compound (CC) to be improved.

[0049]In this example, sodium dodecyl sulfate (SDS) surfactant is CC and the physicochemical property (F(j)) is thermal stability.[0050]2) Construct a molecular model of CC (MM-CC).

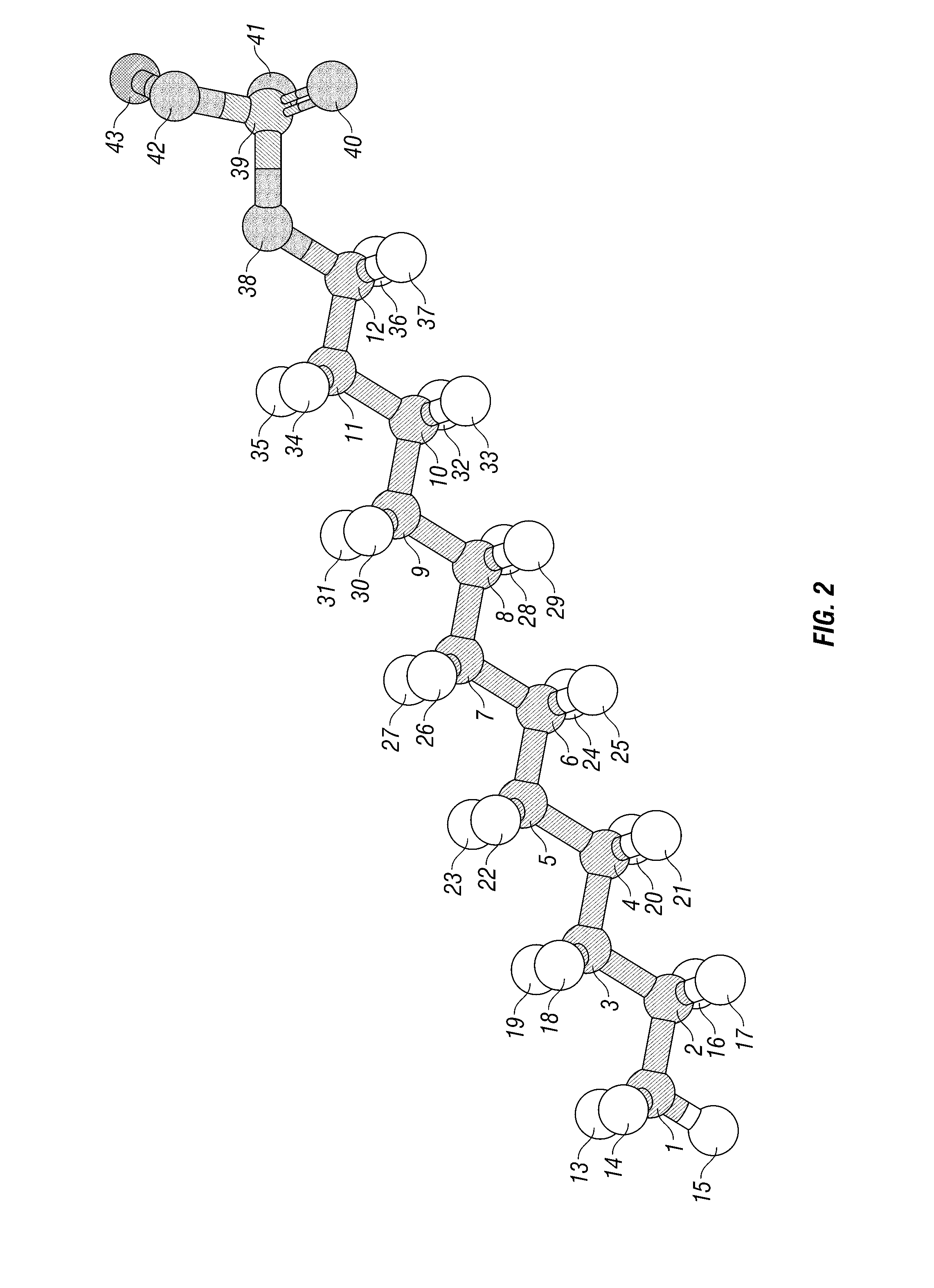

[0051]From the known chemical structure, construct the three-dimensional (3D) molecular model of SDS.

[0052]Geometrical optimization was used to fine-tune the structure of the model. The resulting 3D structure is presented in FIG. 2. This structure is the molecular model of the SDS chemical compound, which is designated as MM-CC. Spheres 13-37 represent hydrogen (H), spheres 1-12, carbon (C), spheres 38 and 40-42, oxygen (O), sphere 39, sulfur (S), and sphere 43, sodium (Na), atoms. The small numbers on the atoms identify the specific atoms. Materials Studio 4.2 software was used for the structure construction and the geometrical optimiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com